General engine

A general-purpose engine and transmission wheel technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of large size of general-purpose engines, smaller crankcase lubricating oil volume, and reduced continuous working time, so as to avoid size and improve The effect of support rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

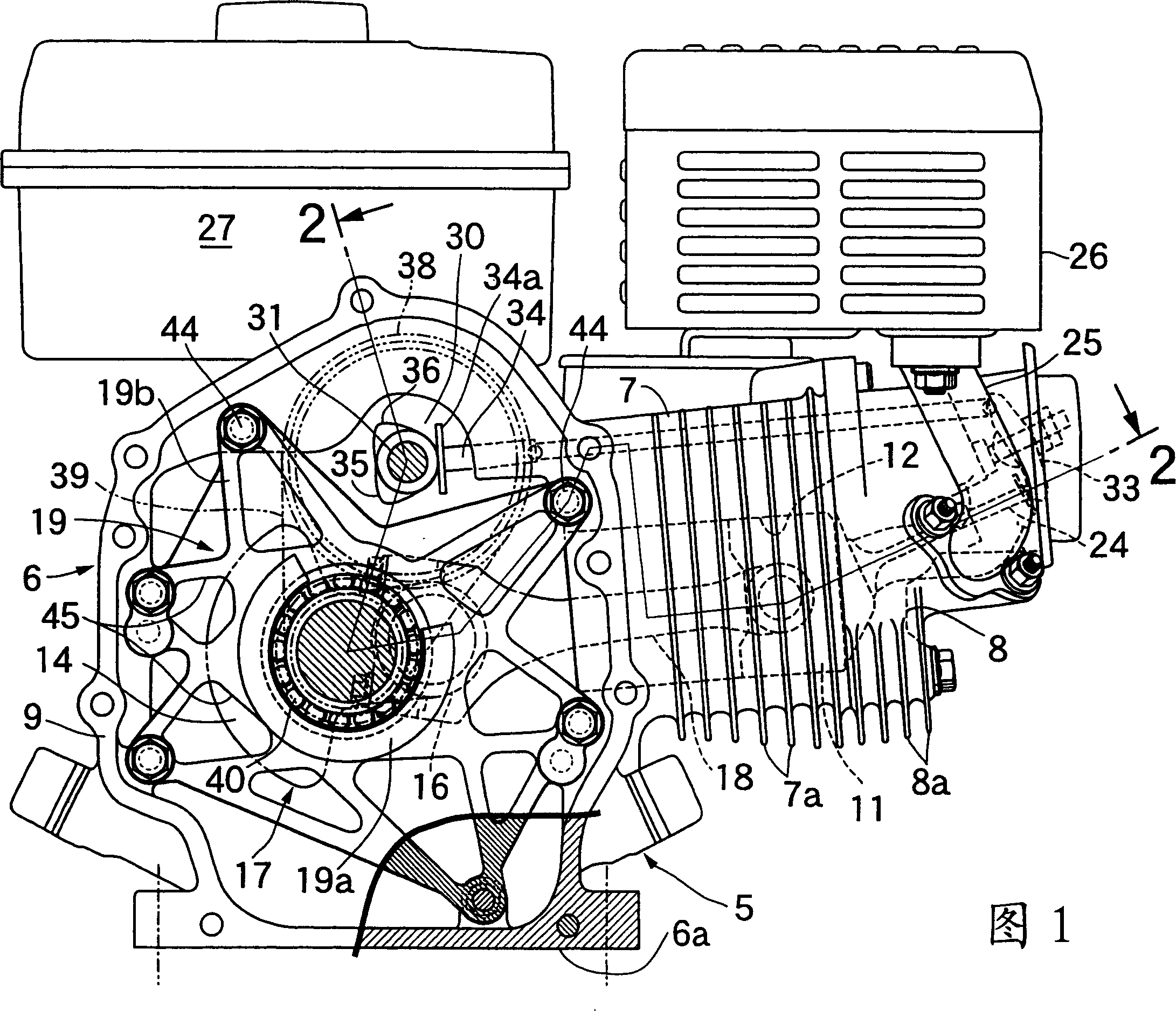

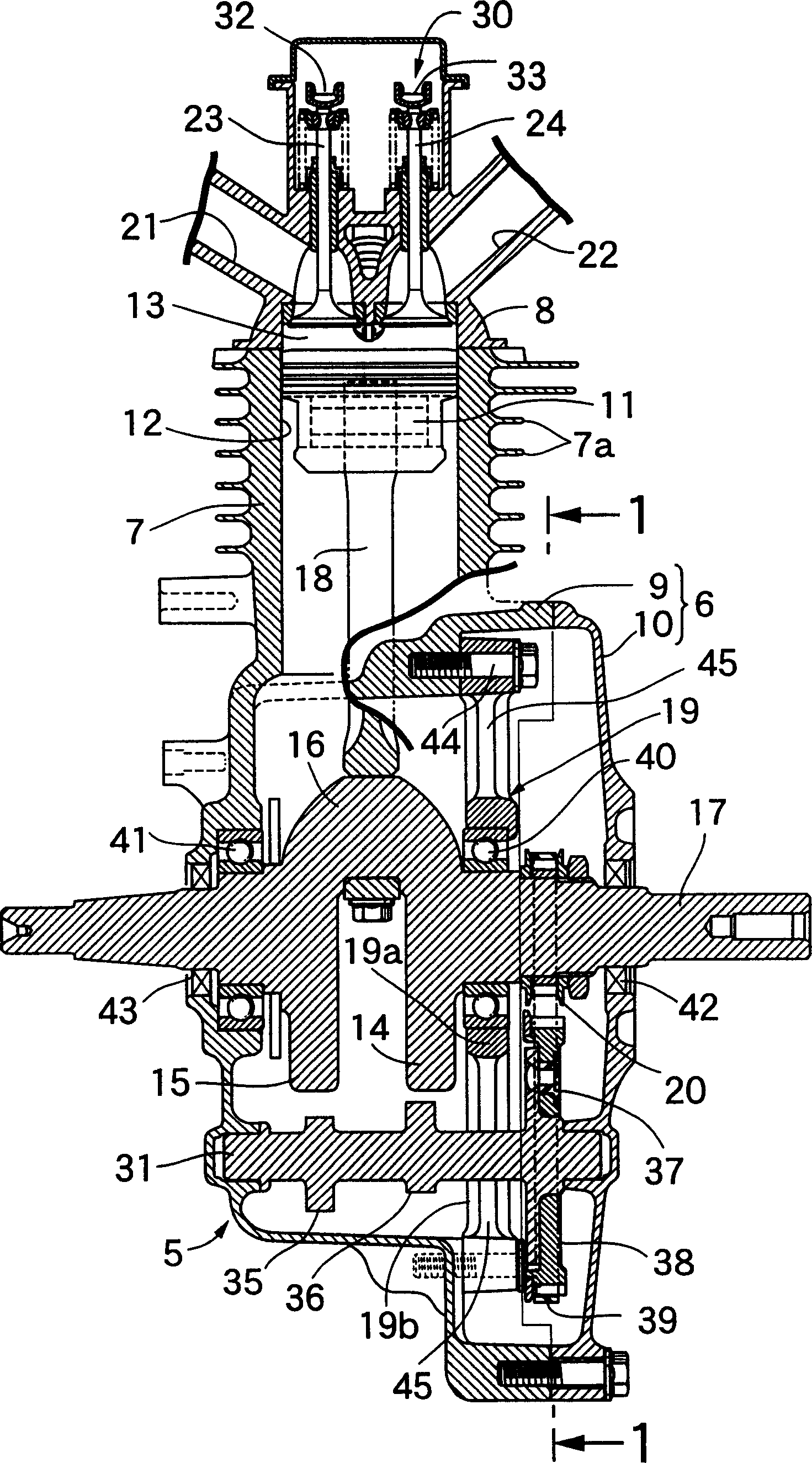

[0012] Figure 1 and figure 2 As shown, the universal engine is an air-cooled single-cylinder engine used, for example, in work machines. The engine main body 5 is formed by a crankcase 6 , a cylinder block 7 protruding slightly upward from one side of the crankcase 6 , and a cylinder head 8 connected to the head of the cylinder block 7 . A large number of air cooling fins 7 a and 8 a are arranged on the outer sides of the cylinder block 7 and the cylinder head 8 . The crankcase 6 is mounted on engine mounts of various machine tools via a mounting surface 6 a which is a bottom surface of the crankcase 6 .

[0013] The crank case 6 is formed of a case main body 9 and a cover body 10 . The case main body 9 is a main part of the crank case 6 and is integrally formed with the cylinder block 7 . A cover 10 is fixed to the tank body 9 so as to close the opening of the tank body 9 in a liquid-tight manner.

[0014] A cylinder bore 12 into which the piston 11 is slidably fitted is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com