Mud circulation system

A circulation system and mud technology, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve problems such as complex operation, complex mechanism, difficult installation and layout, and achieve convenient adjustment and simplification of the mud circulation system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

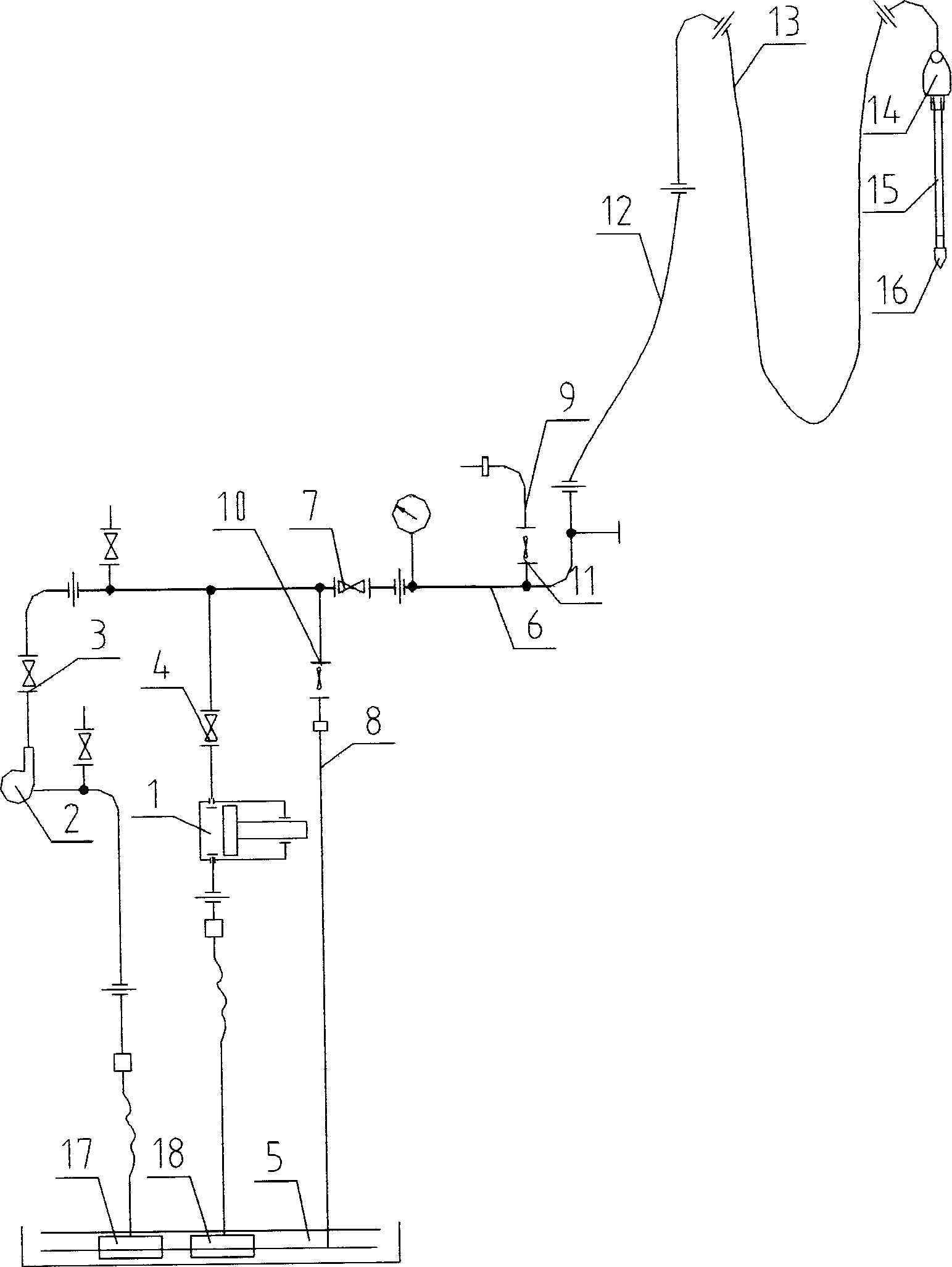

[0017] Such as figure 1 As shown, the centrifugal pump 2 and the reciprocating piston pump 1 are respectively connected between the mud pool 5 and the main line 6 through the valve 3, the valve 4, pipelines, pipe fittings, etc. to form a parallel connection, and the valve 7 is installed on the main line 6, and the main line A return pipeline 8 is also connected between 6 and the mud pool 5, and a grouting pipeline 9 is connected to the main pipeline 6, and a valve 10 and a valve 11 are respectively installed on the return pipeline 8 and the grouting pipeline 9, and the main pipeline 6 and the mud riser 12 , water hose 13, and water tap 14 are connected successively, and the mud that water tap 14 flows out is injected in the well through drill pipe 15, drill bit 16.

[0018] work process:

[0019] When the mud circulation system is used in conventional or slim hole oil and water well drilling, the reciprocating piston pump 1 works and the centrifugal pump 2 does not work becau...

Embodiment 2

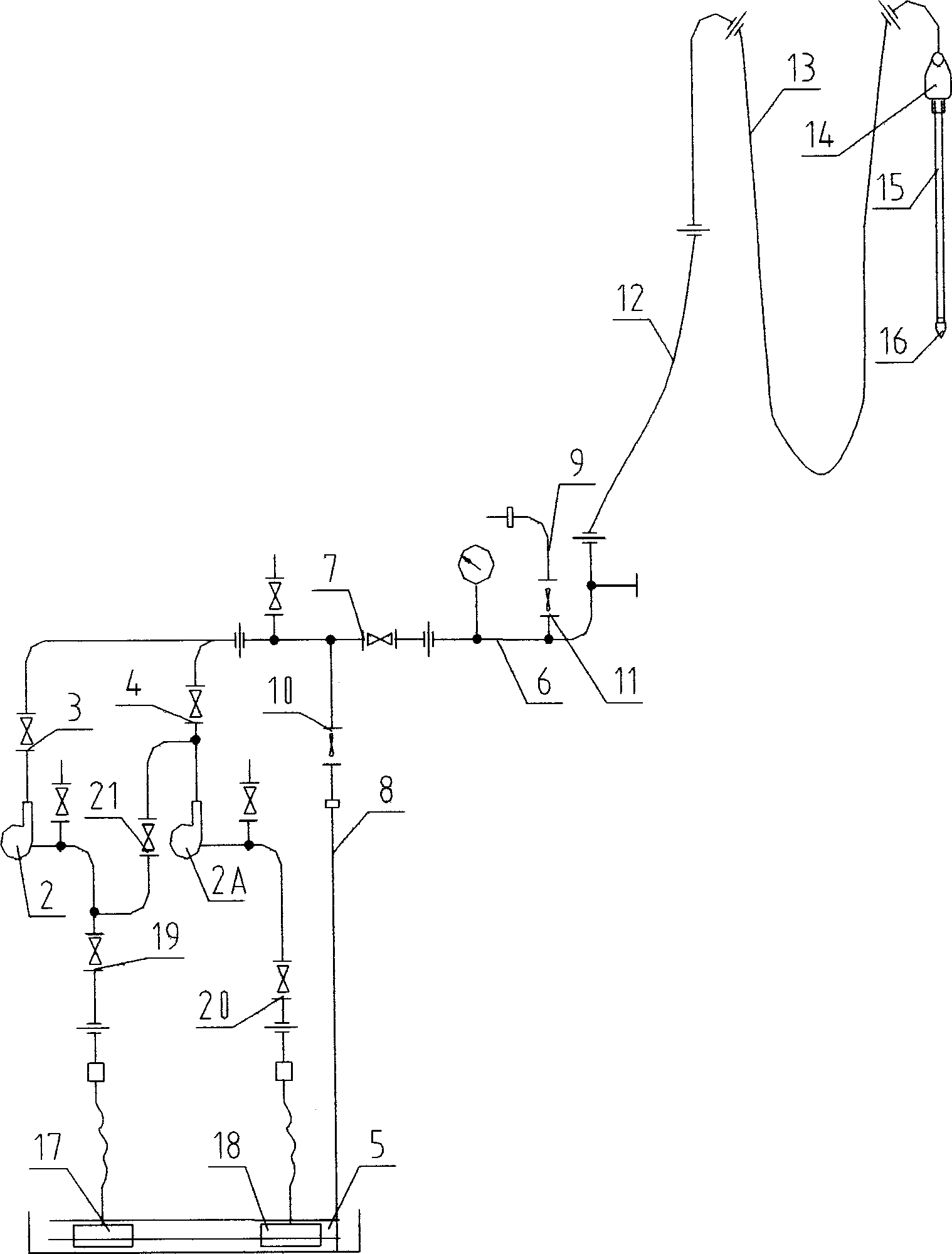

[0024] The reciprocating piston pump 1 in embodiment one is changed into centrifugal pump 2A, as figure 2 As shown, a valve 21 is connected between the inlet of the centrifugal pump 2 and the outlet of the centrifugal pump 2A, and a valve 19 and a valve 20 are respectively installed at the inlets of the centrifugal pump 2 and the centrifugal pump 2A, that is, two centrifugal pumps are connected in series or connected in parallel. When the mud circulation requires large flow and low pressure transportation, the centrifugal pump 2 and the centrifugal pump 2A are connected in parallel, that is, the valve 21 is closed, the valve 3, the valve 4, the valve 19, and the valve 20 are opened, the valve 7 is opened, and the valve 10 and the valve 11 closure. Start centrifugal pump 2, centrifugal pump 2A work, centrifugal pump 2, centrifugal pump 2A suck mud through filter 17, filter 18 respectively, after mud is pressurized, pass main line 6, standpipe 12, water hose 13, water tap 14, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap