Variable reduction ratio enqine

A technology of engine and compression ratio, applied in engine components, engine control, machine/engine, etc., can solve problems such as complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

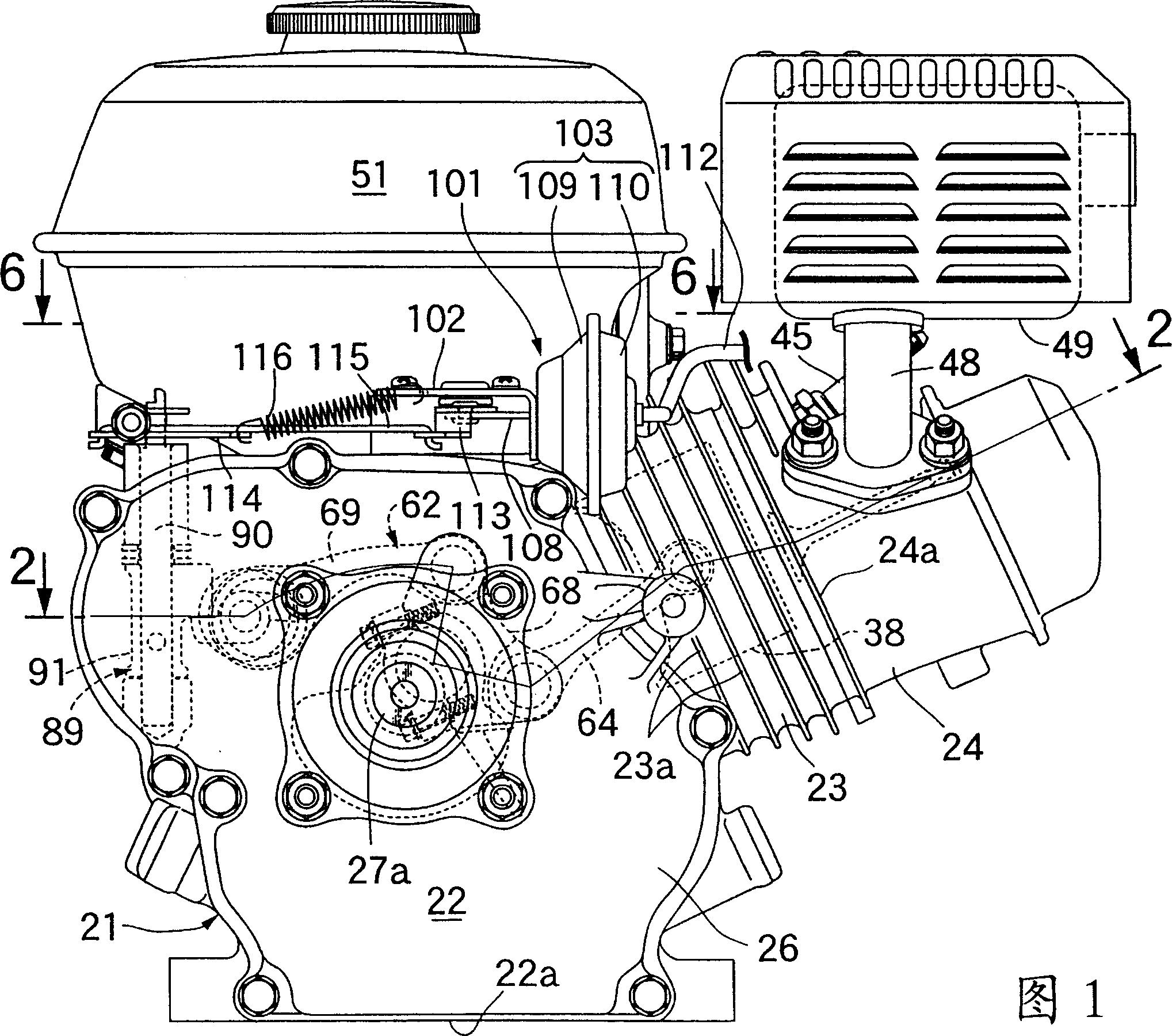

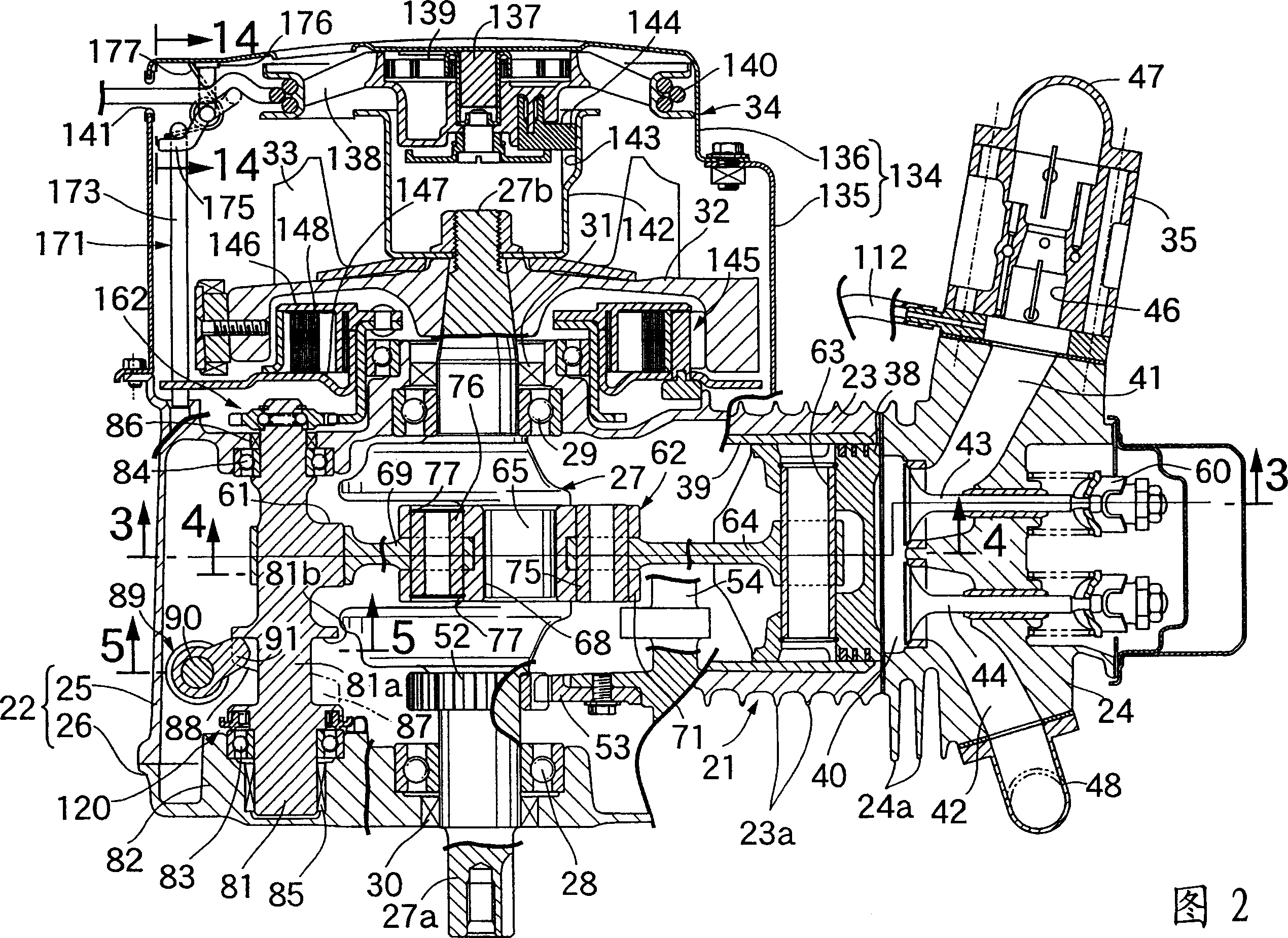

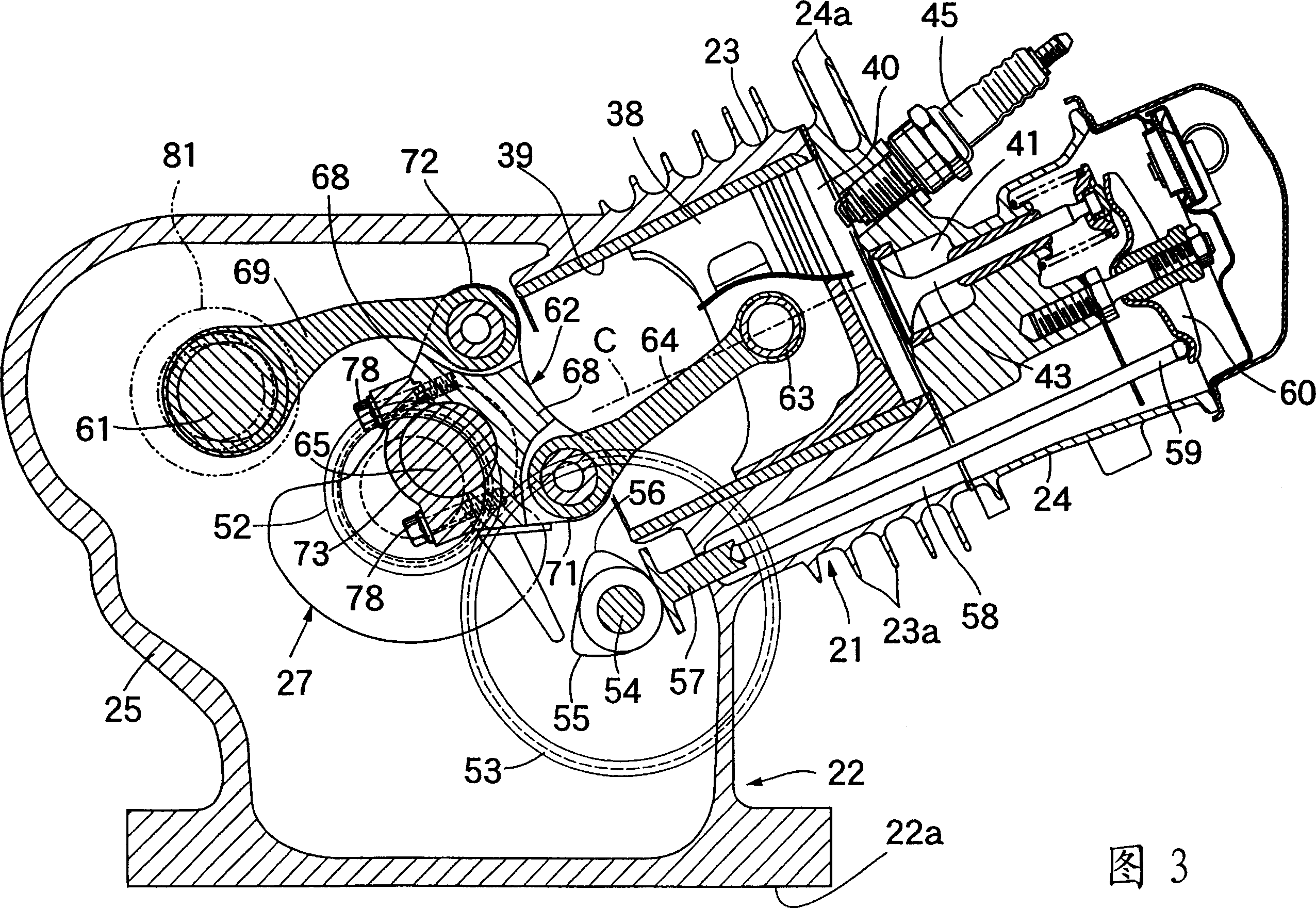

[0029] The present invention will be described below by means of preferred embodiments with reference to the accompanying drawings 1-14.

[0030] Referring to Figures 1 to 3, the engine according to this embodiment is an air-cooled single-cylinder engine, used for example for a working machine, etc., and the engine has an engine body 21, and the engine body includes: a crankcase 22; a cylinder block 23, which slightly upwardly inclined and protruding from one side of the crankcase 22 ; and a cylinder head 24 connected to the top of the cylinder block 23 . A plurality of cooling fins 23 a and 24 a are provided on the outer surfaces of the cylinder block 23 and the cylinder head 24 . Said crankcase 22 is mounted on the cylinder head of any working machine through the mounting surface 22a of its lower surface.

[0031]The crankcase 22 includes a crankcase body 25 formed integrally with the cylinder block 23 by casting, and a side cover 26 connected to an open end of the crankcas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com