Balance plate and its digital correction method

A technology of balance discs and balance weights, which is applied in static/dynamic balance testing, machine/structural component testing, instruments, etc. It can solve problems such as wasting time and difficulty in achieving calibration accuracy, and achieve high calibration accuracy and calibration accuracy. Short time, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

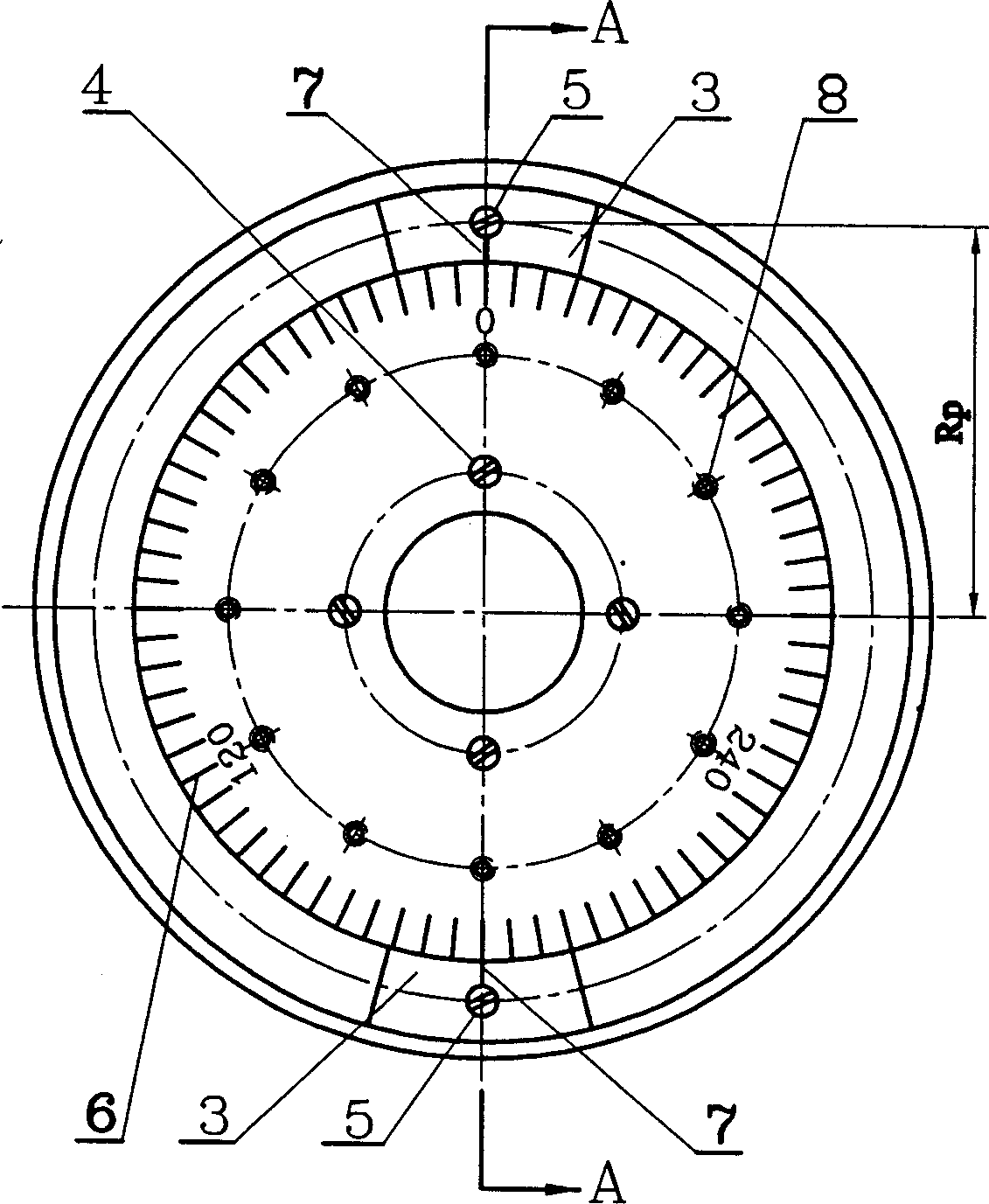

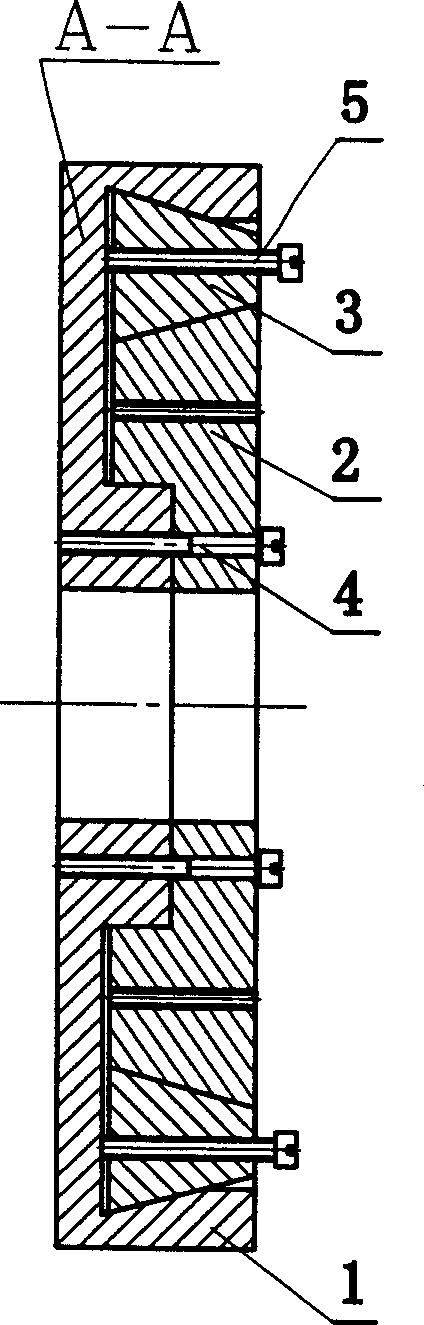

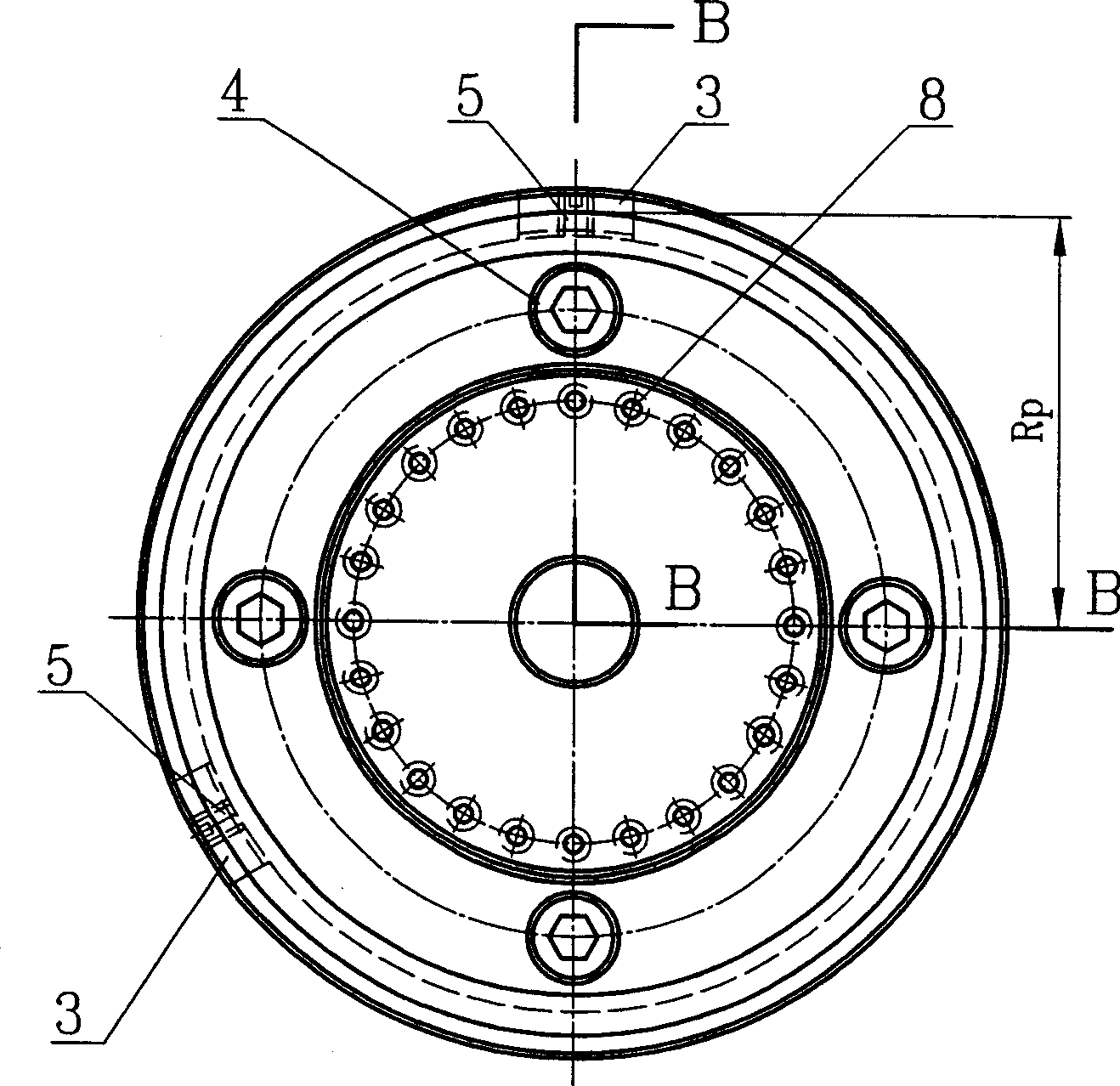

[0045] A balance plate with a structure: the shape of the main plate is cylindrical, and there is a frustum-shaped opening hole with the large end at the bottom in the main plate, and there is a cylindrical boss around the through hole on the axis; the shape of the attached plate is circular. The frustum shape is located in the frustum-shaped opening hole of the main disc body, and the opening hole on it is matched with the cylindrical boss in the main disc body, and the small end face of the attached disc body is opposite to the frustum-shaped hole bottom of the main disc body ;The inner surface of the frustum-shaped opening hole of the main disk body and the frustum-shaped outer surface of the attached disk body form an annular groove with a trapezoidal radial cross-section, and there are two balance weights in the groove; there are 0-360 on the surface of the attached disk body. ° scale.

[0046] Another structure of the balance plate: the main and attached plates are cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com