Composition for generating chlorine dioxide

A chlorine dioxide and composition technology, applied in the fields that need research, disinfection and deodorization, can solve problems such as uneconomical installation and use of generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

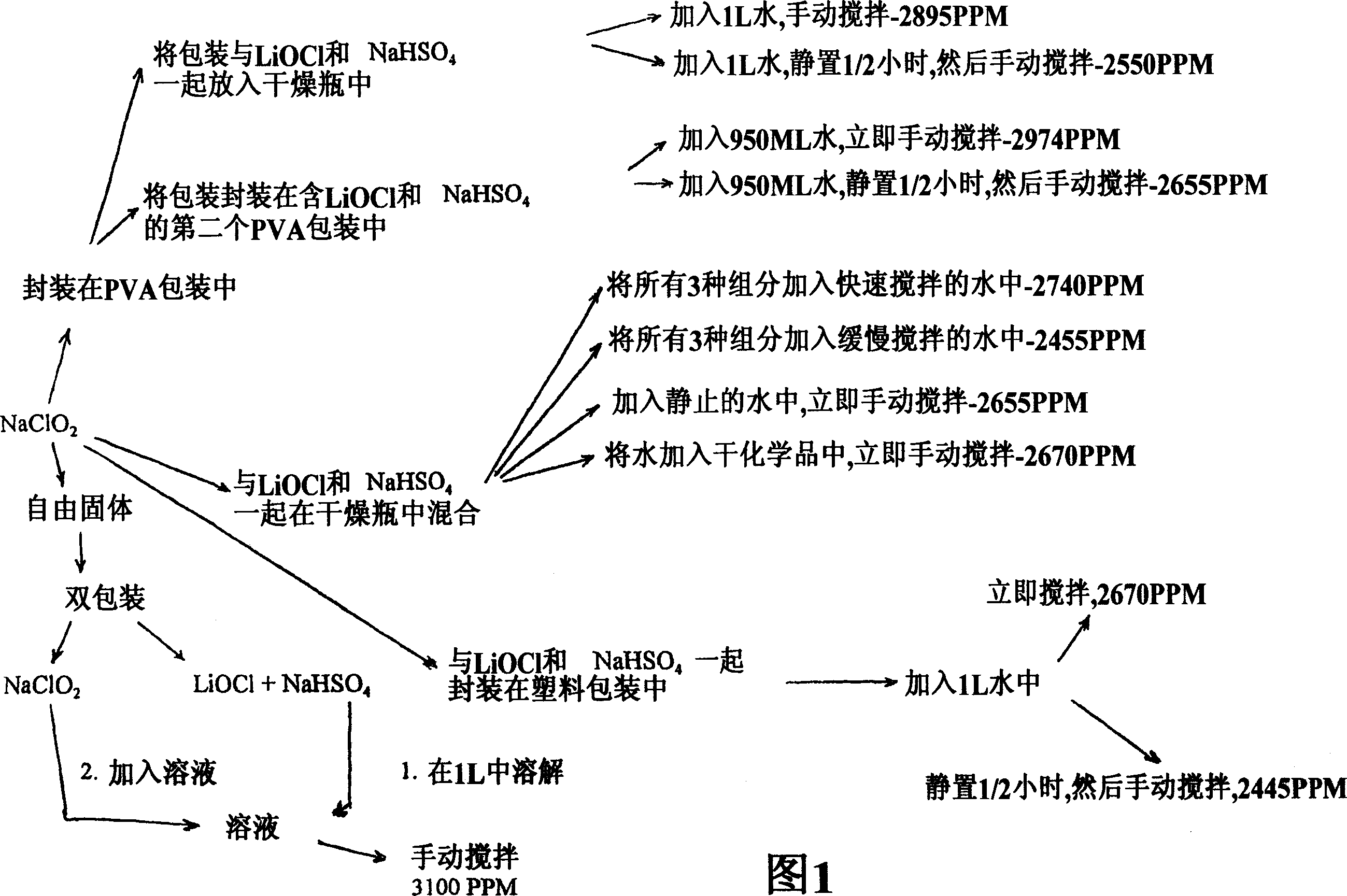

Image

Examples

Embodiment A

[0111] Supplied in a separate container

[0112] container 1

[0113] 4 g sodium bisulfate and

[0114] 1.14g lithium hypochlorite (25%)

[0115] container 2

[0116] 3.36ml 25% sodium chlorite in water

[0117] When the contents of container 1 and container 2 are added to a gallon of water, they will produce 150 ppm chlorine dioxide with a pH of 3.5.

Embodiment B

[0119] Supplied in a separate container

[0120] container 1

[0121] 40.0g sodium bisulfate and

[0122] 11.4g lithium hypochlorite (25%)

[0123] container 2

[0124] 33.6ml 25% sodium chlorite in water

[0125] When the contents of container 1 and container 2 are added to a gallon of water, they will produce 300 ppm chlorine dioxide with a pH of 3.8.

Embodiment C

[0127] To prepare a dilute solution of chlorine dioxide at 150-300 ppm per gallon of water, first make a "dry and wet" formulation of an activator mix containing 4 g sodium bisulfate and 1.14 g lithium hypochlorite (25%) per gallon of water completely dissolved. After complete dissolution, add 3.36 ml of 25% sodium chlorite in water per gallon of water. After complete mixing, the concentration of chlorine dioxide was 150 ppm and the pH of the solution was 3.5. The amount of reactants used to prepare the 150 ppm solution was doubled to obtain a 300 ppm chlorine dioxide solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com