Label sticking machine

A technology for labeling machines and casings, applied to labeling machines, labels, manual label dispensers, etc., which can solve problems such as inaccurate font positions, difficulty in opening, inconvenient opening of the ink roller frame door, etc., and achieve an adjustable typing position , Fast and convenient opening, convenient opening, time-saving and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

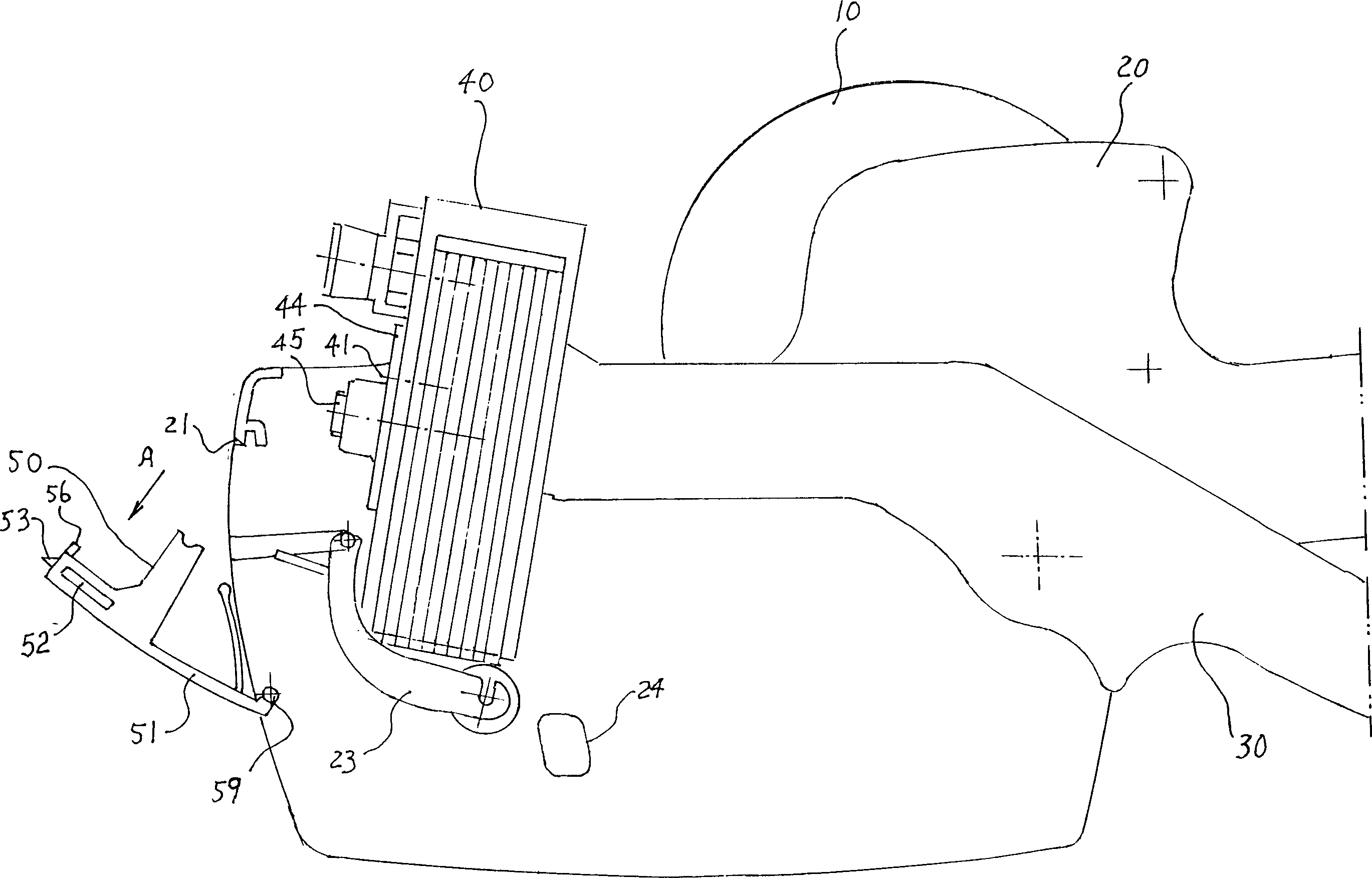

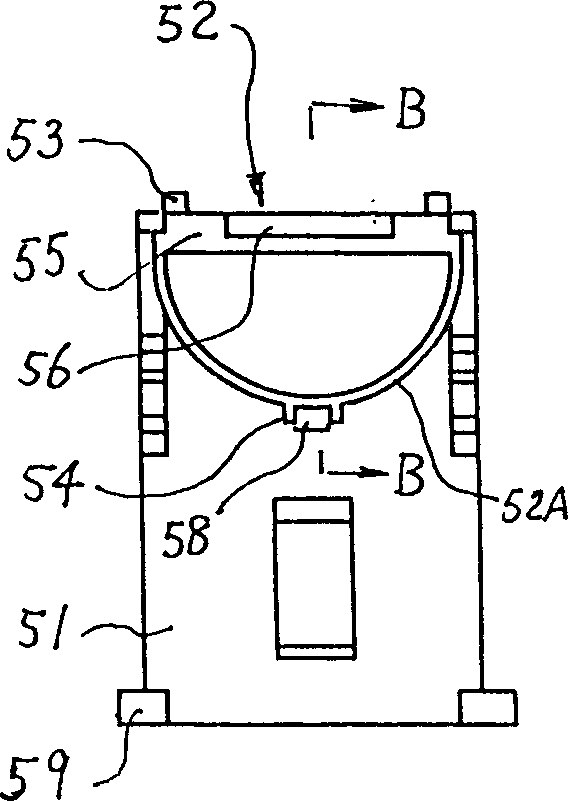

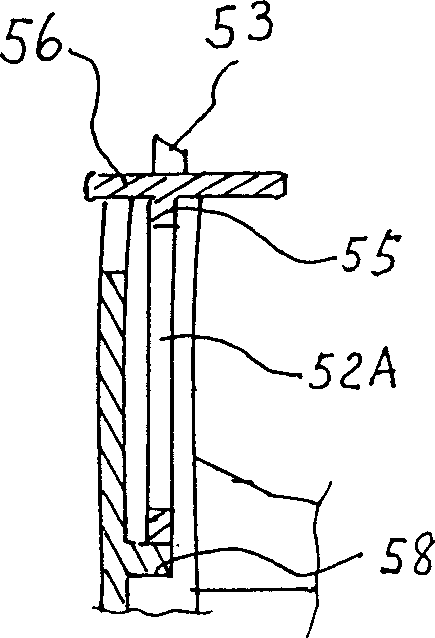

[0038] Such as figure 1 It is a structural schematic diagram of a labeling machine of the present invention, comprising a casing 20 and a handle 30, on which a label roll 10 and an ink roller frame door 50 are mounted, and a word box 40 is installed at the left end of the handle 30, and the handle and the word box The connection section is rectangular to keep the two from rotating and displacing. Such as figure 2 , 3 , the ink roller frame door 50 includes an elastic member 52, the elastic member 52 has an elastic arc 52A and a crossbeam 55 integrally connected with two ends of the elastic arc to form a closed elastic member 52, and each side of the crossbeam 55 has a claw 53 , there is a bayonet 54 in the middle of the elastic arc 52A; the door body 51 is installed on the casing 20 with a shaft 59, the elastic member 52 is installed on the inner side of the door body 51, and the bayonet 54 is clamped on the block 58 on the door body 51 On the top, the shoulder 52B of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com