Differential/pressure transmitter

A transmitter, pressure technology, applied in the direction of measuring fluid pressure, pressure difference measurement between multiple valves, instruments, etc., can solve the increase in the number of types of caps or adapters, cannot meet customer requirements, and the results cannot be shipped after transportation. changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

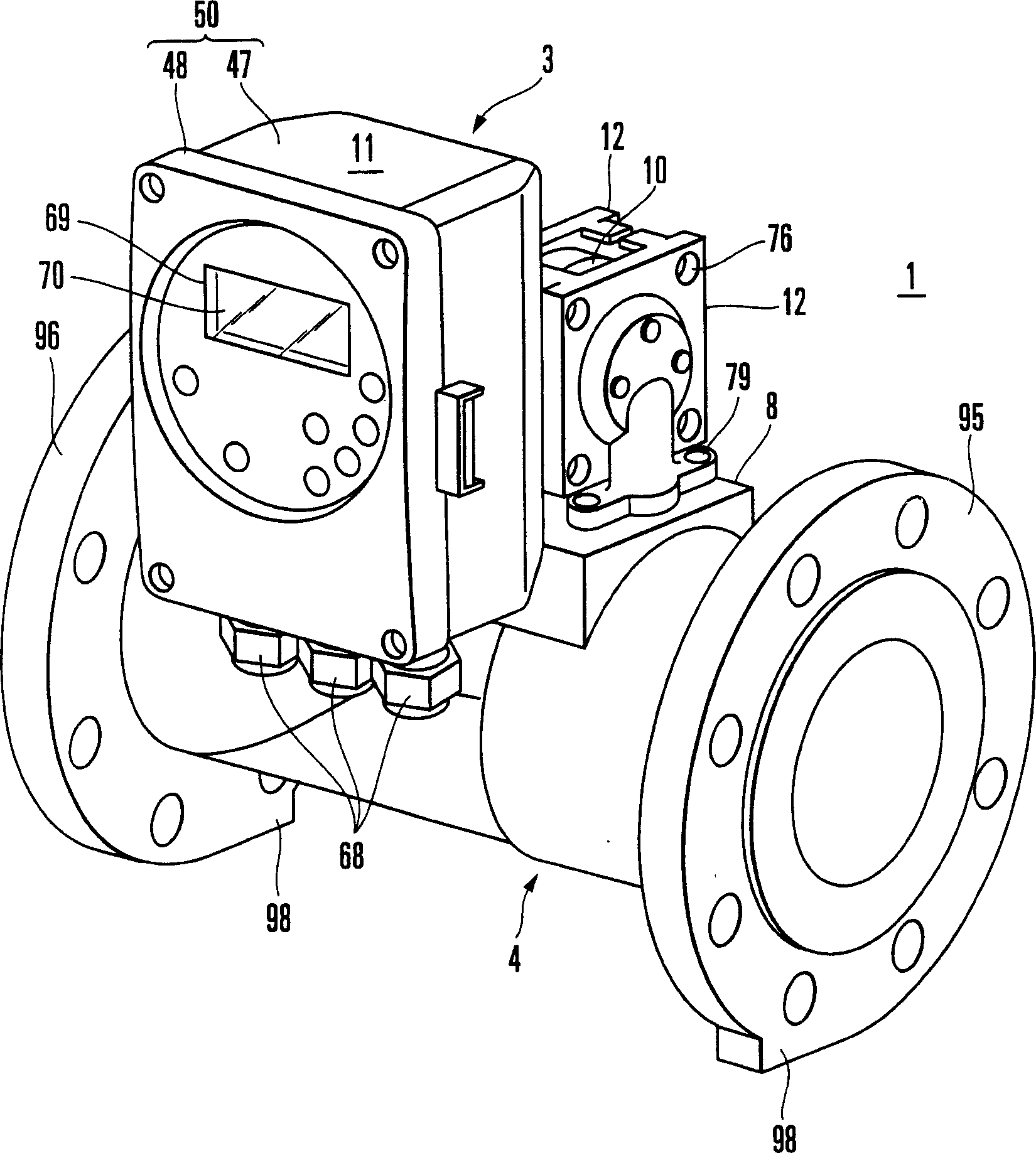

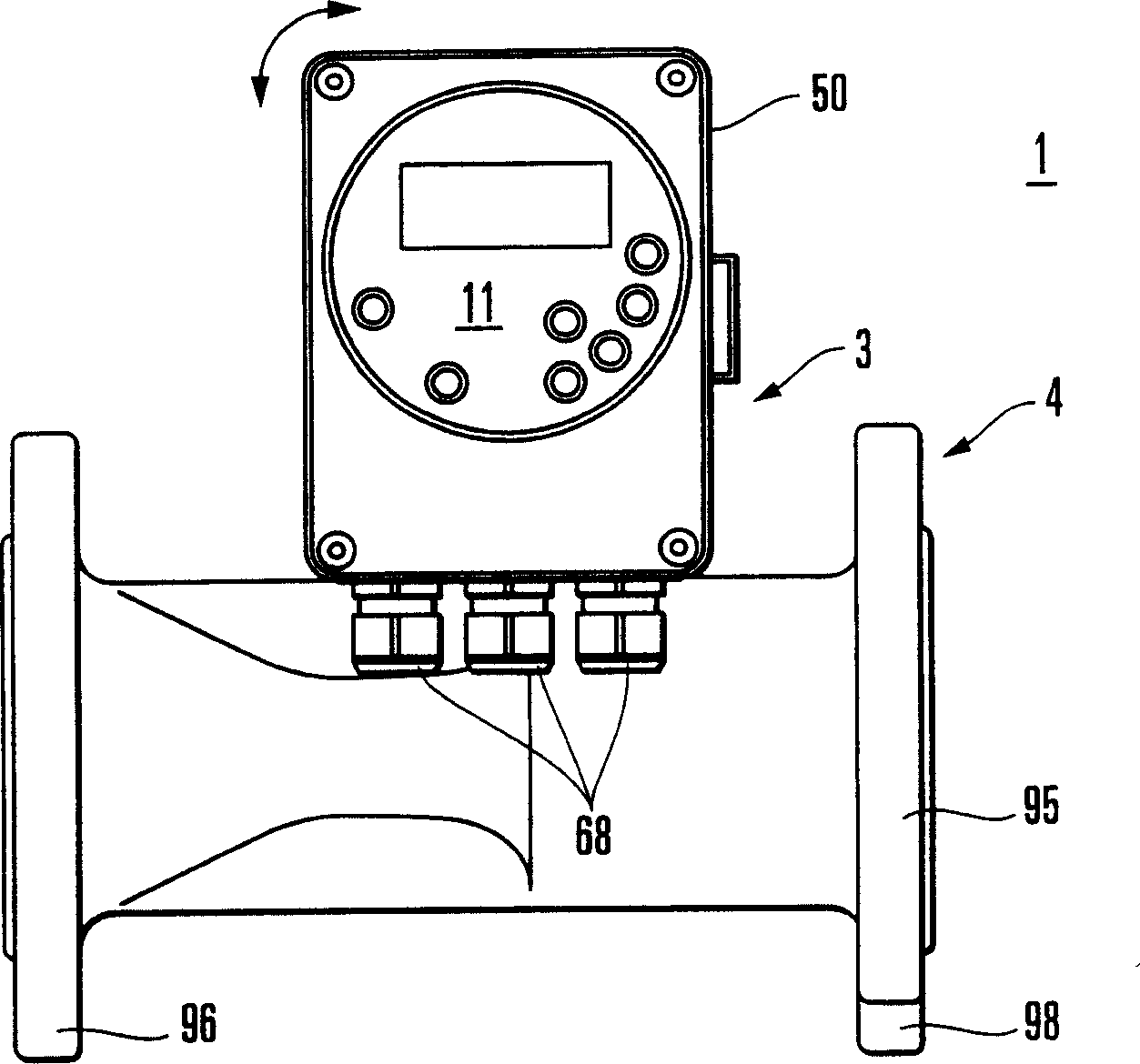

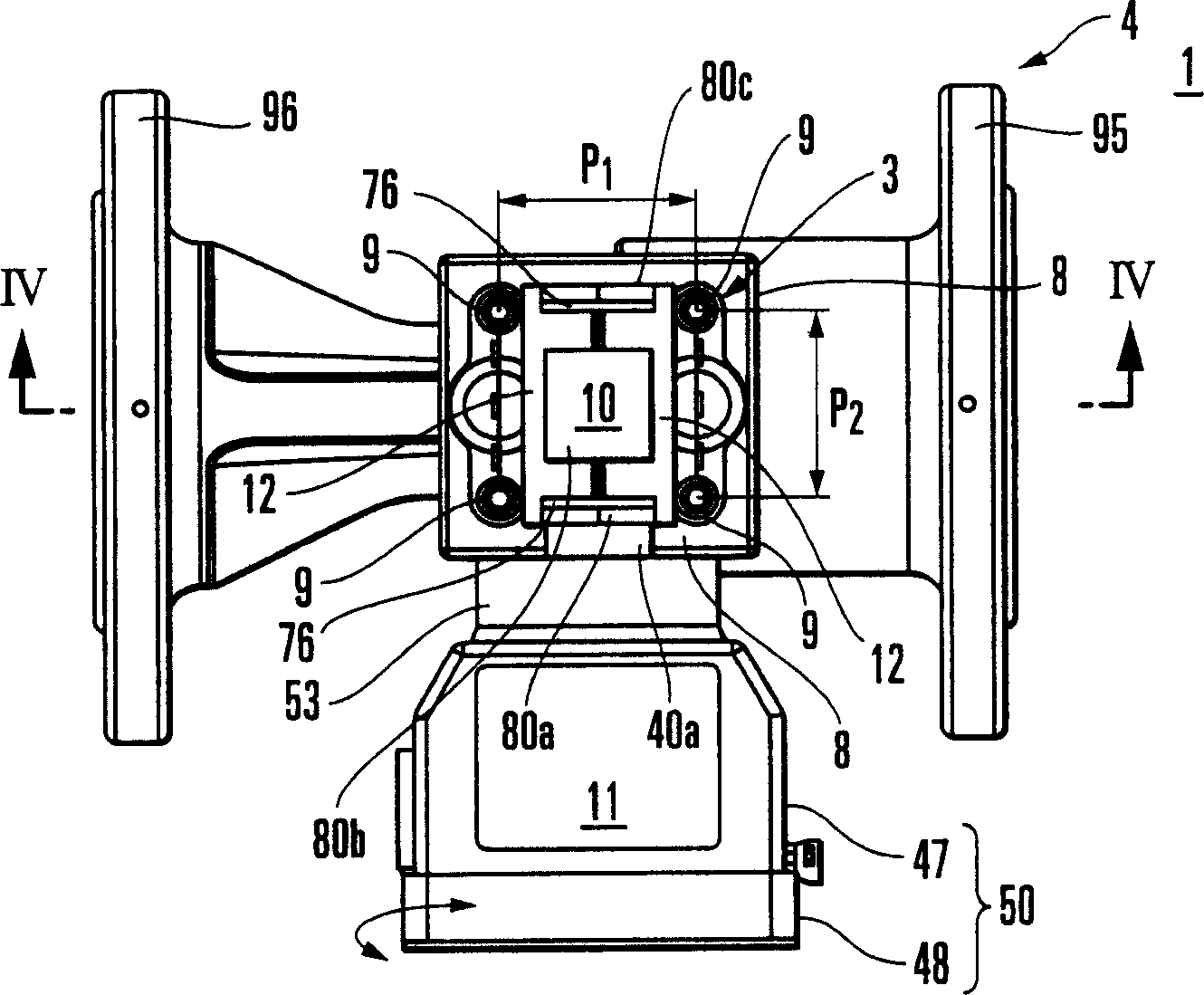

[0029] Figures 1 to 7 Shown is a restrictive flow meter according to a first embodiment of the present invention. In this embodiment, a differential pressure / pressure transmitter is used as a restricted flow meter. This embodiment shows a case where the restrictive flow meter 1 is installed horizontally with respect to horizontally arranged process fluid supply pipes (hereinafter simply referred to as pipes) 2A and 2B. Such as figure 1 As shown, the limiting flow meter 1 is composed of a pipe body 4 formed by a straight pipe, and a differential pressure transmitter 3 installed to the pipe body 4 . Note that the adapter 5 is not used when the restrictor flowmeter 1 is installed horizontally.

[0030] The differential pressure transmitter 3 includes a detection portion 10 fixed to the pipe body 4 , an in-meter transfer portion 11 pivotably connected to the detection portion 10 , and a pair of pressure guide covers 12 covering both side surfaces of the detection portion 10 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com