Mechanism helping to make traction on flat surface and non-flat surface

A towed, link mechanism technology, used in mechanical equipment, construction, earth-moving drilling, etc., can solve the problems of not allowing the pipe diameter and the inability to pull the system through the casing connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

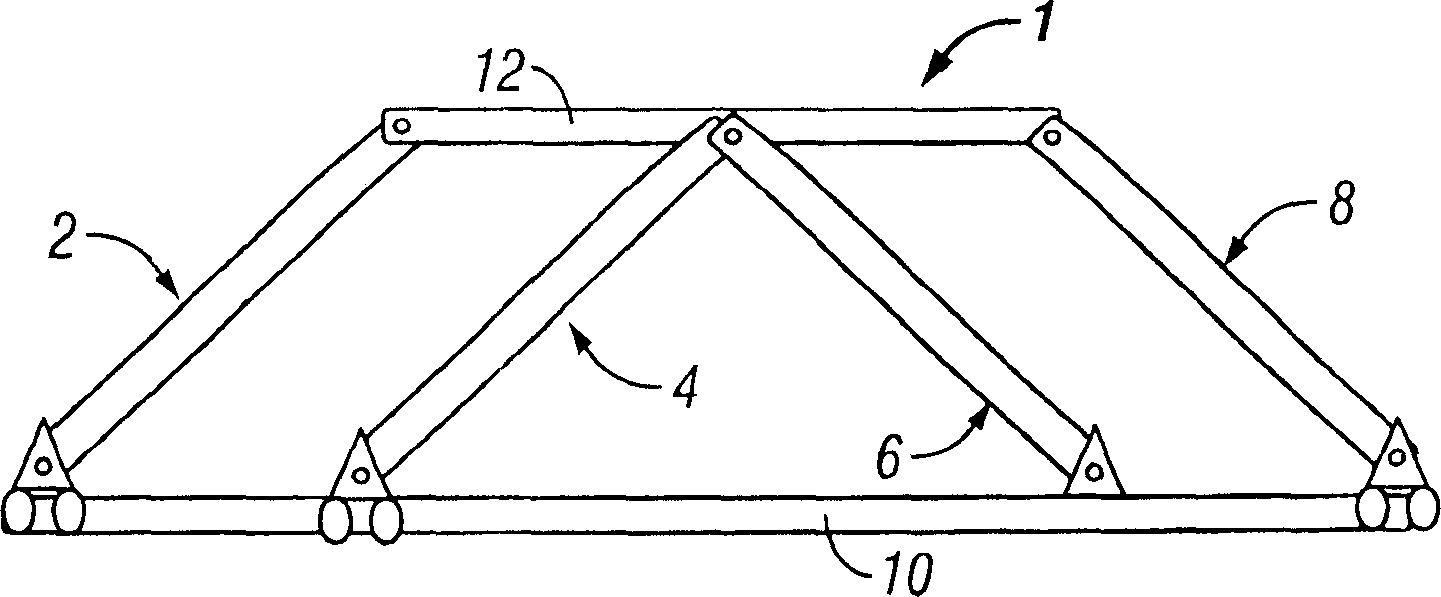

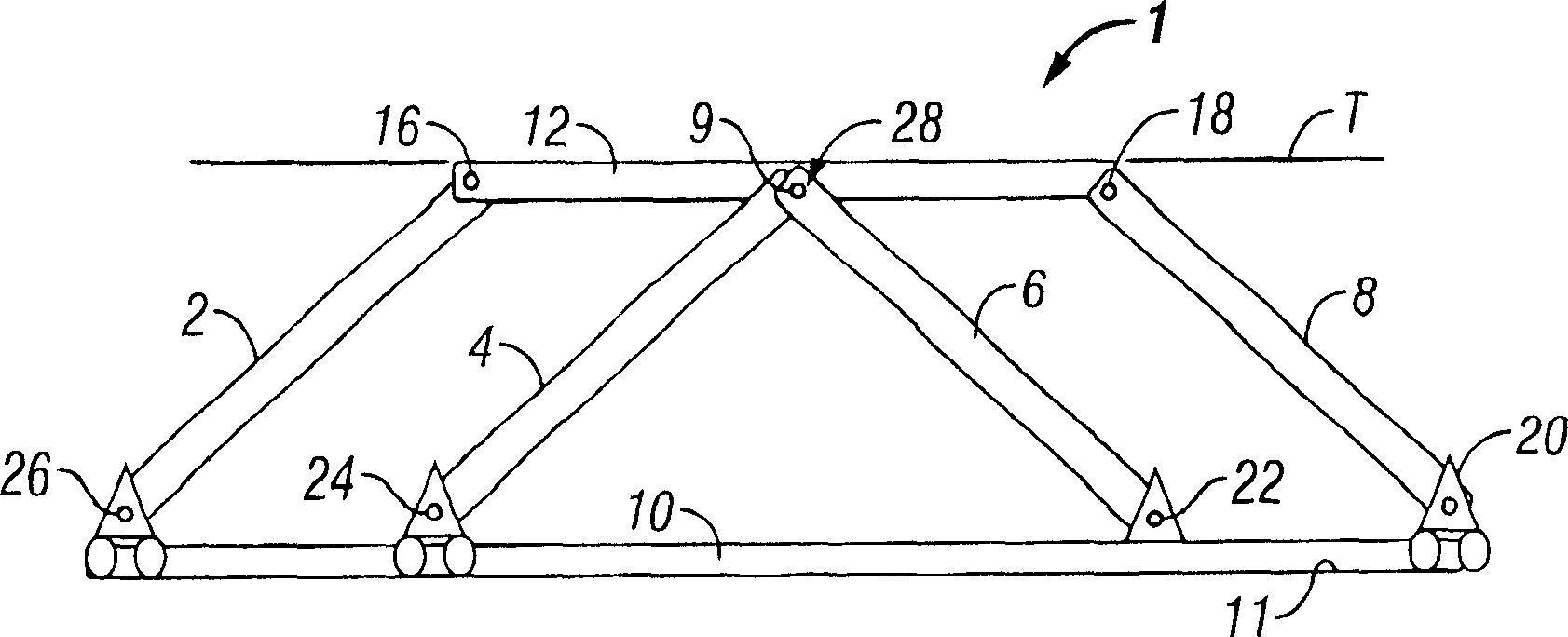

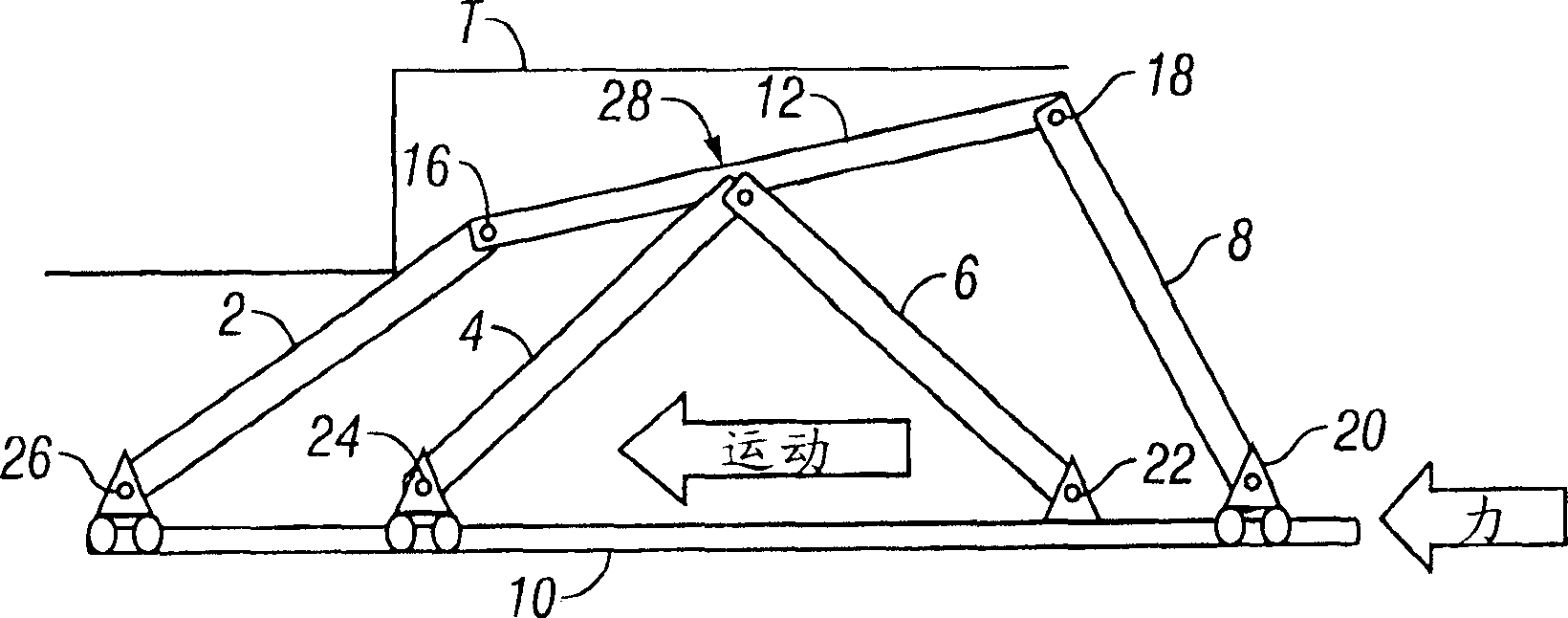

[0021] Such as figure 1 and 2 As shown, the six-bar linkage mechanism constituted according to the principles of the present invention is generally represented by a reference number 1, and it is provided with a pair of centering links 4 and 6, each centering link has an upper end and a lower end, and its upper end is connected to the supporting link 12 Link to each other, and its lower end links to each other with central link 10. Although the centering and centering links may be of any desired configuration depending on the tool mechanism they are associated with, for purposes of illustration they and the other links in the six-bar linkage are shown as essentially thin Long straight rod pieces. The centering link 6 is rotatably connected to the central link 10 so as to be rotatable relative to the central link 10 around a pivotal connection 22 having a pivot between the ends of the central link 10 It is fixed on the central link 10 at the middle point of it. The pivot con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com