Methane explosion prevention controlling process

A control method and gas technology, applied in the field of innovation and invention, can solve problems such as danger, deflagration, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

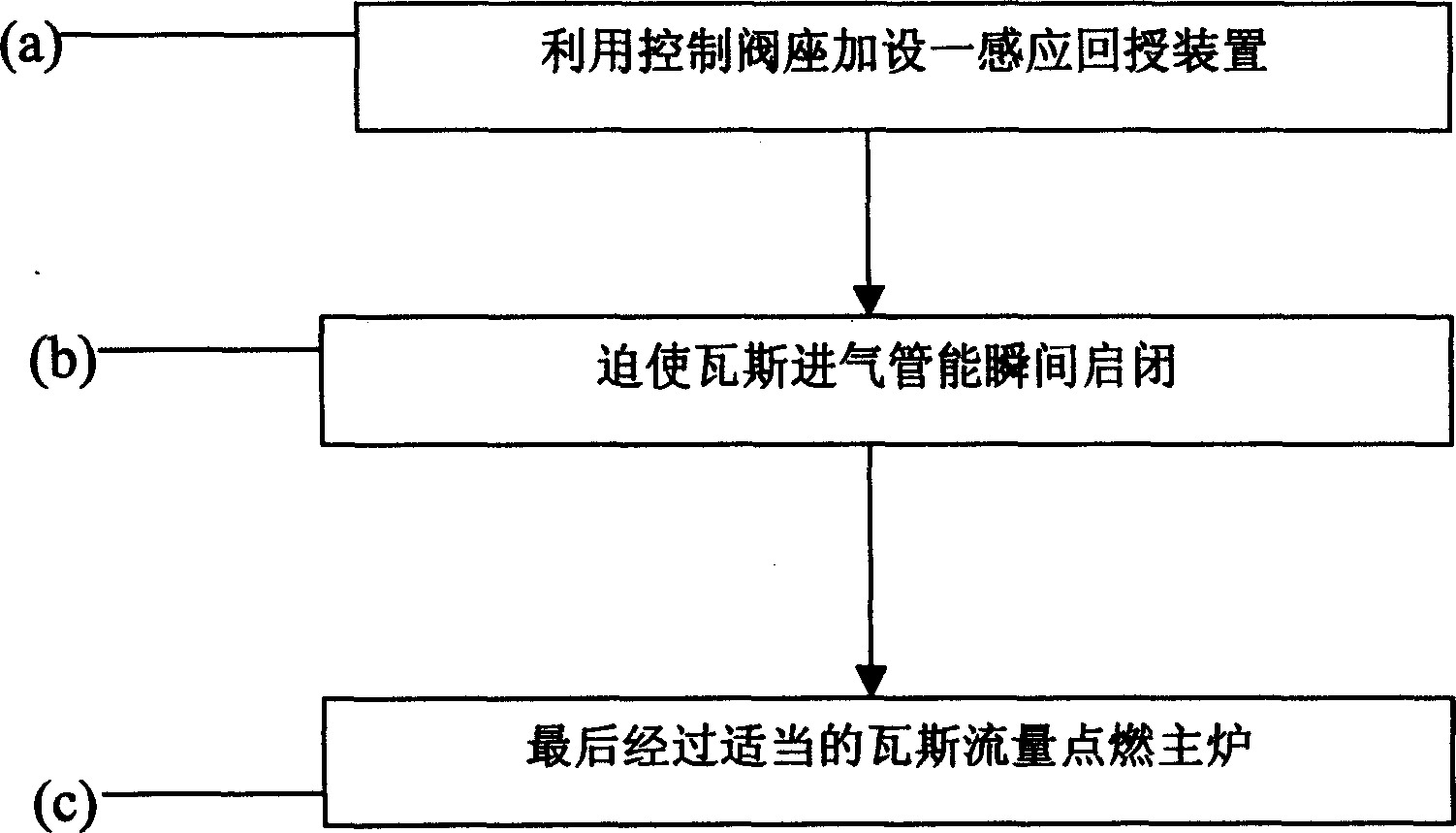

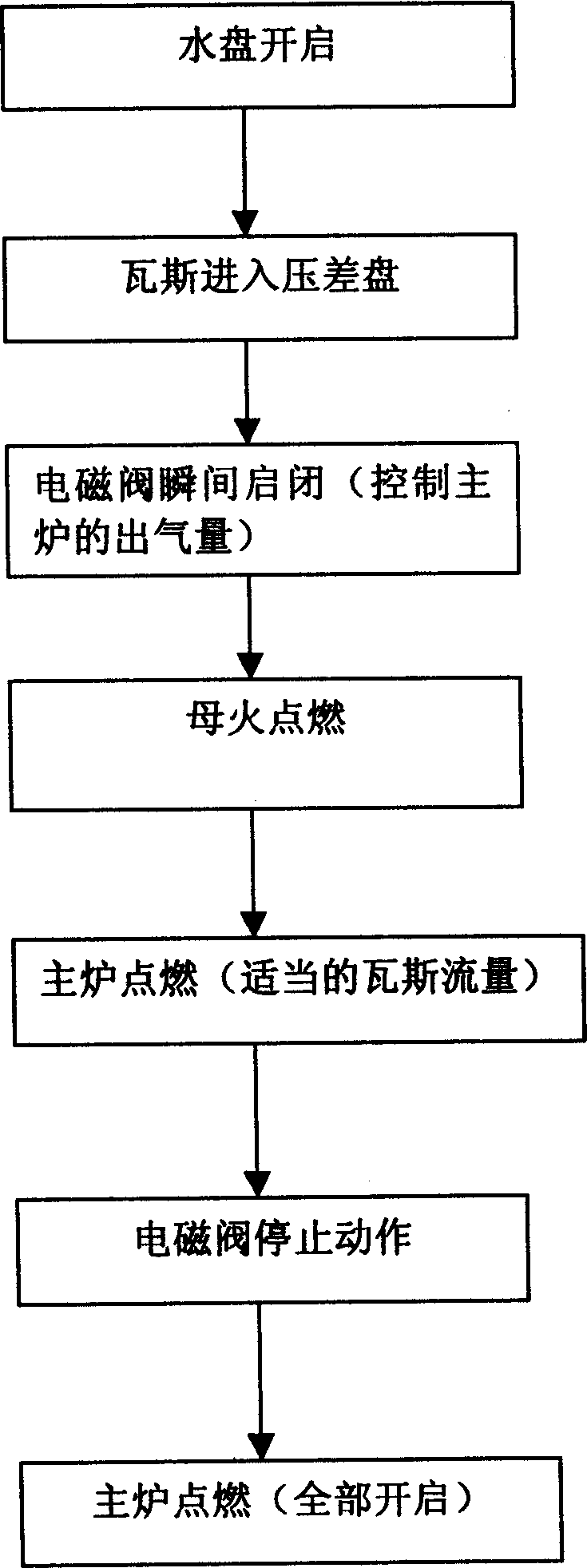

[0012] The present invention relates to a gas explosion-proof control method, especially an innovative invention that breaks through the design limitations of traditional water heaters, etc., and at the same time achieves increased safety with a more stable gas flow rate. Please refer to figure 1 Shown is a schematic flow sheet of the present invention, and its steps are as follows:

[0013] (a) Use the control valve seat to add an induction feedback device; it forms a feedback induction device in the control valve and electromagnetic valve of the water heater, and enables the feedback device to sense the flow of gas. Wherein, the feedback sensing device can be a circuit, and is controlled and activated by alternating current or direct current.

[0014] (b) Force the gas inlet pipe to open and close instantaneously; make the rubber diaphragm and valve device of the differential pressure disc in the water heater achieve stable control of the gas outlet flow.

[0015] (c) Final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com