Liquid atomizer

A liquid atomization and liquid technology, which is applied in liquid injection devices, injection devices, atomizers for treatment, etc., can solve the problems of stable quantitative spray, unsatisfactory, unstable atomization, etc., to improve convenience and stability. The effect of liquid delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Hereinafter, the present invention will be described in more detail based on embodiments.

[0086] (Embodiment 1)

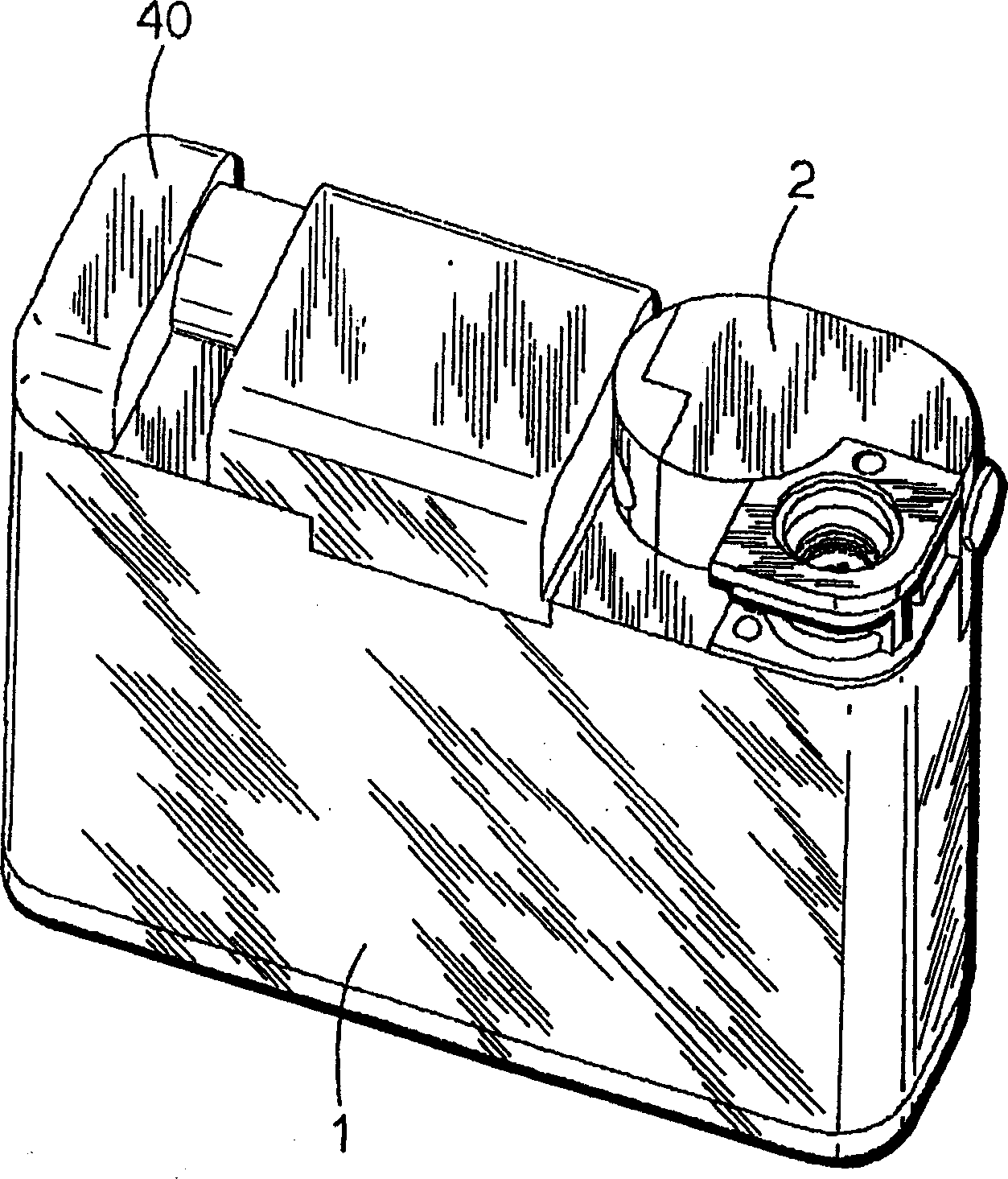

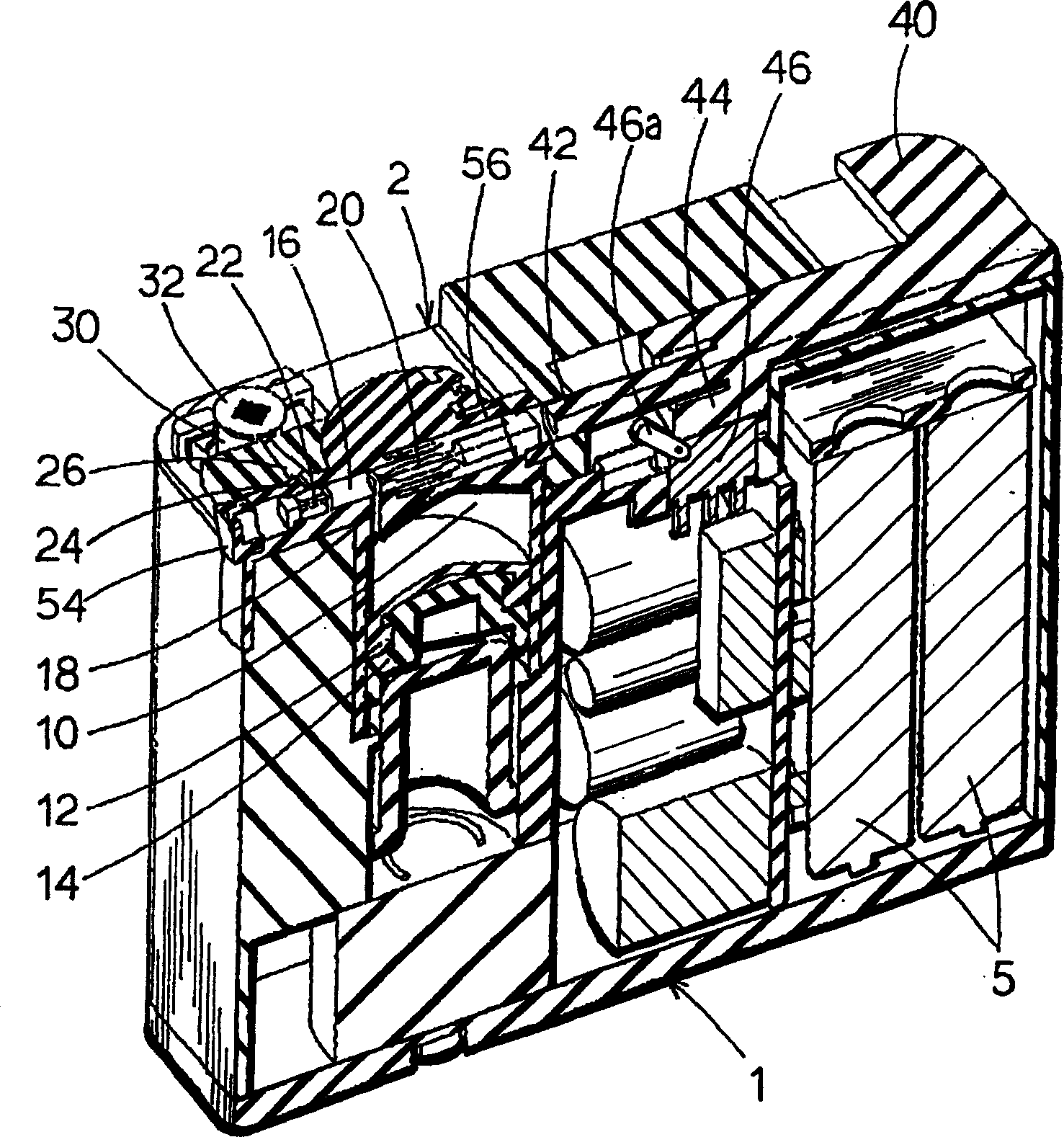

[0087] figure 1 A perspective view showing the appearance of the liquid atomizing device of the first embodiment. The liquid atomizing device is composed of a main body 1 and a liquid supply assembly 2, and the main body 1 has a battery housing portion 5 therein (refer to image 3 ) and the circuit part, etc., the liquid supply assembly 2 is detachably mounted on the main body part 1 .

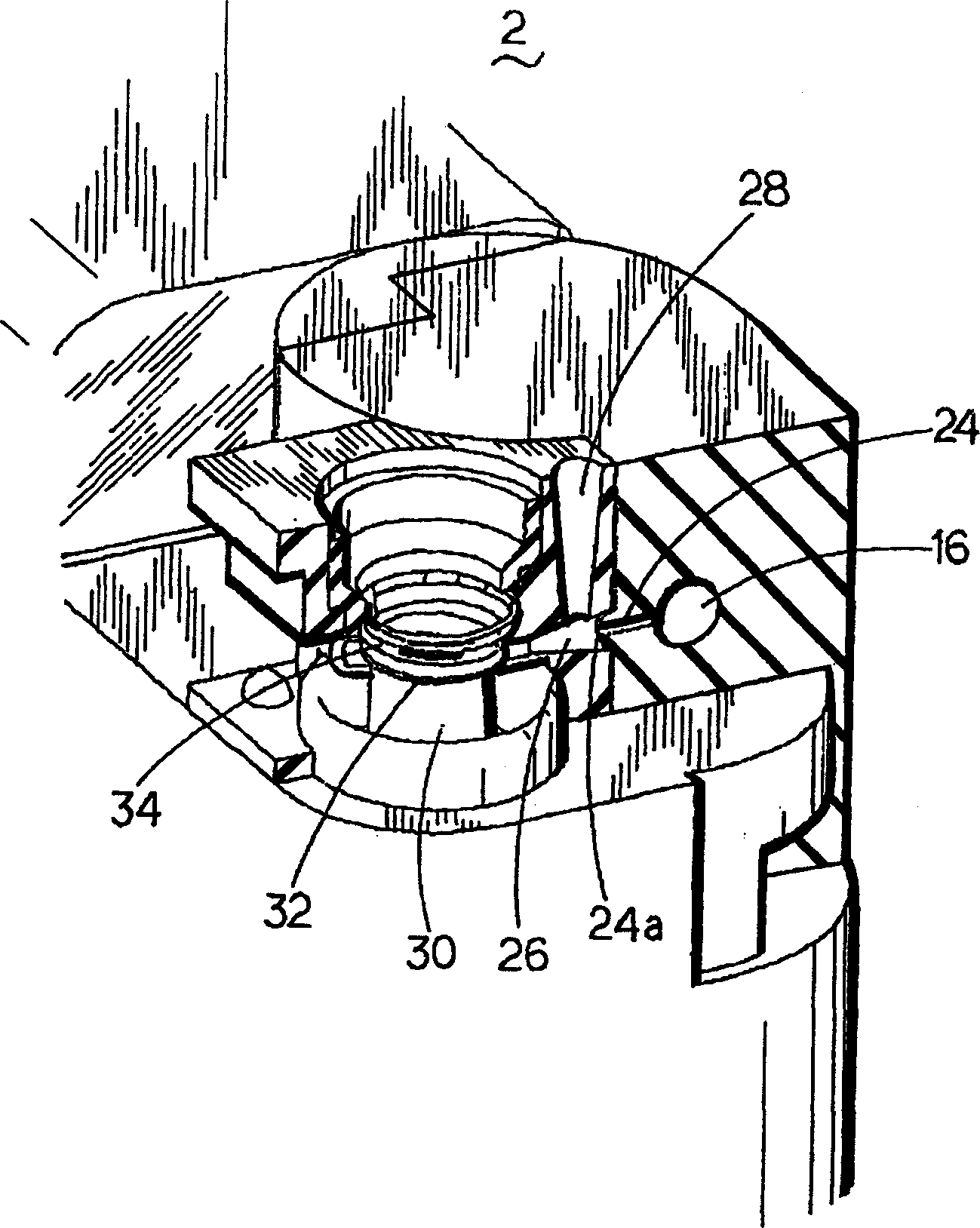

[0088] In a partially cutaway perspective view showing the liquid supply assembly 2 figure 2 and a longitudinal section showing the interior of the device image 3 In the device, a primary liquid storage part 10 for storing the liquid (medicine liquid) to be atomized is disposed inside the device, and a movable member 12 that can move up and down is installed in a liquid-tight manner at the bottom of the primary liquid storage part 10, and the movable member 12 doubles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com