An internal cooling structure of double-layer turbine blades based on steam cooling

A technology for turbine blades, steam cooling, applied in the direction of blade support elements, machines/engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

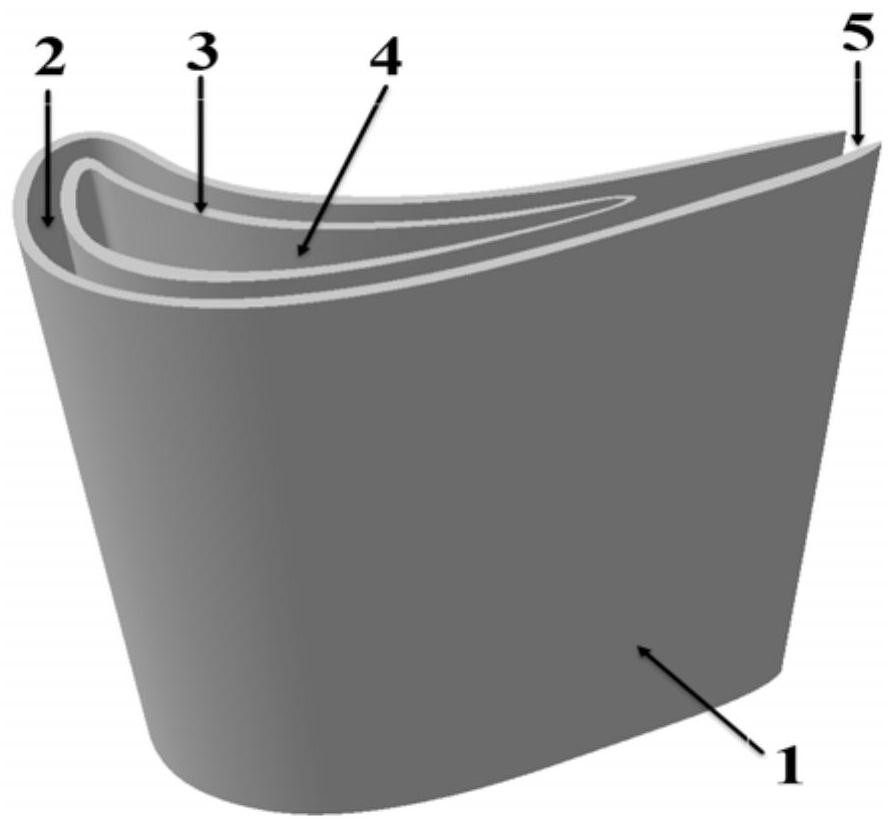

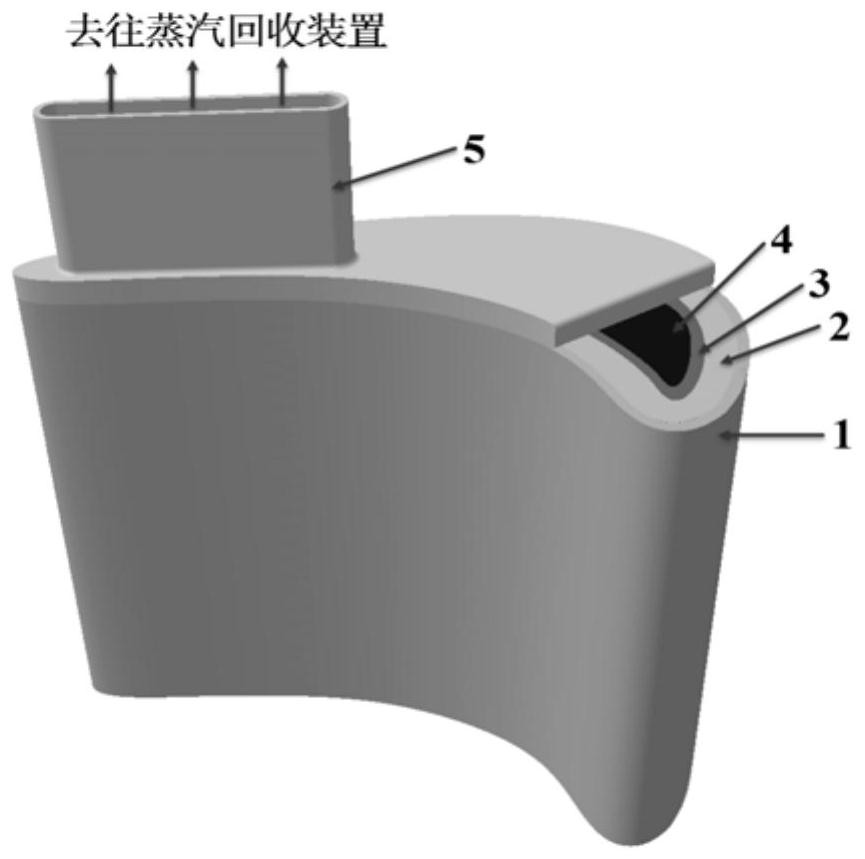

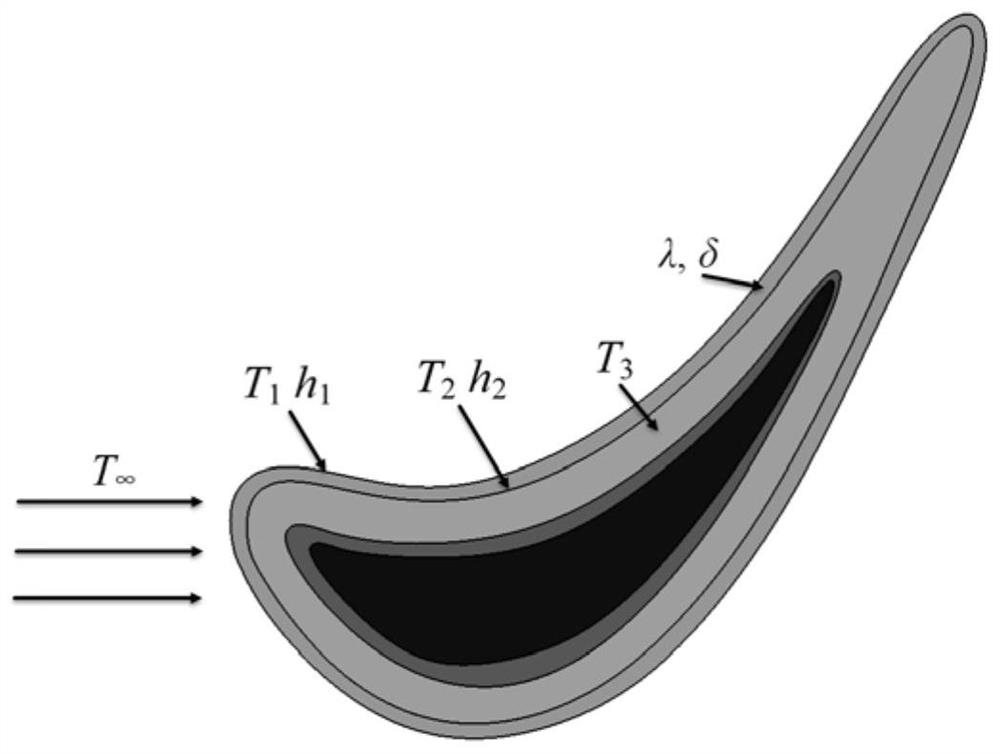

[0028] refer to figure 1 The steam-cooled double-layer turbine blade internal cooling structure of the present invention includes a turbine blade 1 and a porous medium layer 3; a cavity is provided in the turbine blade 1, and the porous medium layer 3 is located in the turbine blade 1. In the cavity, the porous medium layer 3 is provided with an internal chamber 4, an intermediate chamber 2 is formed between the outer wall of the porous medium layer 3 and the inner wall of the turbine blade 1, and the trailing edge or end of the turbine blade 1 is provided with steam Outlet 5, the inner chamber 4 is filled with saturated water, and the middle chamber 2 is filled with superheated steam; the size and shape of the porous medium layer 3 are determined according to the blade shape of the turbine blade 1, and the porous medium layer 3 is located on the turbine blade 1 at th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap