Refrigeration circulation and control method thereof

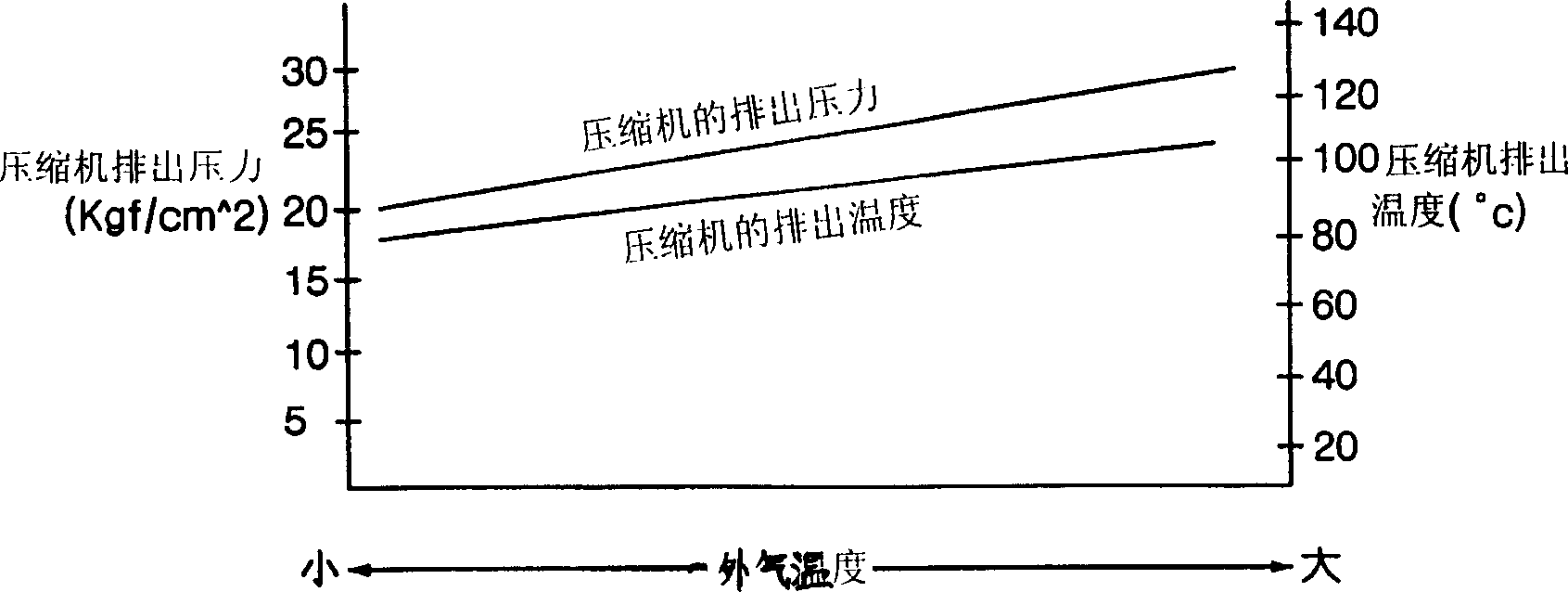

A refrigerant and liquid cooling technology, applied in the field of control, can solve problems such as pressure and temperature rise, pressure and temperature rise, and lower refrigeration efficiency, so as to prevent excessive pressure rise, improve reliability, and improve refrigeration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

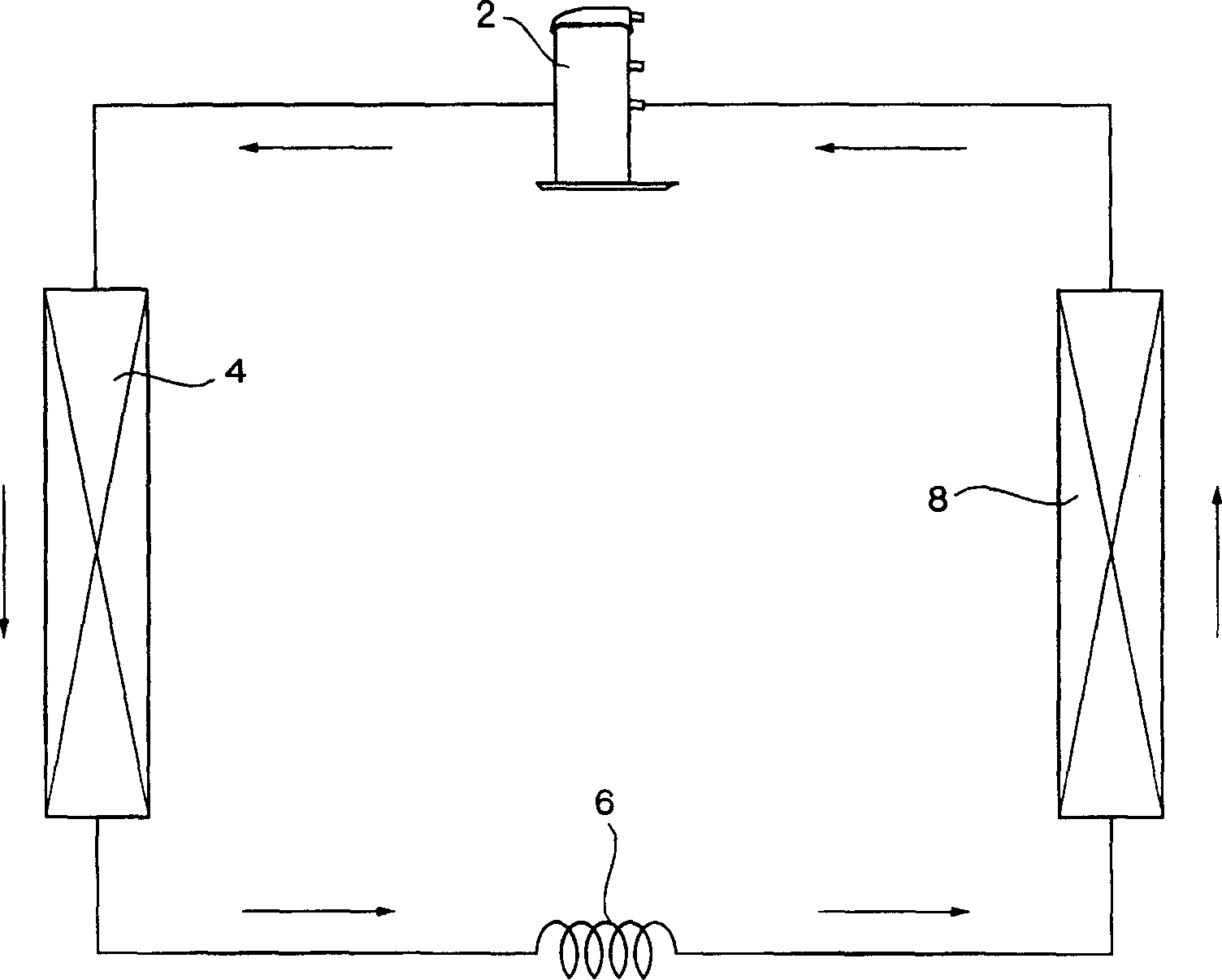

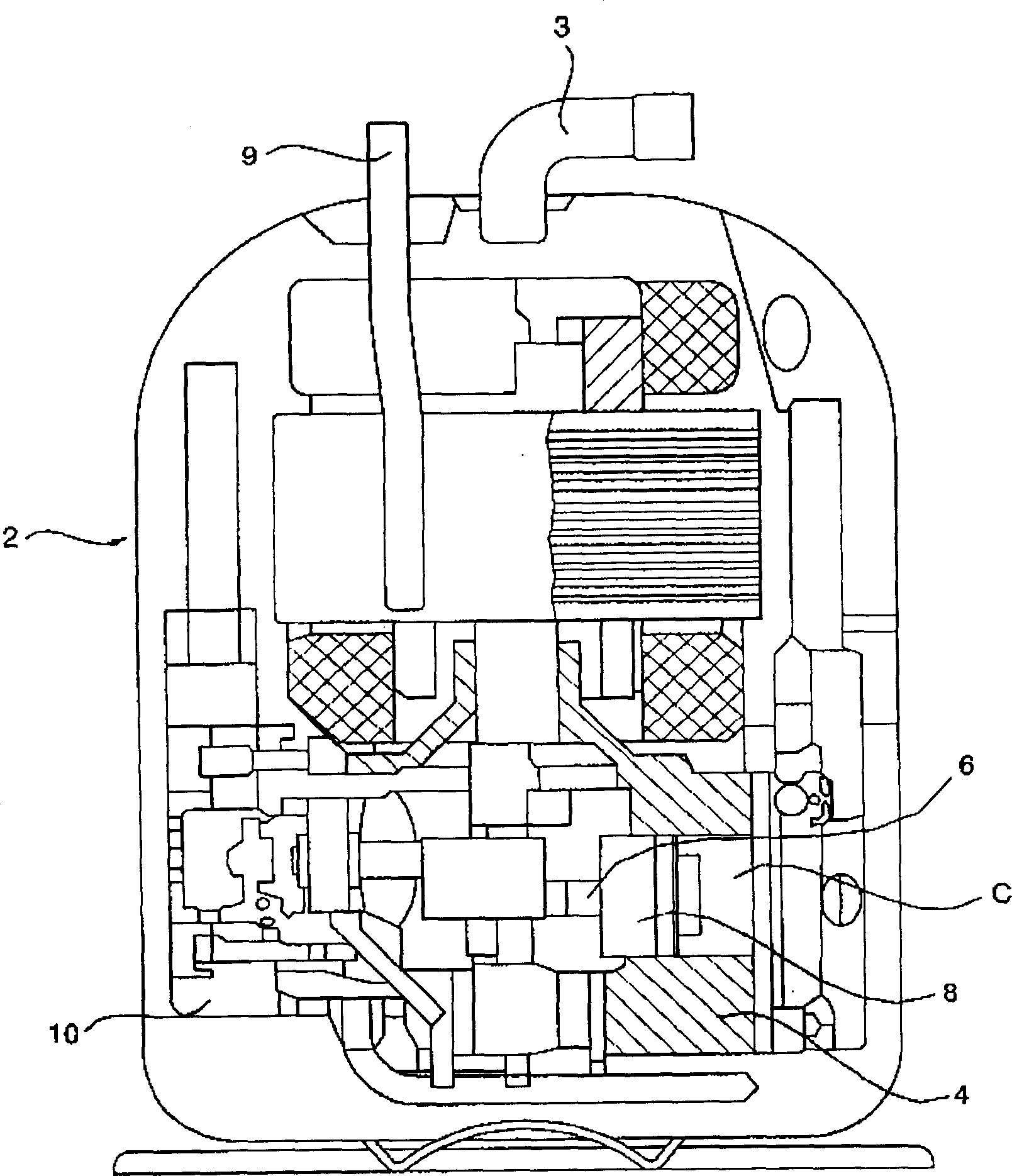

[0034] Such as Figure 4 as well as Image 6 As shown, in the refrigeration cycle of the present invention, the compressor (52) compresses the refrigerant into a high-temperature and high-pressure refrigerant; the high-temperature and high-pressure gas refrigerant discharged from the compressor (52) passes through the condenser (54) and passes through the indoor The outdoor air forced by the side blower (not shown in the drawing) is condensed after heat exchange; the medium-temperature and high-pressure liquid refrigerant passing through the condenser (54) is decompressed while passing through the first decompression device (56). A phase change occurs; the low-temperature and low-pressure liquid refrigerant passing through the first decompression device (56) exchanges heat with the indoor air forced by the indoor side blower (not indicated in the drawing) when passing through the evaporator (58) After that, it flows into the compressor (52) again; a flow divider is arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com