Motor rotating speed control method for optical drive and its control device

A speed control, optical drive technology, applied in the recording of information on magnetic disks, instruments, magnetic recording, etc., can solve the problems of increasing complexity and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

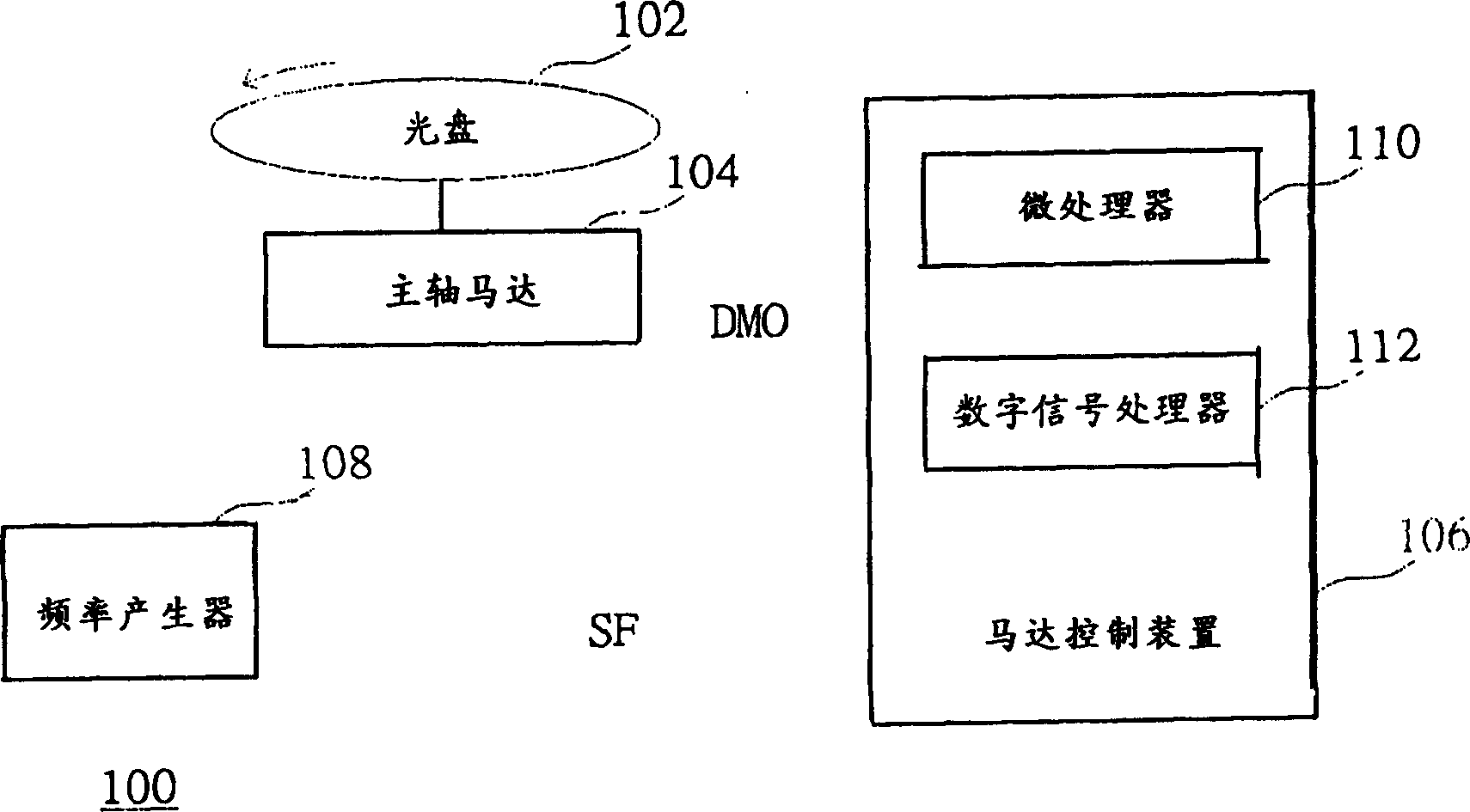

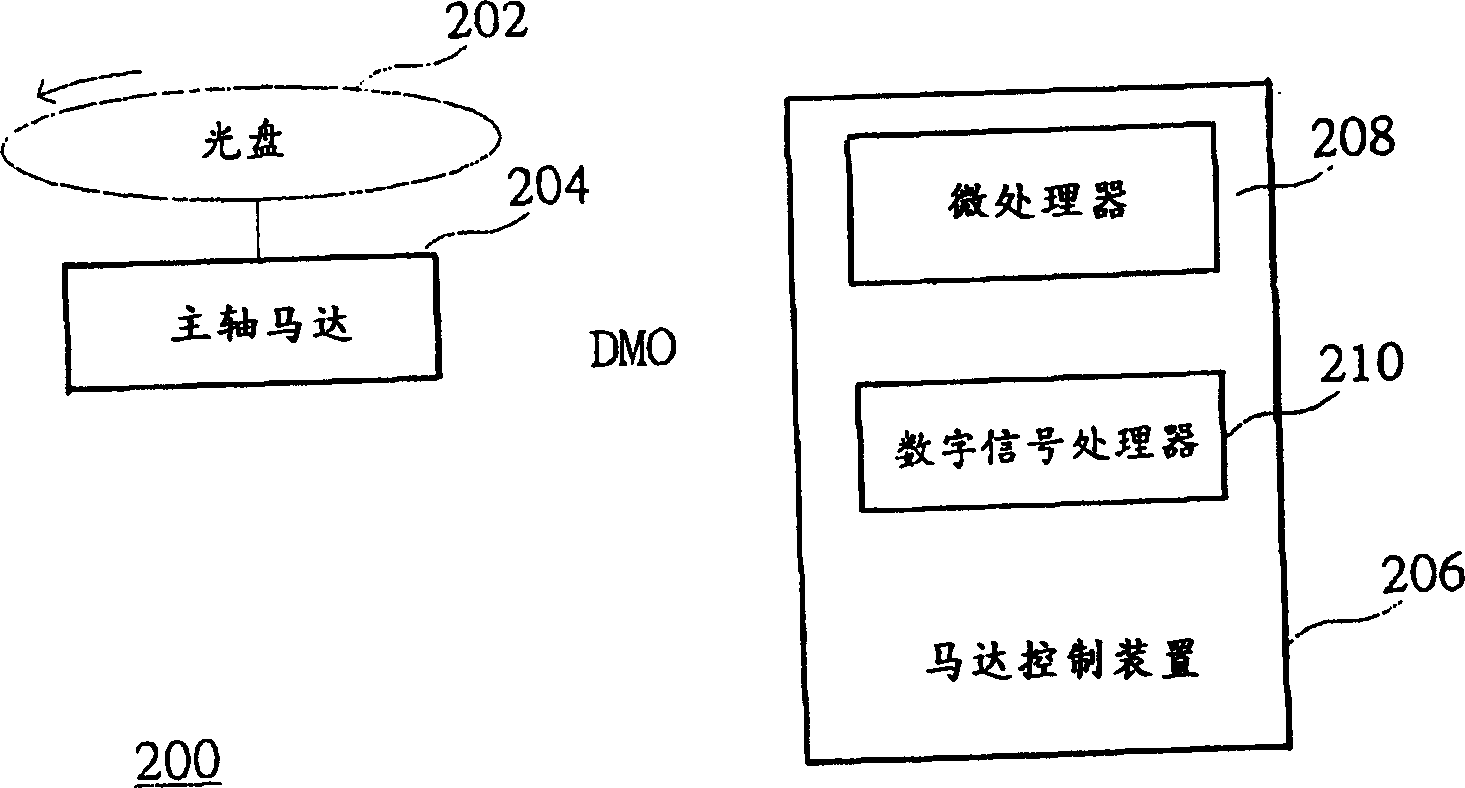

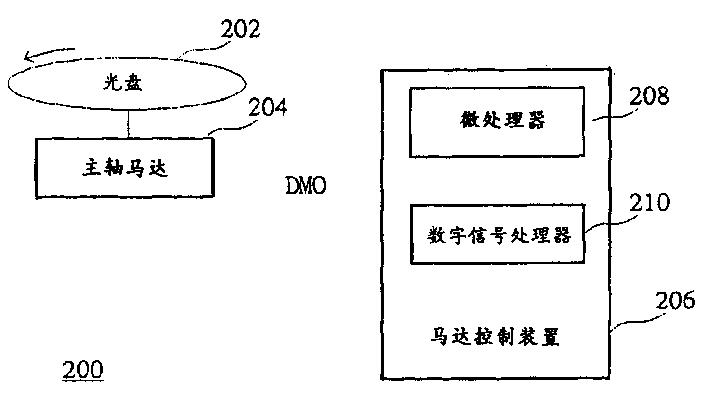

Image

Examples

Embodiment Construction

[0021] The feature of the present invention is that no matter how much the rotating speed of the optical disc is at that time, the braking time required to stop the optical disc from rotating is a fixed value. The principle is explained as follows:

[0022] Please refer to formula (1):

[0023] (1) T=J×α+f×ω

[0024] To make the disc rotate, the relationship between the torque T required by the spindle motor and the moment of inertia J of the disc, angular acceleration α, friction coefficient f and rotational speed ω is shown in formula (1). Wherein, the angular acceleration α and the rotational speed ω are functions of time.

[0025] Make formula (1) Laplace transform (Laplace transform) to get formula (2): ( 2 ) - - - T s = J ( s · Ω ( s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com