Electronic element and its manufacturing method

A technology of electronic components and manufacturing methods, which is applied in the direction of electrical components, electric solid devices, circuits, etc., and can solve problems such as cracking of the sealing cover and reduction of the mechanical strength of the sealing cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

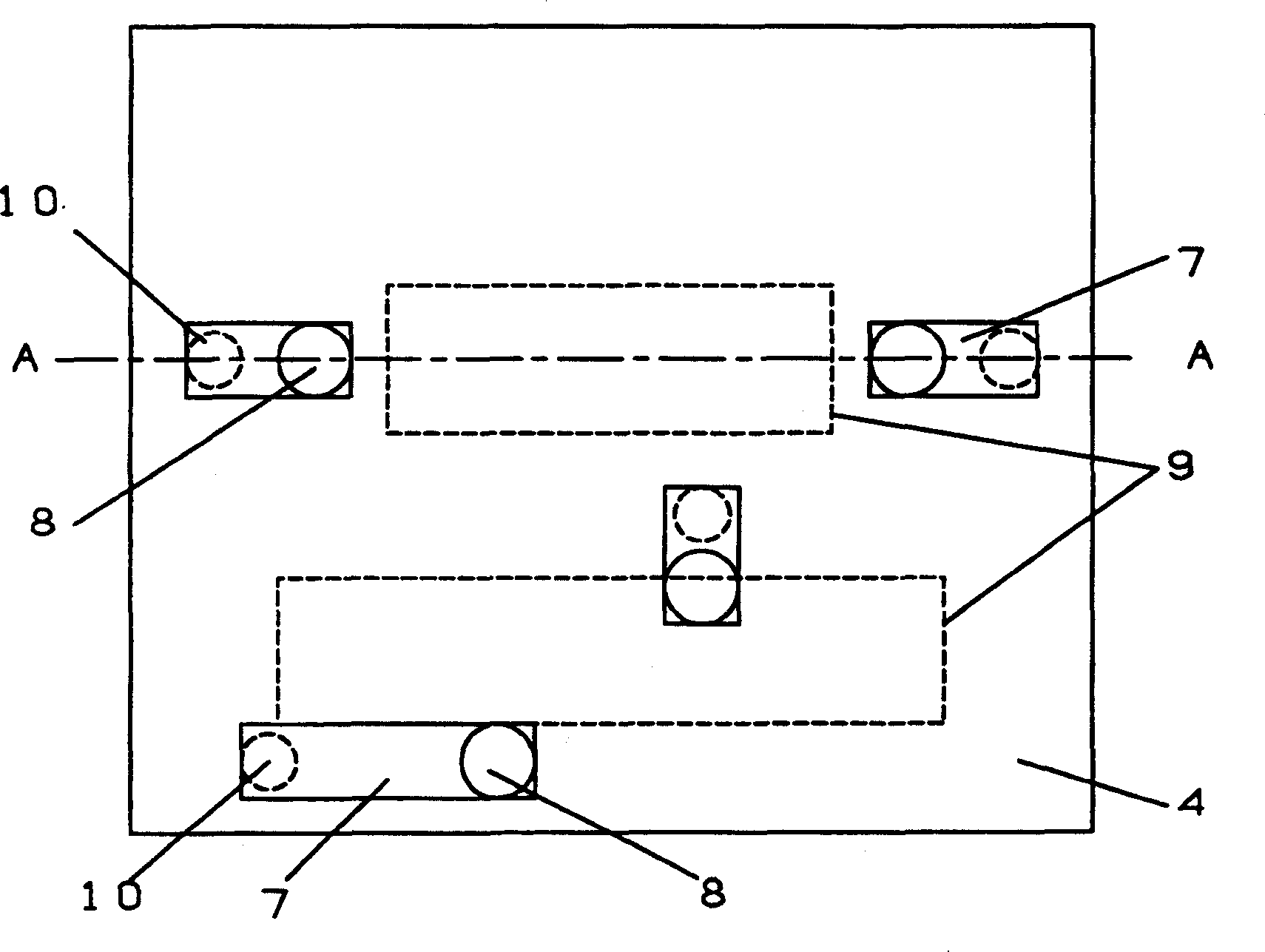

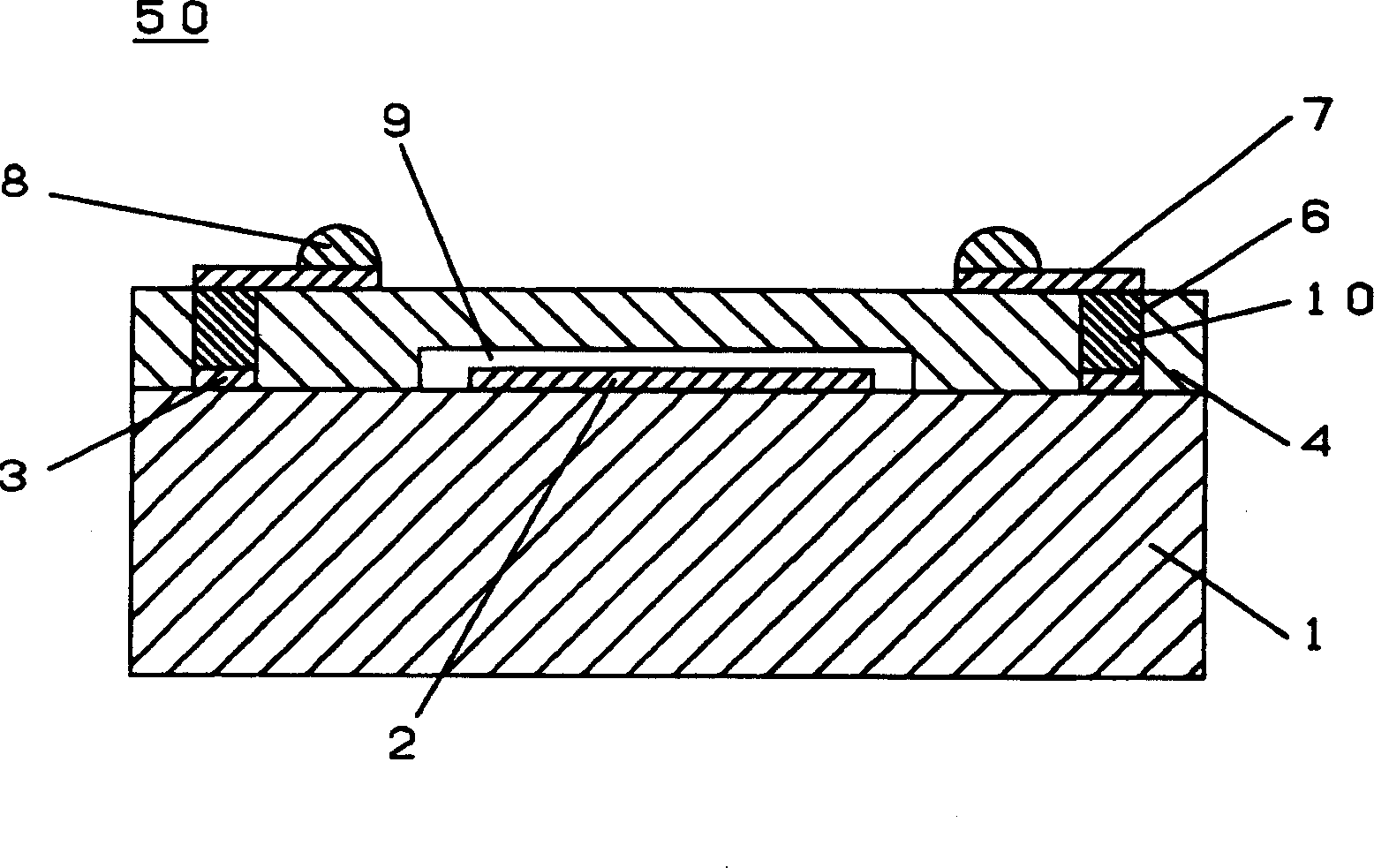

[0036] figure 1 is a schematic plan view of an electronic component of a preferred embodiment of the present invention. figure 2 is along figure 1 Sectional view taken along line A-A.

[0037] Refer to the following figure 1 and 2 , an electronic component 50 includes a substrate 1 and a structural component 4 .

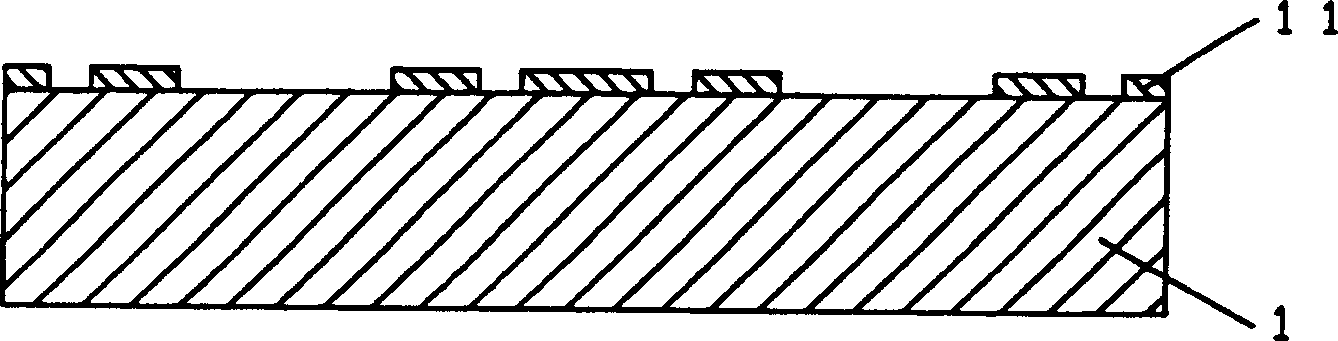

[0038] A plurality of IDT electrodes 2 and connection portions 3 are provided on the substrate 1 . Each connection portion 3 is electrically connected to the IDT electrode 2 . In order to achieve the desired function. In addition, electrodes are provided on each IDT electrode 2, and these electrodes have various patterns and film thicknesses suitable for required functions. The respective patterns are not limited to the IDT electrodes 2 . These patterns can also be applied to electrodes defining piezoelectric vibrating porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com