Plane curve capacity type for removing system intelligent sensor for automobile glass

A technology of smart sensor, flat curves, applied in the direction of windshield, vehicle parts, electrical circuits or fluid lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

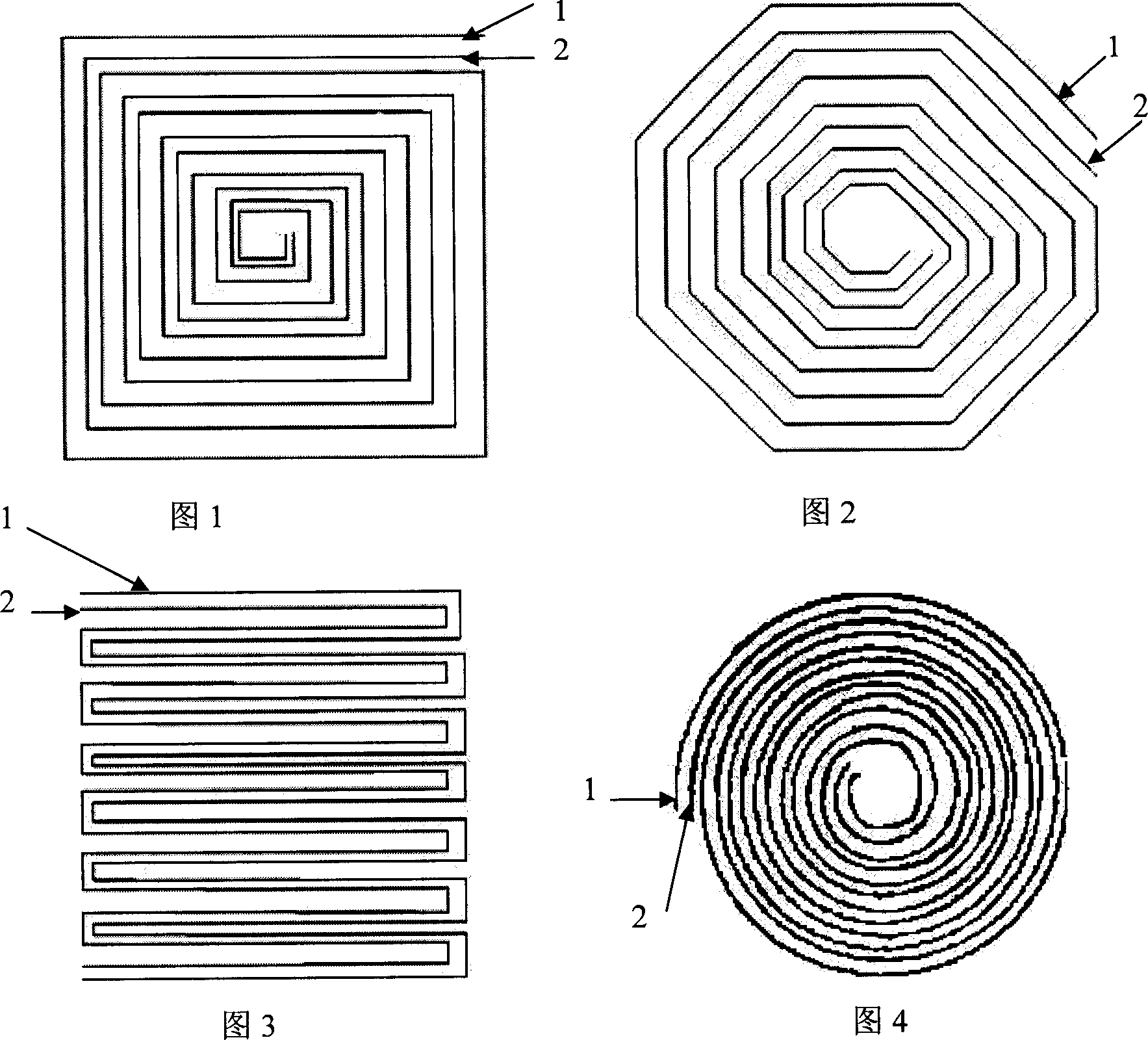

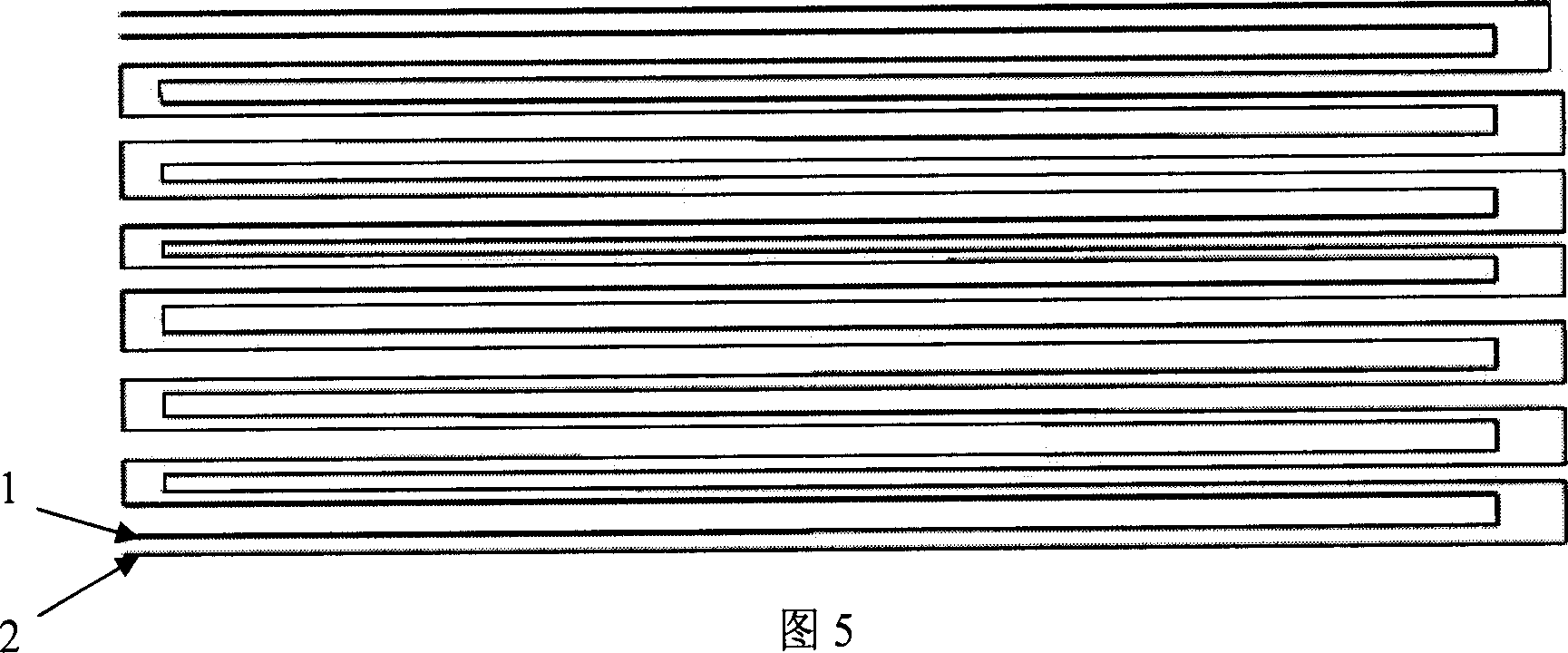

[0043] In this embodiment, a flexible circuit board with a transparent plastic film as the substrate is processed into a pair of Figure 13 The shown radius is r=3cm, spacing d=0.5mm, line width is w=0.3mm polygonal spiral planar curve electrode, the electrode total area is about 10 square centimeters, and wherein, 1 and 2 are two parts of planar curve capacitance respectively An electrode, 8 is a transparent plastic film substrate. according to Figure 14 The shown position is pasted on the lower right corner of the front windshield glass 3 inner surface of the car (for the car of left-hand drive, for the car of right-hand drive, it should be pasted on the lower left corner of the front windshield glass of the car). According to the theory of hot and cold air convection, cold air descends and hot air rises. Therefore, fogging of automobile glass is usually bottom-up. Selecting the transparent conductive film and the position of the lower right corner of the front windshield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com