Defrost heater component element of electric refrigerator

A technology for defrosting heaters and refrigerators, which is applied in defrosting, lighting and heating equipment, household appliances, etc. It can solve the problems of high temperature, no consideration, and waste of electric energy in refrigerators, so as to achieve effective defrosting and minimize electric energy , to prevent the effect of internal conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings.

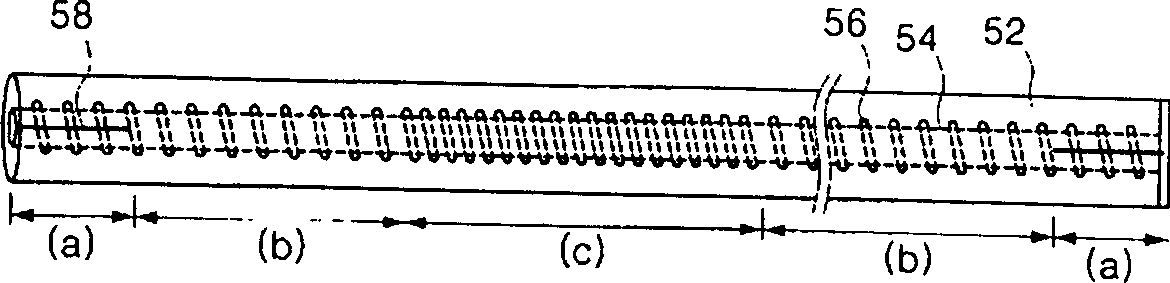

[0024] image 3 It is a cross-sectional view showing that a heater is placed inside a heater tube made of an aluminum tube in the present invention. Such as image 3 As shown, the heater of the present invention includes a heating wire 56 and an insulating sheath 52 . The above-mentioned heating wire 56 is wound on the core 54; the above-mentioned insulating sheath 52 surrounds the outer part of the above-mentioned heating wire.

[0025] In addition, a non-heat generating section a is formed at both end portions of the heater. The non-heat generating section a is formed by connecting a highly conductive metal material in parallel to the outer portion of the heating wire wound around the core 54 and having a constant resistance.

[0026] In the present invention, the heating wire 56 wound on the above-mentioned core 54 is composed of portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com