Swinging hydraulic dipper shovelling machine

A swing-type excavator technology, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve problems such as the inability to ensure the size of the pedal 61, increase costs, etc., and achieve ride-and-drop Good stability, realize the effect of operating rate and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Refer to the following Figure 1-10 Embodiments of the present invention will be described in detail.

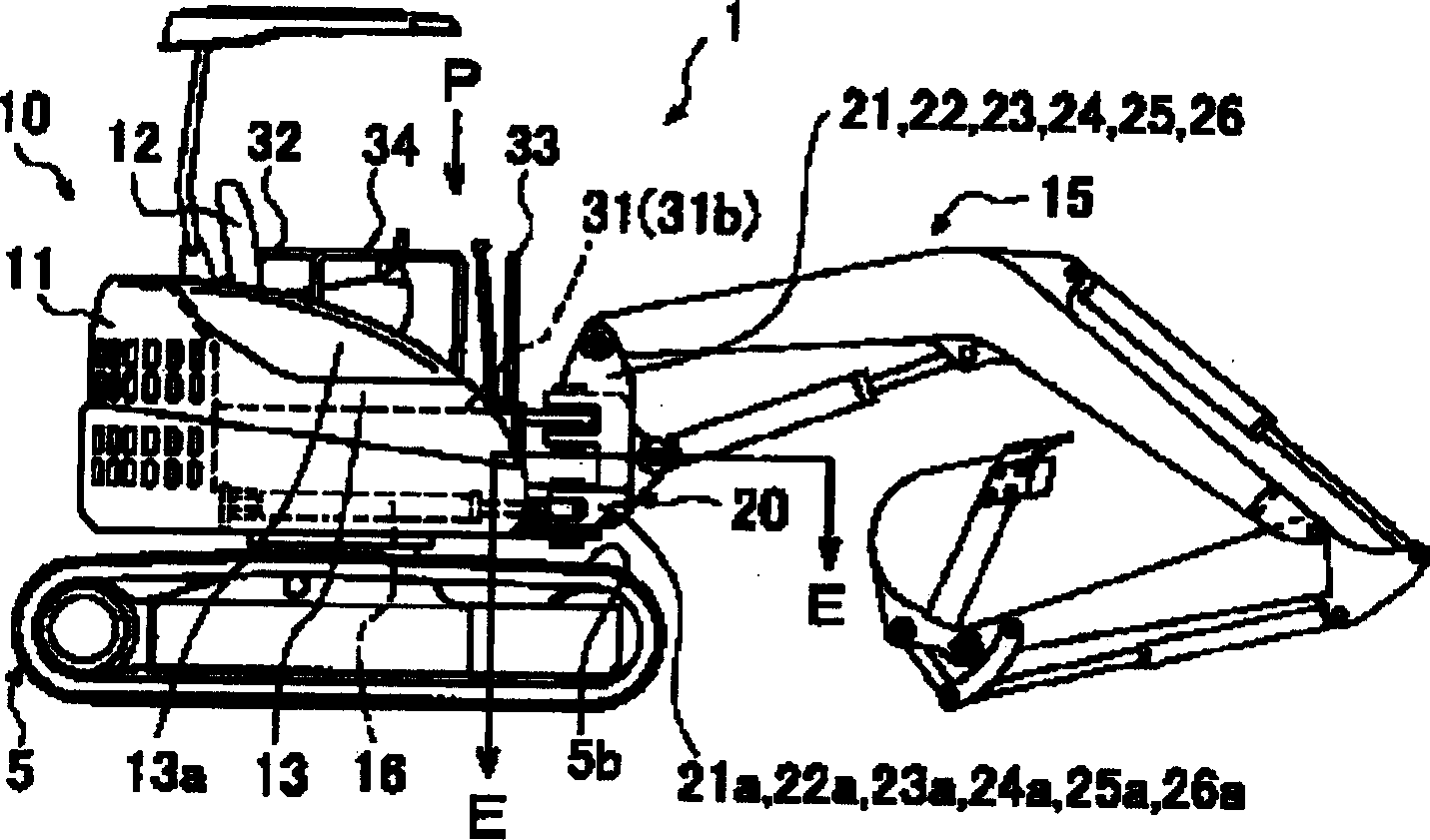

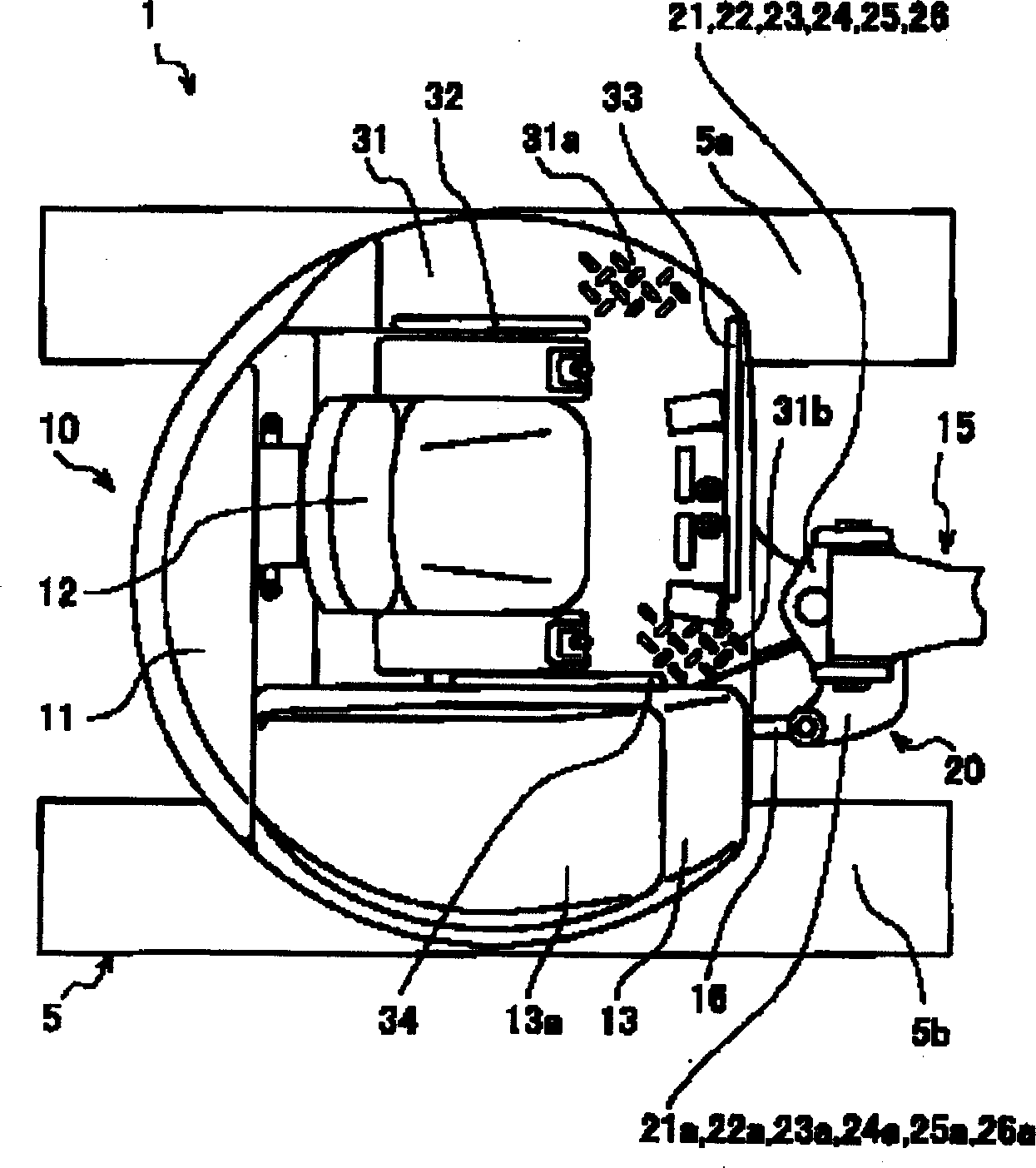

[0035] first according to Figure 1~2 Examples of the present invention will be described. figure 1 It is a side view of the swing hydraulic bucket excavator of the present invention. figure 2 It is a top view of the main part of the same hydraulic bucket excavator, which is figure 1 The P-direction view. In addition, in the following description, the same code|symbol is attached|subjected to the same component as the previous figure, and description is abbreviate|omitted.

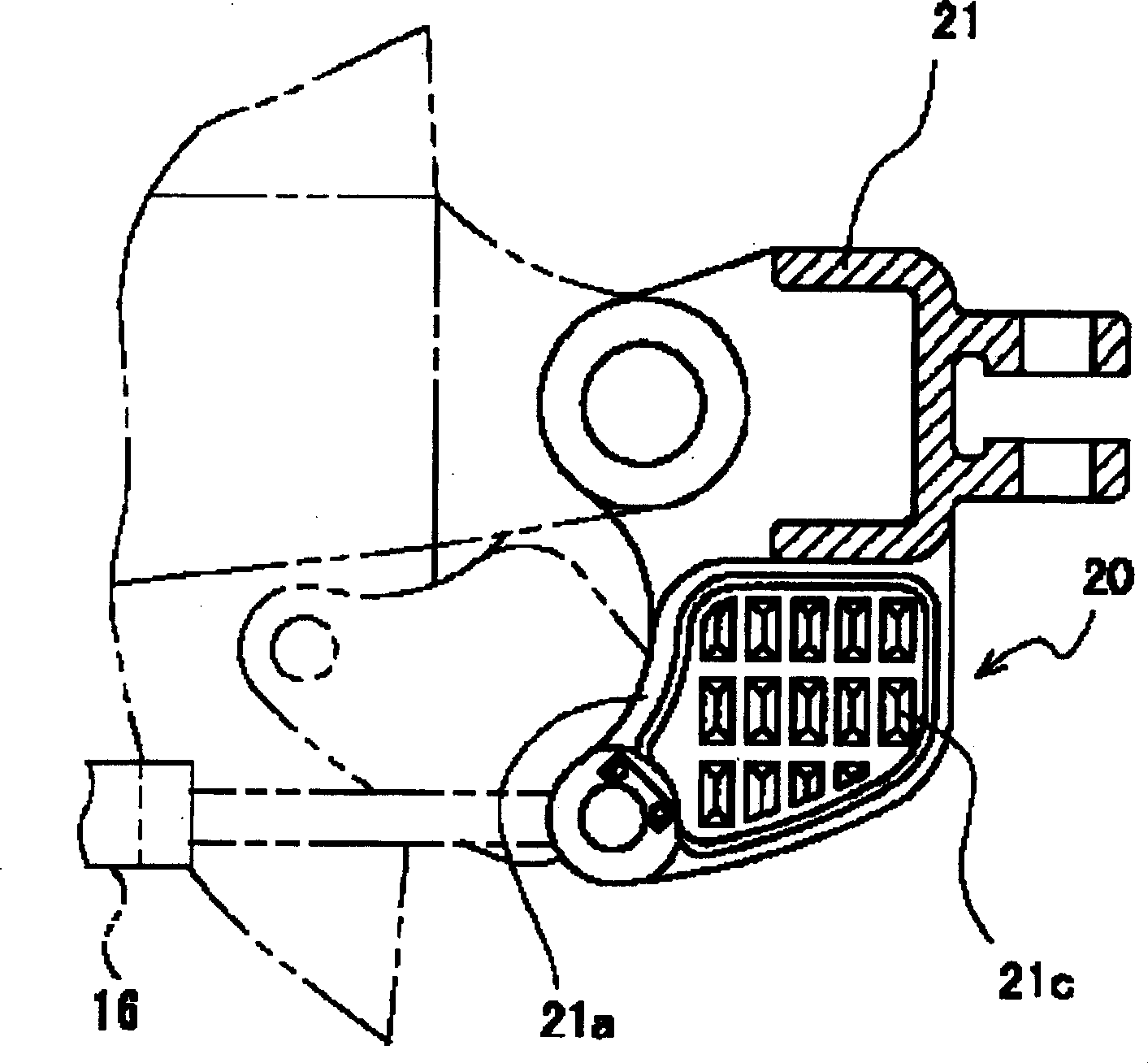

[0036] first according to Figure 1~2 , the swing type hydraulic bucket excavator 1 of the present invention will be described. In the front part of the upper rotating body 10 of the swing type hydraulic bucket excavator 1, swing brackets 21, 22, 23, 24, 25, 26, which will be described in detail in the following embodiments, are installed in the left and right direction. A work machine 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com