Method for reducing noise and cavitation in machines and pressure exchangers which pressurize or depressurize fluids by means of displacement principle

A pressure exchanger, principle technology, applied in the direction of fluid pressure converter, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the problems of unacceptable noise level and limited time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

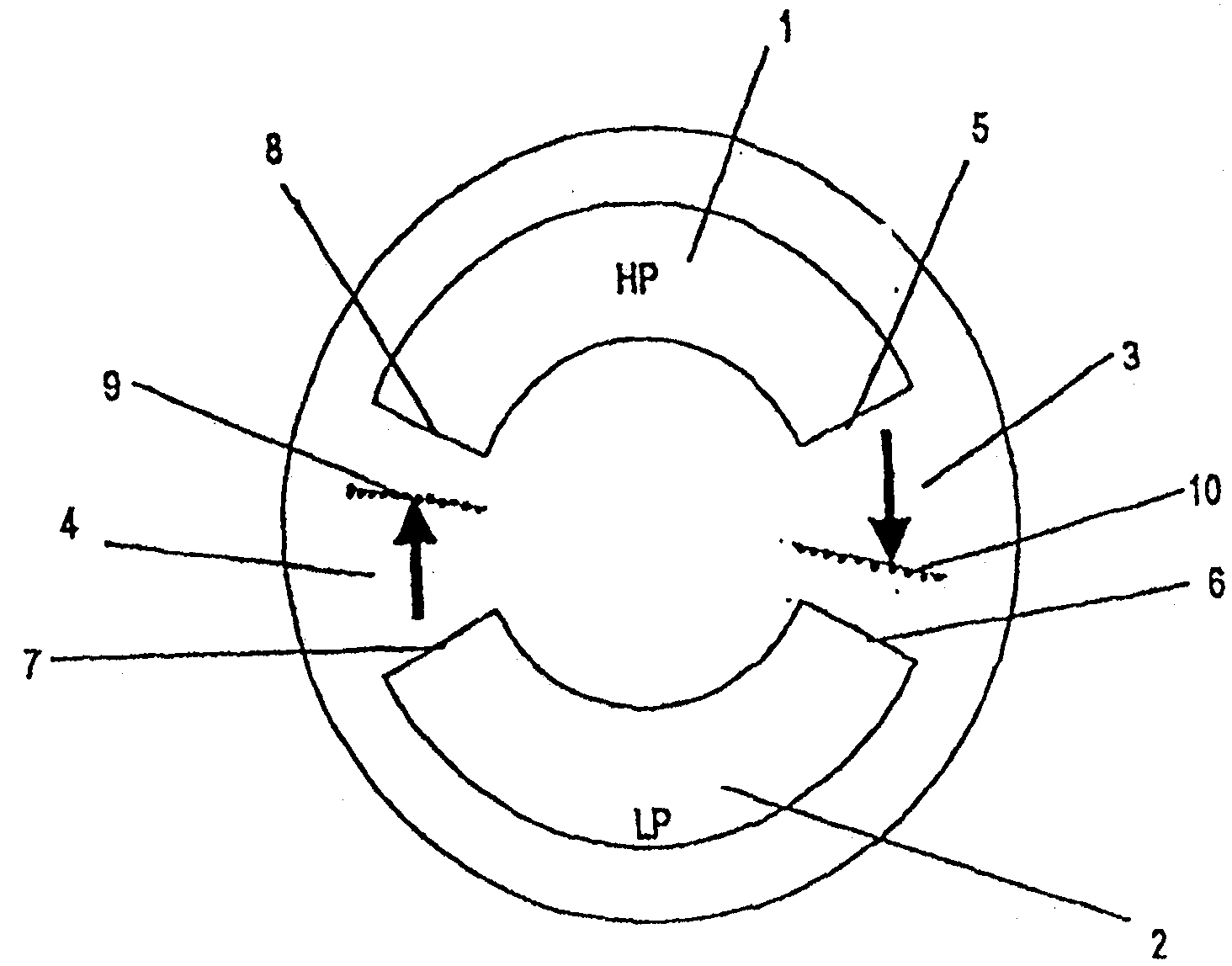

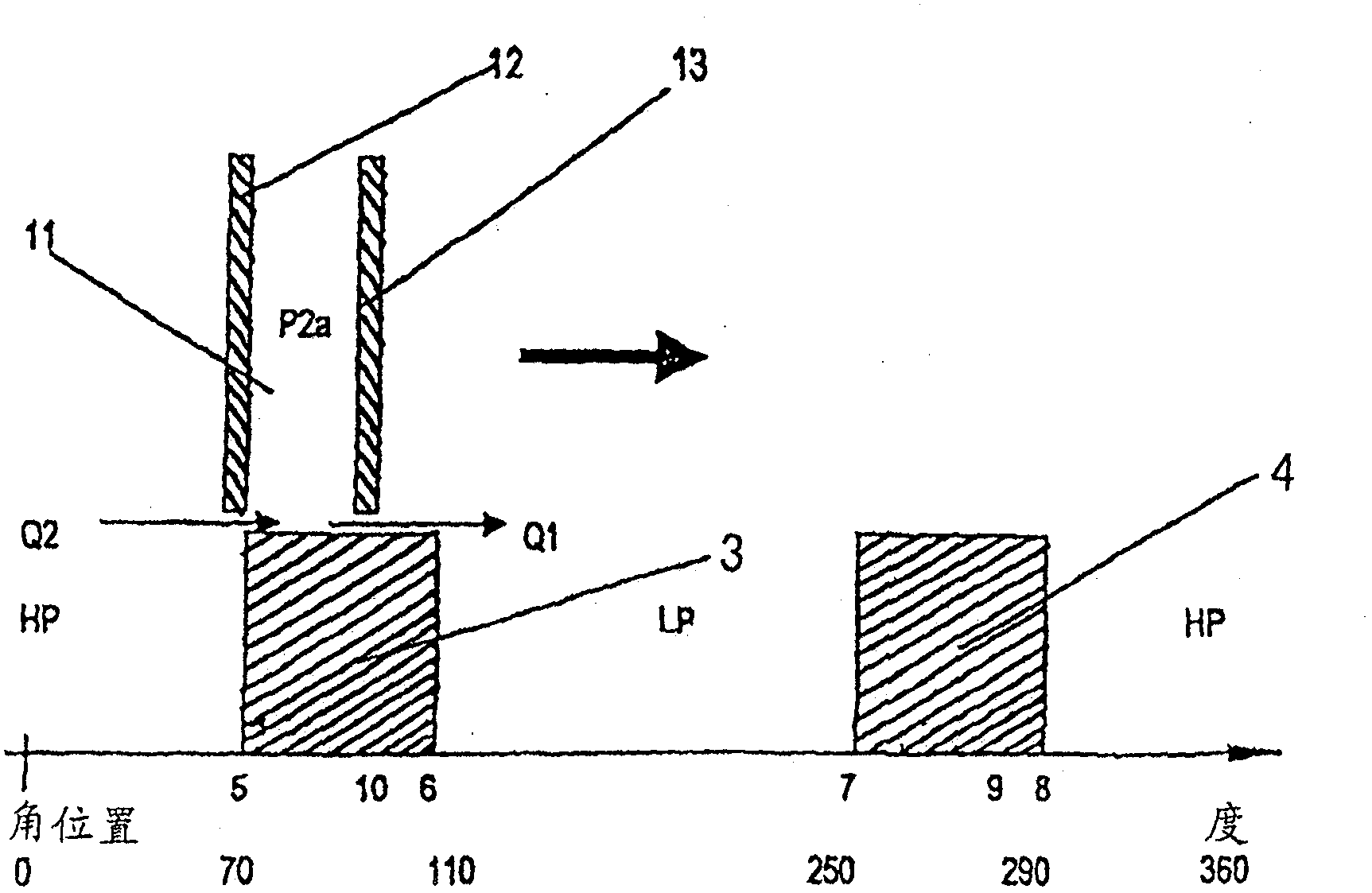

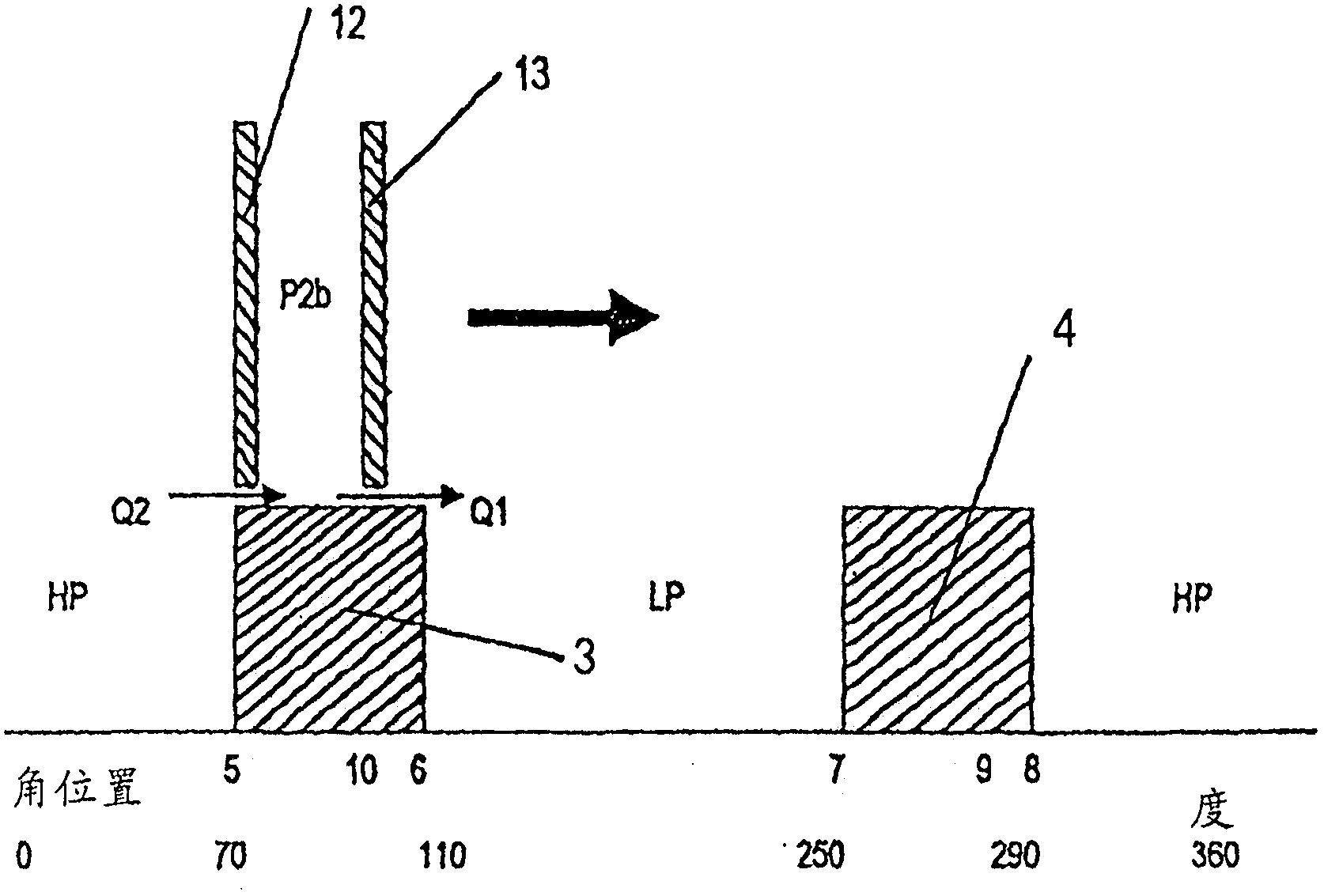

[0013] figure 1 All major components of a symmetrical end cap with high pressure port 1 and low pressure port 2 are shown. Although the aperture angles are the same in the figures, this is not necessary and may be advantageous in combination with a different number of channels in the rotor. There are two sealing areas on the end cover, one is the decompression area 3 between the high pressure side and the low pressure side, and the other is the pressurized area 4. According to the fact that the rotor channels rotate clockwise, all the rotor channels will pass from the high pressure port 1 through the decompression zone 3 to the low pressure port 2, so as to pass through the pressurized zone 4 and enter the high pressure port 1 again. Furthermore, the decompression zone 3 has an inlet edge and an outlet edge 6 , and the pressurization zone 4 has an inlet edge 7 and an outlet edge 8 , respectively. The angular extent of the sealing areas 3 and 4 covers at least one complete ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com