Single barrel vertical placed fire coal boiler

A single drum and grate technology, applied in the field of coal-fired boilers, can solve the problems of high cost, large steel ratio, complicated production process, etc., and achieve the effects of low cost, reasonable structure and small steel ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

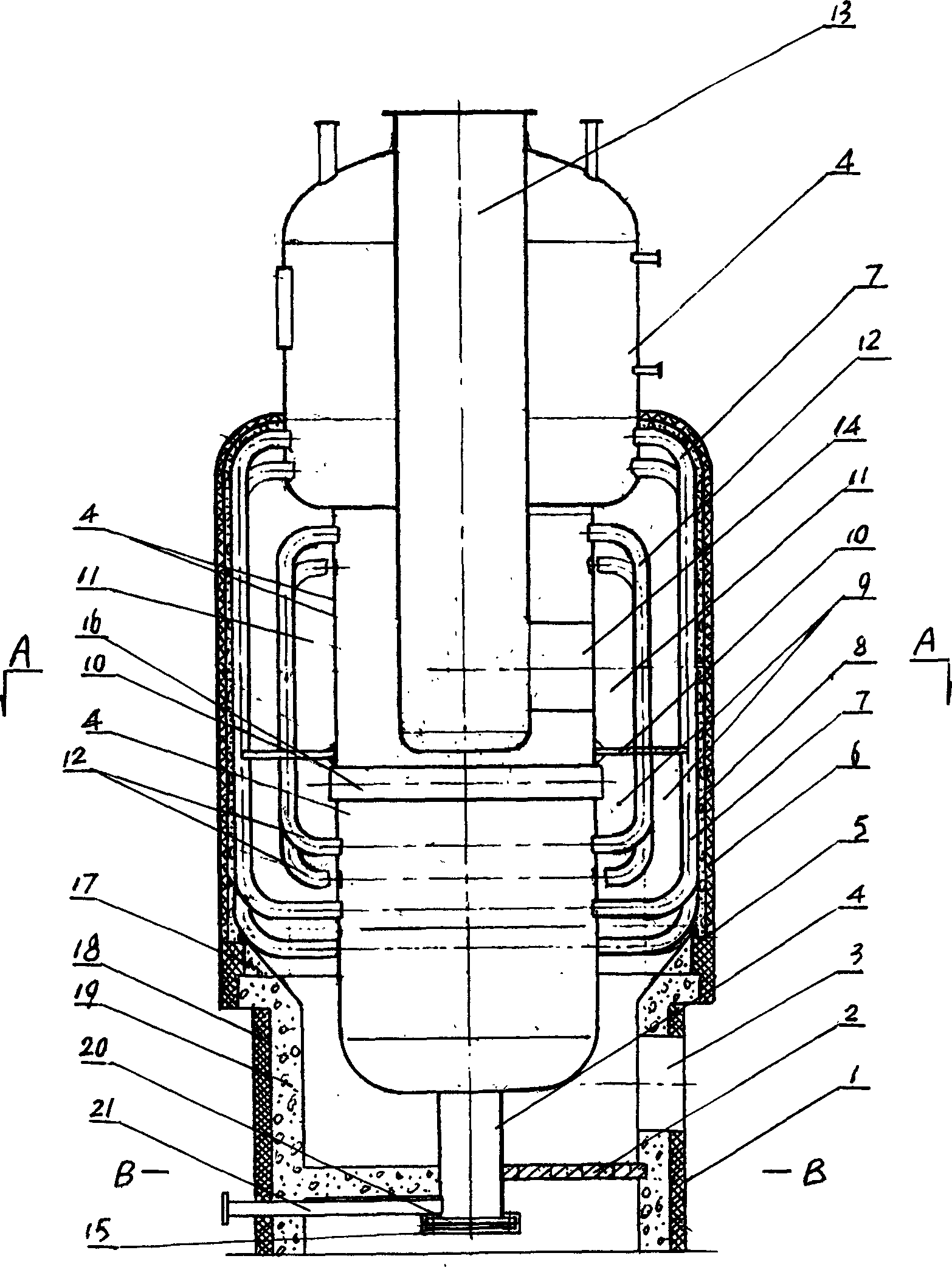

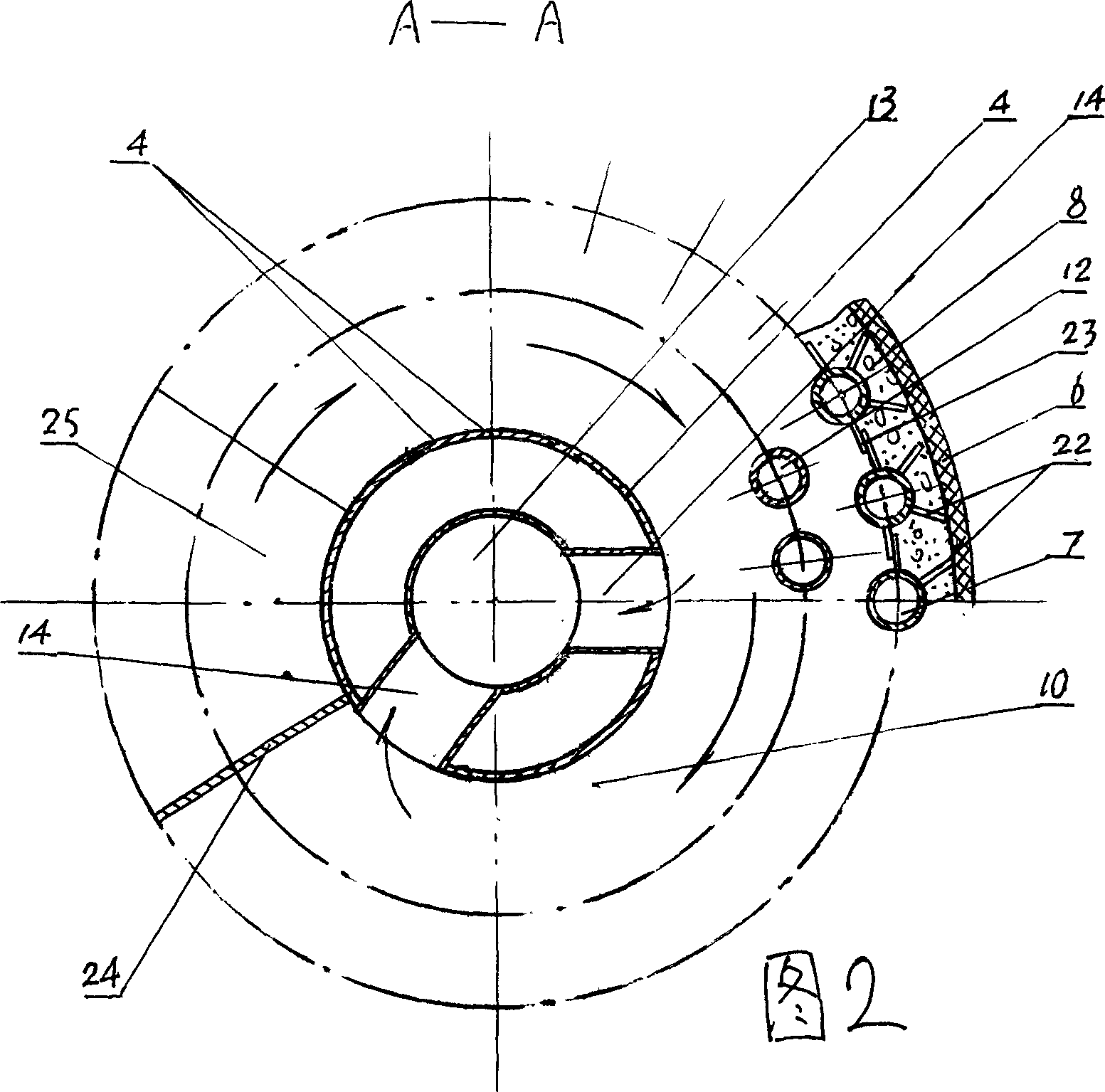

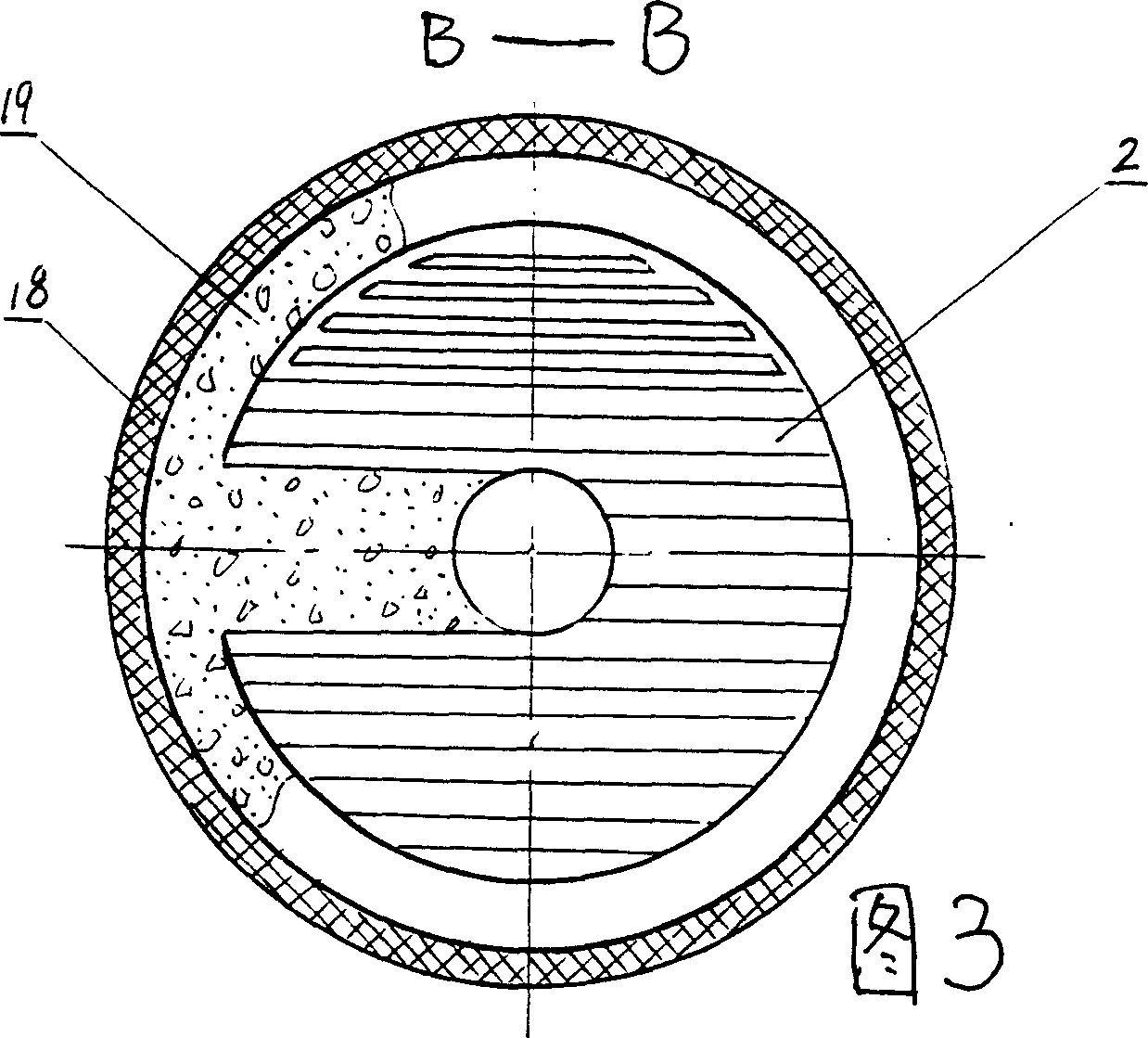

[0009] from figure 1 , Figure 2 and Figure 3, it can be seen that it is composed of furnace base 1, furnace grate 2, coal filling port 3, single drum 4, outer water-cooled elbow 7, inner water-cooled elbow 12, cupola 13, pyrotechnic pipe 14, etc. The single-drum vertical coal-fired boiler is characterized in that: the lower end of the single drum 4 extends to the lower part of the grate 2 and is equipped with a sewage pipe 21, and its end is a detachable flange 20 connected by bolts. The outer circumference of the blue plate 20 is installed with a snap-in type half-divided protective cover 15, so that the lowest part of the single drum 4 is in a non-heated area and the effect of sewage and scale removal is good, and the outer water-cooled curved pipes 7 evenly distributed on the outer circumference of the single drum 4 Two overlapping main fins 23 and two opposite secondary fins 22 are welded on the two of them. With the main fins 23 and secondary fins 22 as the skeleton, refr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap