Improved electric motor

A technology of electric motors and armatures, applied to synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc., which can solve problems such as low motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

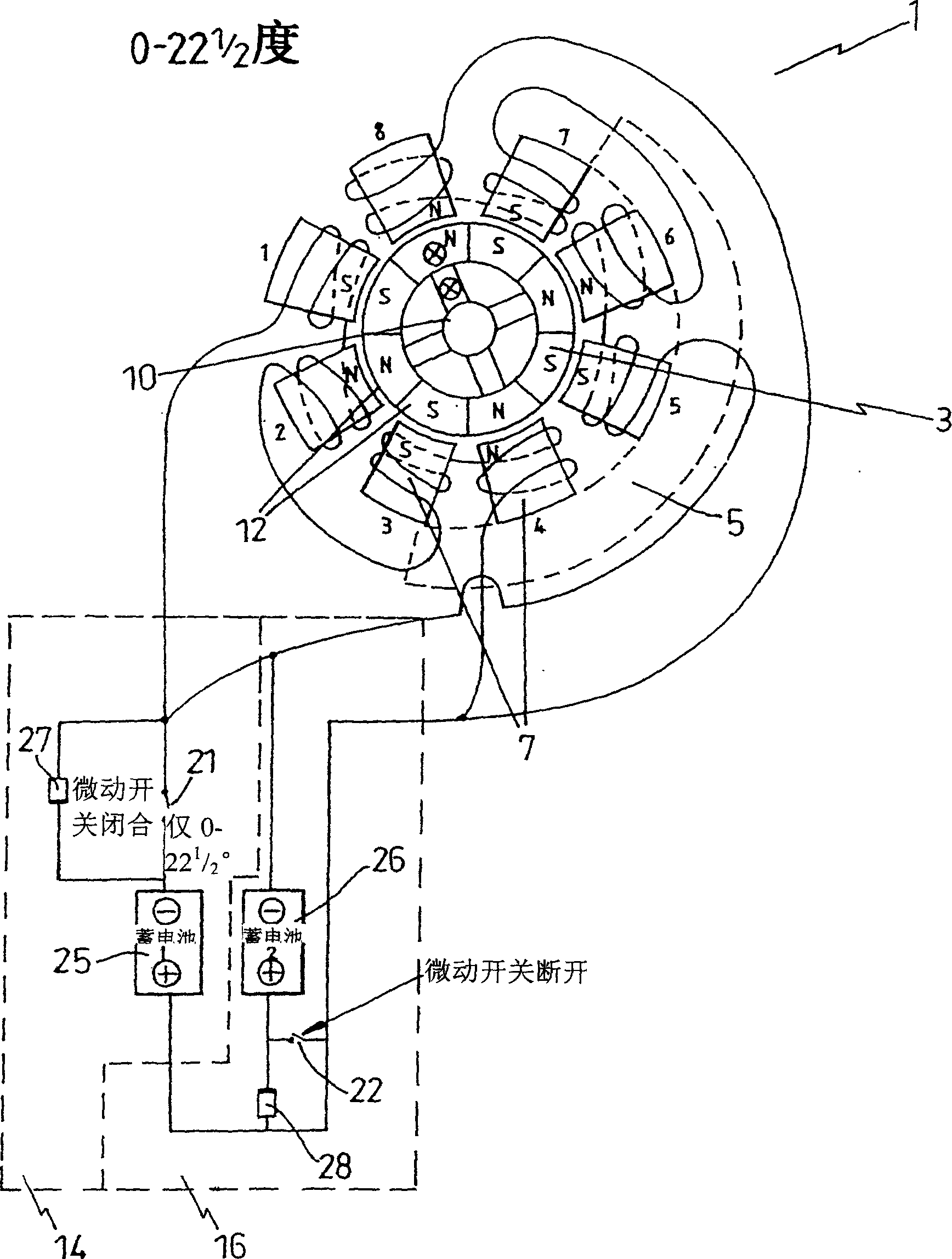

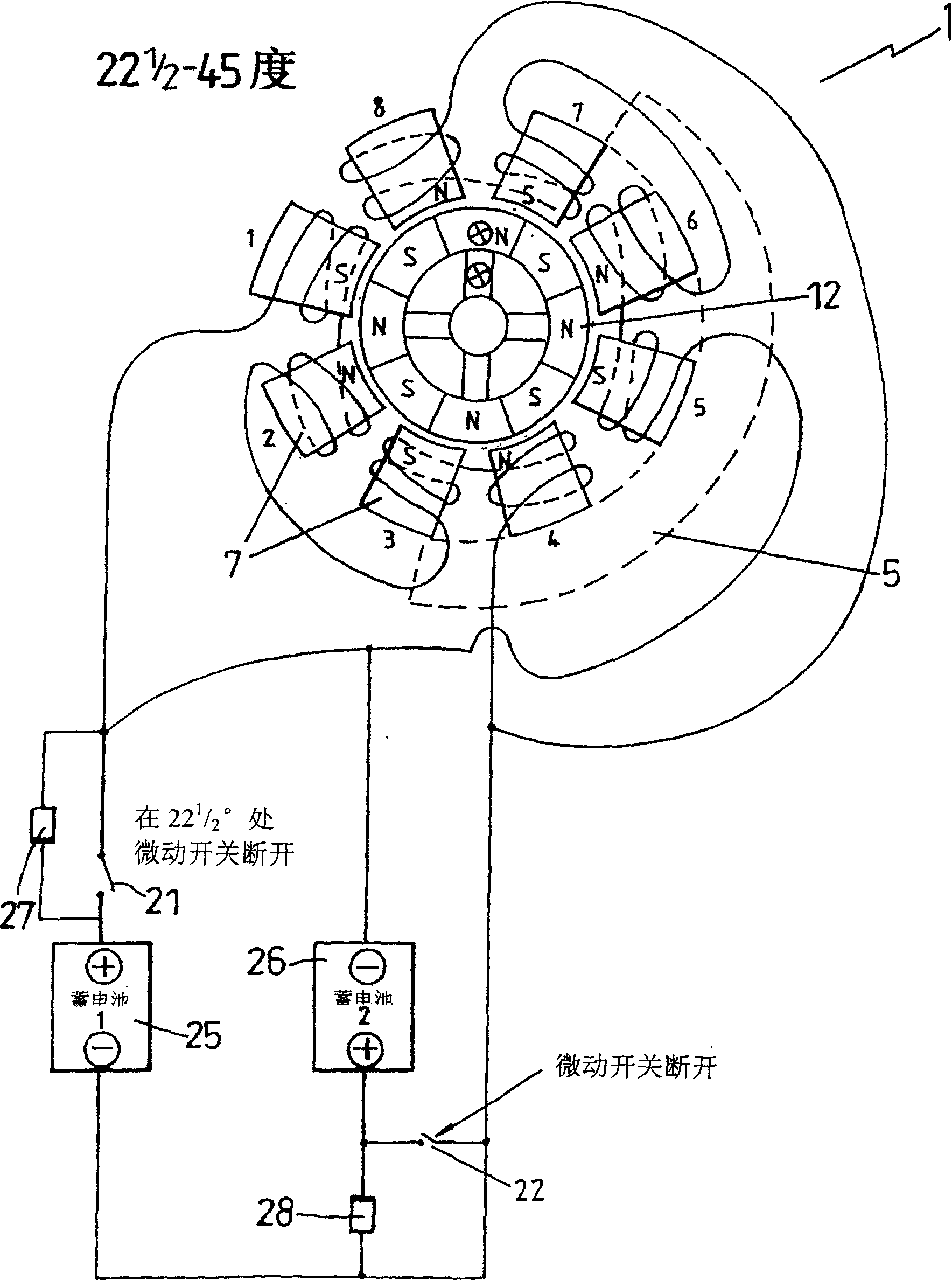

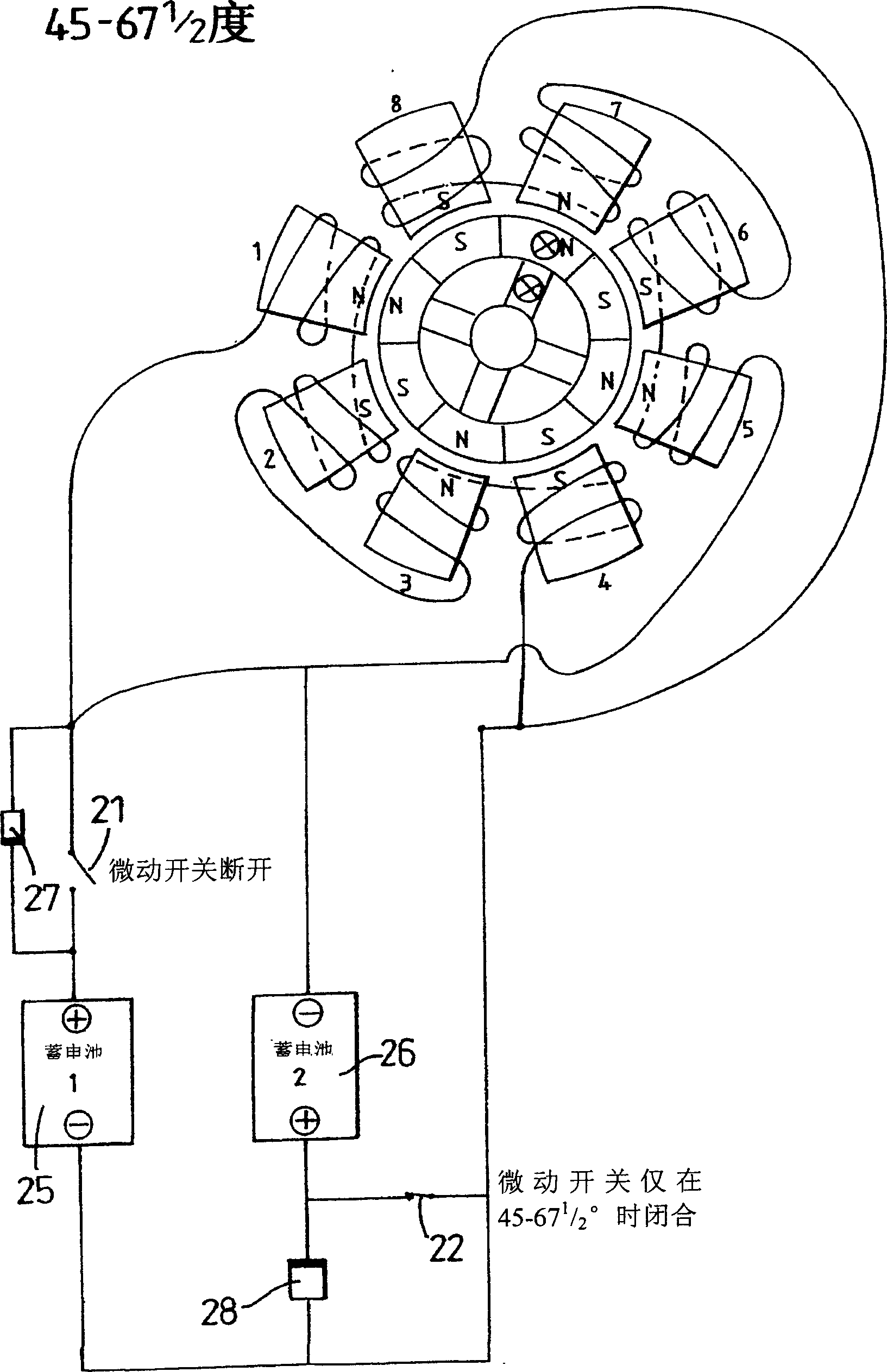

[0025] Refer to the attached drawings and first to Figures 1 to 4 , the motor has a stator 1 and a rotor 3 . The stator 1 includes an annular armature 5 (in figure 1 and 2 is represented by a dotted line, while in Figure 5 As more clearly illustrated in ), the armature 5 has a plurality of magnetic poles 7 spaced evenly along the inner circumferential surface of the armature 5 and directed towards a central longitudinal axis defined by the rotor shaft 10 . The rotor 3 is mounted for rotation about an axis 10 and has (as will be more clearly illustrated through this example) 8 permanent magnets 12 mounted on or embedded in them. Magnets arranged in series with alternating polarity extend around the circumference of the rotor 3 .

[0026] A pair of starter / accumulator circuits 14, 16 are connected in common and in series with respective sets of coils wound around the poles 7 of the stator 5, depending on the rotational position of the rotor 3 relative to the stator 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com