Weft holding device in fluid spraying type weaving machine

A fluid jet and weft yarn technology, applied in looms, auxiliary equipment for weaving, textile and other directions, can solve the problems of large time difference, difficult to accept weft yarn, weft yarn detachment, etc., to prevent cloth defects and improve responsiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

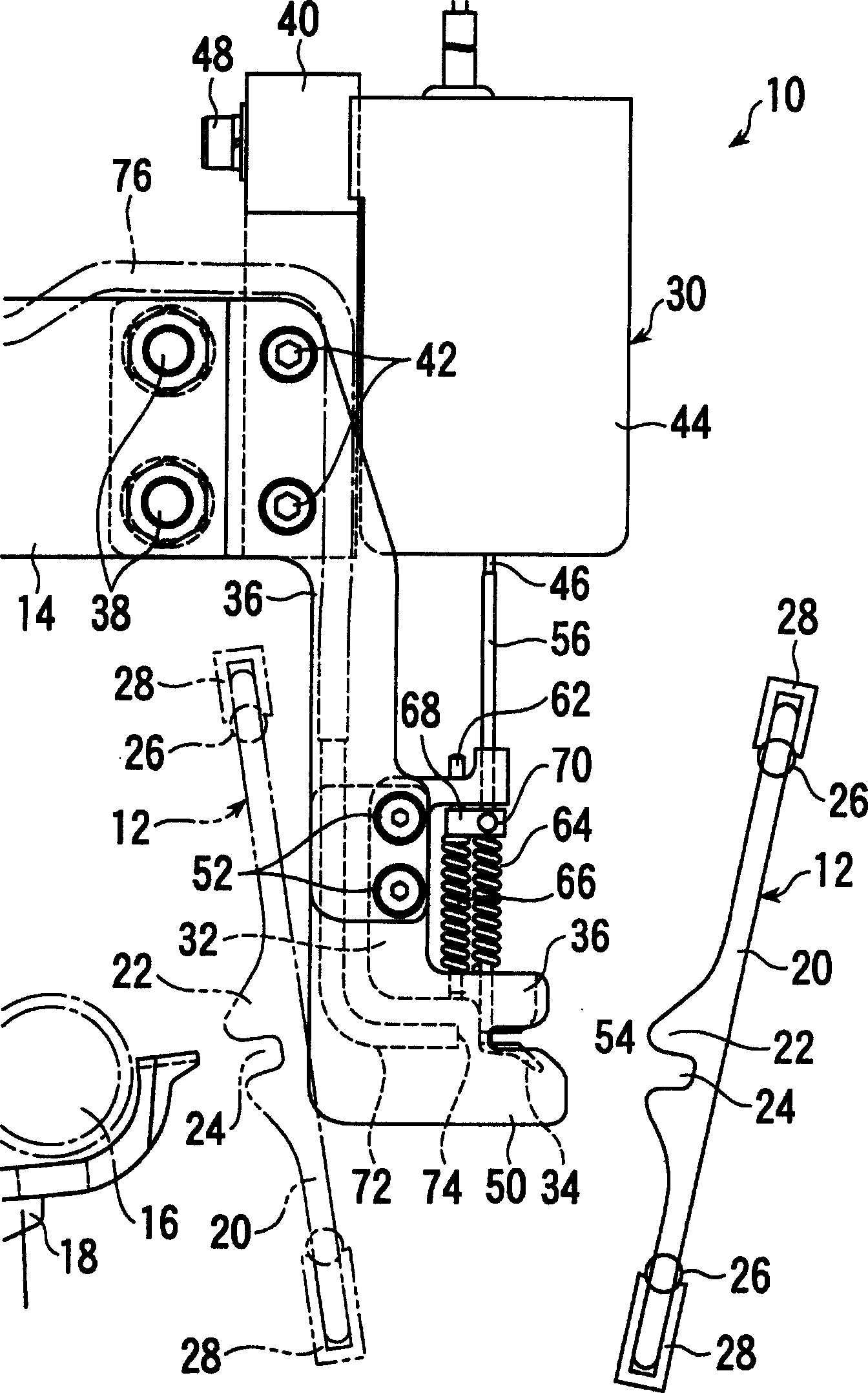

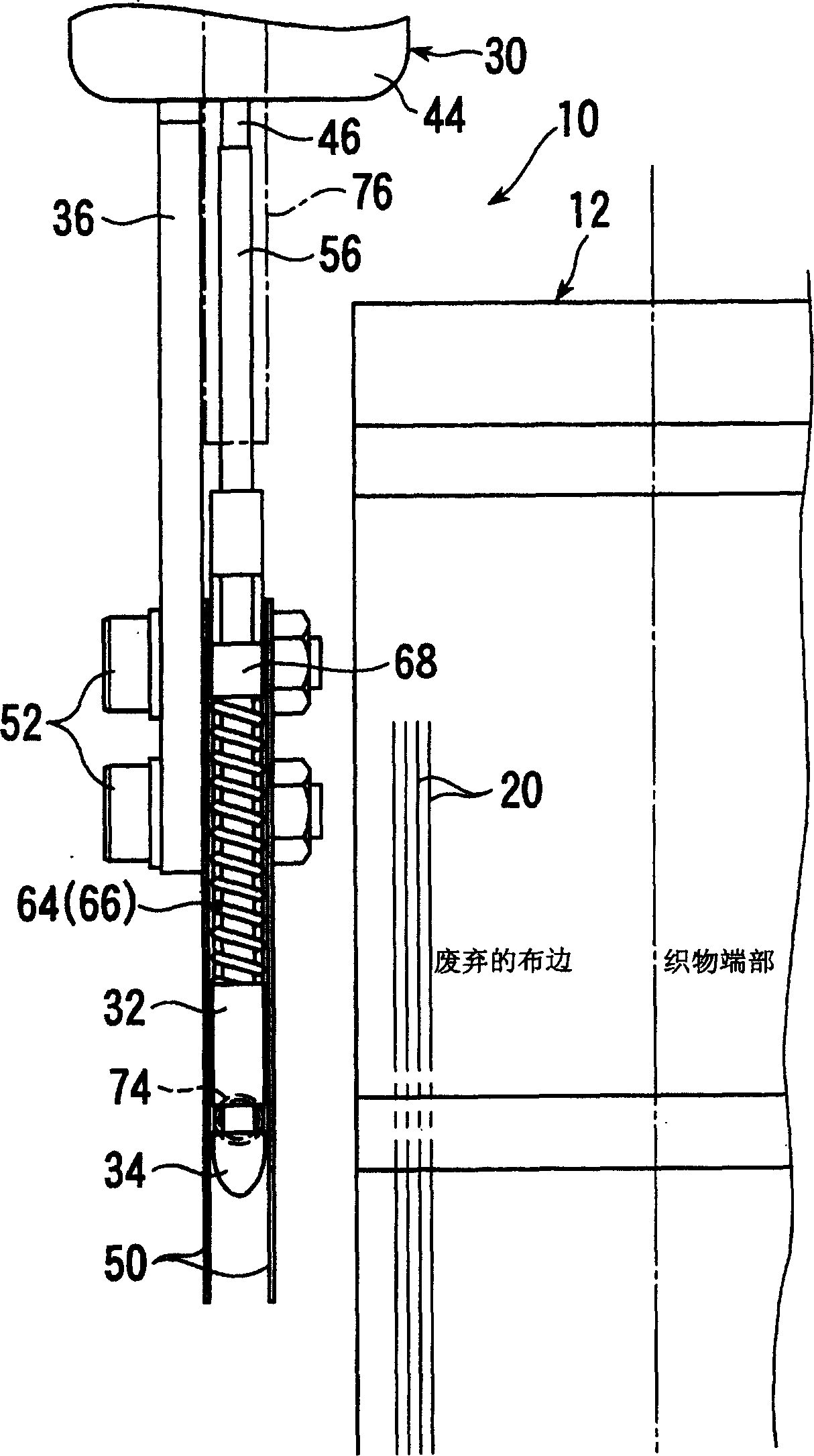

[0027] refer to Figure 1 ~ Figure 4 , the weft yarn holding device 10 is arranged on the anti-weft insertion side of the air jet loom, and performs weft insertion, and is used to hold the weft yarn 80 that is dropped into and advances to the cloth fell through the reed 12 (refer to Figure 4 ).

[0028] The weft yarn gripping device 10 is disposed on the reverse weft insertion side than the reed 12 that reeds the input weft yarn 80, and is detachably attached to a member different from the sley (not shown) by using the support arm 14. , For example, on the temple base 18 which rotatably supports the temple 16 . However, the installation position and installation state of the weft yarn gripping device 10 may be arbitrary as long as weaving and weft yarn gripping are not hindered.

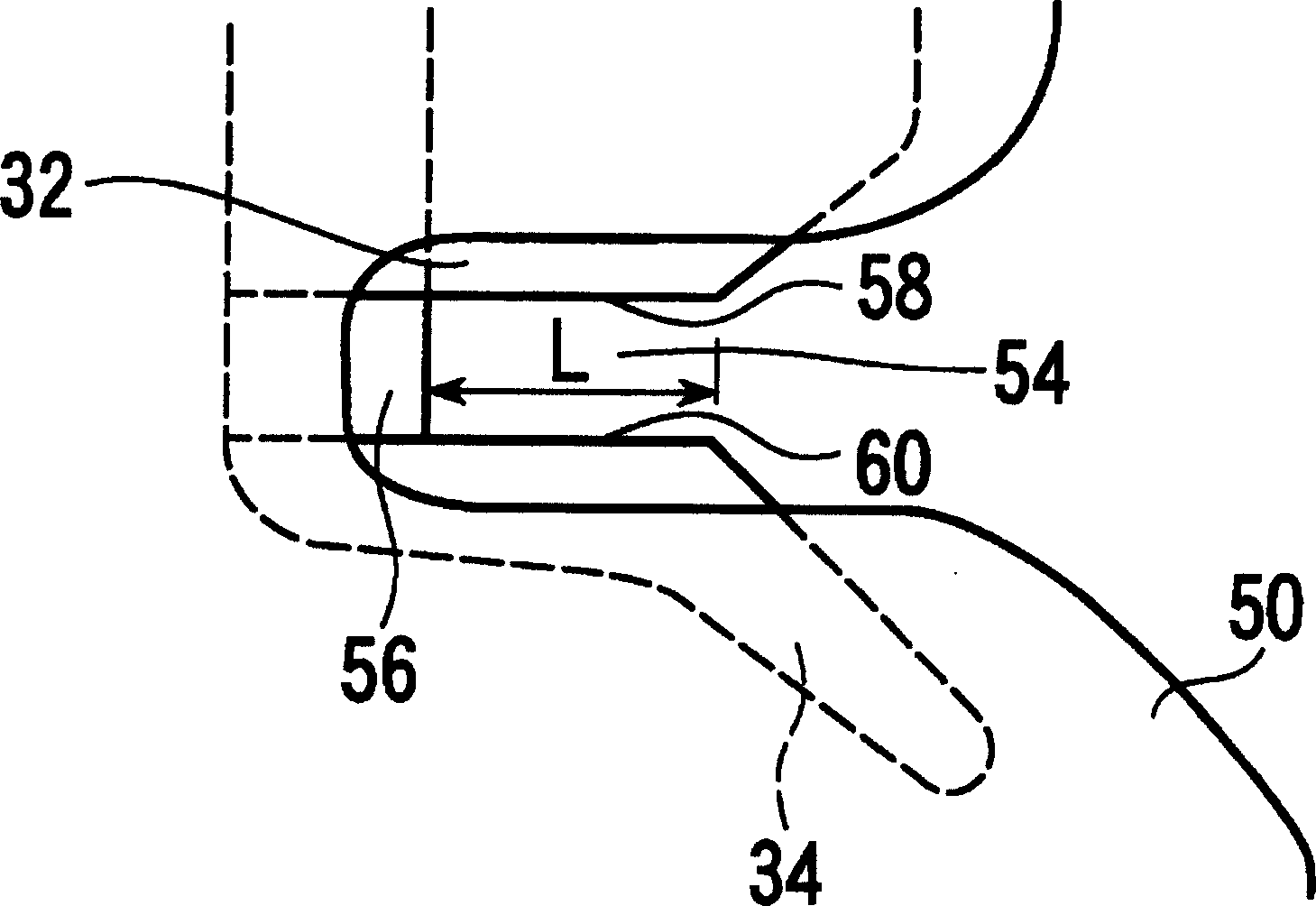

[0029] The reed 12 has a plurality of belt-shaped reed blades 20 at intervals in the fabric width direction. Each reed blade 20 has a convex portion 22 protruding toward the cloth fell side near ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap