Air-entraniing concrete mould for simultaneously completing casting and cutting and use

A technology of aerated concrete and mould, applied in the direction of manufacturing tools, ceramic forming machines, etc., can solve problems such as mould leakage, and achieve the effect of preventing leakage, overcoming material loss and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

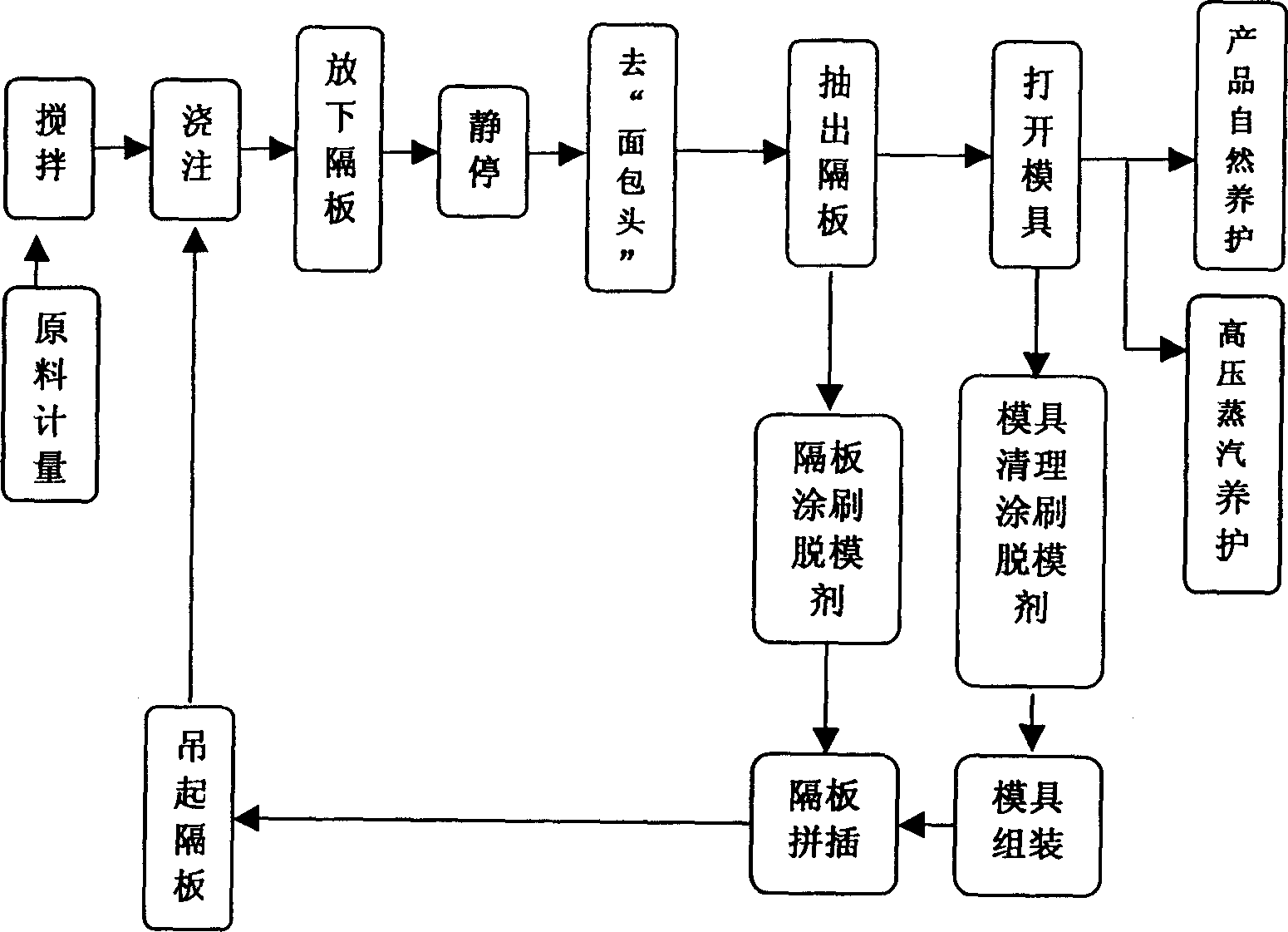

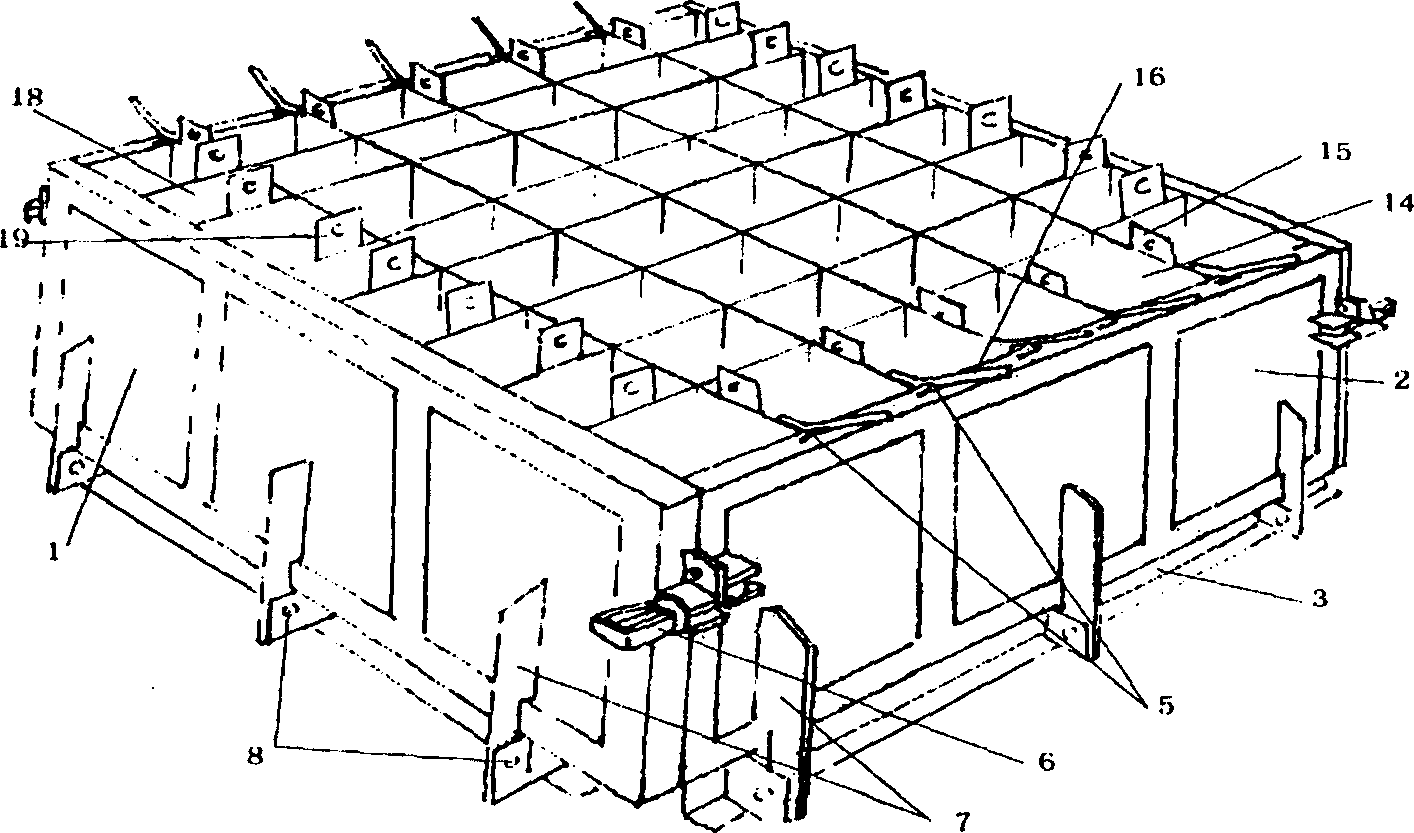

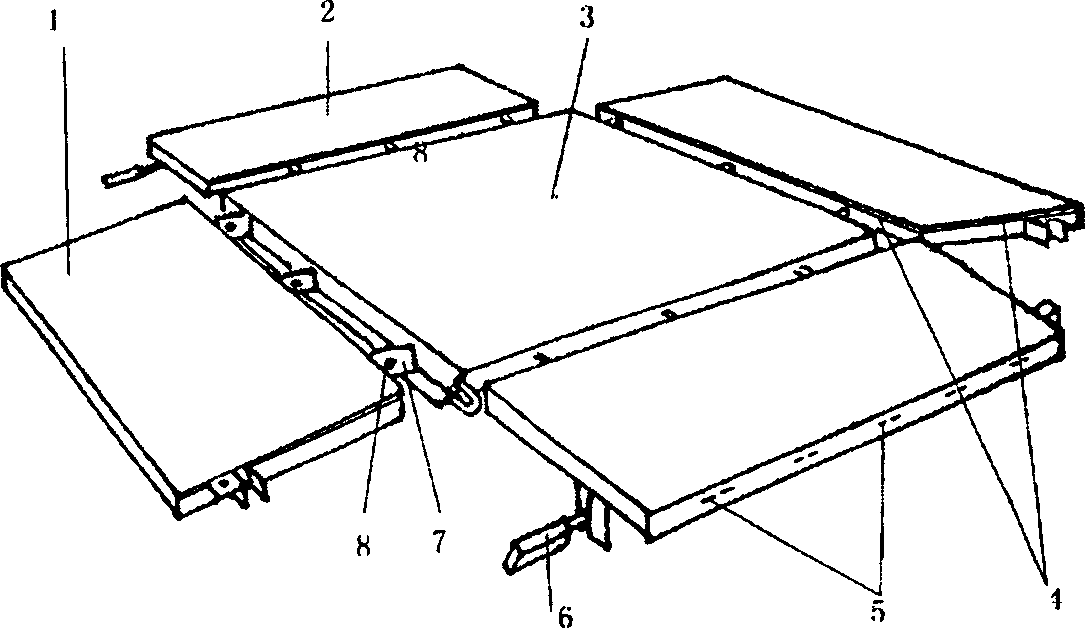

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] As shown in the figure, 1 longitudinal side plate, 2 transverse side plate, 3 bottom plate, 4 sealing strip, 5 longitudinal partition positioning groove, 6 connecting bolt, 7 connecting rib between side plate and bottom plate, 8 rotating shaft, 9 bolt fixing seat , 10 pin, 11 pin perforated seat, 12 bolt fixing slot, 13 nut, 14 longitudinal partition, 15 lifting ear (longitudinal partition), 16 positioning handle, 17 slit (longitudinal partition), 18 horizontal partition, 19 Lifting lug (transverse partition), 20 slits (transverse partition), 21 lifting rod, 22 steel wire rope, 23 suspension hook, 24 stirring equipment, 25 pouring connecting pipe.

[0034] The mold mainly consists of vertical and horizontal side plates, vertical and horizontal partitions, bottom plates, lifting rods, connecting ribs and connecting bolts. The longitudinal side panels 1 and the t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap