Porous pipe and pipe connector, manufacturing method thereof

A manufacturing method and technology of porous pipes, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of material waste, uneconomical cost, etc., to save materials, save material costs, and increase anti-aging strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

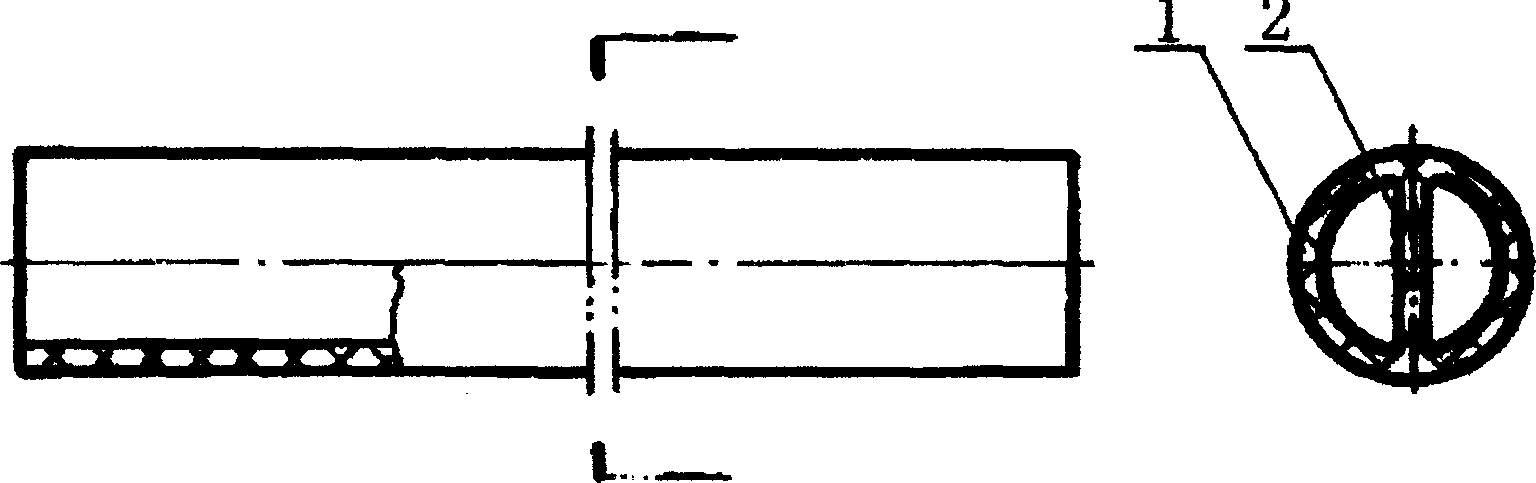

[0029] Embodiment 1, by figure 1 It can be seen that the inner cavity of the tube diameter of the present invention is provided with a reinforced isolation rib 2 passing through the center of the tube diameter to divide the inner cavity of the tube into two passages.

Embodiment 2

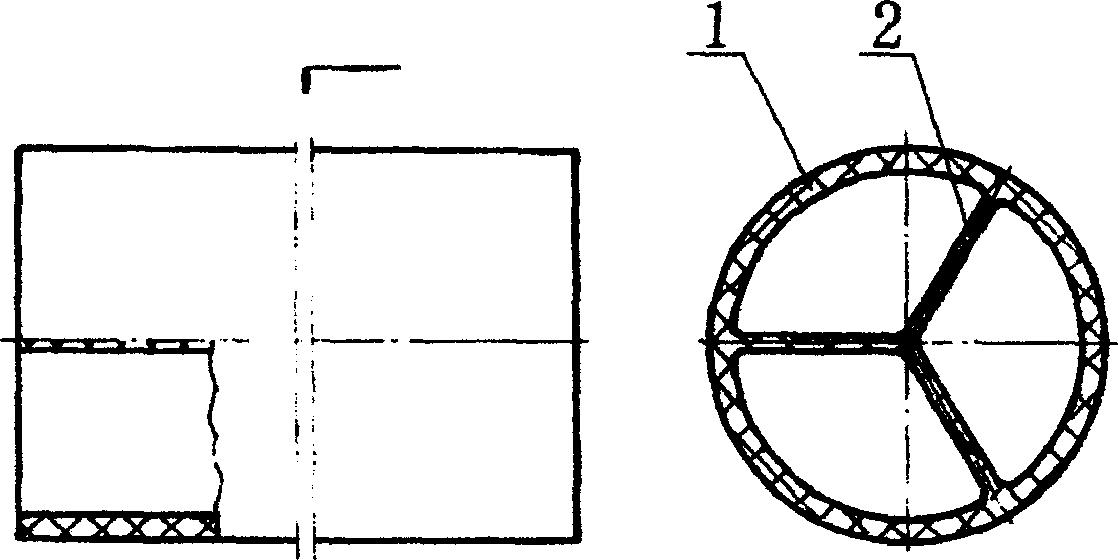

[0030] Embodiment 2, by figure 2 It can be seen that the inner cavity of the tube diameter of the present invention is provided with three reinforced isolation ribs 2 connected at the center of the tube diameter to divide the inner cavity of the tube equally into three channels.

Embodiment 3

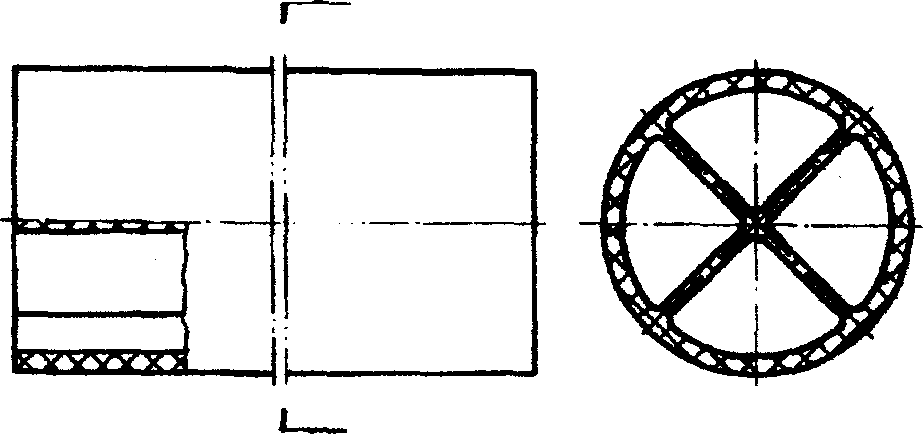

[0031] Embodiment 3, by image 3 It can be seen that the inner cavity of the tube diameter of the present invention is provided with two reinforced isolation ribs 2 crossing through the center of the tube diameter to divide the inner cavity of the tube equally into four channels.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap