Low temperature liquid filling method for a tank car

A low-temperature liquid and tanker technology, which is applied to liquid distribution, transportation or transfer devices, packaging, distribution devices, etc., can solve the problems of reduced filling volume and increased cost of single-vehicle transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

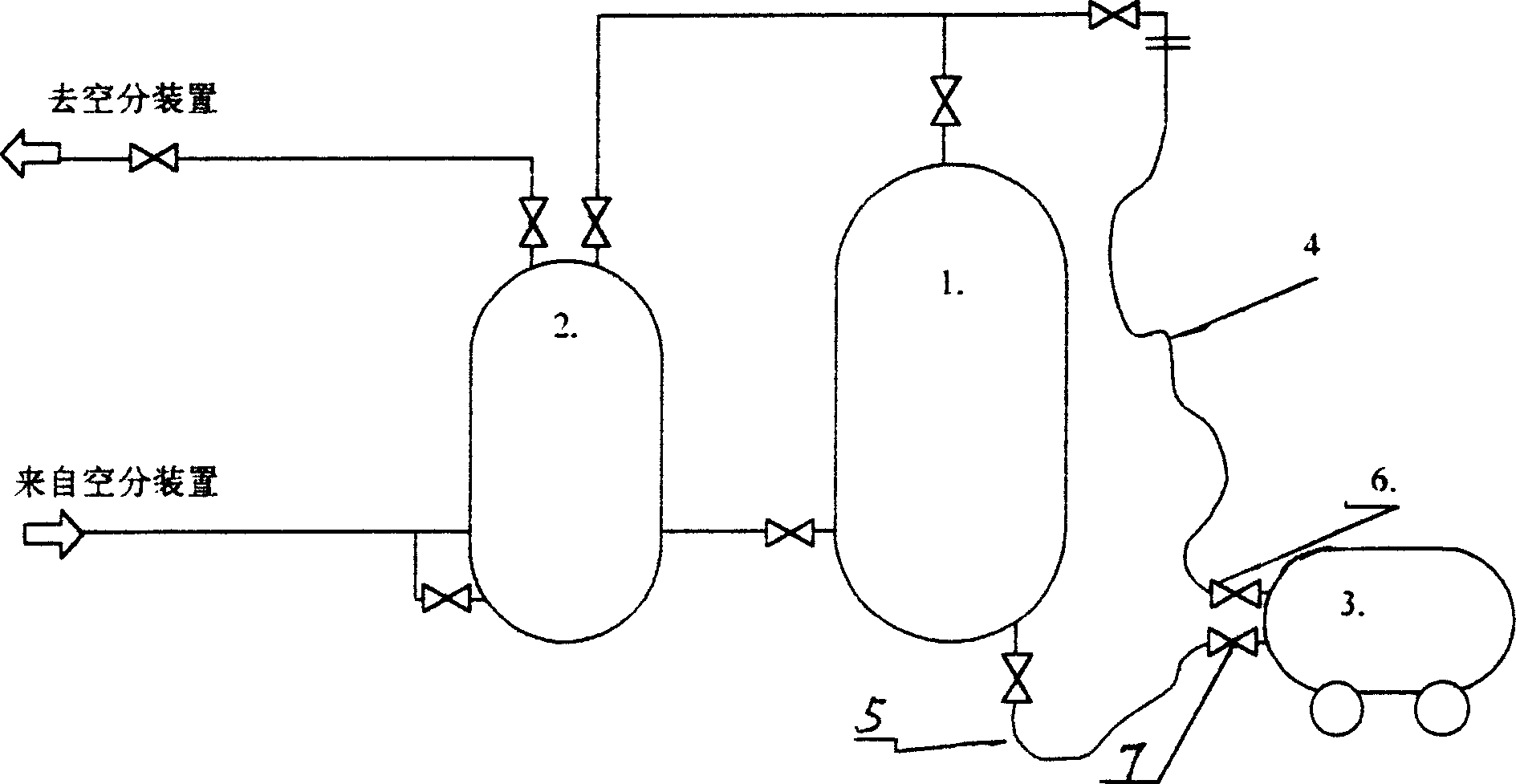

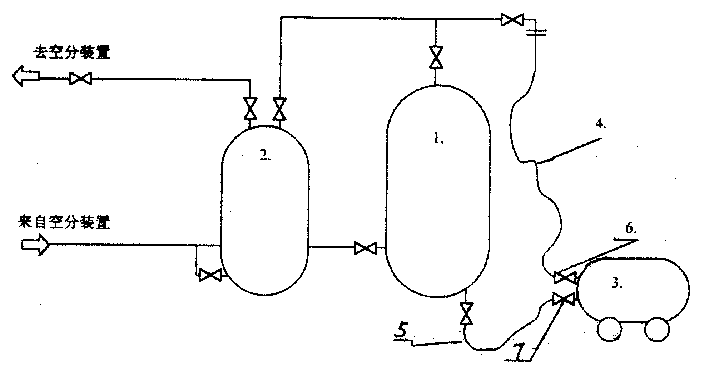

[0014] The liquid argon storage tank of the 14,000 oxygen generator has undergone low-pressure filling and tail gas recovery transformation, and the two ends of the recovery hose (4) are respectively connected to the exhaust valve (2) of the tail gas recovery storage tank (2) and the tank car (3). 6) communicate, connect the filling hose (5) on the cryogenic liquid storage tank (1) with the liquid inlet (7) of the tank car (3), start the pressurization device of the cryogenic liquid storage tank (1), make The vehicle filling pressure rises to 0.2-0.3Mpa, and the tank vehicle (3) is filled with liquid from the cryogenic liquid storage tank (1) through the filling hose (5). At the same time, the tanker exhaust gas recovered by the vent valve (6) of the tanker (3) through the recovery hose (4) and the exhaust gas recovery storage tank (2) is liquefied by the argon tower of the low-temperature air separation device and then transported to the cryogenic liquid storage tank (1). Af...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap