Needle-use threading device having height regulatable thread push pedal

A threader and pusher technology, applied in the field of needle threader, can solve the problems of complex overall structure, difficulty in determining, adding parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

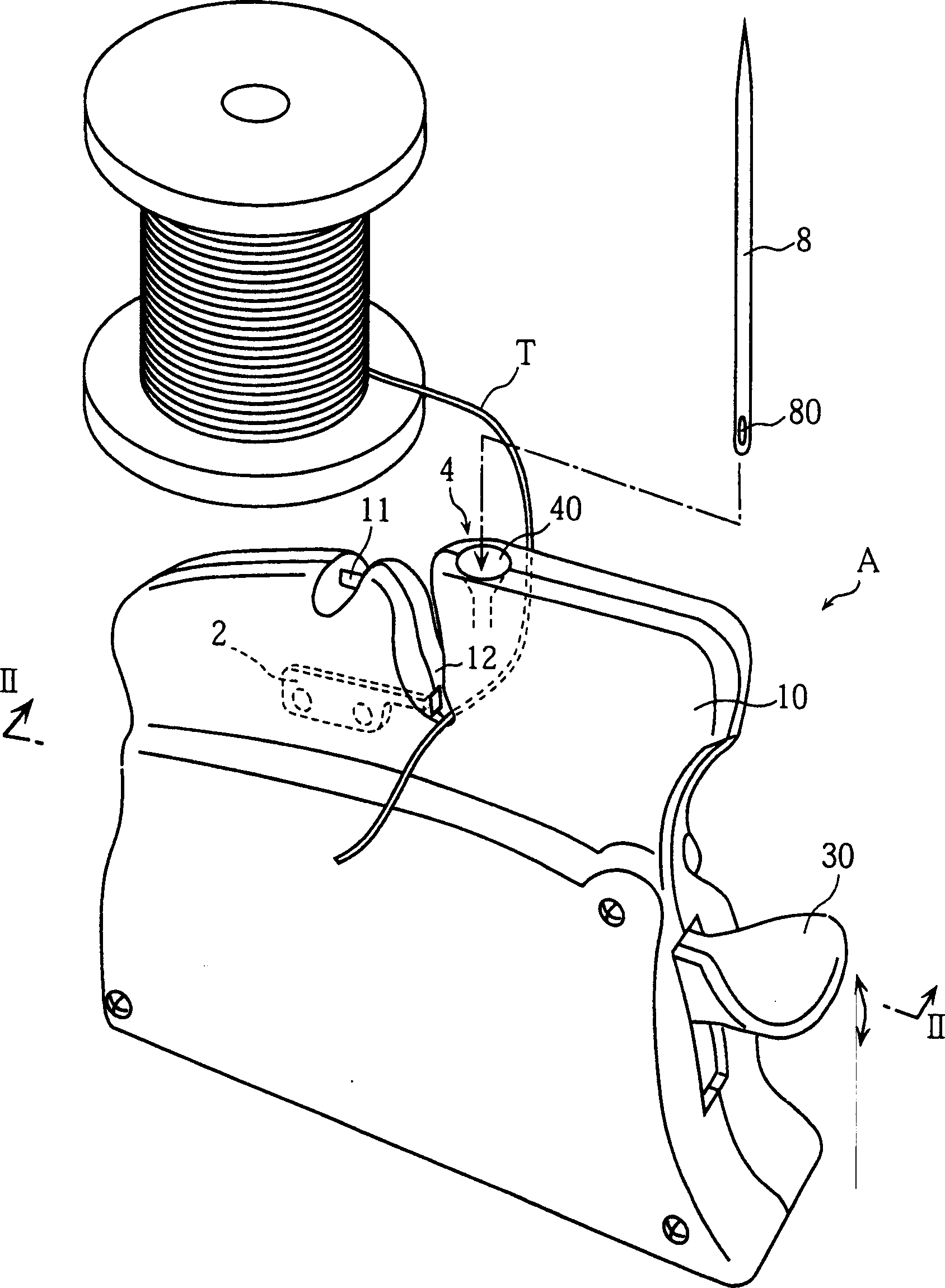

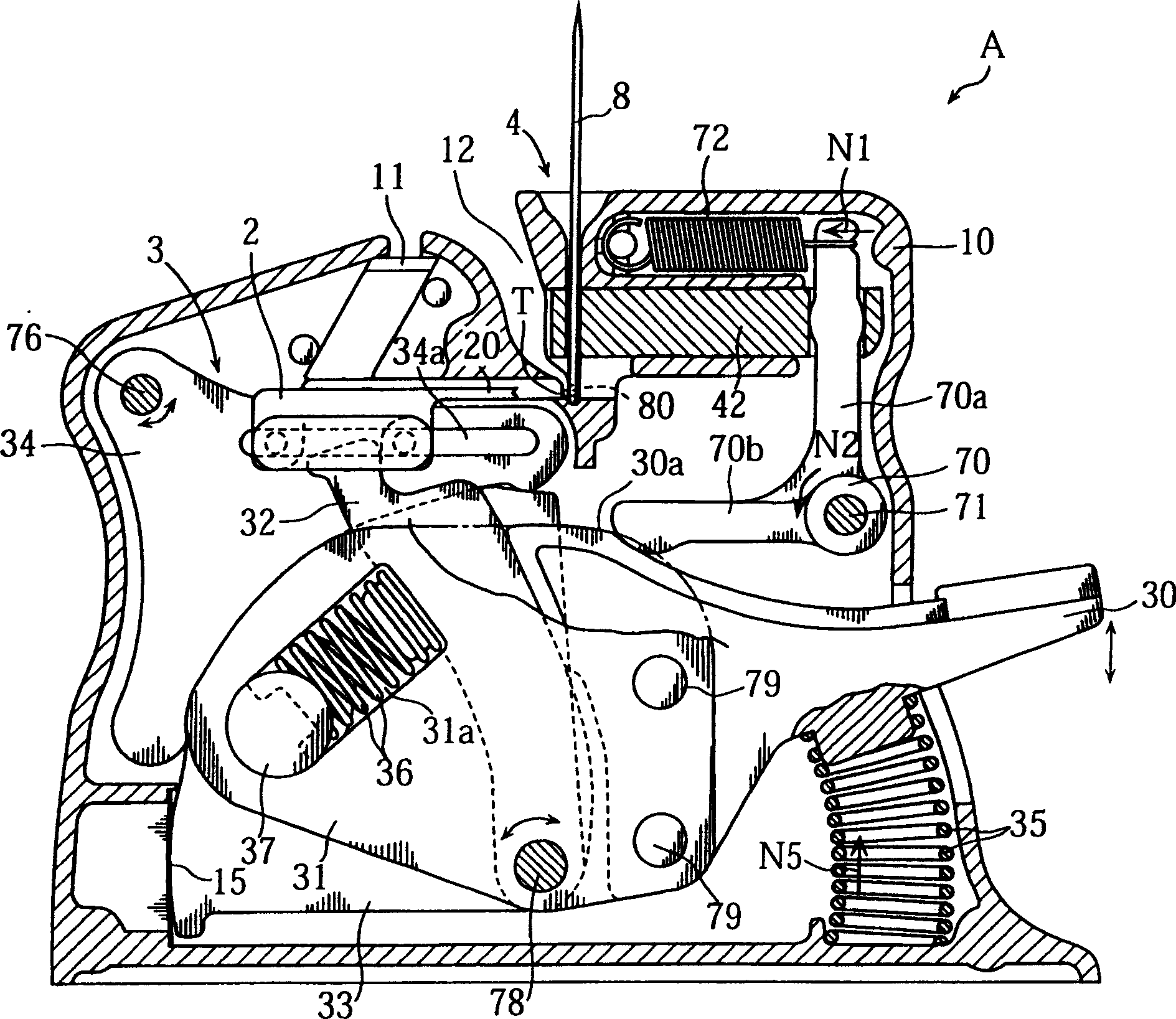

[0038] Picture 1-1 2 shows a needle threader according to an embodiment of the present invention. The appearance of the needle threader A of this embodiment is shown in figure 1 , where for the push plate operation the figure 2 The operating mechanism 3 shown is housed in a housing 10 of synthetic resin.

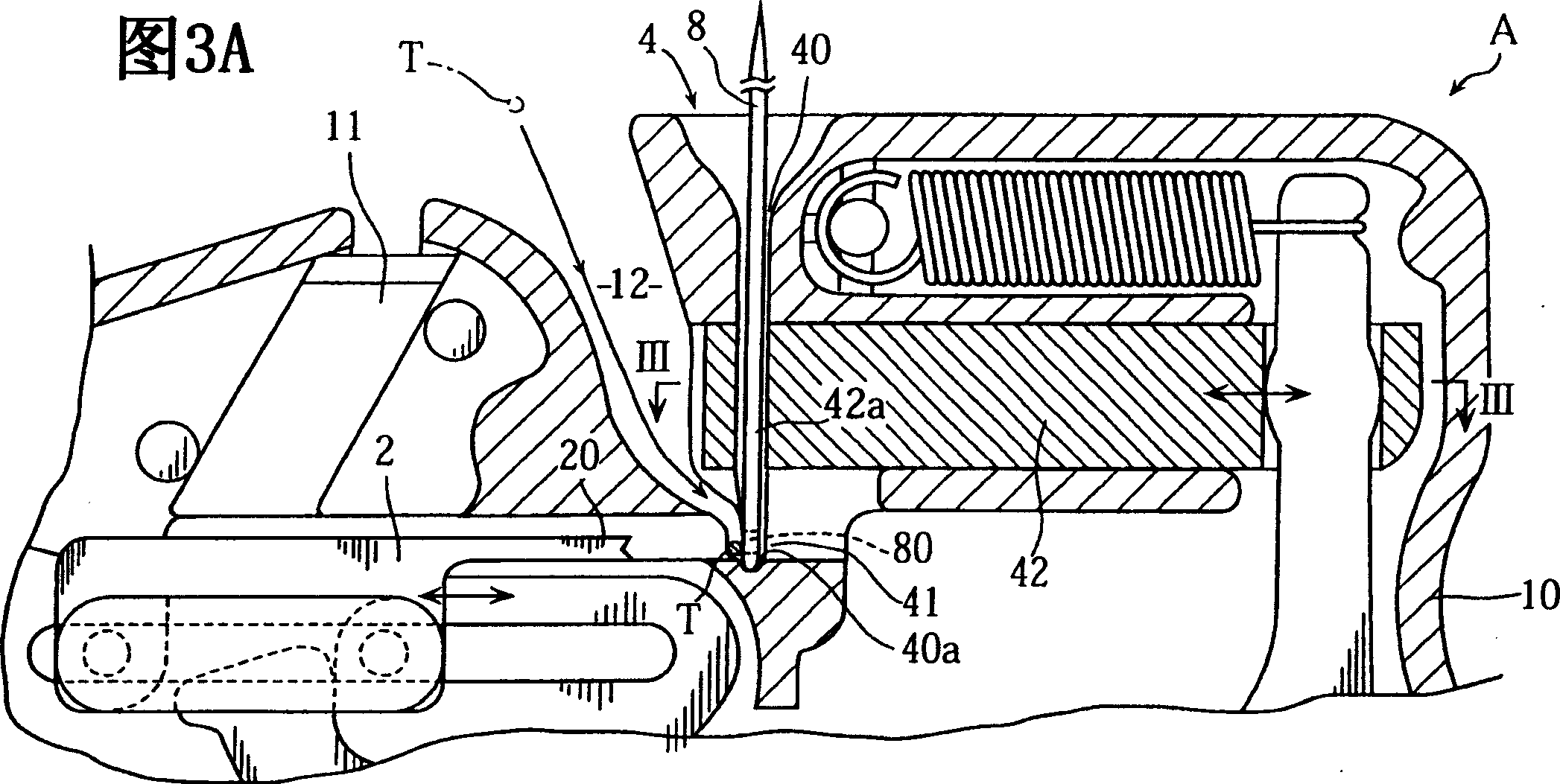

[0039] The housing 10 includes a side surface from which an operating rod 30 protrudes for controlling the operating mechanism 3 . The upper part of the housing 10 is provided with a needle holder 4 for holding the needle 8 in an upward posture; a cutter 11 for cutting the thread; and a valley-shaped depression 12 . When the needle threader A is used, a part of the thread is blocked by the bottom of the valley-shaped depression 12.

[0040] As clearly shown in FIG. 3A , the needle holder 4 includes a needle receiving hole 40 with a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap