Patents

Literature

40results about "DC interrupters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High efficiency electro-mechanical energy conversion device

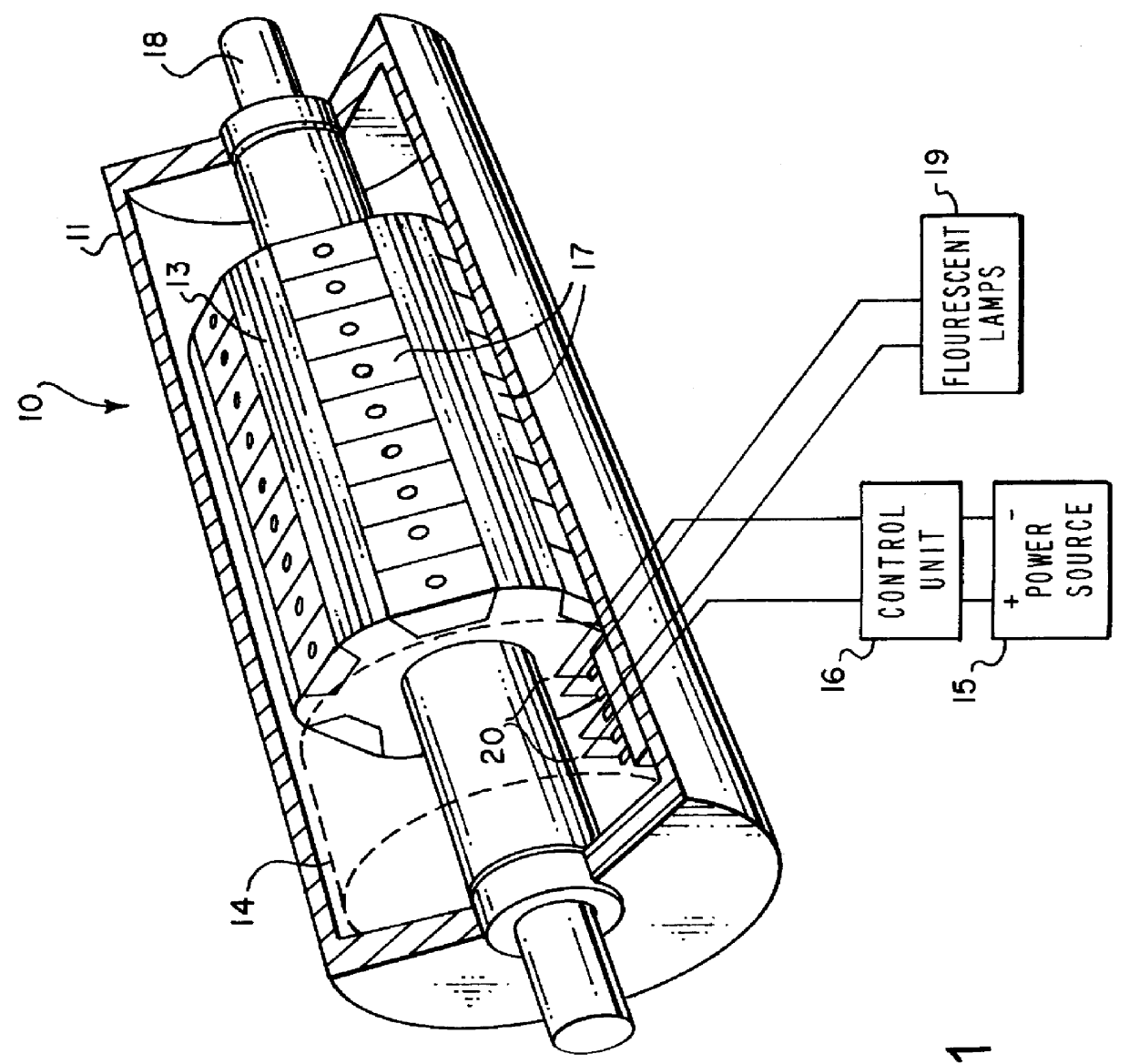

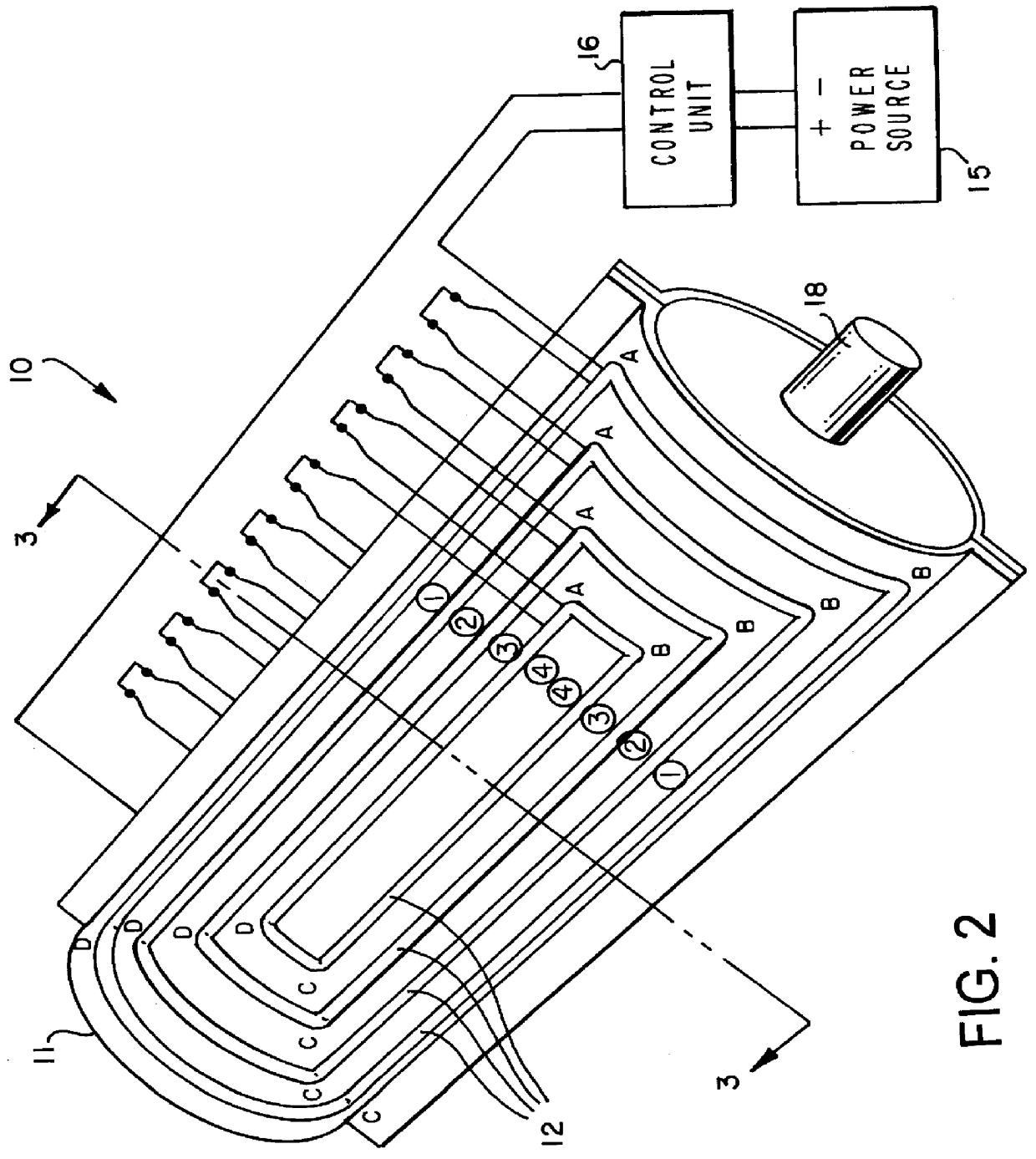

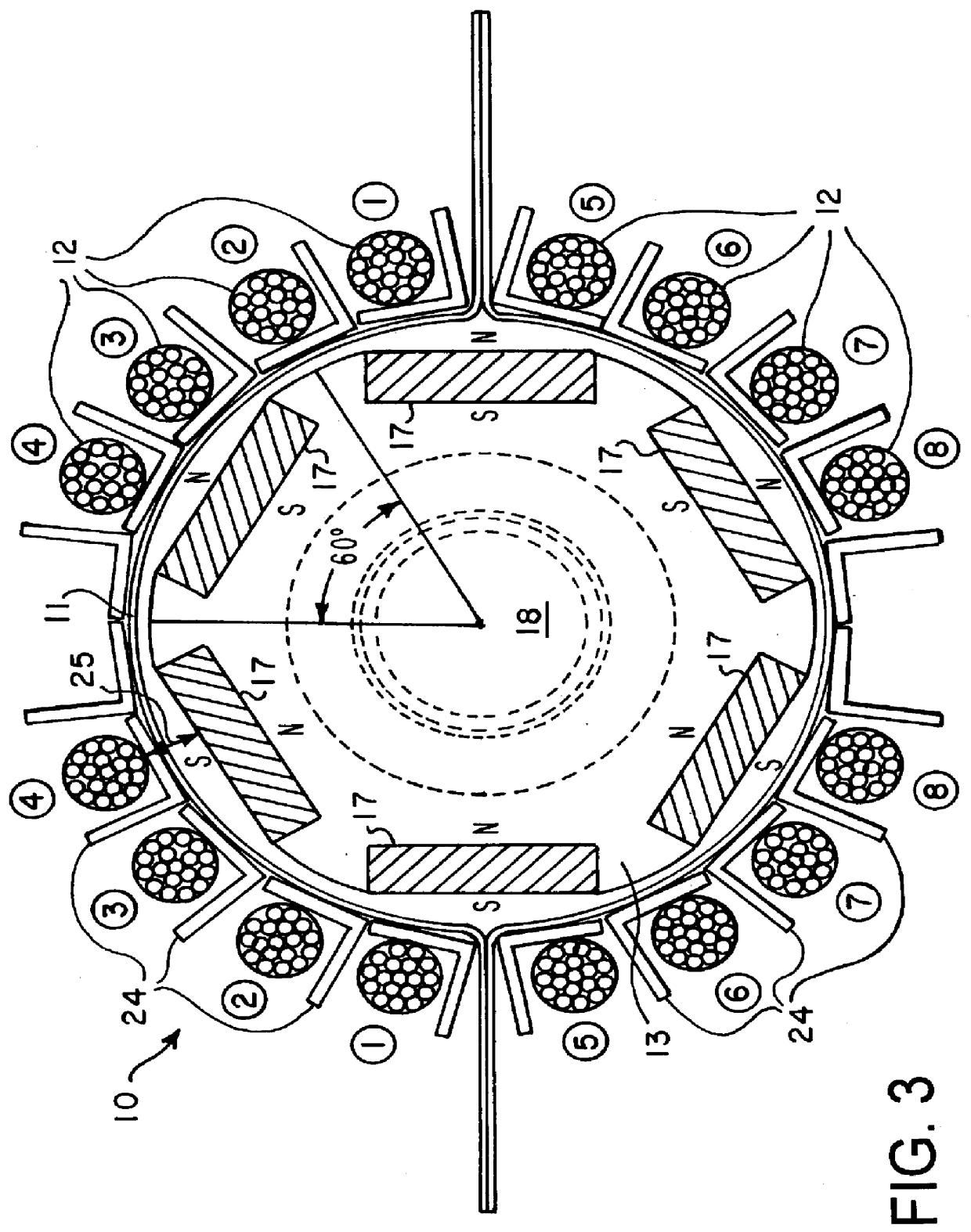

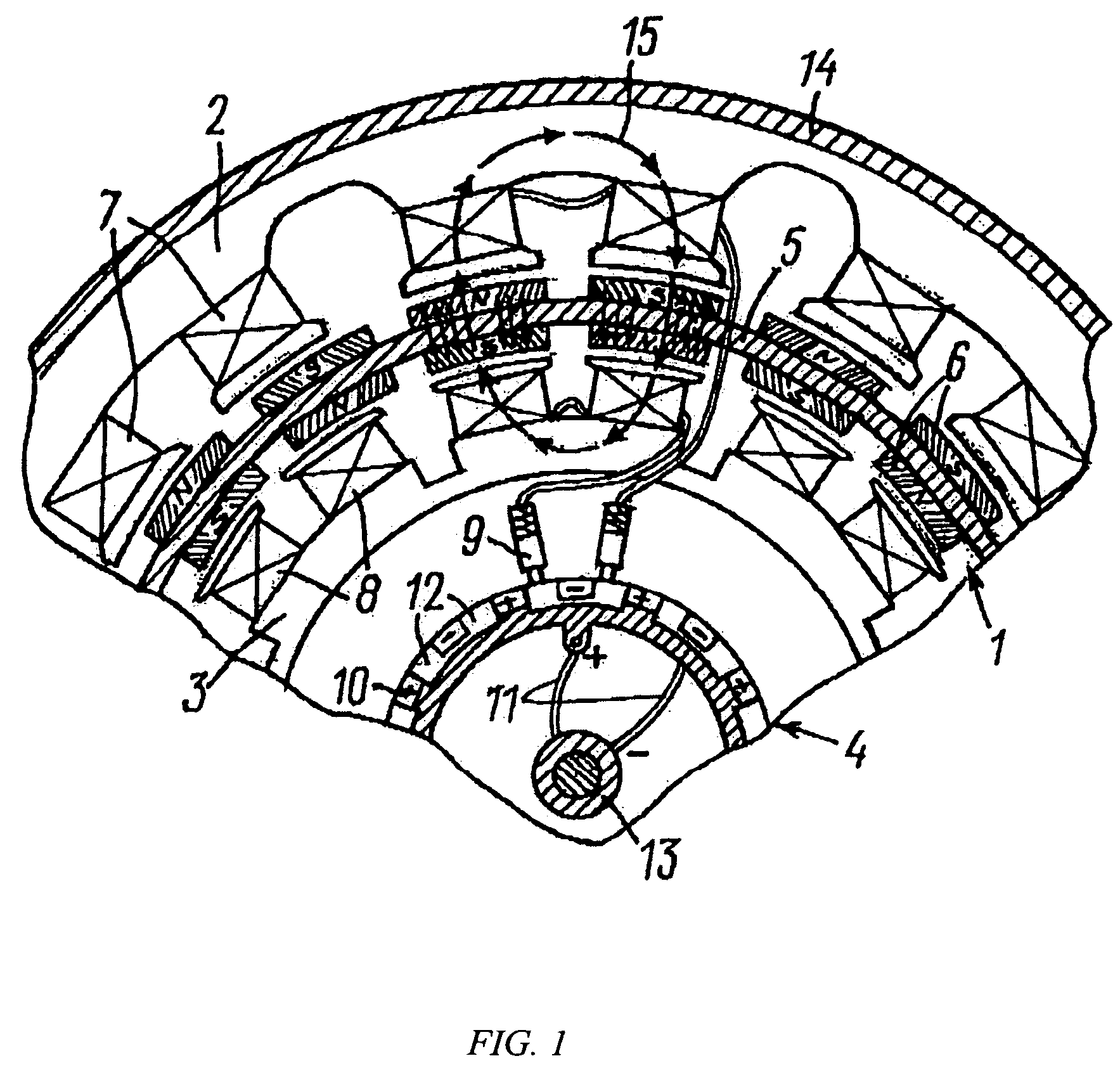

An Electro-Mechanical Energy Conversion (EMEC) device and a method of electro-magnetically converting electrical energy to mechanical energy and electrical energy. The EMEC device comprises a stator; a rotor; a direct current power source; a commutator, and flourescent lamps acting as a non-linear, capacitive, voltage-limiting load. Four armature coils of a first magnetic polarity are concentrically mounted on a first side of the outer surface of a non-magnetic cylindrical stator casing, and four armature coils of an opposite polarity are concentrically mounted on an opposite side of the stator casing. Each coil is wound with an average of 6,650 turns of 34 AWG gauge teflon-coated wire. The rotor is constructed of non-magnetic material, and is rotationally mounted in the stator casing. A plurality of neodymium iron-boron permanent magnets are circumferentially mounted on the rotor. The magnets on a first side of the rotor are mounted with a first outward polarity, and the magnets on an opposite side of the rotor are mounted with an opposite outward polarity. The power source is connected to the coils and produces an output of 0-5,000 volts at 30 to 40 milliamperes maximum. The flourescent lamps are connected to the coils for rapidly dumping magnetic energy from the coils when the polarity is reversed. The commutator reverses the polarity of the first and second coils every 180 DEG of rotor rotation, and guides the magnetic energy from the coils to the load.

Owner:EMEC ENERGY L L C

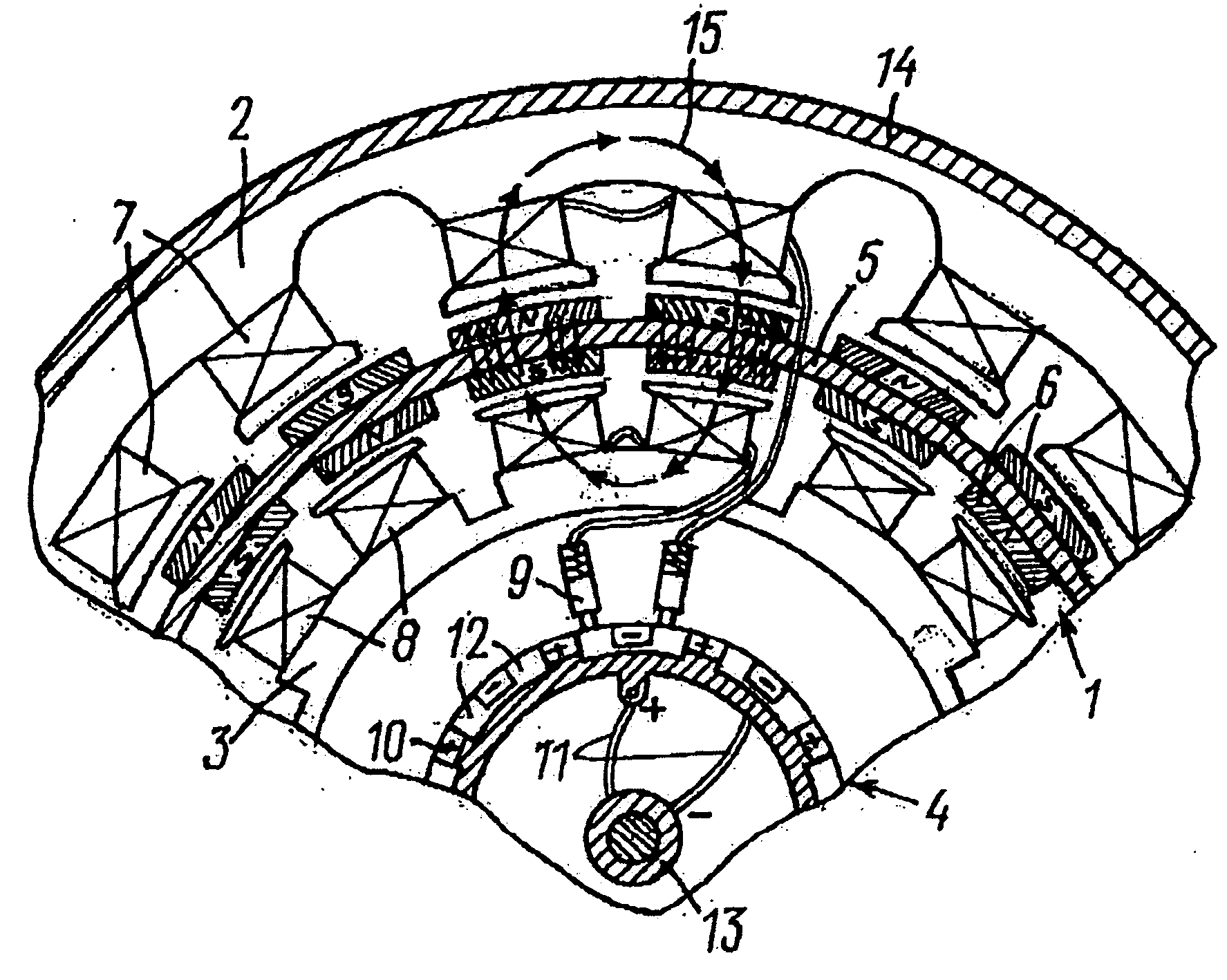

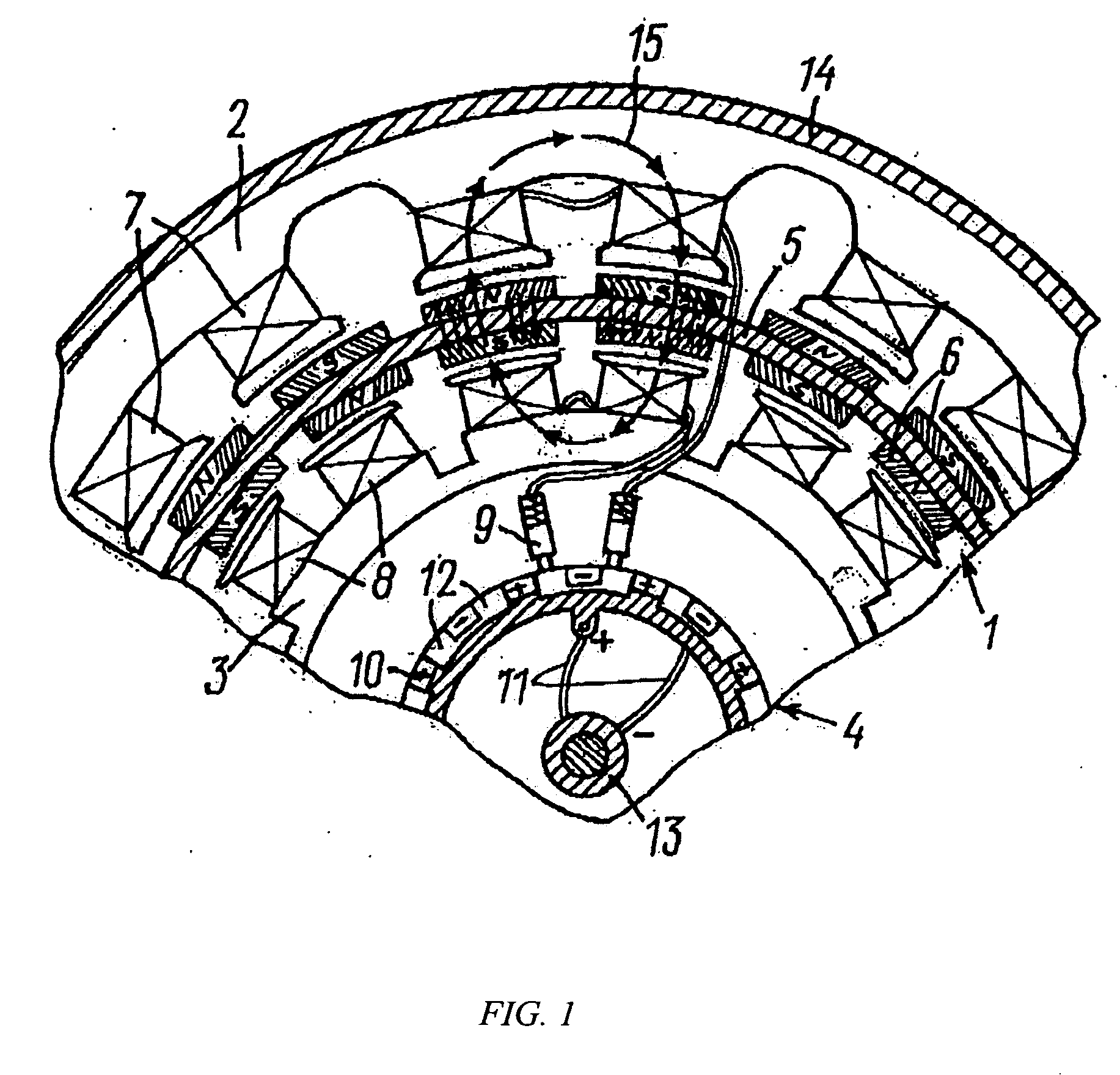

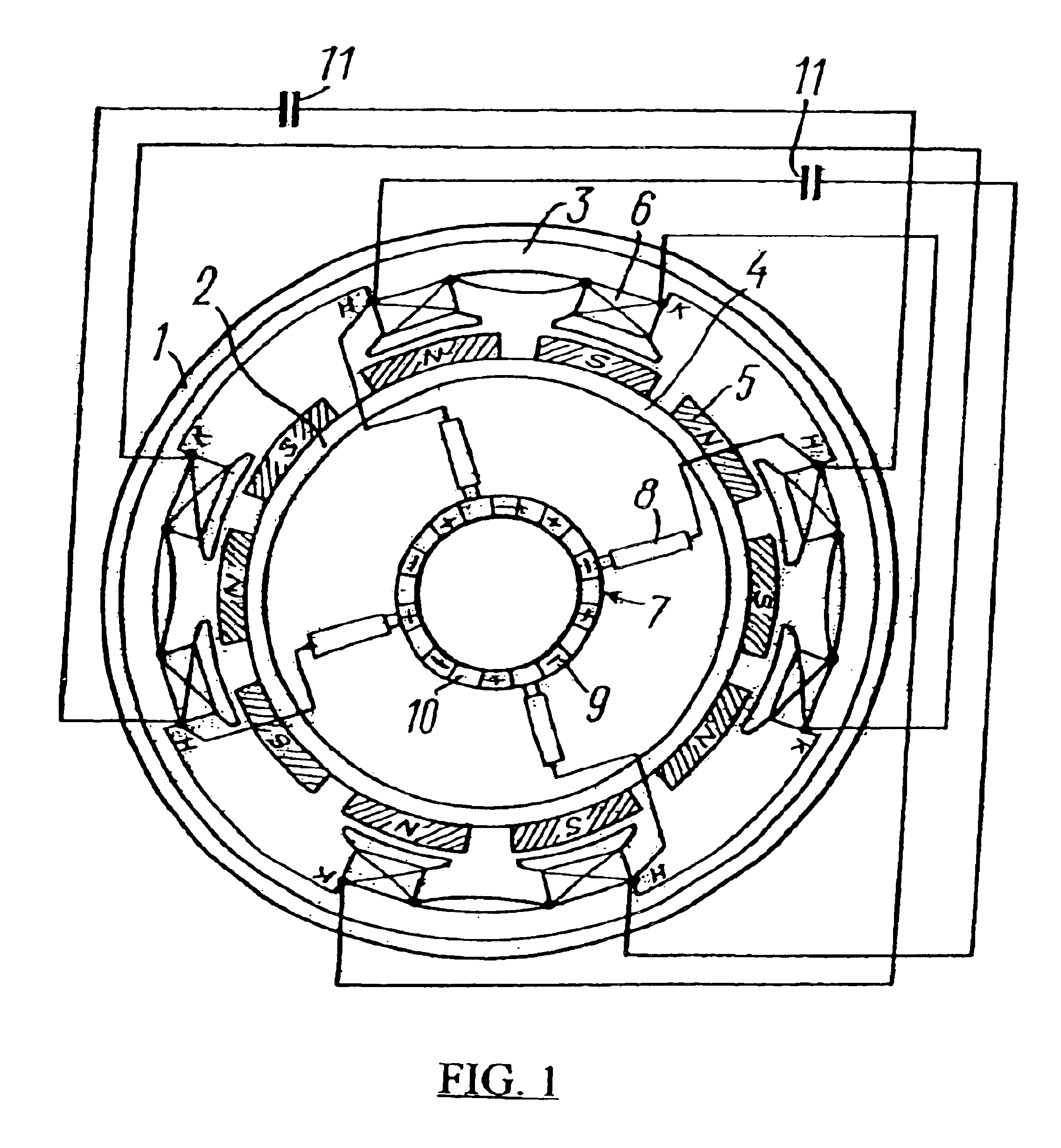

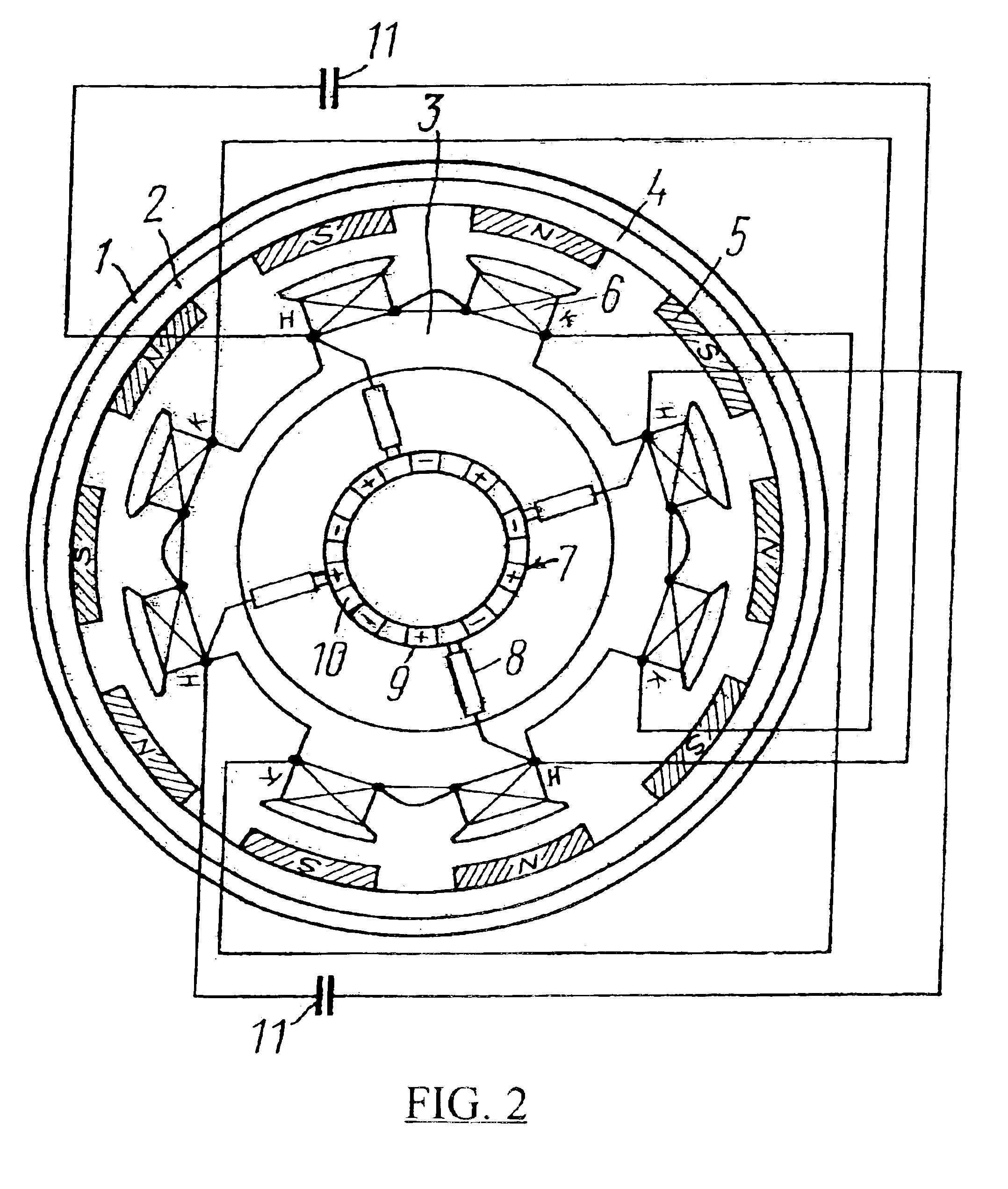

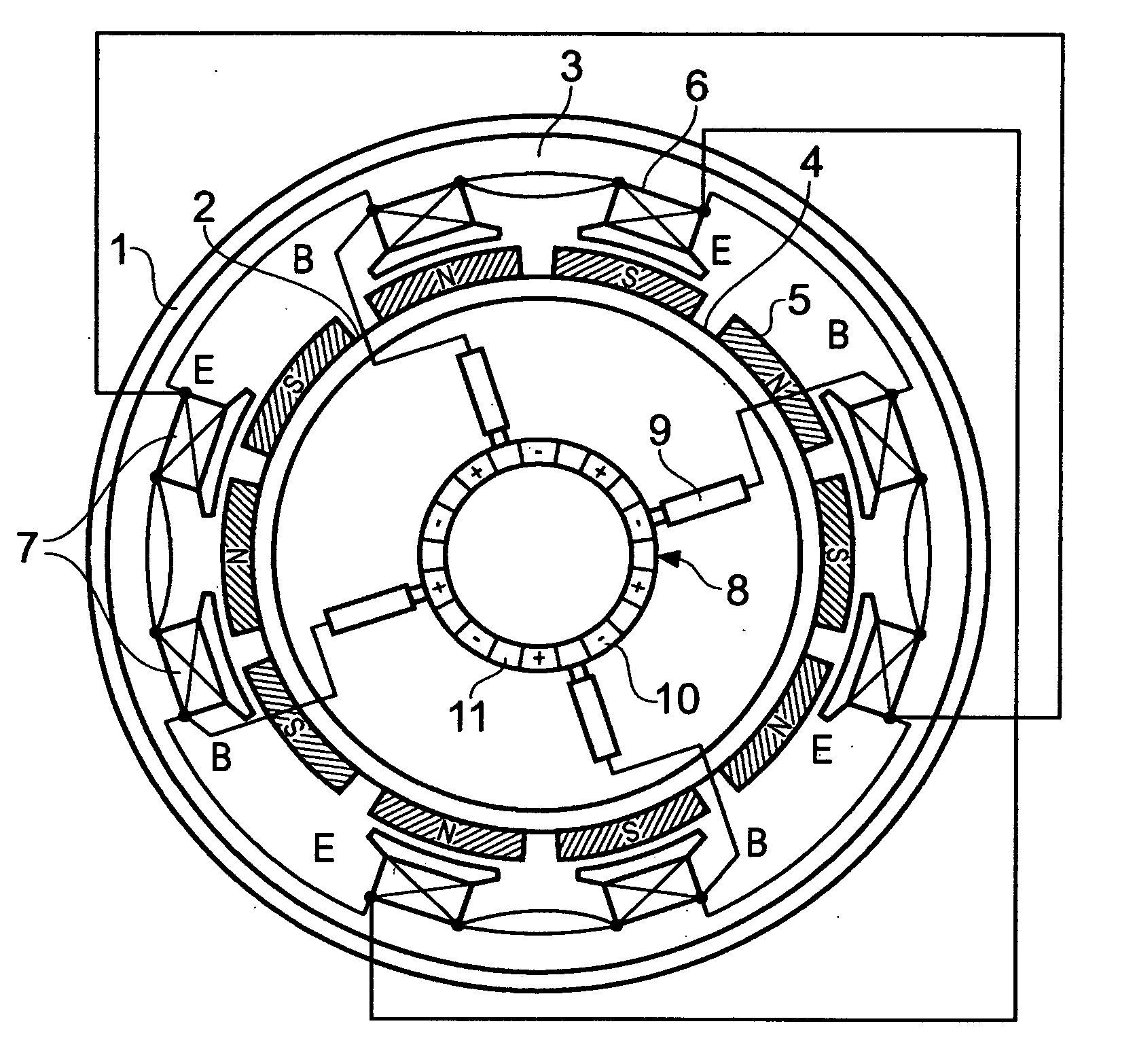

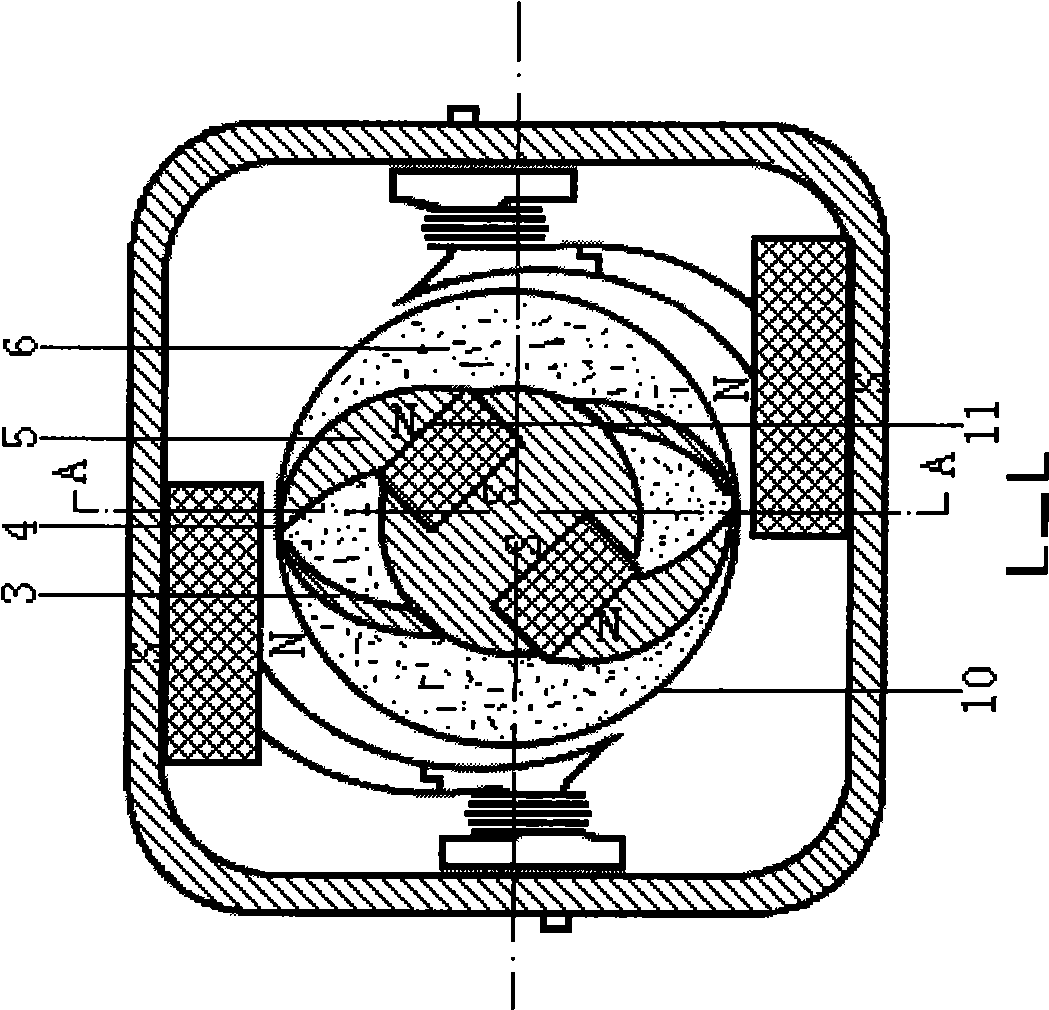

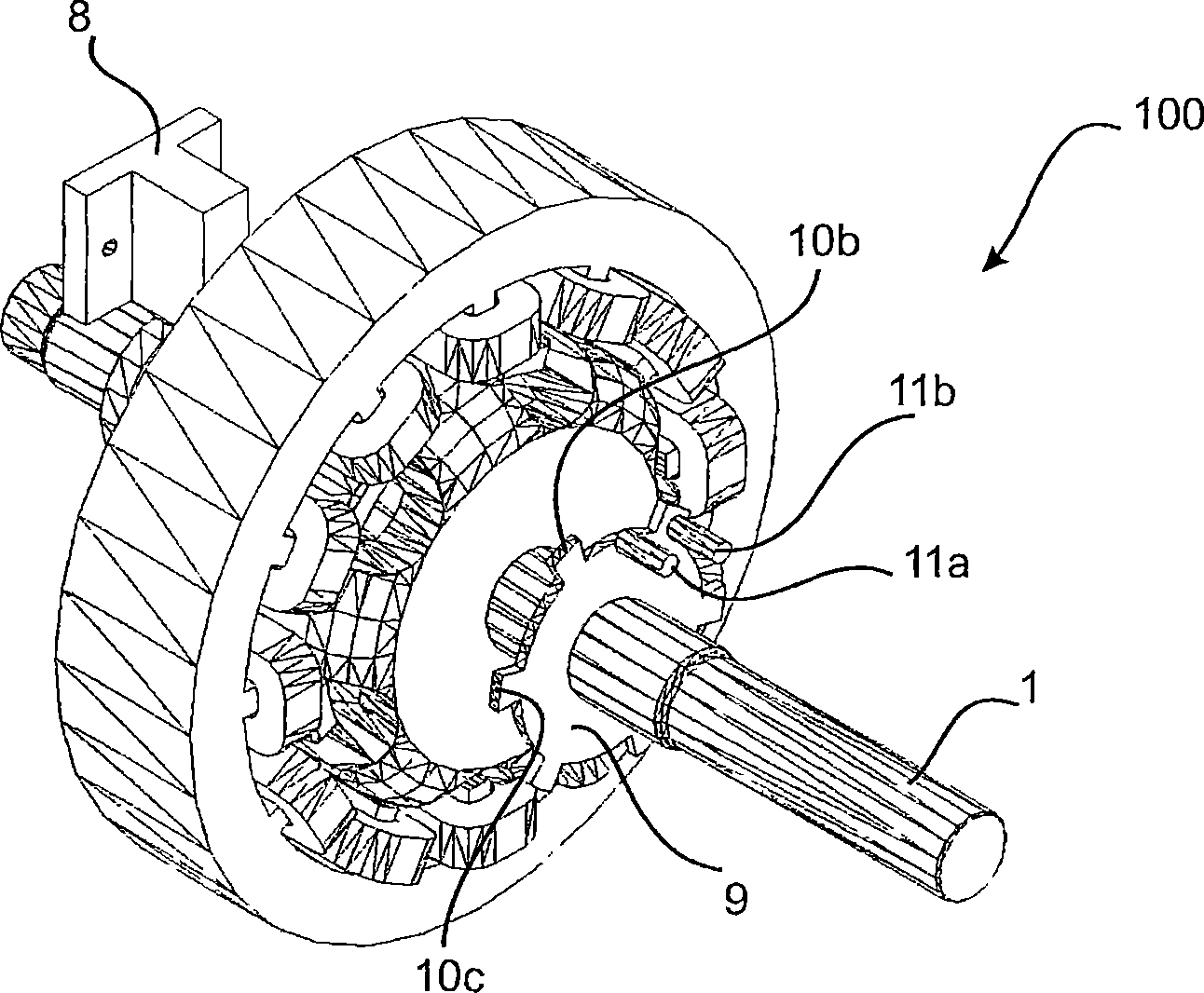

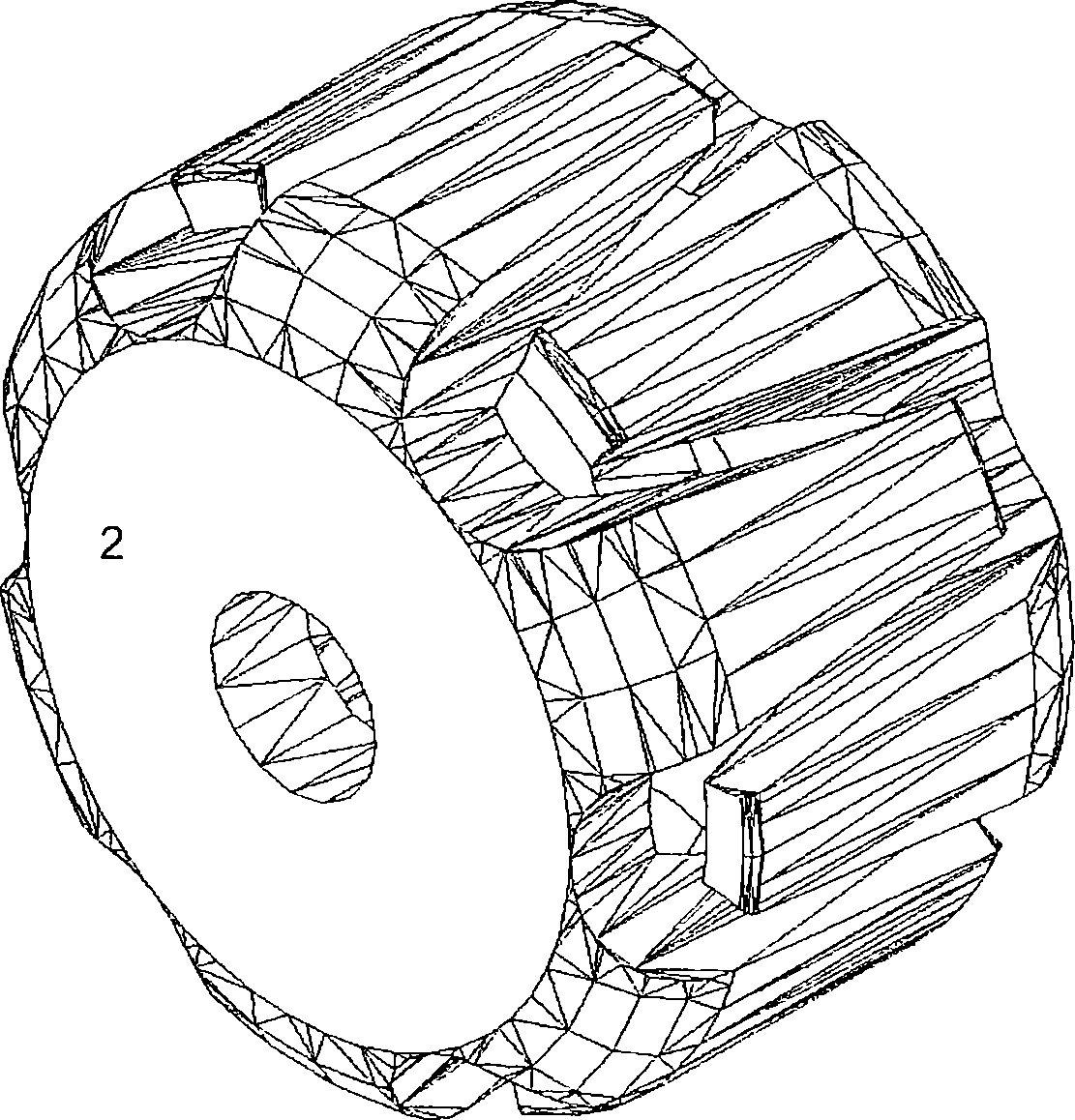

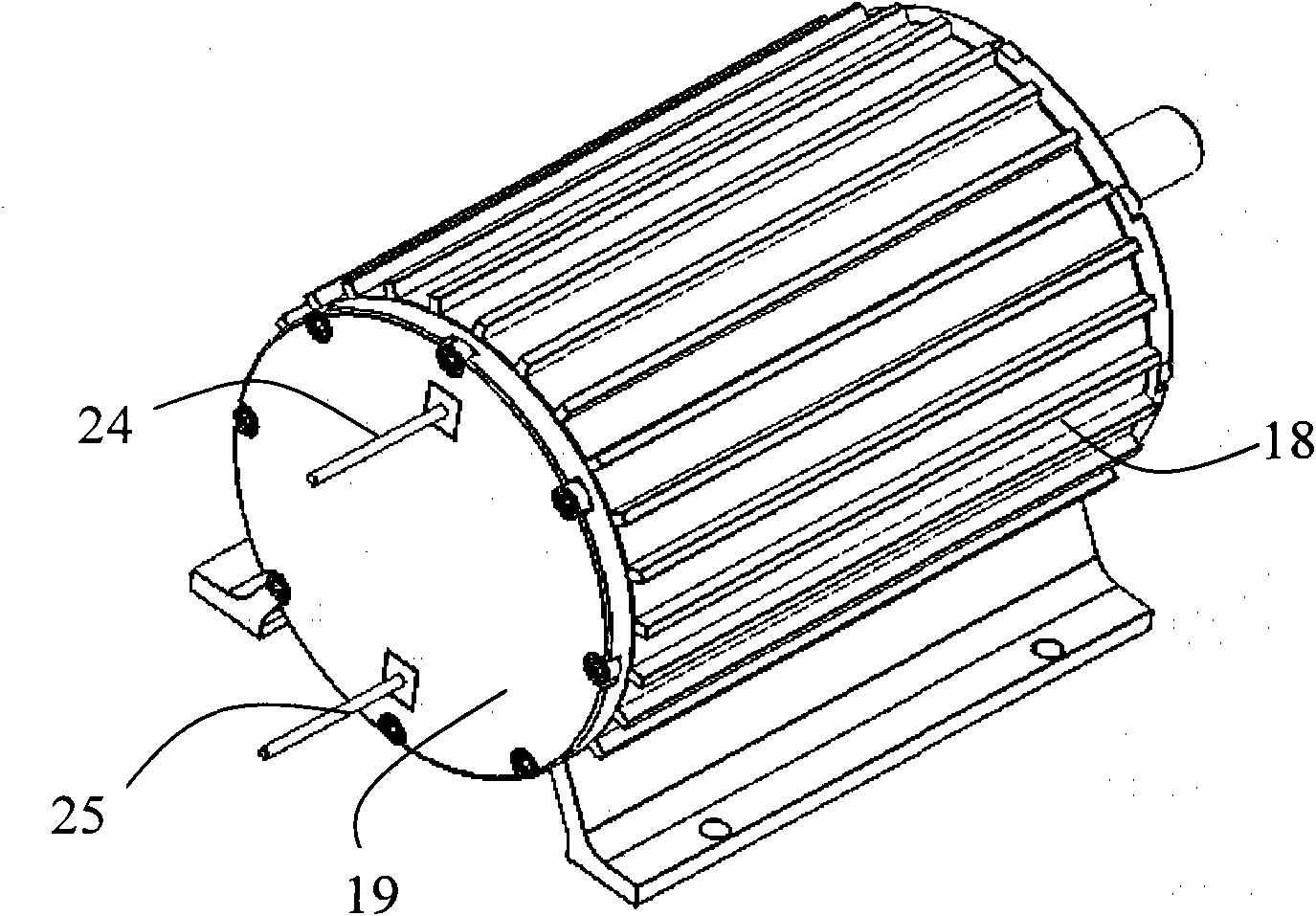

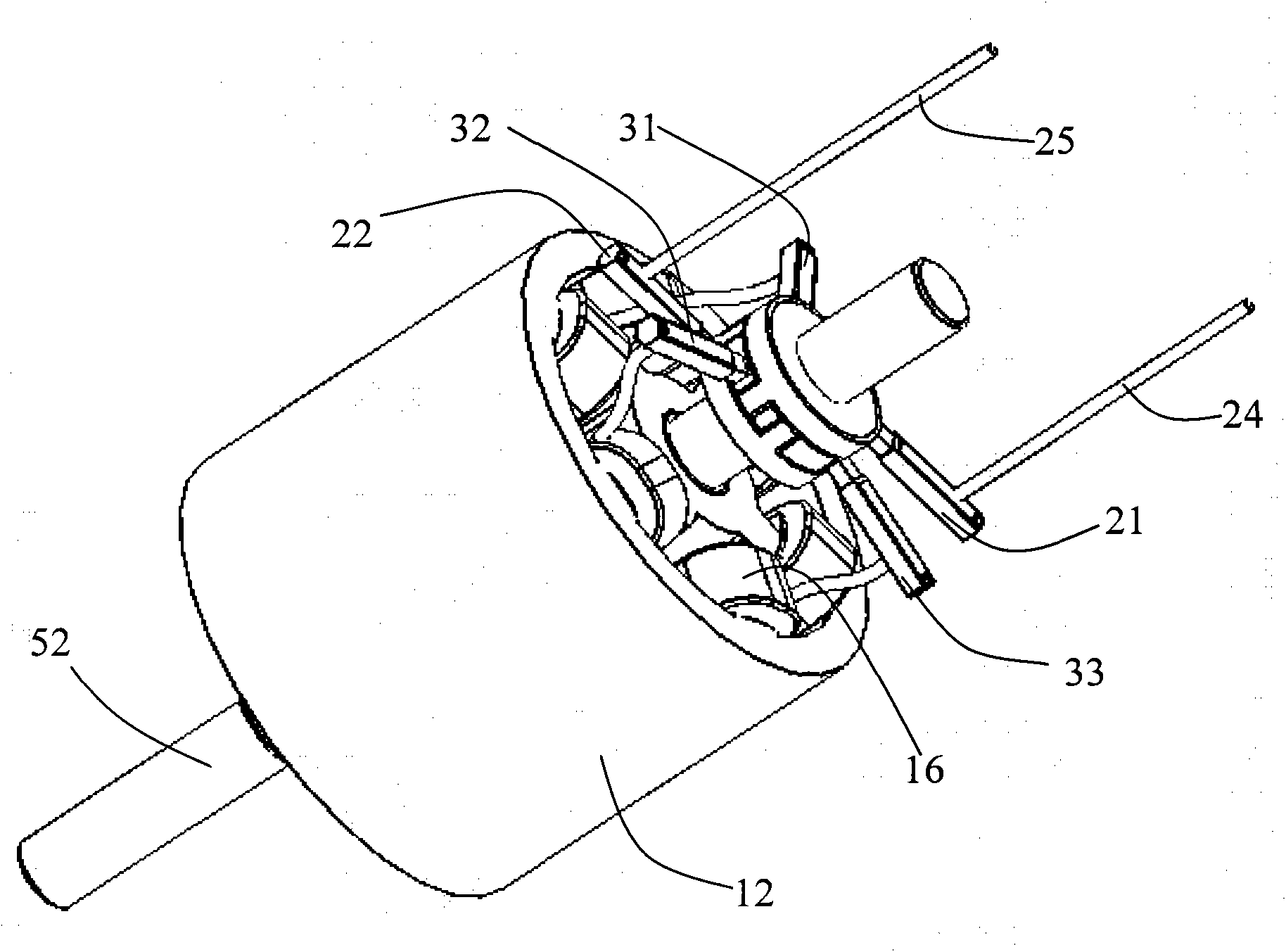

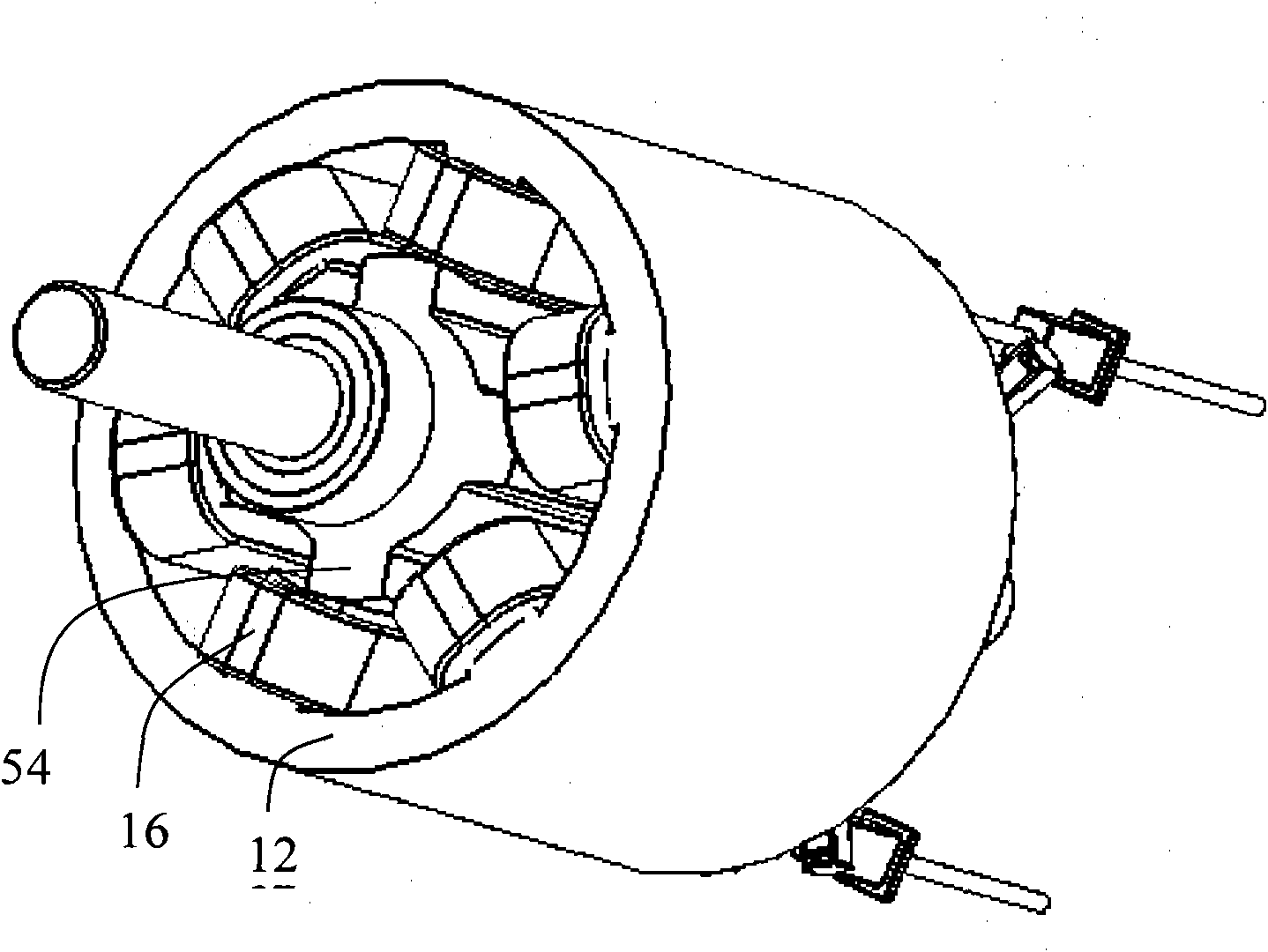

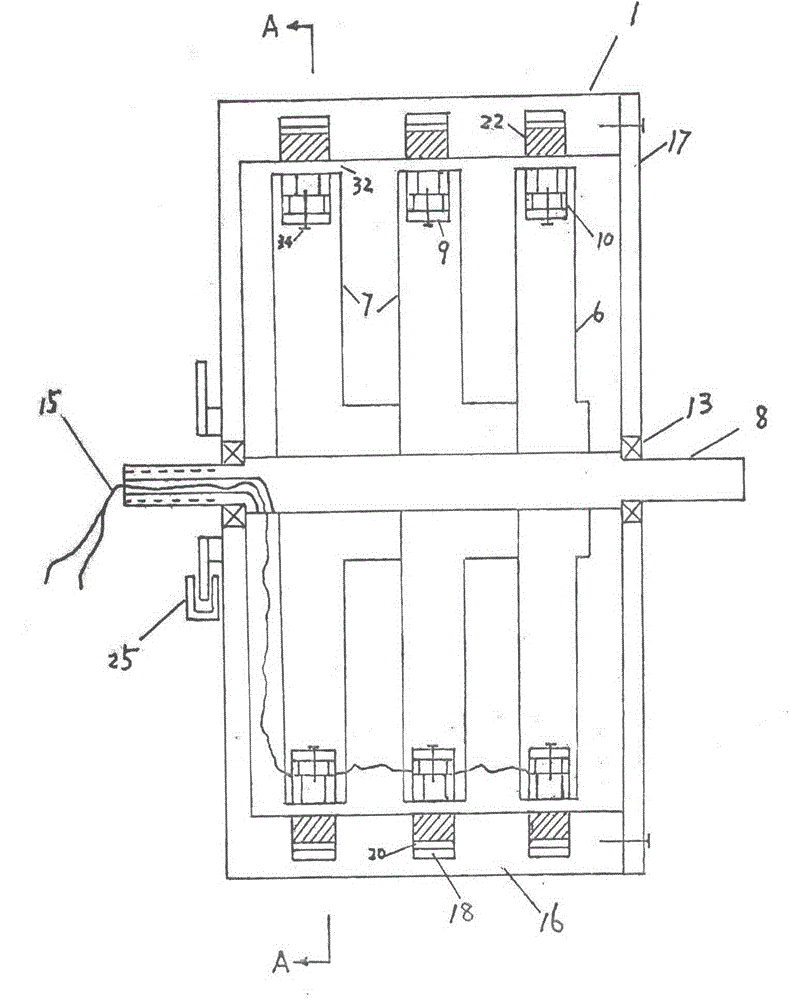

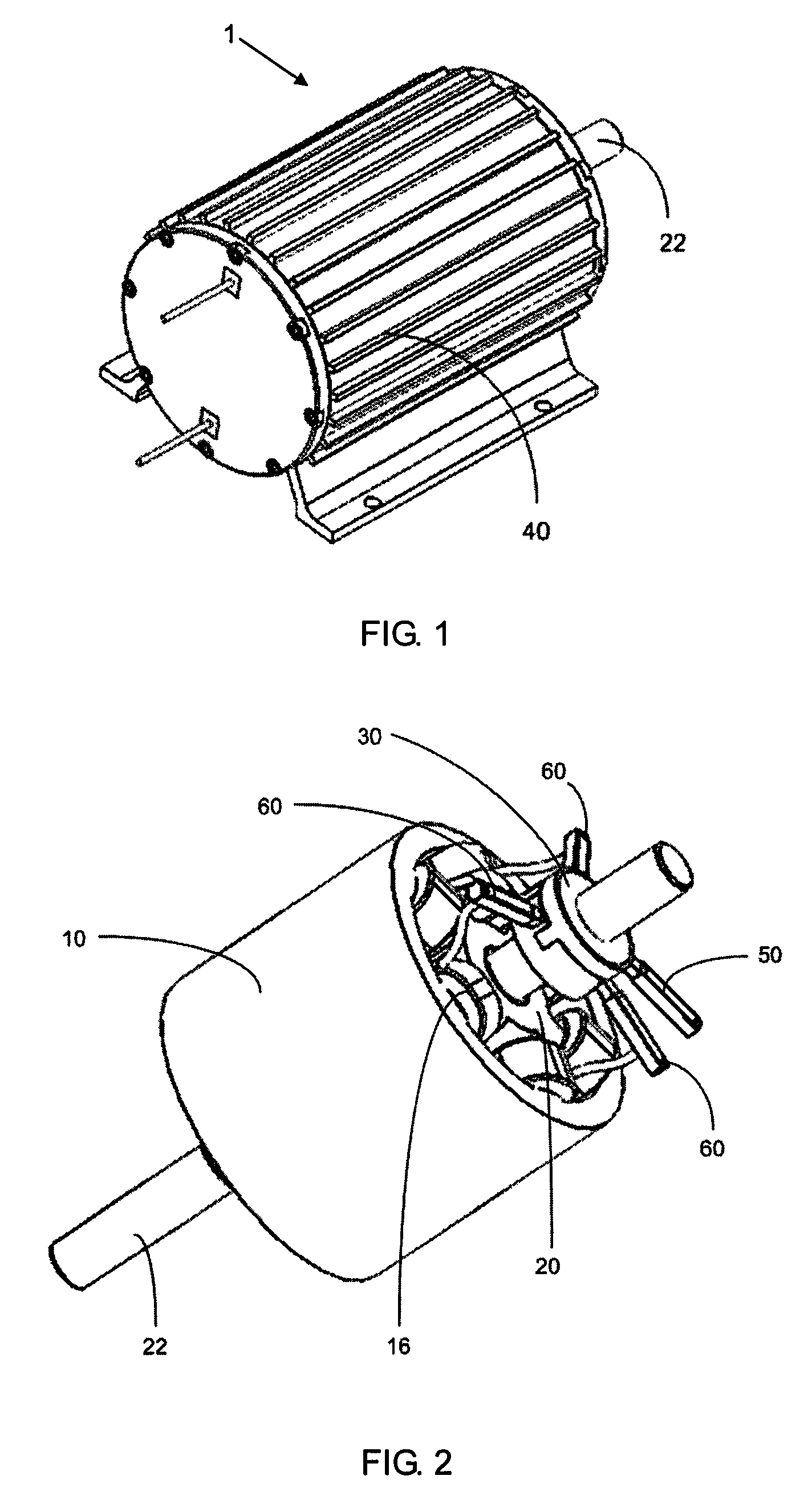

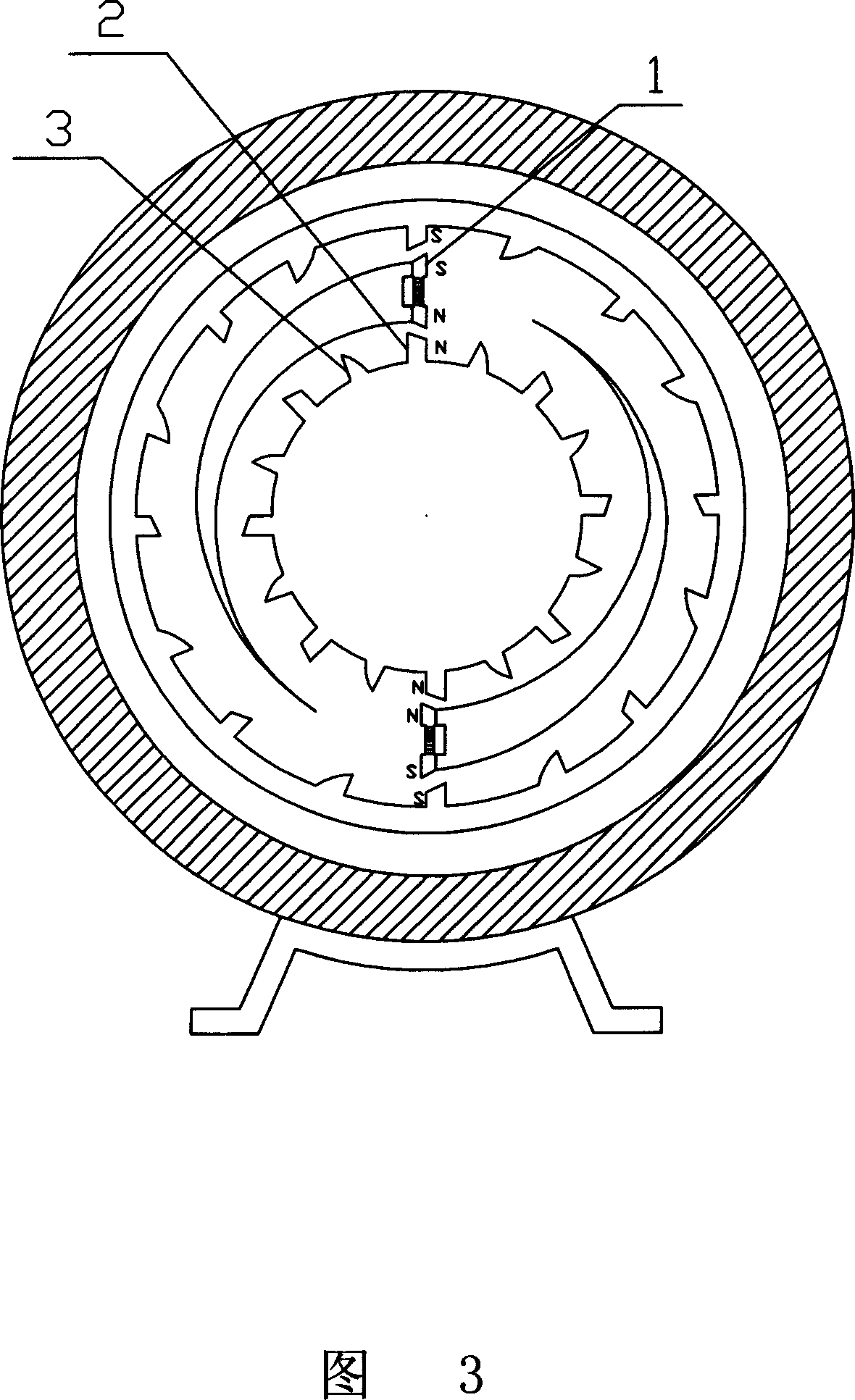

Electric motor

InactiveUS7119468B2Increase of torqueReduce vertical sizeRotary current collectorMagnetic circuit rotating partsEngineeringMagnet

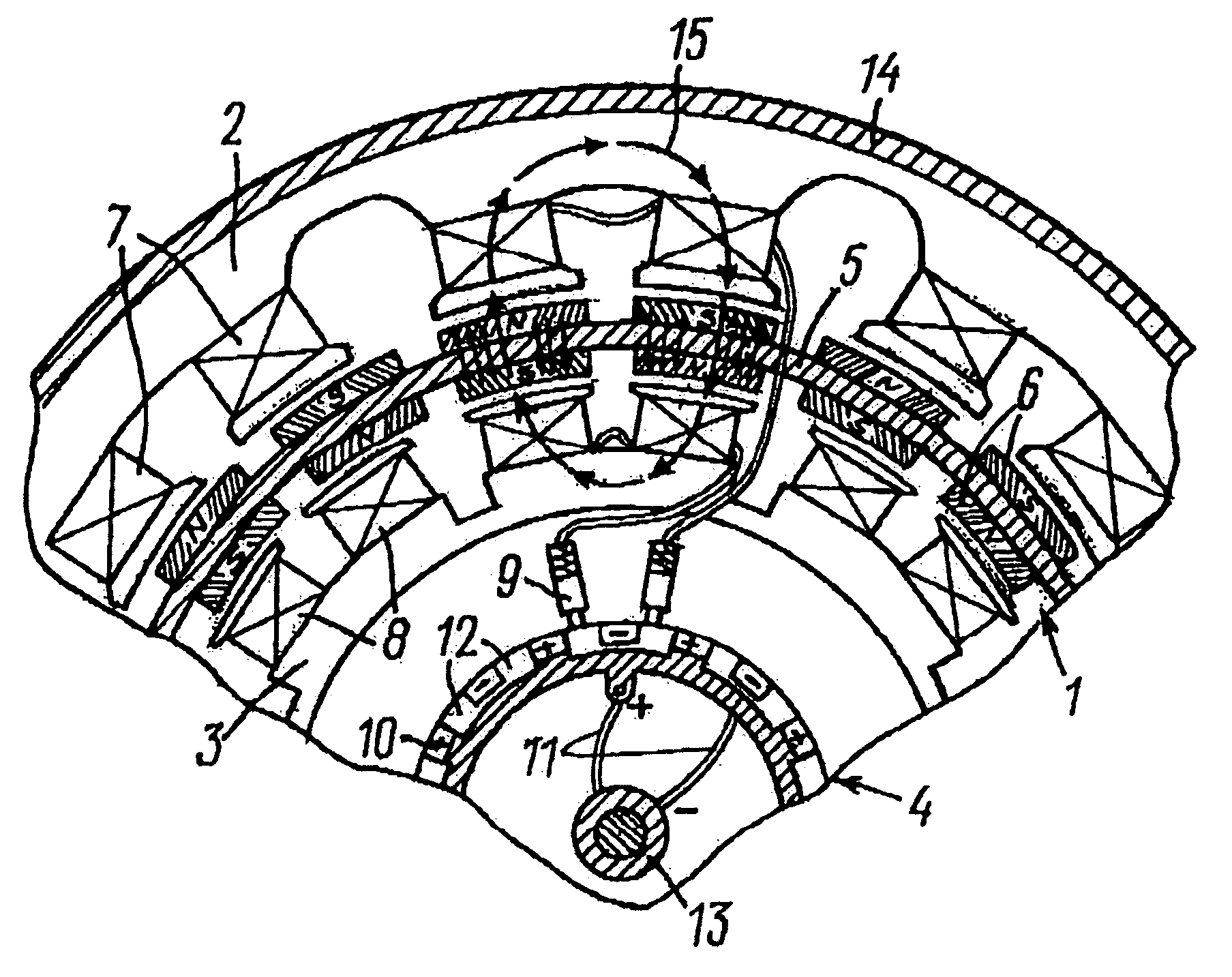

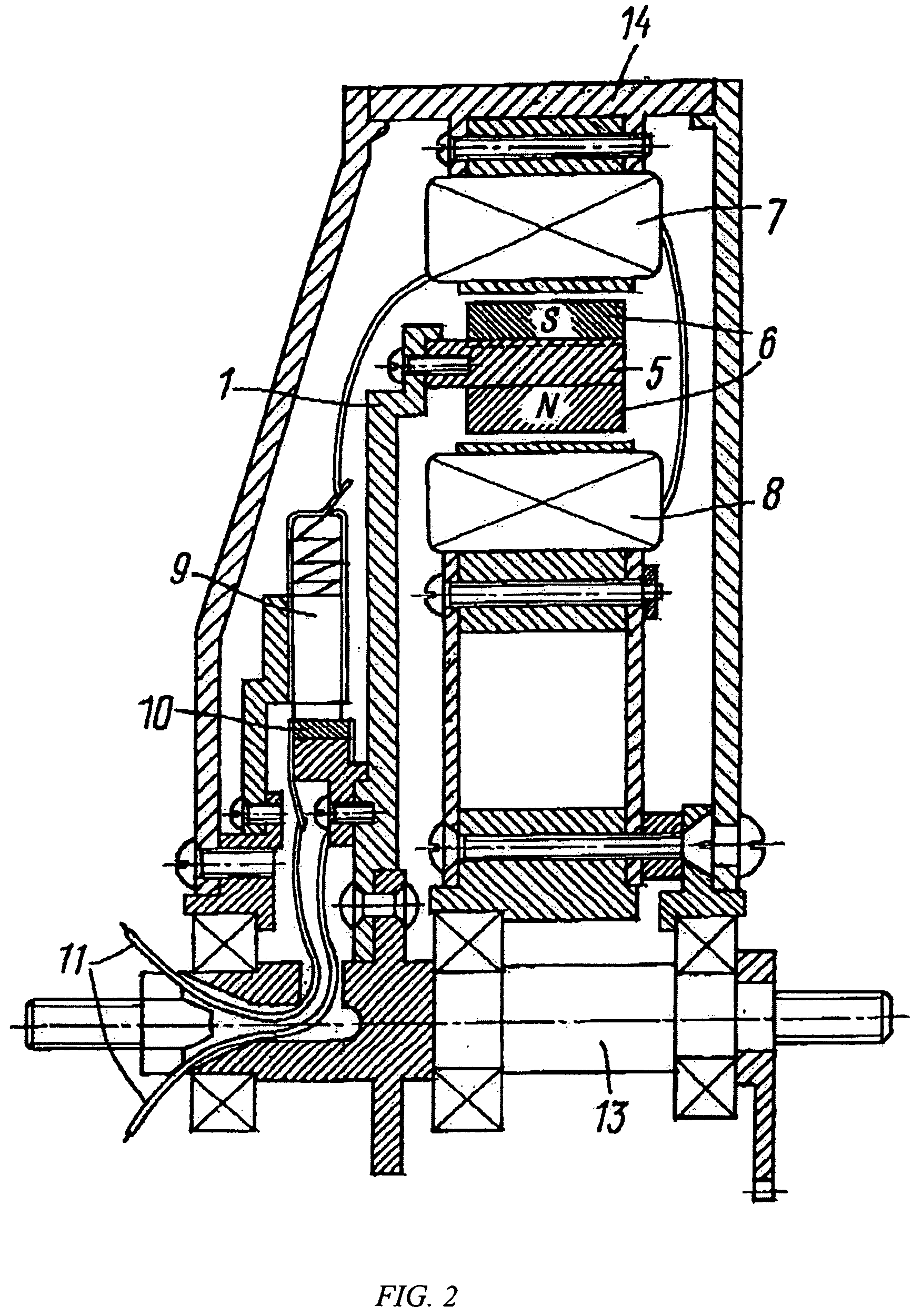

An electric motor intended for driving transport vehicles without a reduction gear is described. The electric motor can have an annular magnetic conductor of the stator with permanent magnets located on opposite sides of the magnetic conductor, and a two-section rotor, one section of which goes round the stator, while the other is inside it. The electric motor provides greater torque.

Owner:ULTRA MOTOR CO LTD

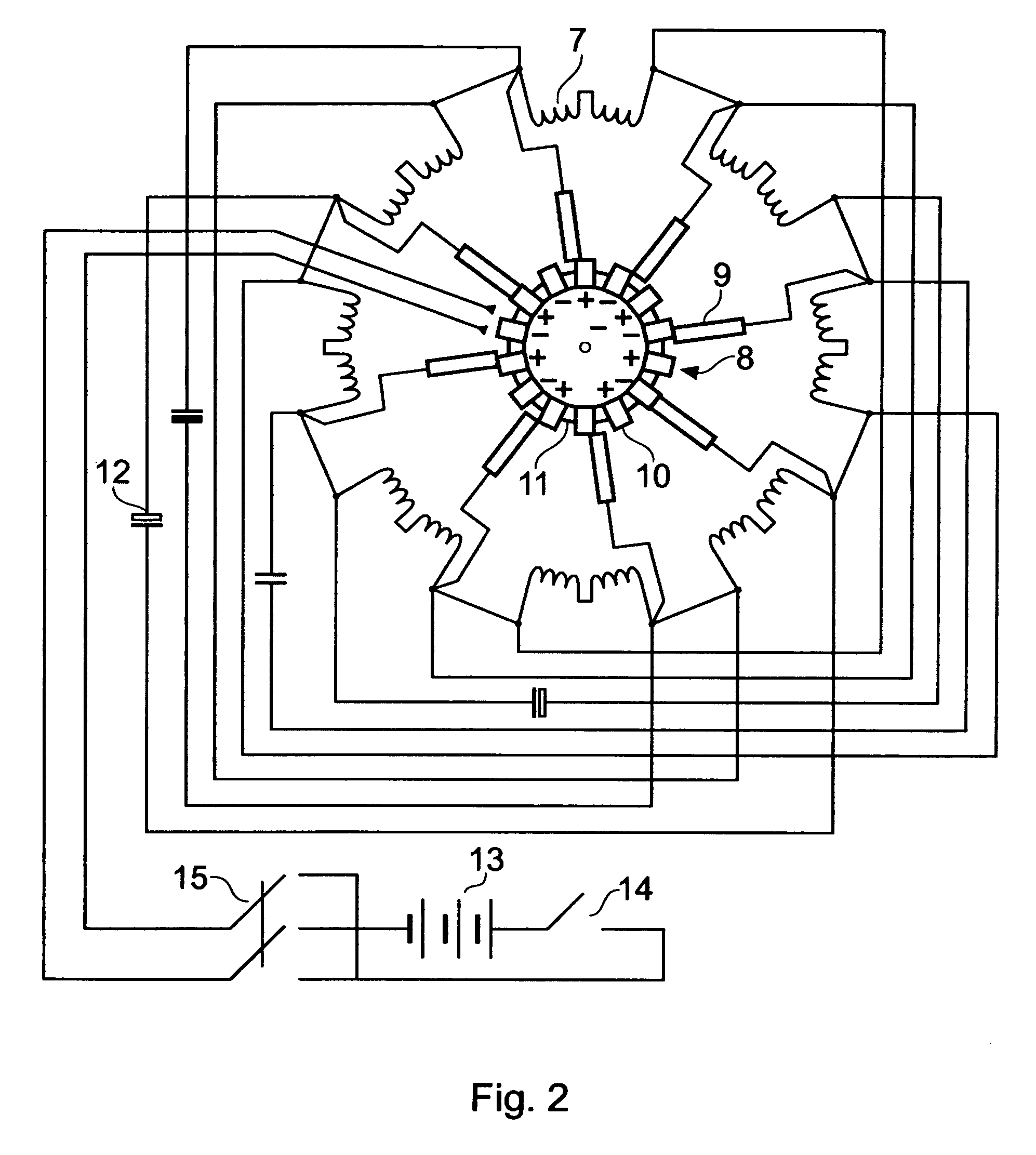

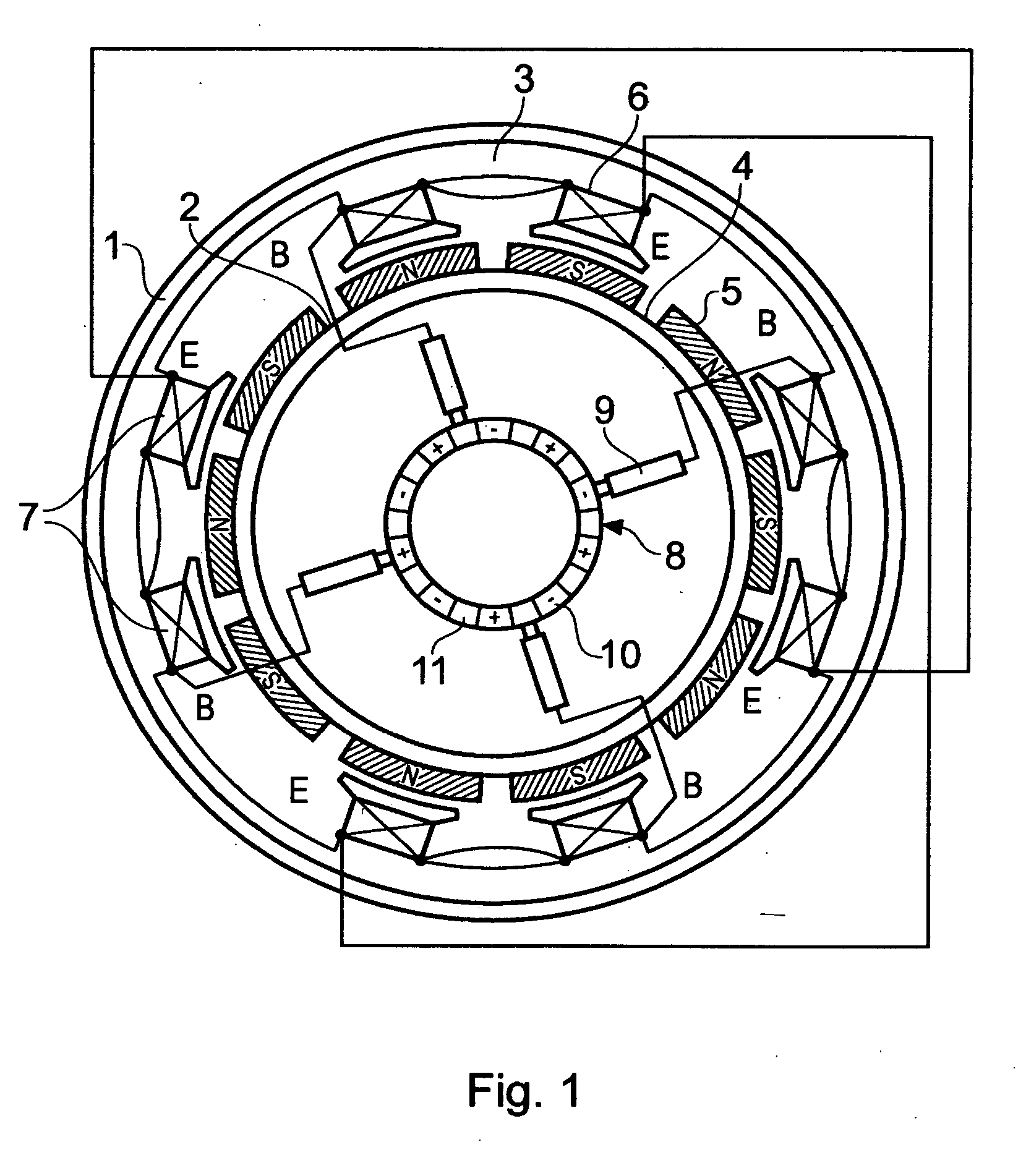

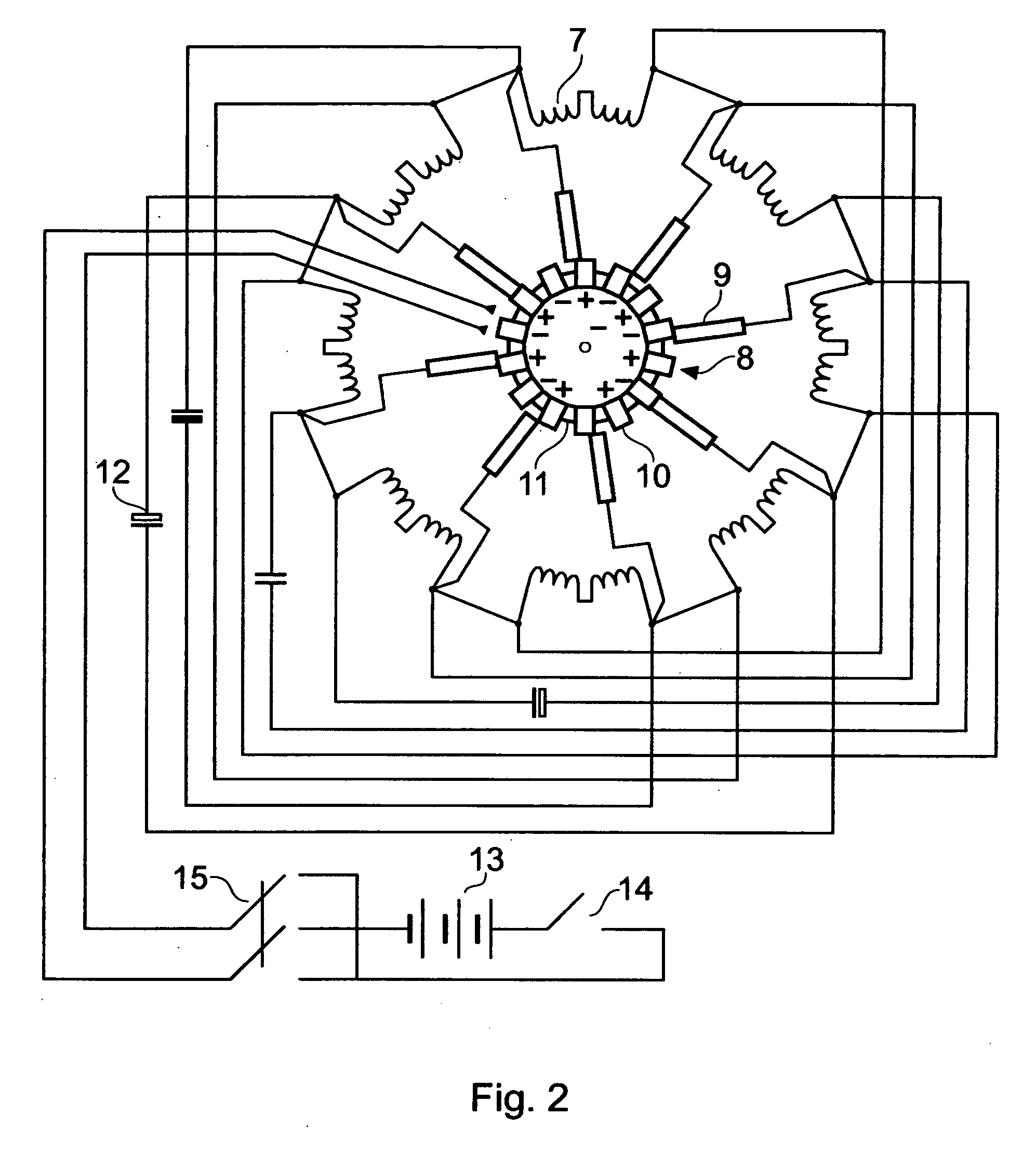

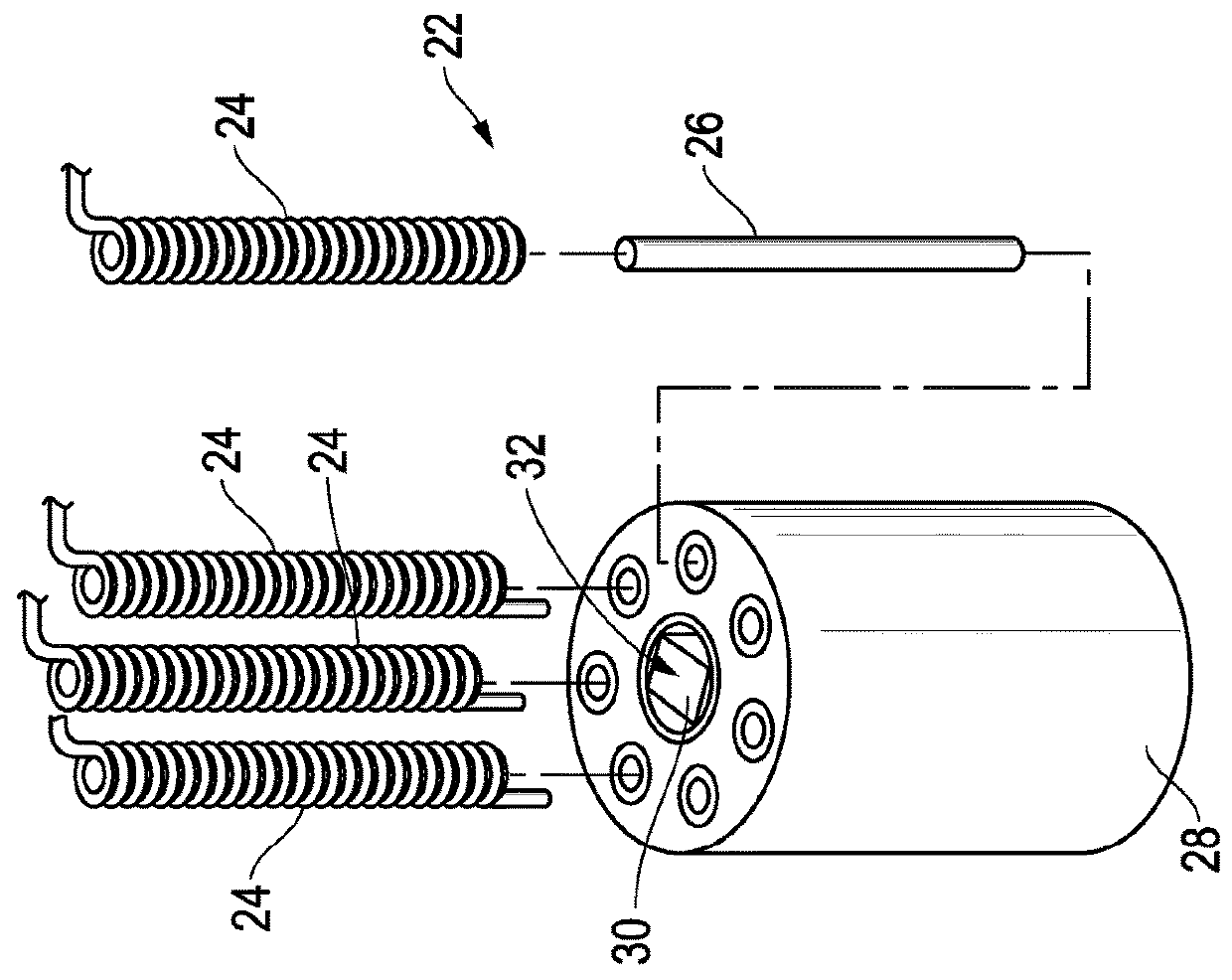

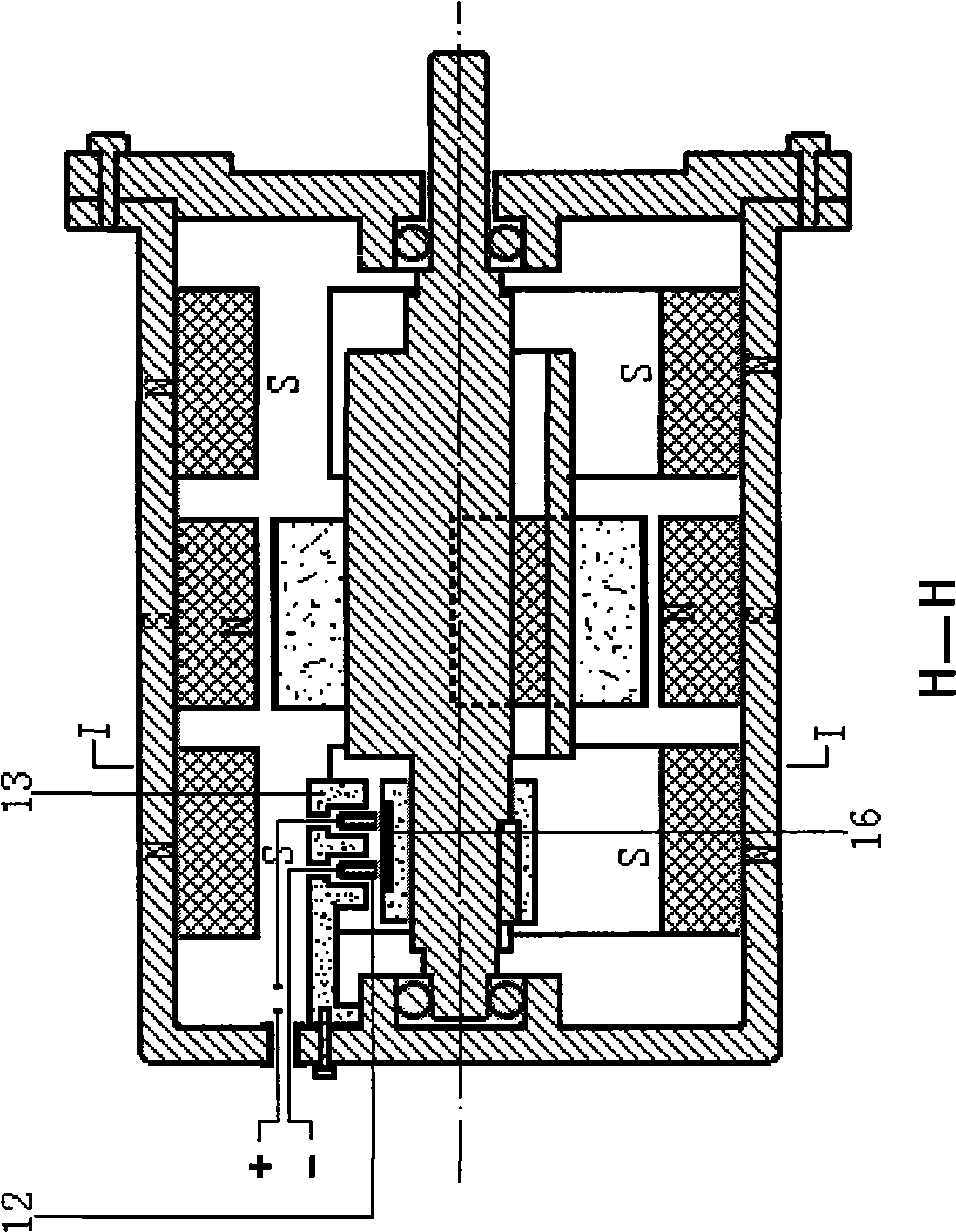

Pulsed-inertial electric motor

InactiveUS7285889B2Improved performance characteristicsSimple designWindingsMagnetic circuitLow voltageDc current

Owner:ULTRA MOTOR CO LTD

Electric motor

InactiveUS20050110365A1Reduce vertical sizeIncrease of torqueRotary current collectorMagnetic circuit rotating partsEngineeringMagnet

An electric motor intended for driving transport vehicles without a reduction gear is described. The electric motor can have an annular magnetic conductor of the stator with permanent magnets located on opposite sides of the magnetic conductor, and a two-section rotor, one section of which goes round the stator, while the other is inside it. The electric motor provides greater torque.

Owner:ULTRA MOTOR CO LTD

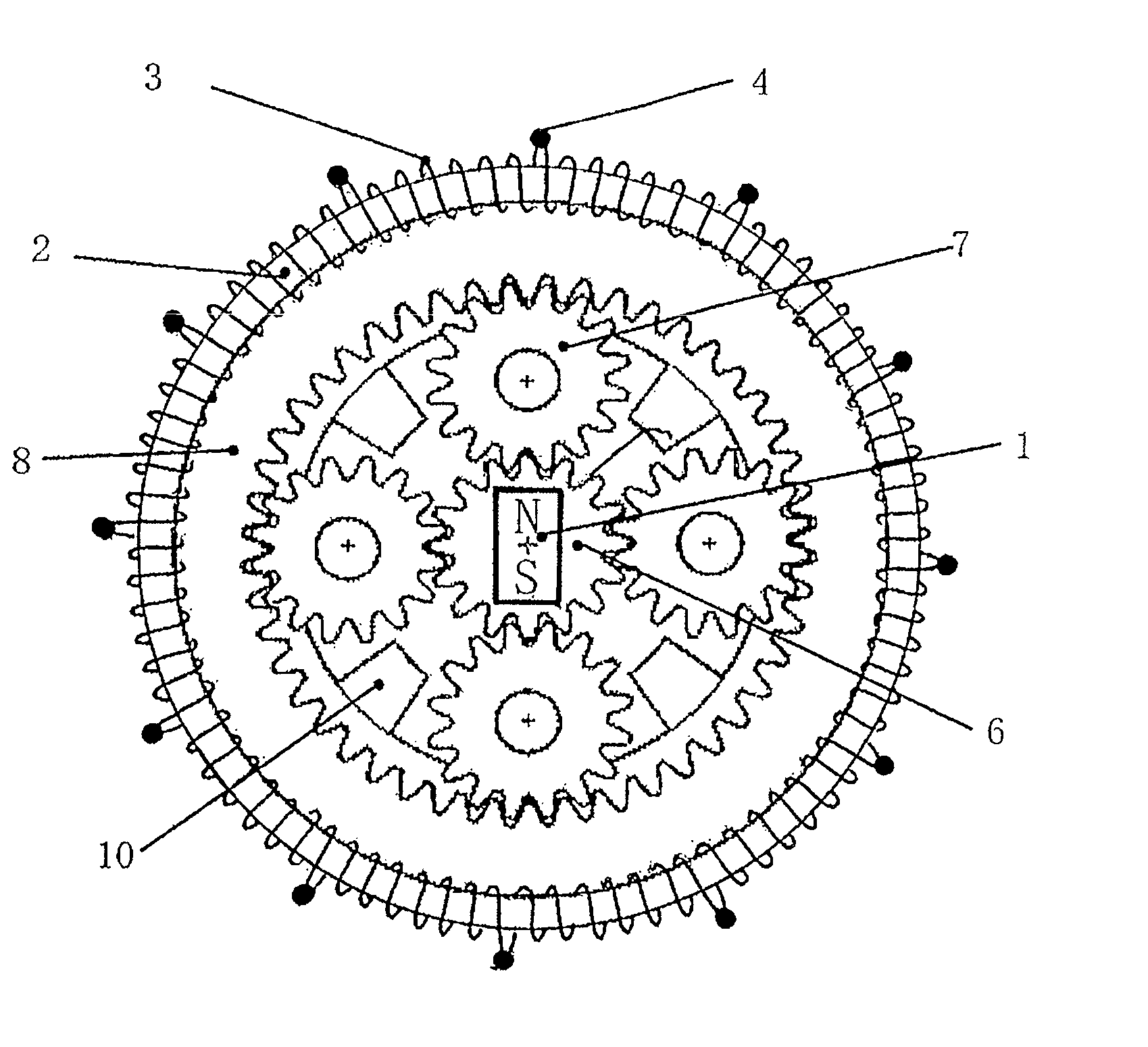

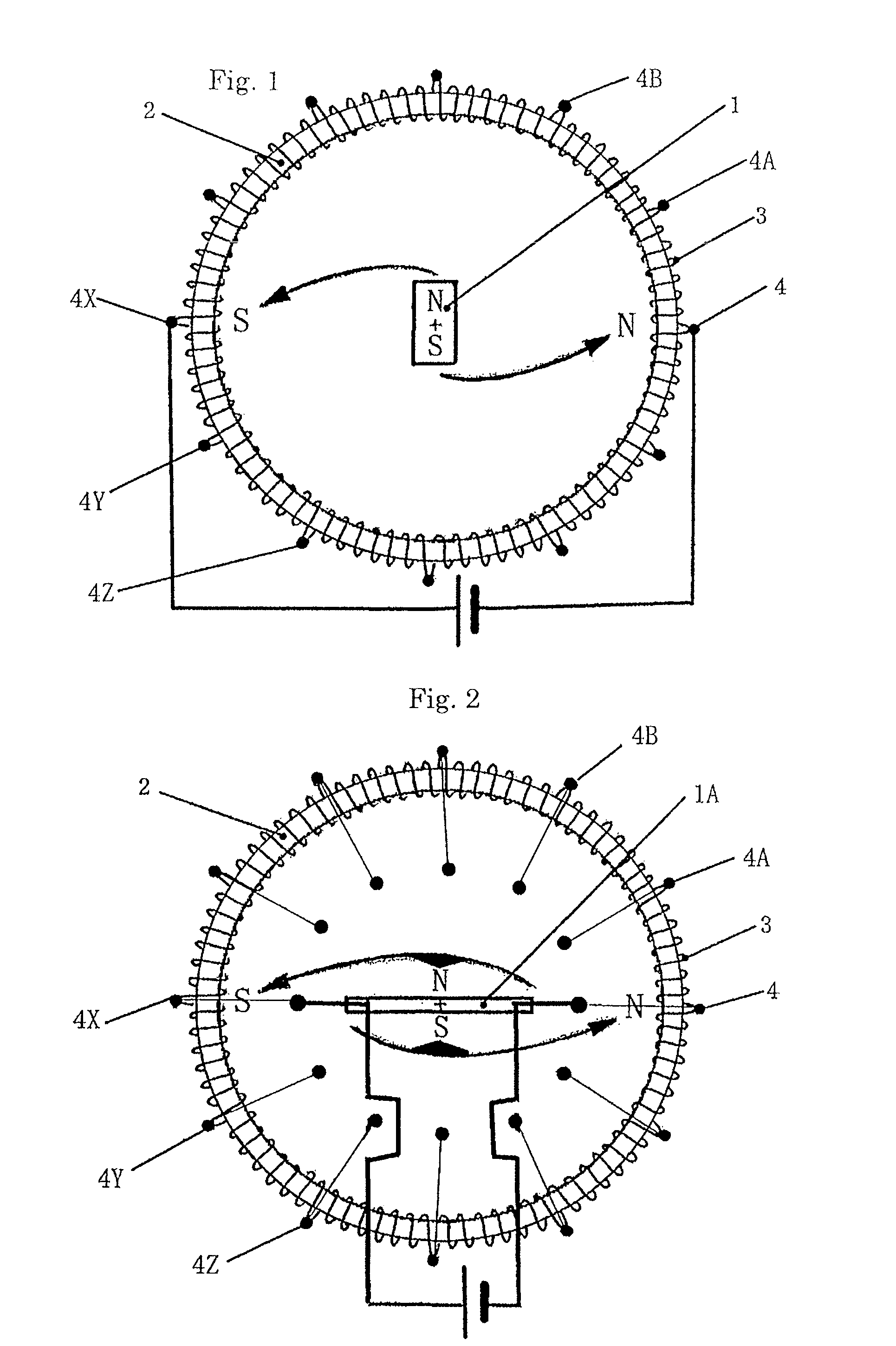

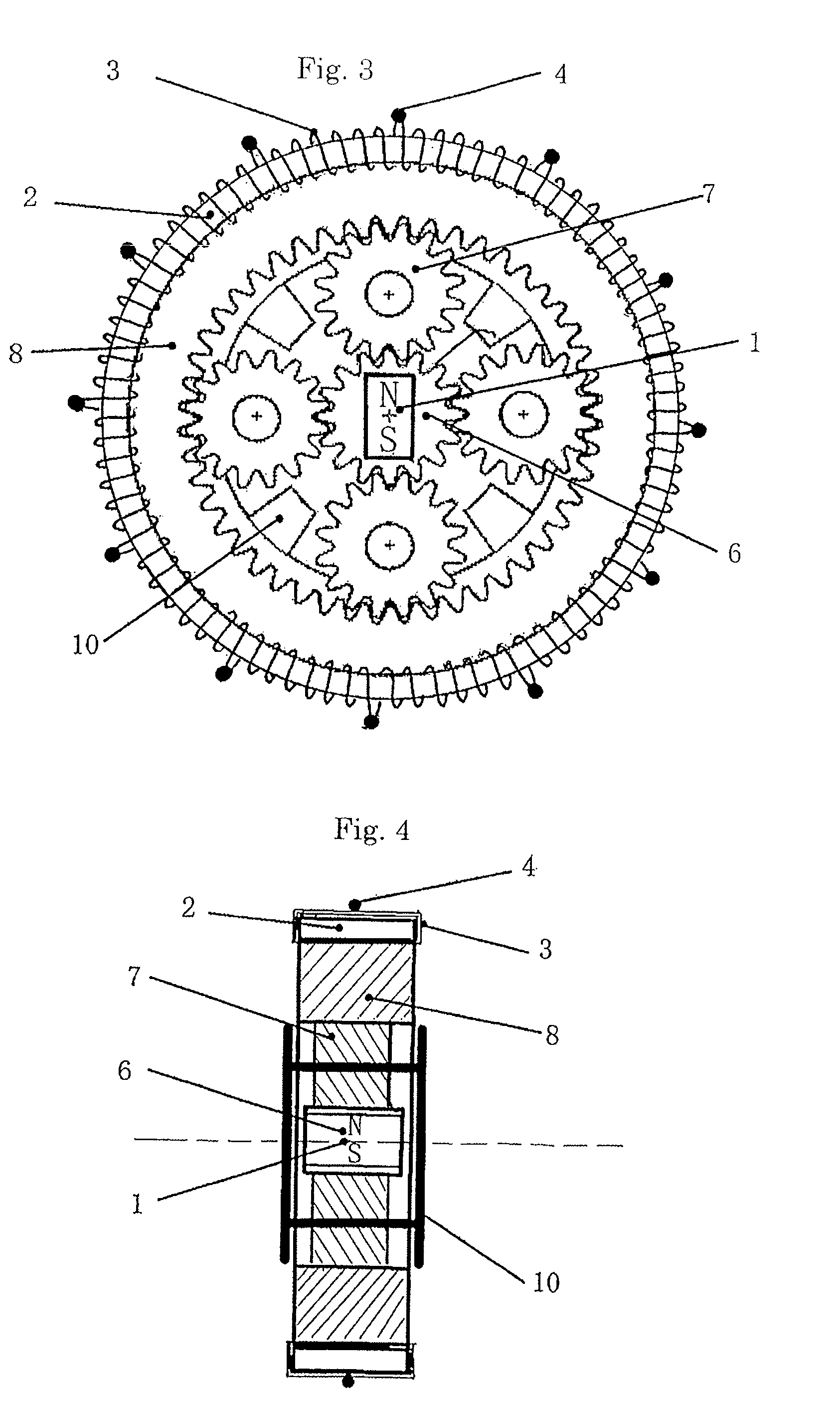

Planetary geared motor and dynamo

Owner:VENERA LAB CO LTD

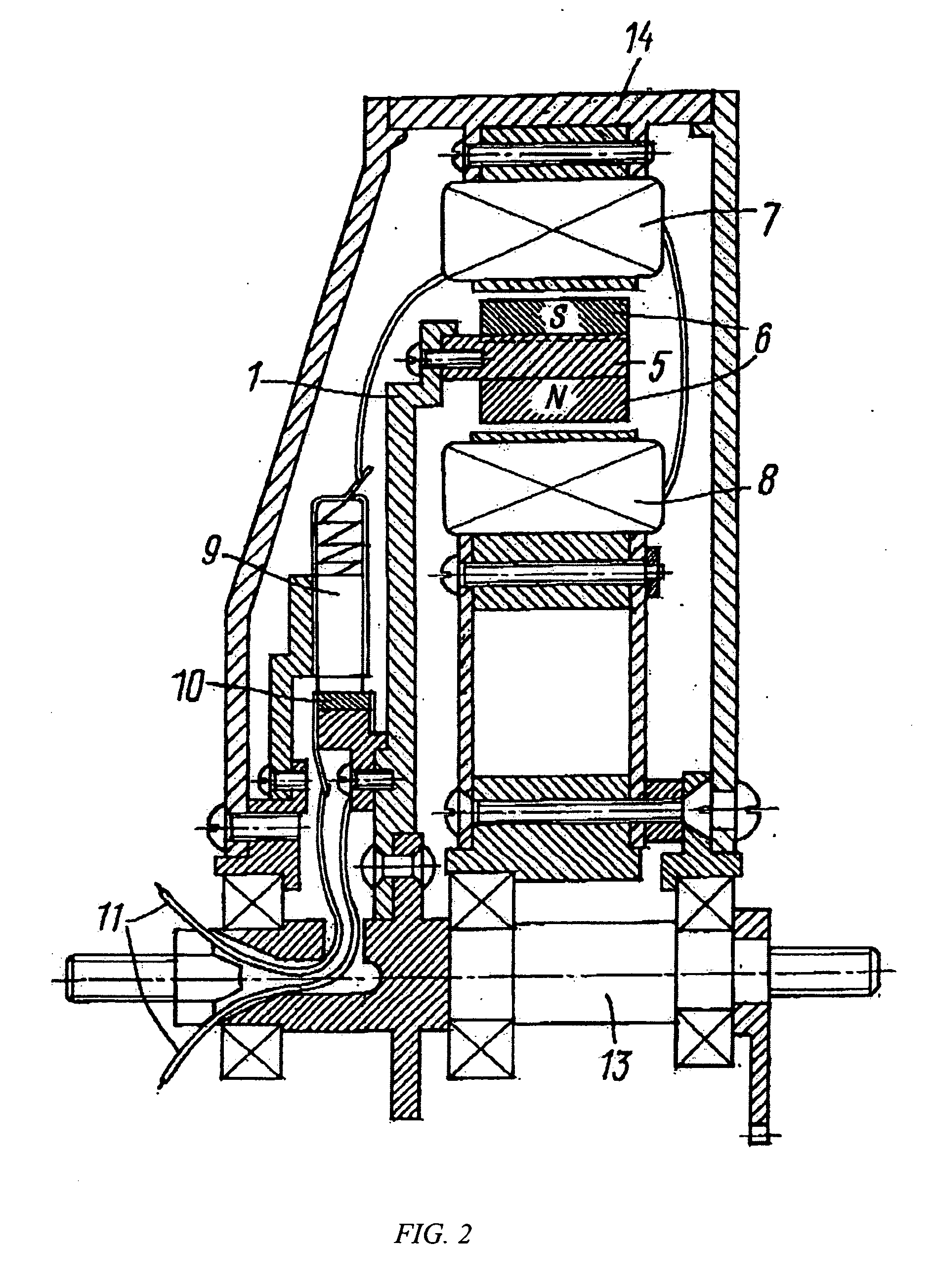

Electric motor

InactiveUS6975054B2Improve featuresIncrease torqueSynchronous generatorsRotary current collectorHigh torqueControl theory

An electric motor includes a stator which carries permanent magnets, and a rotor which carries electromagnets. A particular arrangement of connecting up the windings of the electromagnets to the distributing collector and the selection of the ratio of stator magnets to rotor electromagnets enable higher torque to be achieved. The main field of application is in motor-wheels of vehicles.

Owner:ULTRA MOTOR CO LTD

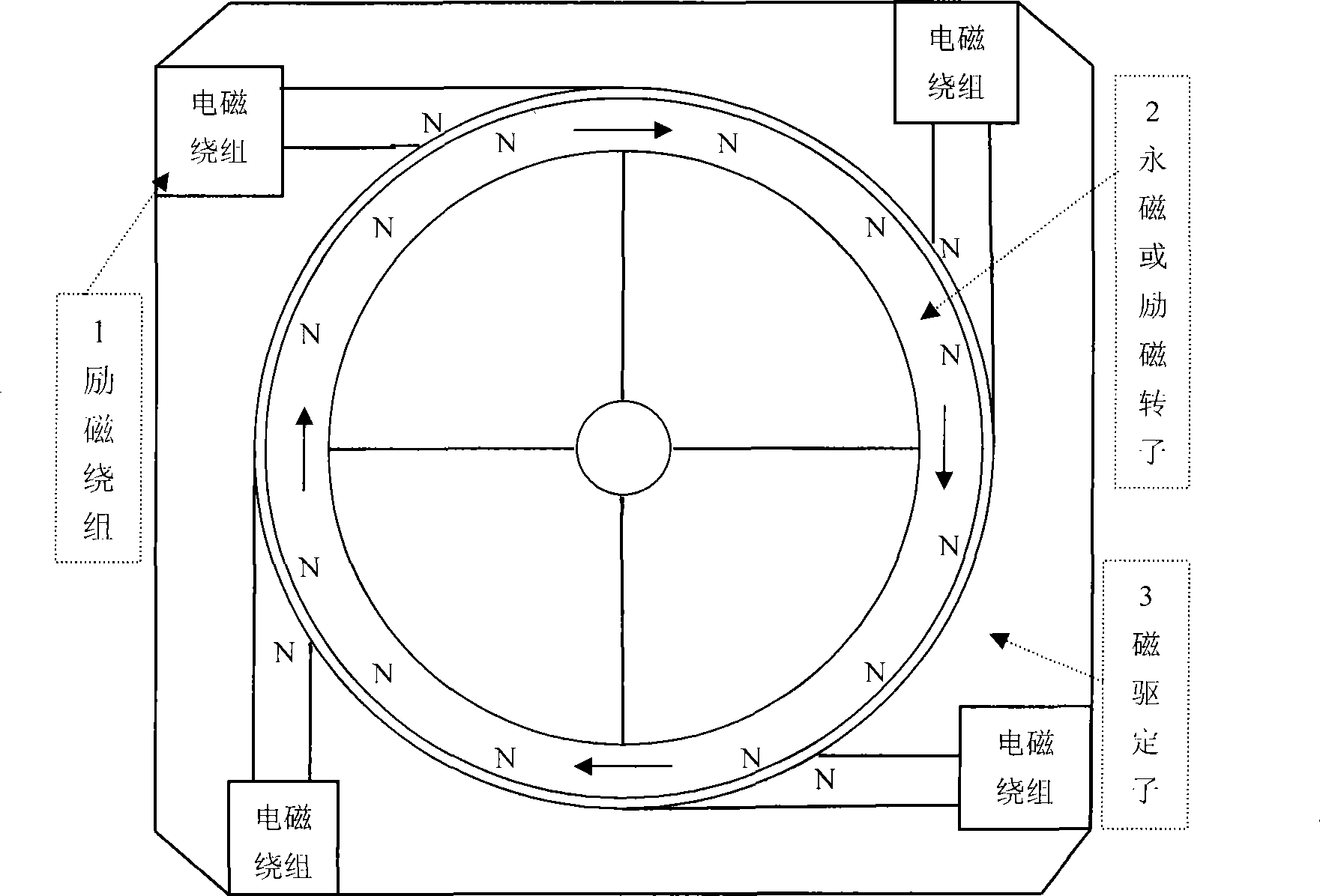

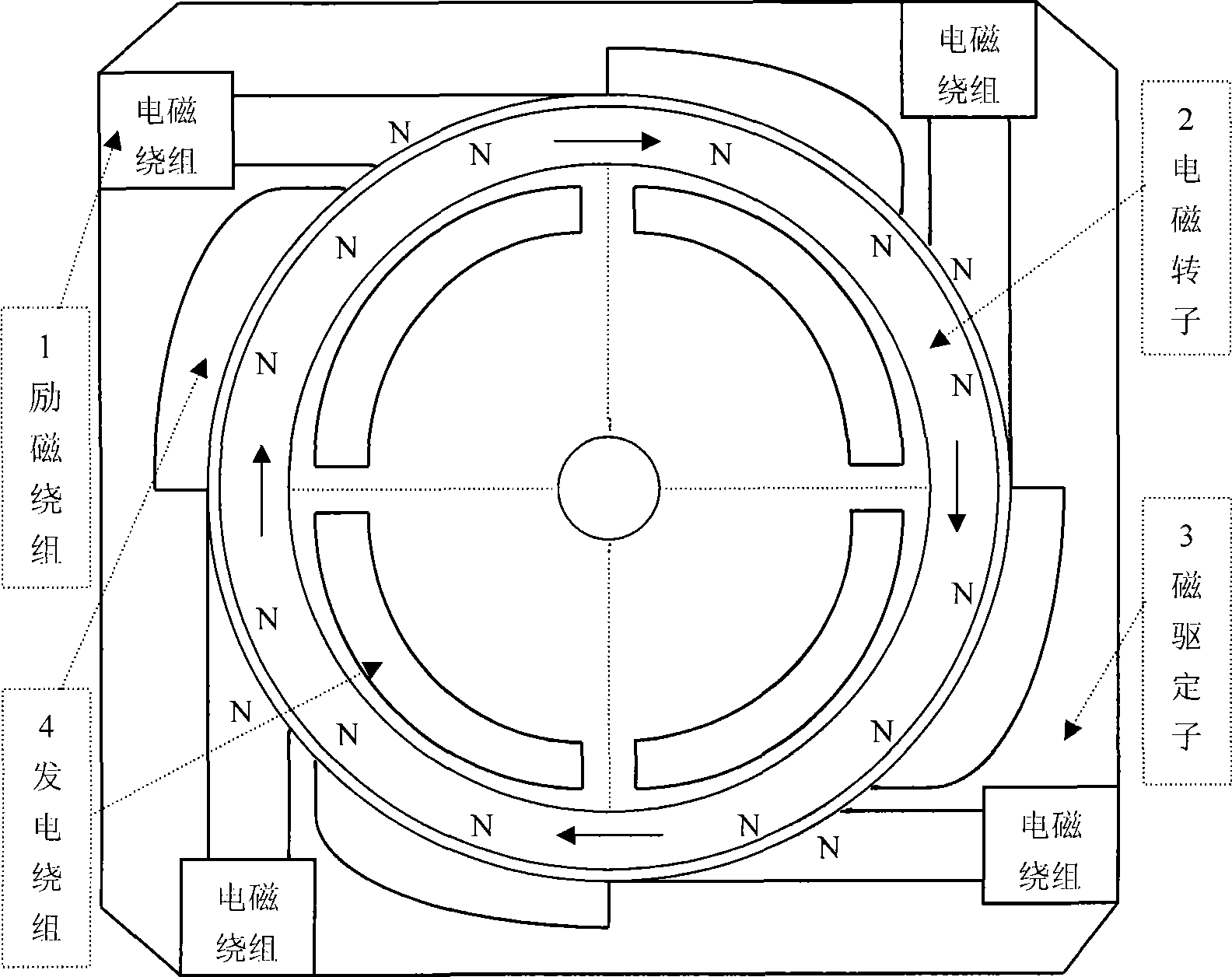

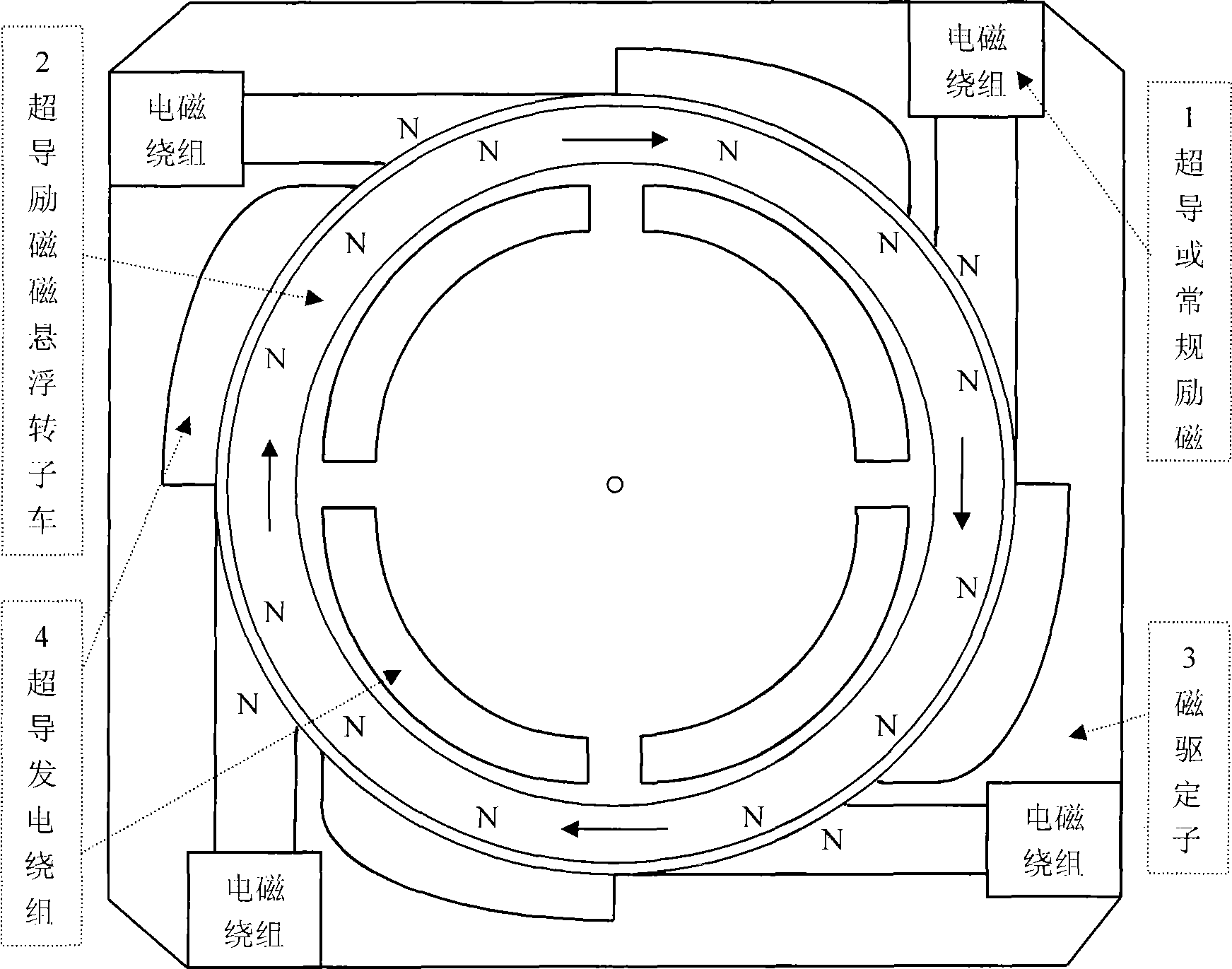

Mechanical energy electromagnetic power system and design method of related application technique

InactiveCN101483373AImprove work efficiencyReduce resistanceMechanical energy handlingElectric propulsionEnvironmental resistanceMechanical energy

The present invention discloses a mechanical energy electro-magnetism dynamic system and relevant application technique design method, which relates to motive power machine technology of energy sources and transportation field; takes electromagnetic force as dynamic force using principle of magnetic pole same repulse and designed mechanical energy electro-magnetism dynamic system special electric motor according to mechanical energy dynamic system principle; a rotor wheel shaft type cog free wheel permanent magnetism or direct current excitation field; a external stator electro-magnetism dynamic force application device; do work by applying force on multi points utilizing tangent point of wheel shaft rotor on outer edge of the wheel; startup by external electric energy or self-feed electrical source, mechanical energy electro-magnetism dynamic system do work and is straightly converted into electric energy to realize repeatable circle work of mechanical energy electro-magnetism dynamic system. The system relevant application technique is suitable for high-performance mechanical energy electro-magnetism dynamic force integration system, overcomes two problems of energy sources and environmental protection facing by human beings, realizes exploitation applications of future ideal energy sources.

Owner:戚成吉

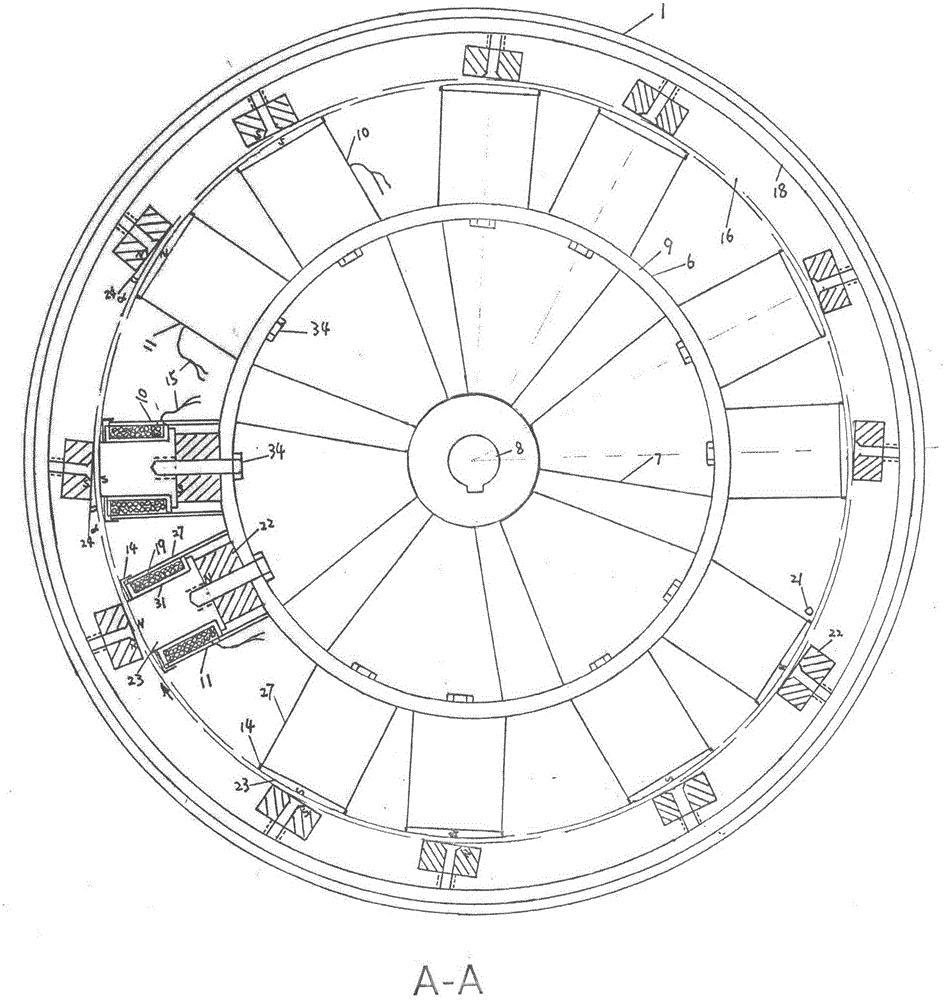

Pulsed-inertial electric motor

InactiveUS20060232154A1Improved performance characteristicsSimple designWindingsMagnetic circuitLow voltageDc current

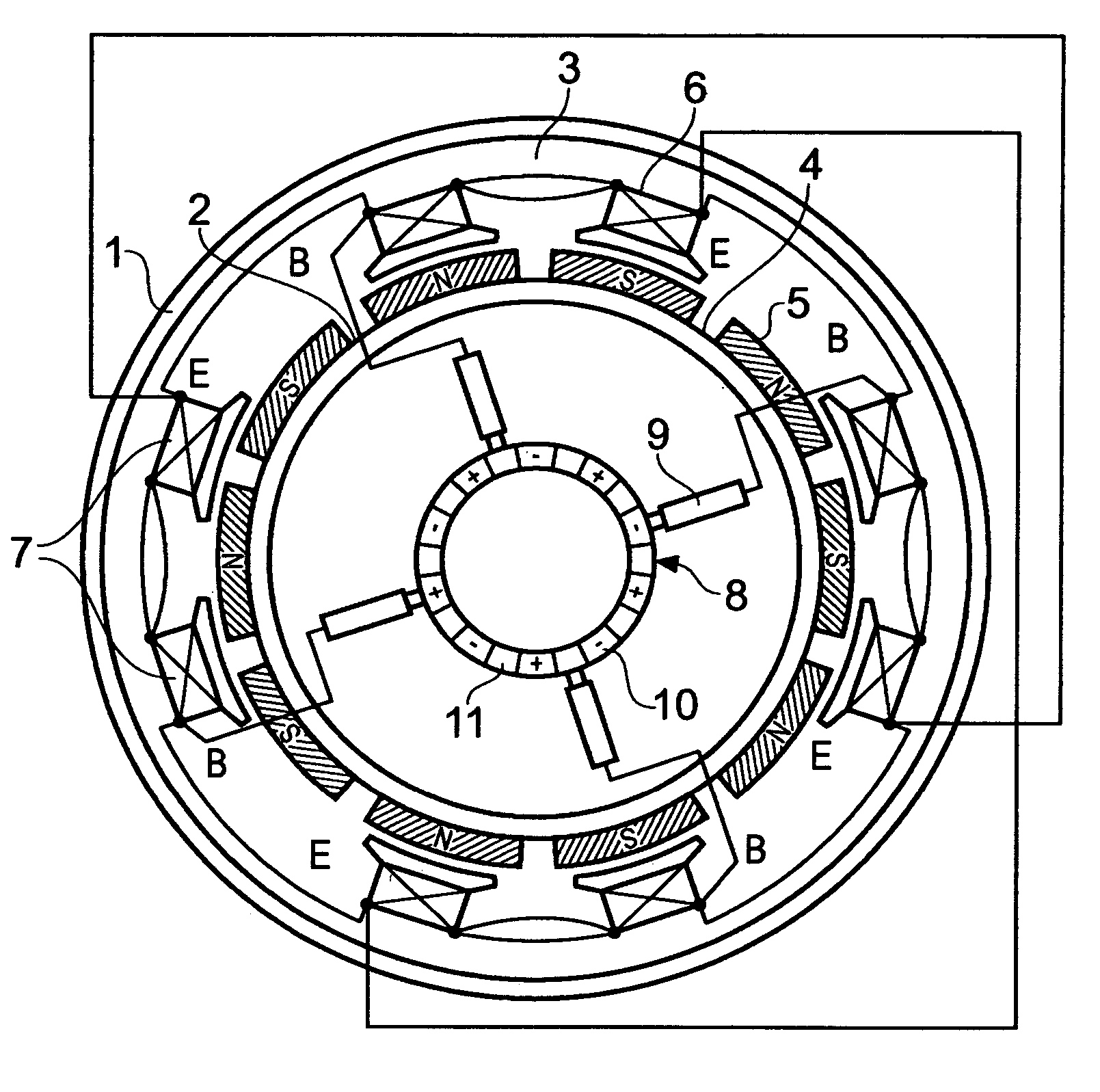

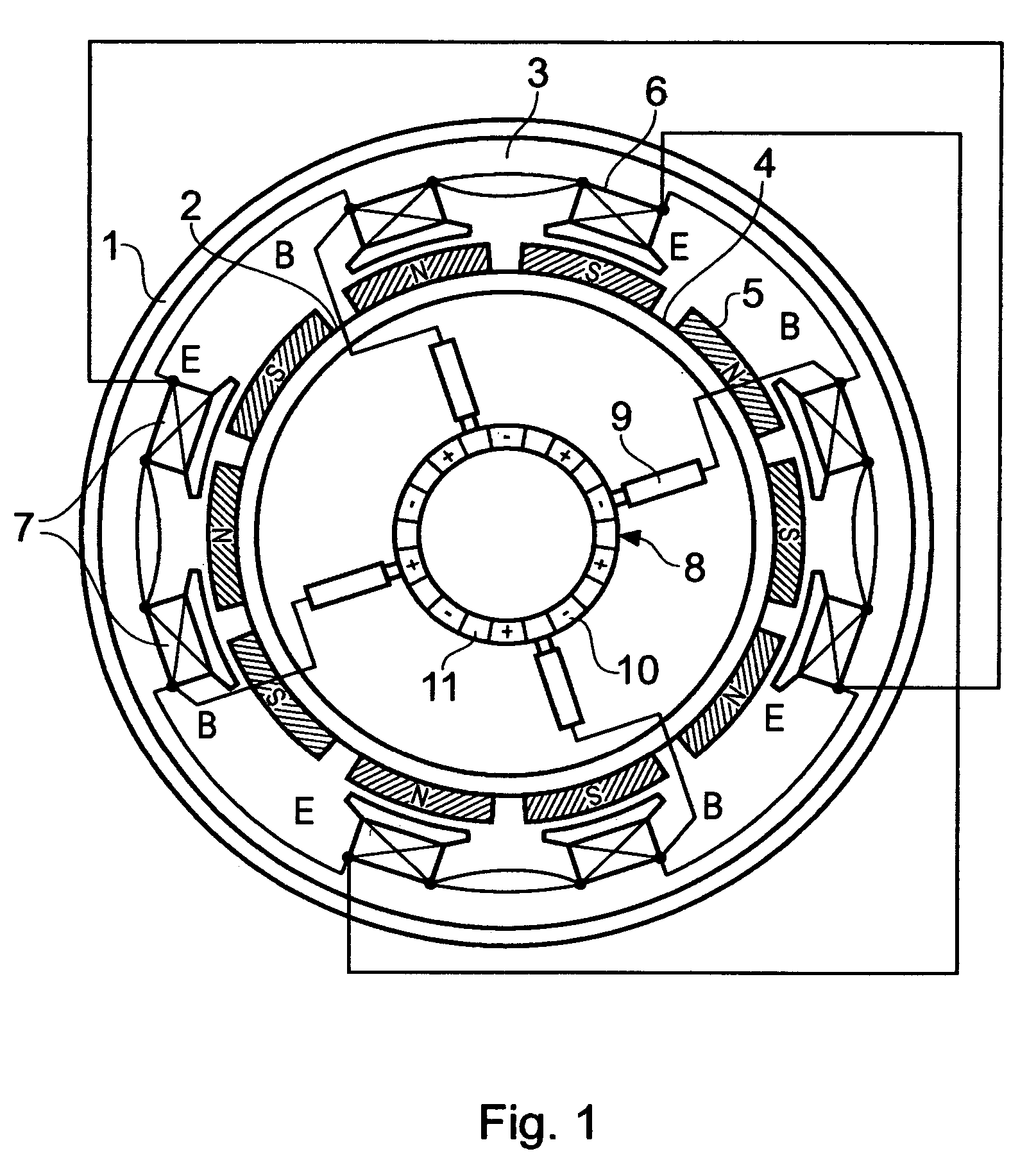

The invention relates to electric motors, particularly to low-voltage gearless commutator motors, and can be used as motor-wheels in transportation vehicles and in other technologies. The aim of the present invention is to provide an electric motor with increased performance characteristics, relatively simple design, and high reliability. A pulsed inertial electric motor according to the invention comprises: (i) a stator with circular magnetic conductor on which an even number of permanent magnets are uniformly arranged with a certain pitch; (ii) a rotor separated from the stator by air gap and bearing an even number of electromagnets, each electromagnet consisting of two coils with opposite winding directions connected in series, which are arranged over the circle in pairs one opposite to another; (iii) a collector distributor mounted on the stator body, containing circularly arranged current-conducting plates separated by insulating spacers and connected with alternating polarity to a dc current source, and (iv) current collectors-brushes mounted on the rotor and capable of contacting with plates of the collector distributor, whereby all brushes are connected to identical (beginning or end) terminals of the windings of said electromagnets and interconnected so that the coils in the opposite electromagnets are connected to each other via one identical terminal and to the opposite brushes via another identical terminal, with the number n of permanent magnets in the stator and the number m of electromagnets in the rotor selected so as to obey the relations n=10+4k, m=4+2l, where k is an arbitrary integer (k=0, 1, 2, . . . ) and l is any integer such that 0≦l≦k.

Owner:ULTRA MOTOR CO LTD

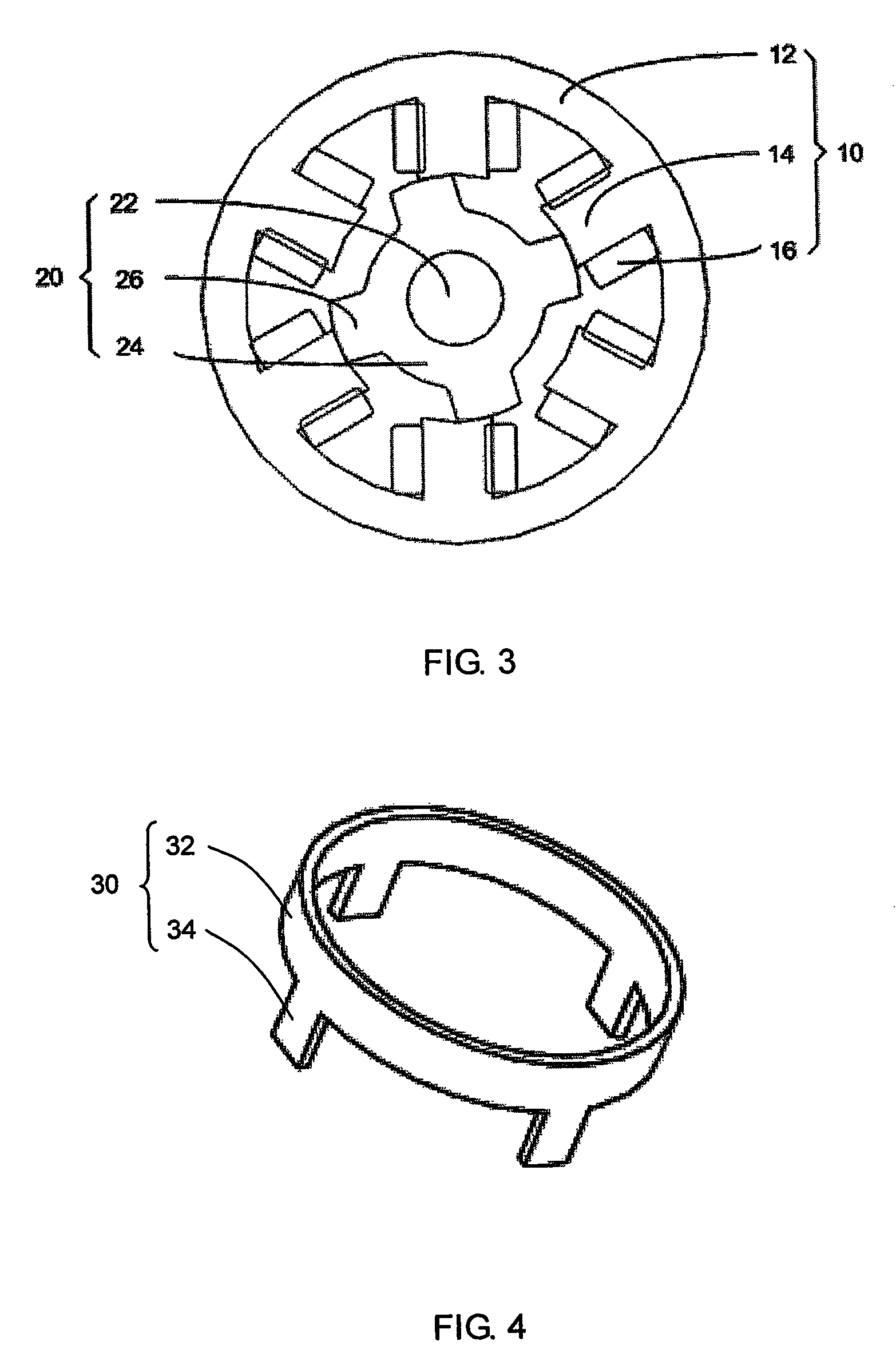

Electromagnetic circuit and servo mechanism for articulated cameras

InactiveUS7071591B2High-speed motion and accurate positioningReduce quality problemsMagnetic circuit rotating partsDC commutatorServomechanismMagnet

An electromagnetic circuit that may be advantageously employed in an articulated camera, such as a CCTV camera, as a part of a servo mechanism to directly drive the camera and optical lens assembly, for example, in the pan and / or tilt axes. In one embodiment, the coil assembly of the servo mechanism may comprise four separate coils that rotate about the center of the ring shape of a single one-piece ring-shaped permanent magnet that has been pre-magnetized in two pair of opposing polarities. The magnet assembly that includes the magnet ring, may be bonded to a circular plate made of ferrous metal.

Owner:GE SECURITY INC

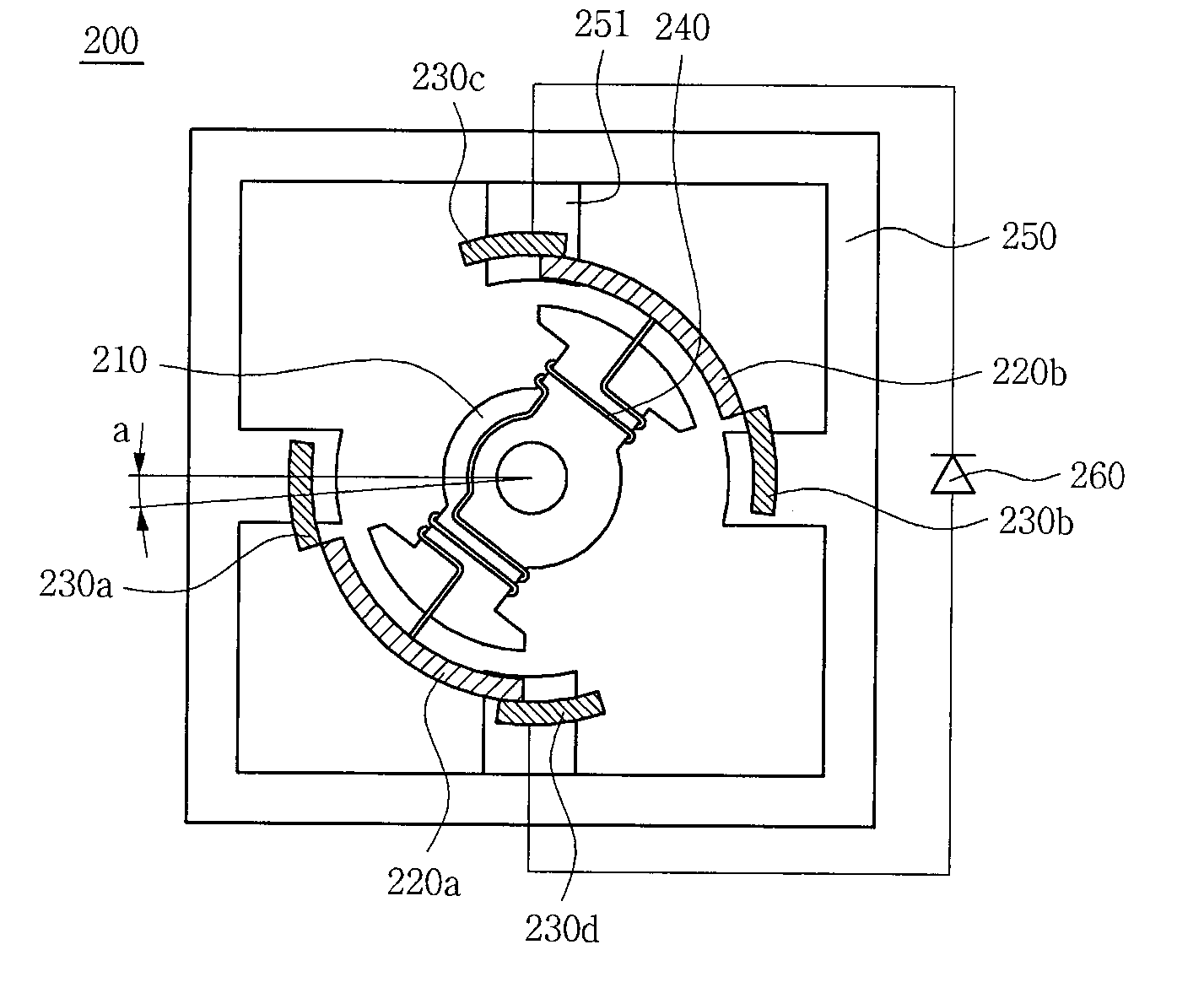

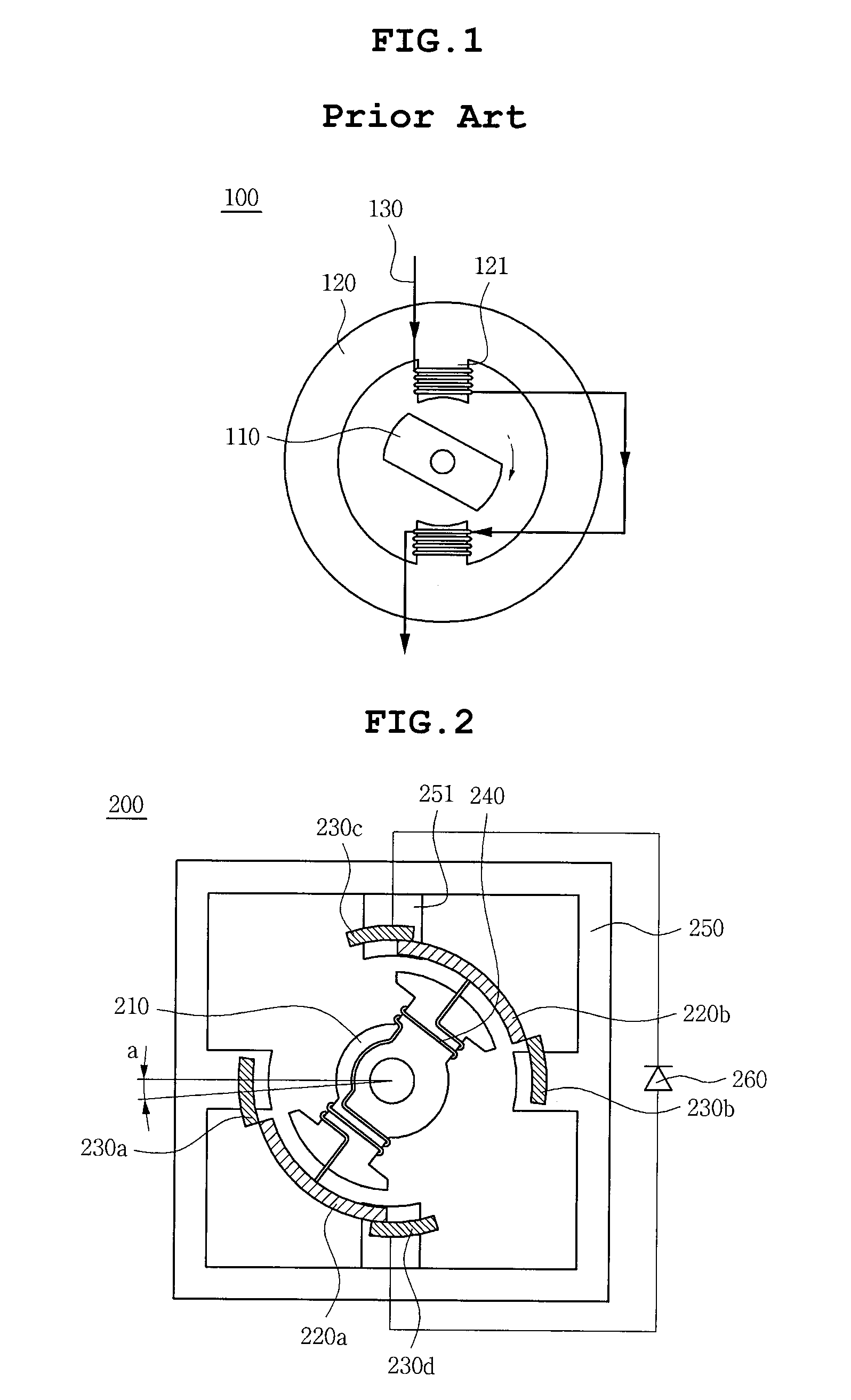

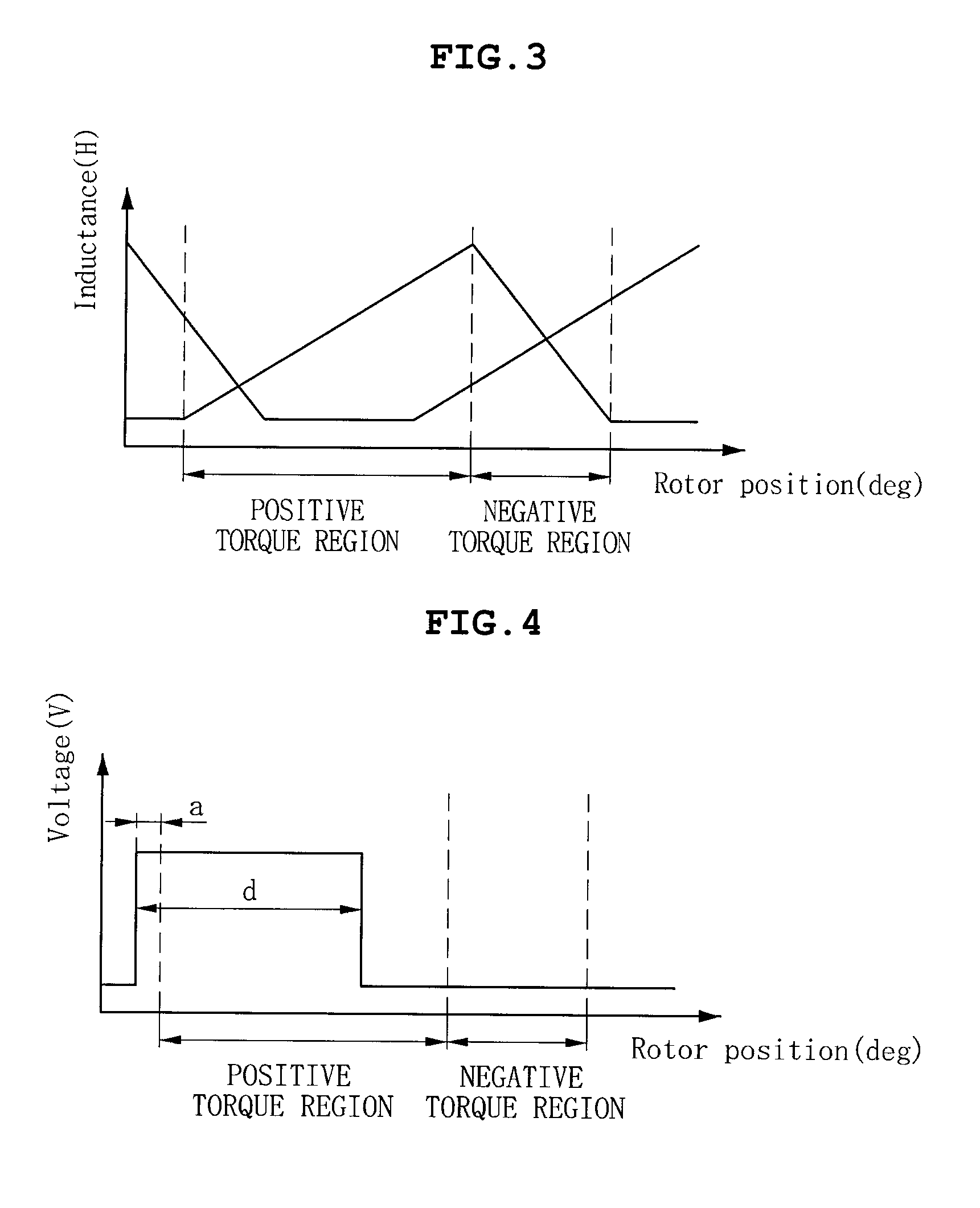

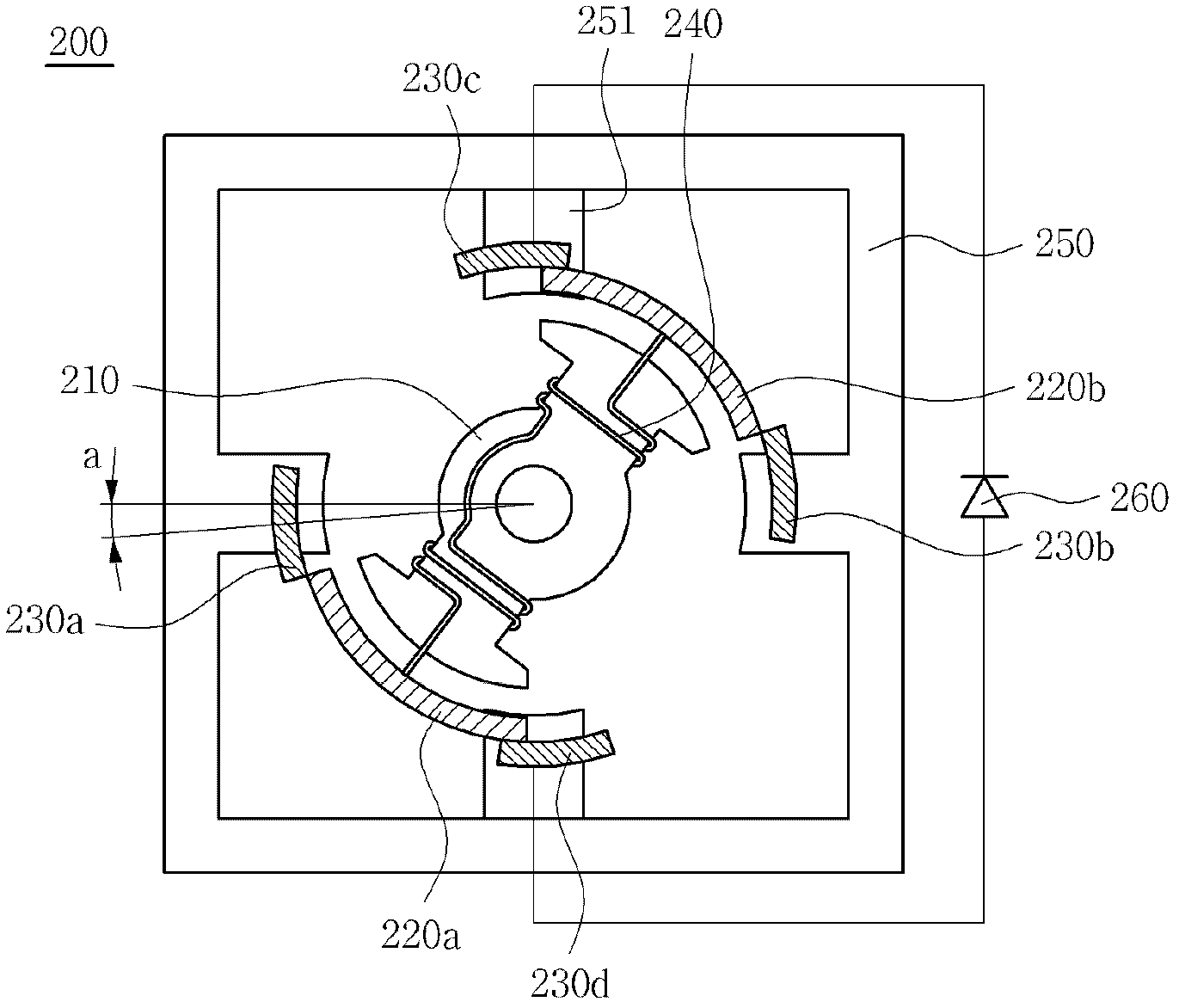

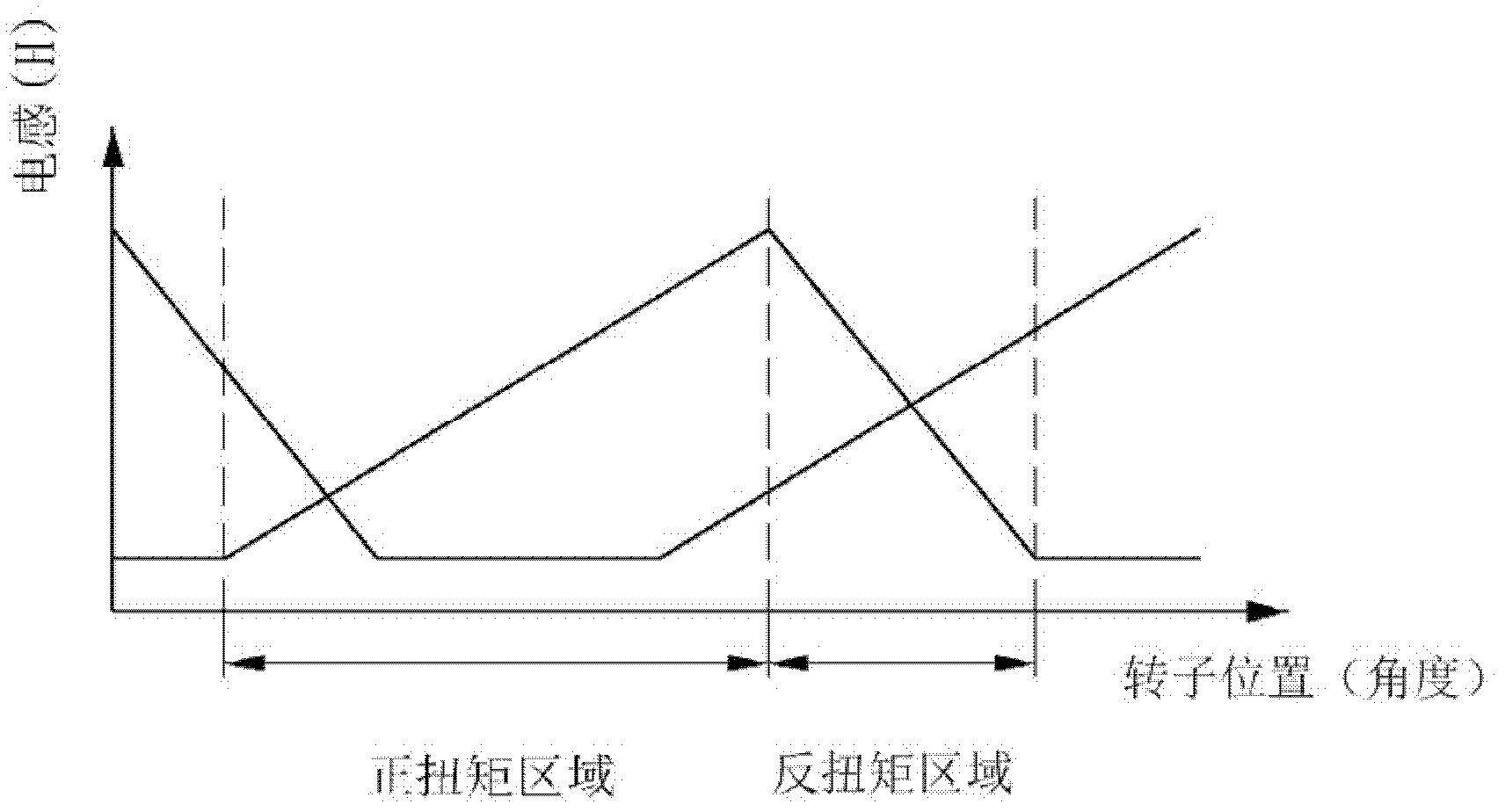

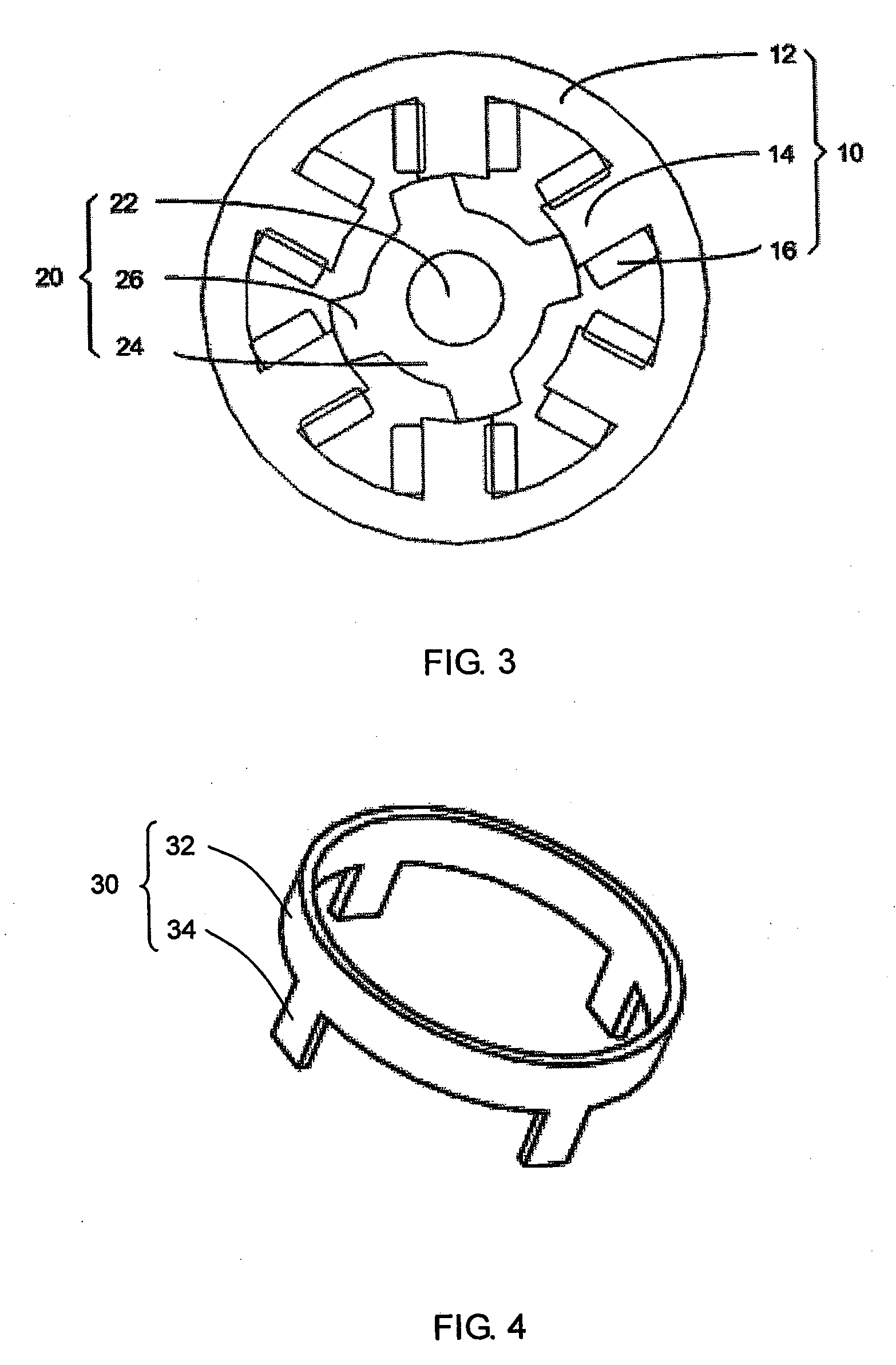

Switched reluctance motor

InactiveUS20120175997A1Improve performanceLow production costRotary current collectorCleaning using toolsStator polesVoltage

Disclosed herein is a switched reluctance motor including a rotor having a coil wound therearound; commutators connected to both ends of the rotor; brushes mechanically contacting the commutators by rotation of the rotor; and a stator having the brushes fixed thereto and having stator poles, wherein the brushes are moved by an advance angle from a connection axis of stator poles counterclockwise, and a dwell angle, a voltage application period is controlled by arc angles of the commutator and the brush.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

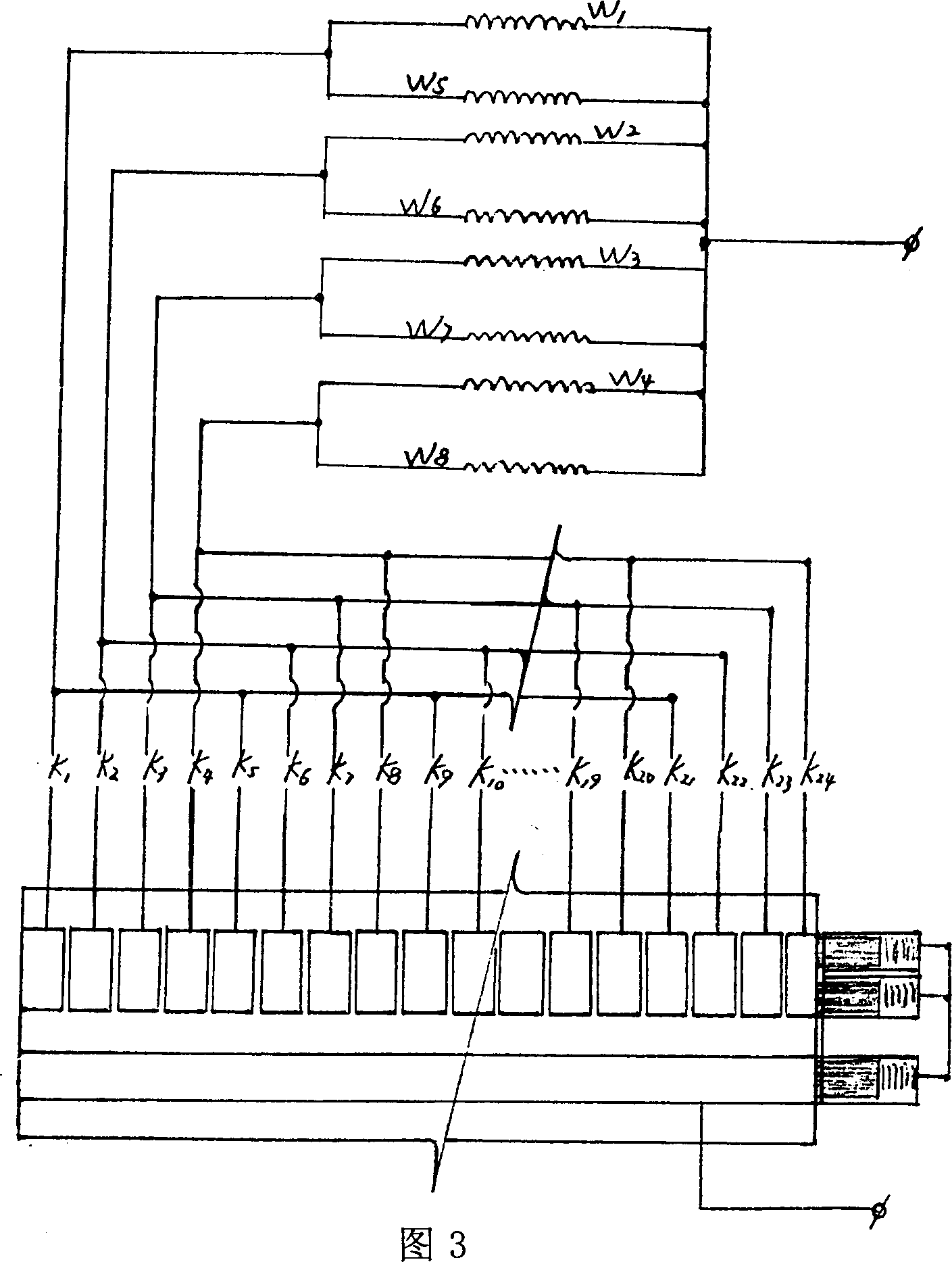

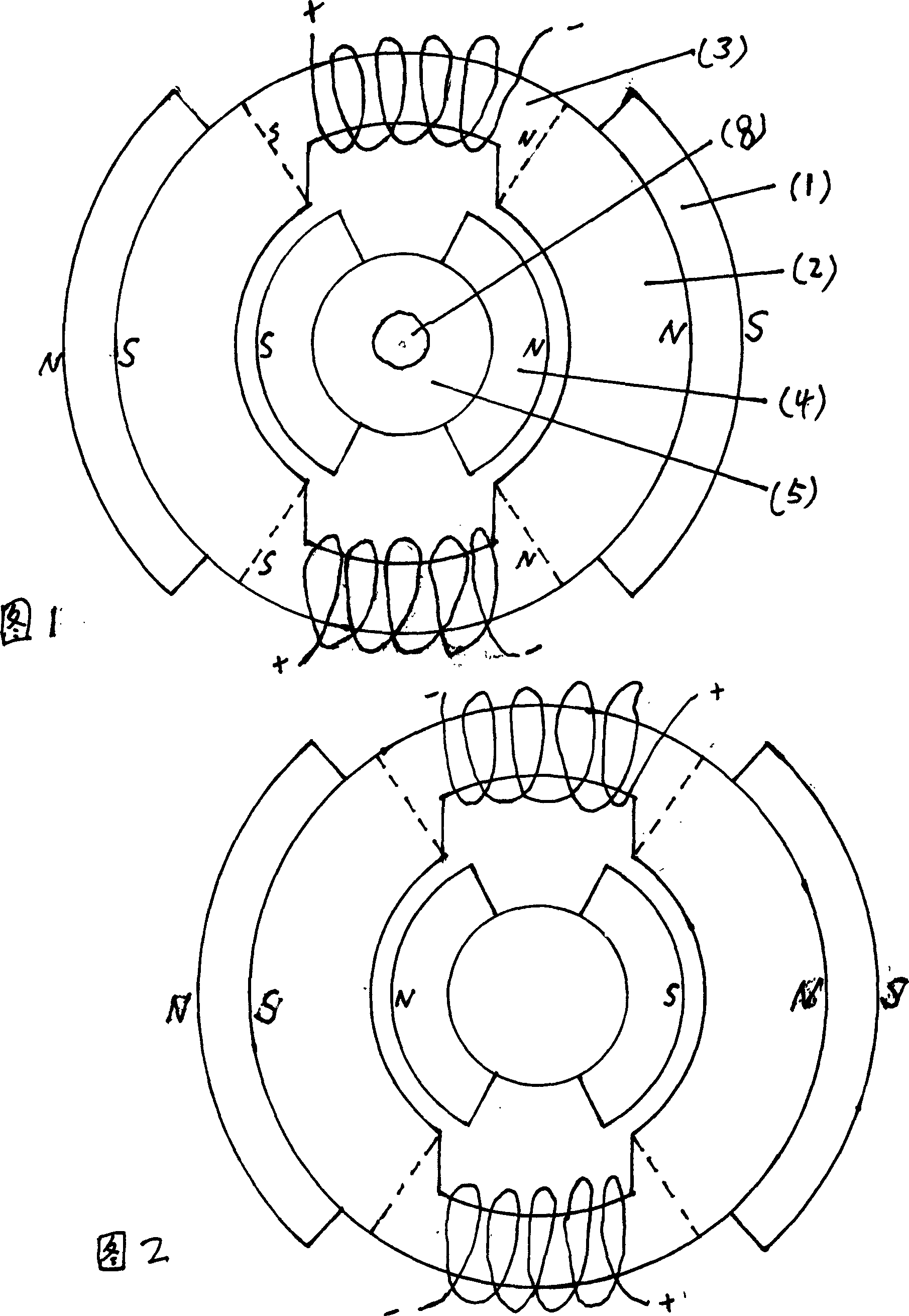

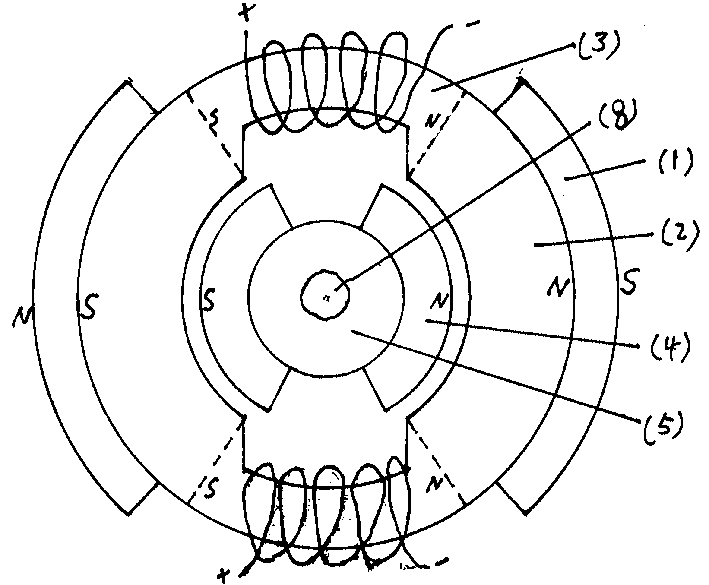

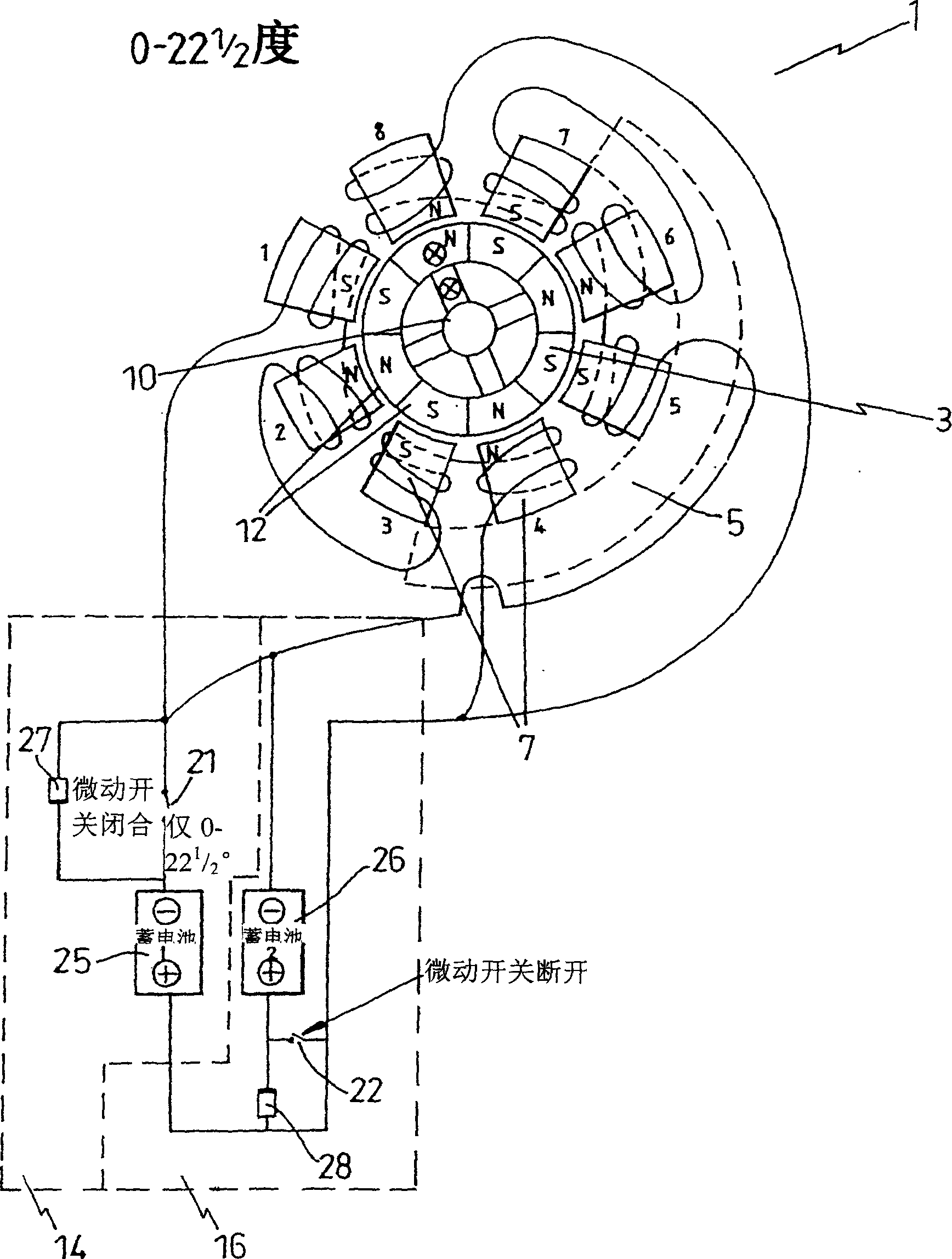

DC exciting magnetic motor

InactiveCN1449095ASimple structureEasy to controlDC commutatorDC interruptersElectric machineElectrical polarity

The DC exciting magnetic motor has rotor on the rotating shaft and with several sets of rotor magnetic poles in the same polarity, and stator connected to the seat and with several sets of stator magnetic poles in the same polarity. At least one kind of the stator magnetic poles and the rotor magnetic poles is exciting magnetic poles operating under the control of the control mechanism comprising electric brush, metal slip ring, synchronous switching metal piece. The central line of the rotor magnetic pole cross section and that of the stator magnetic pole cross section are in an angle of 0-45 deg, and in any time,, only one set of exciting magnetic poles inside the angle excites. The pair number of the stator magnetic poles is greater than that of the rotor magnetic poles, and the motor may change its rotation direction via altering the polarity of the power supply. The present invention has no commutator, simple structure, high efficiency, great torque and other features.

Owner:何明雄

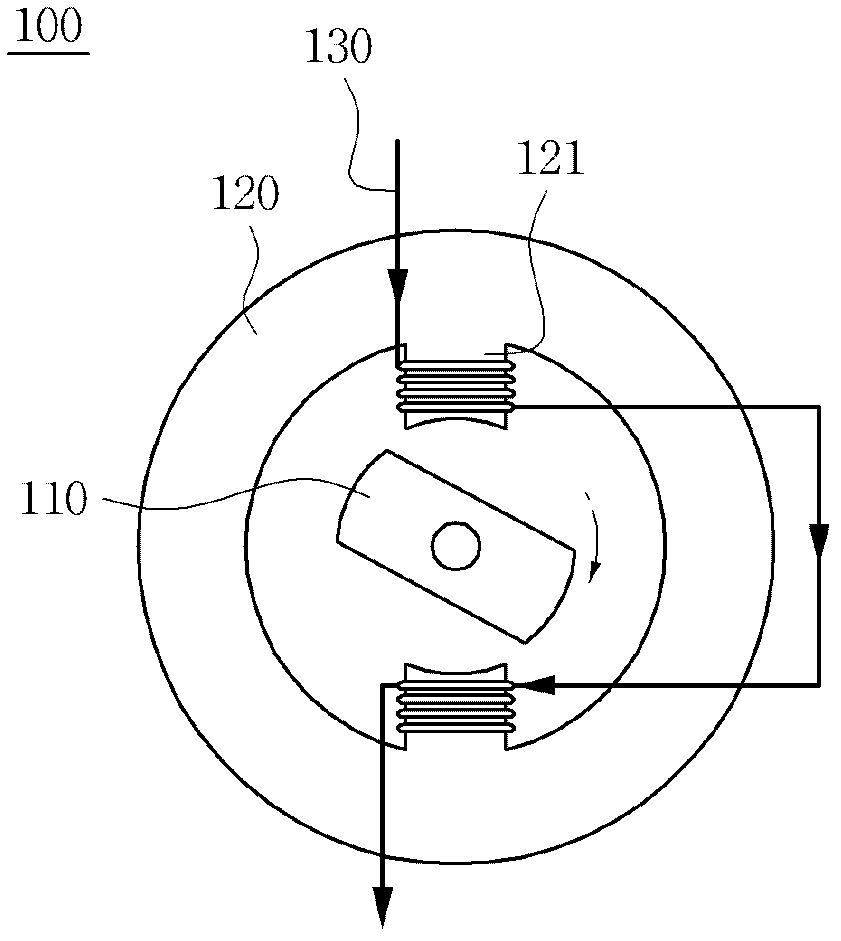

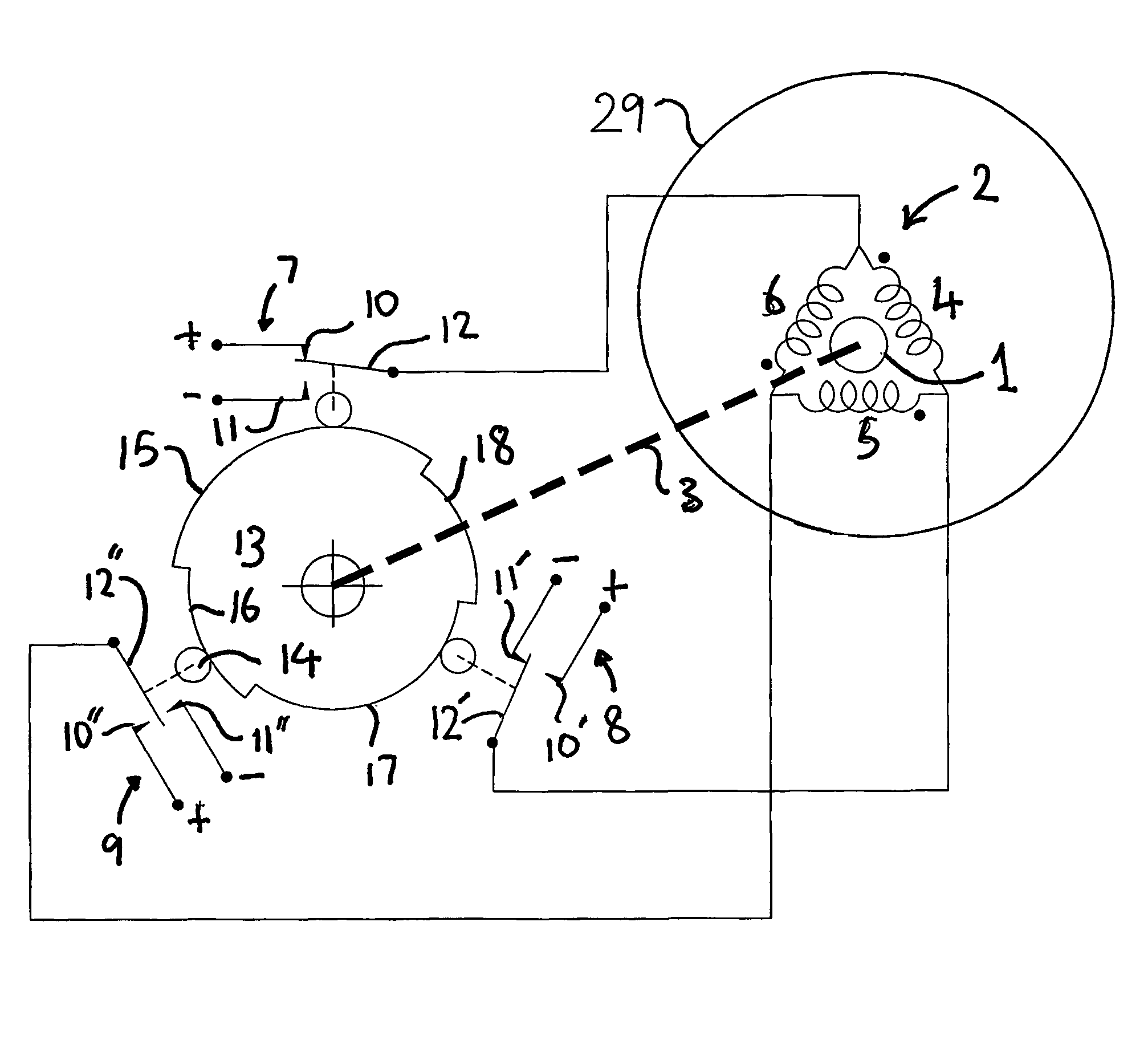

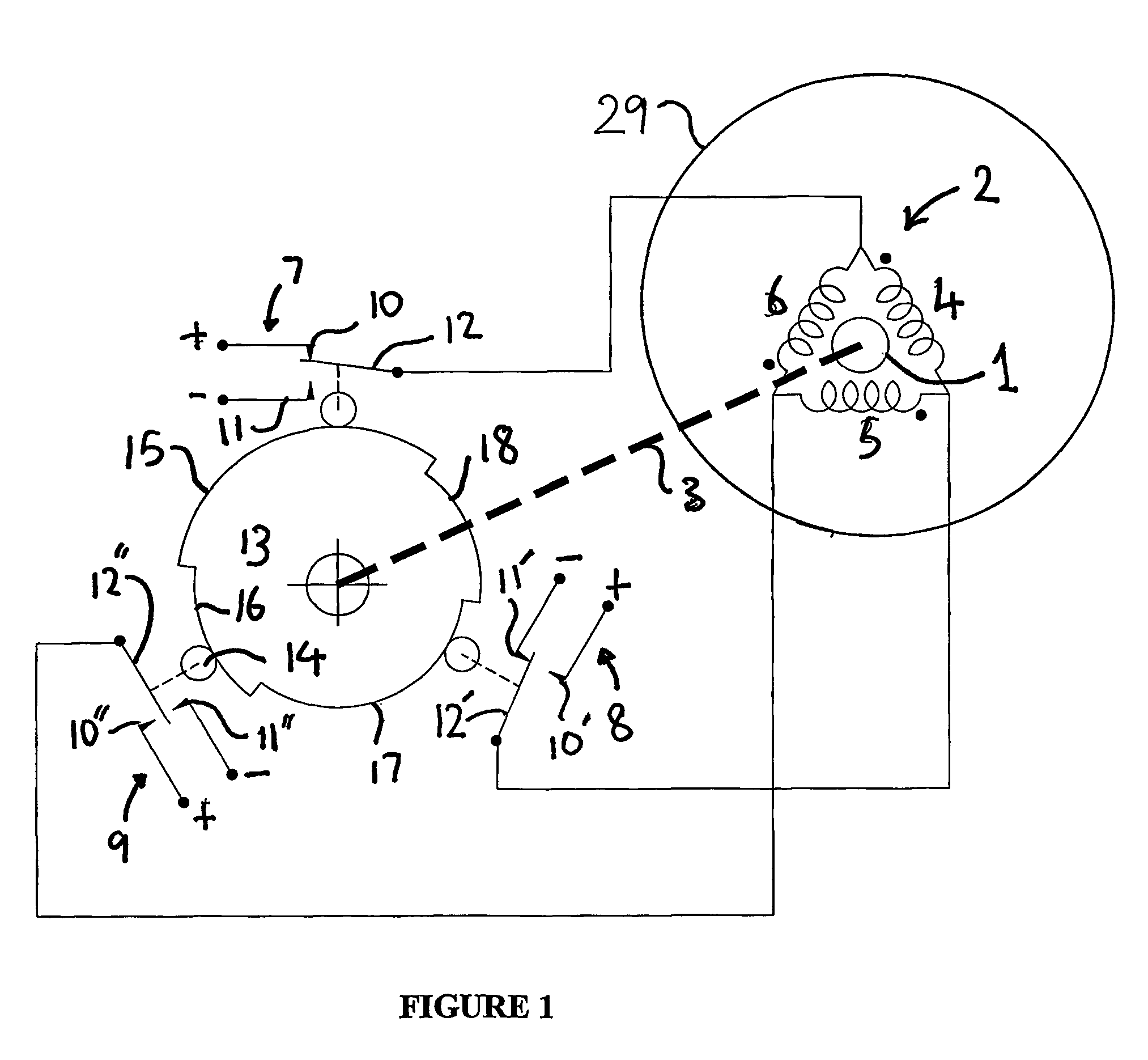

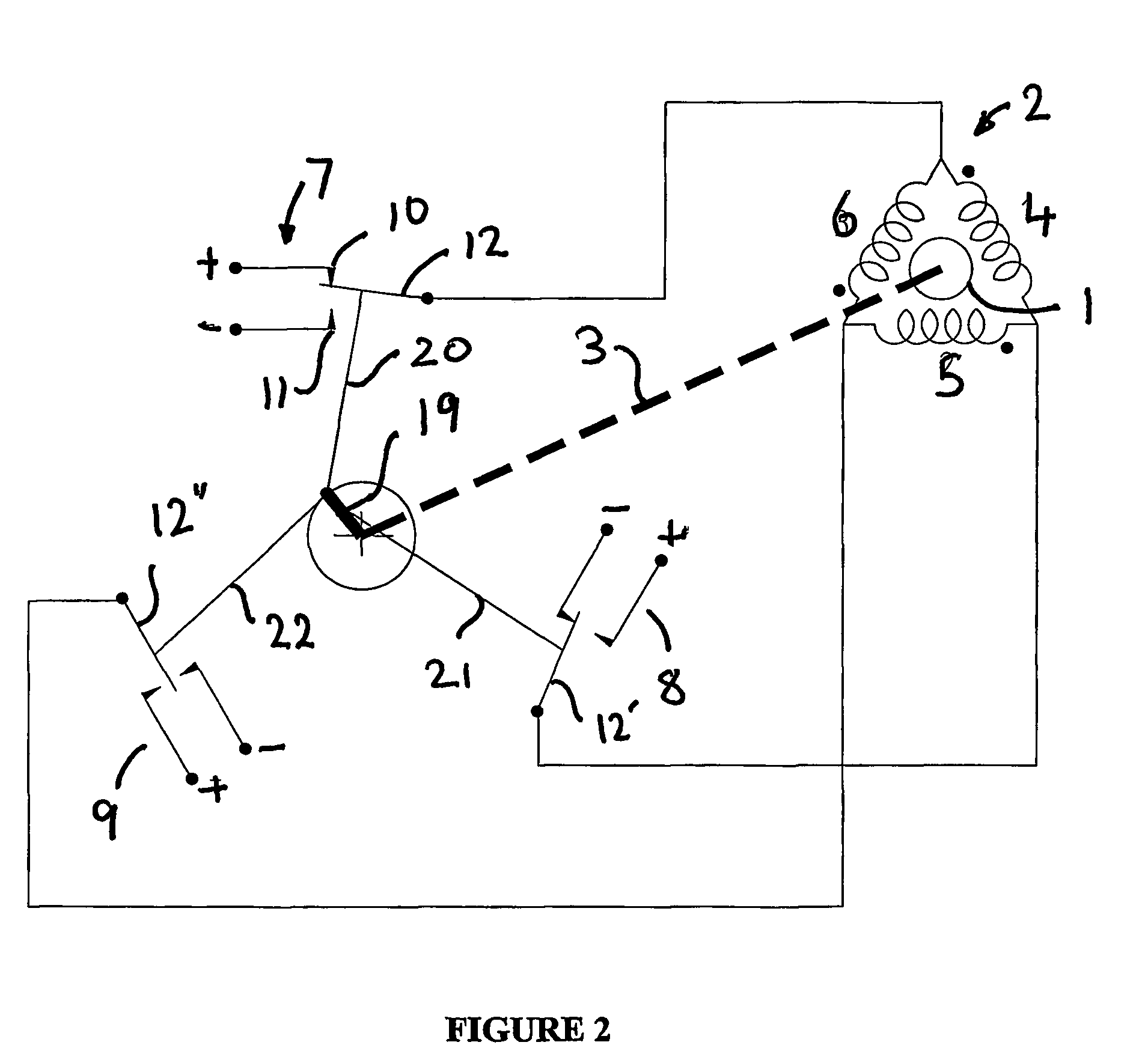

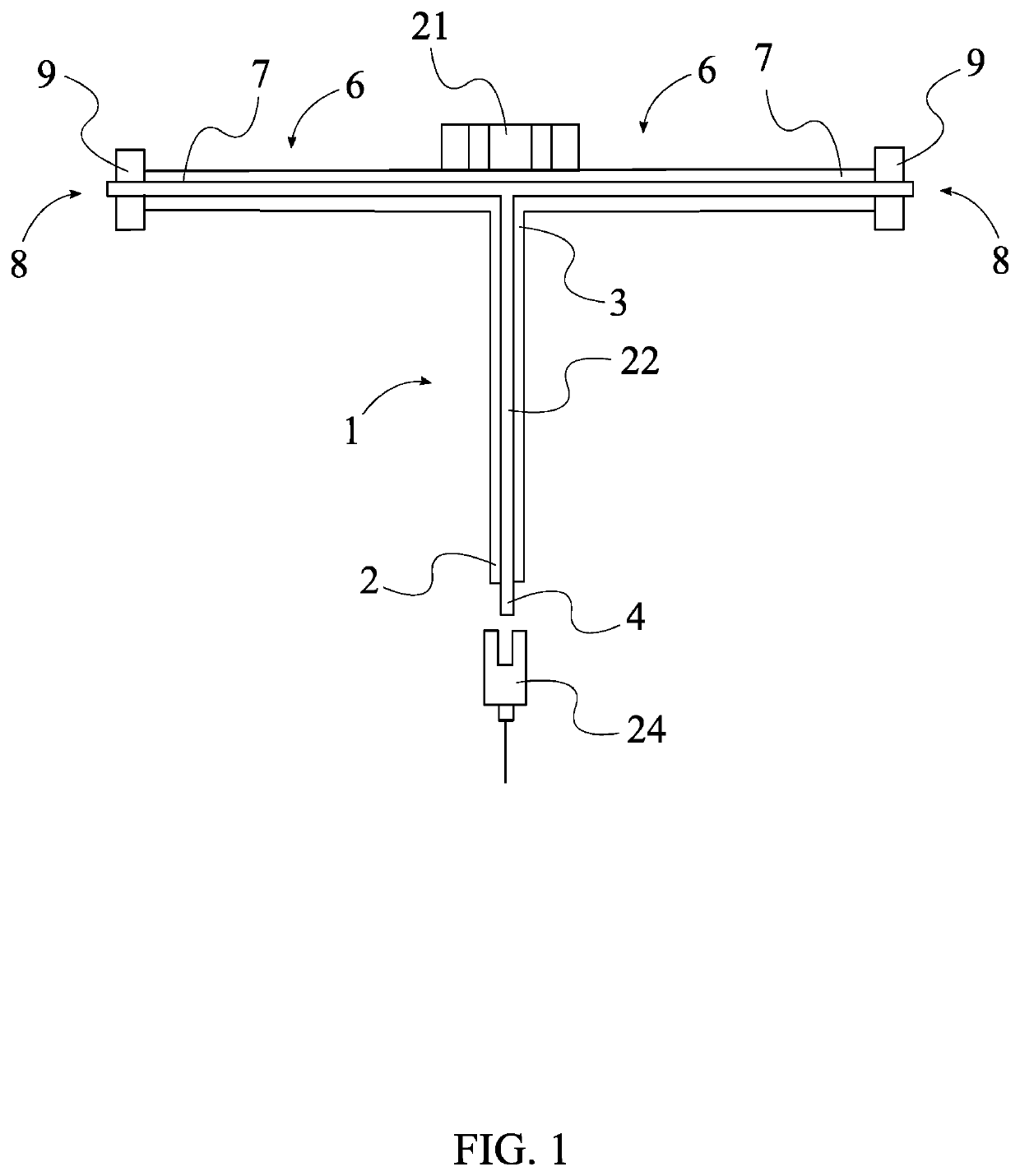

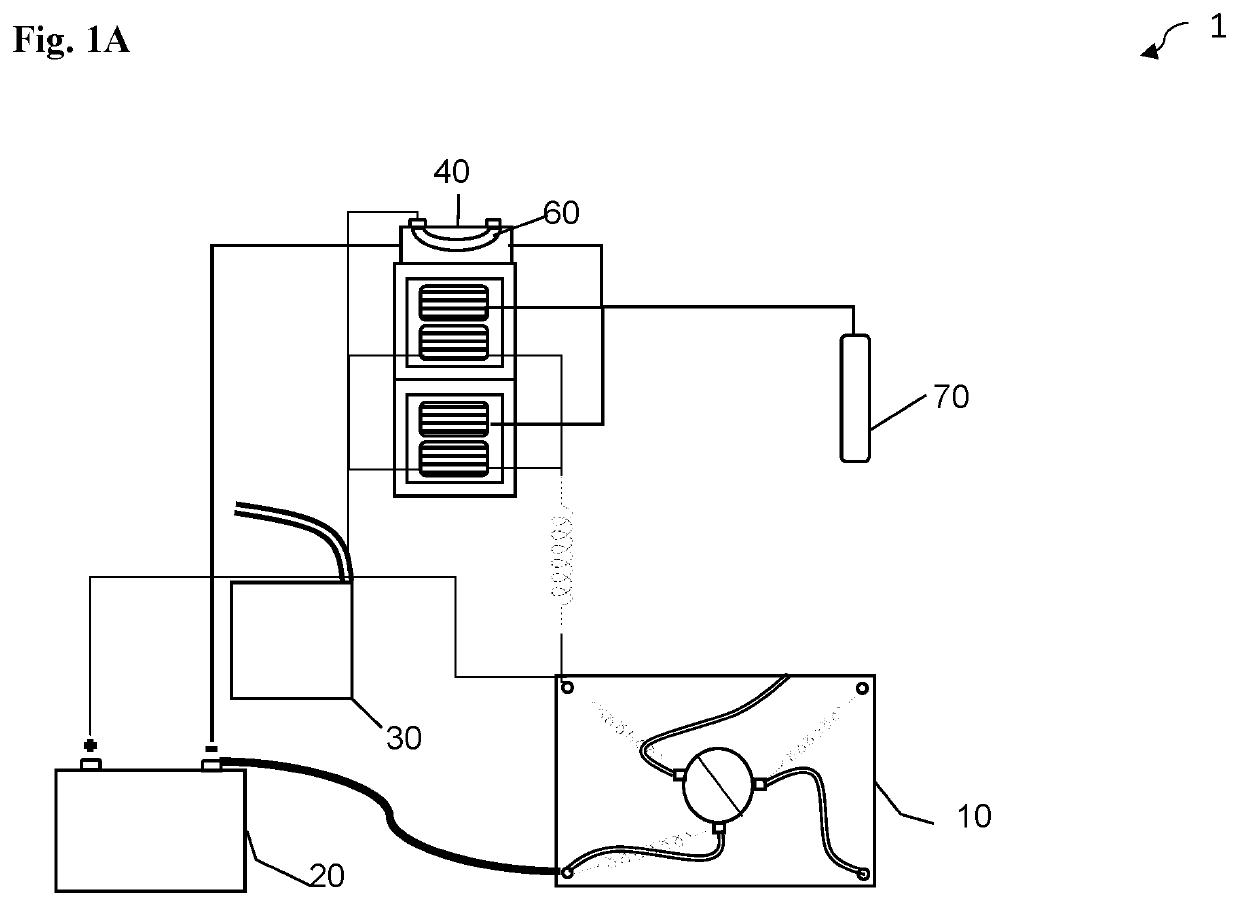

Magnetic kinetic propulsion motor apparatus and method

InactiveUS9997979B1Association with control/drive circuitsEfficient propulsion technologiesElectrical batteryEngineering

A magnetic kinetic propulsion motor apparatus and method includes a shaft with a first two ended rotational blade attached at a midpoint of the two ended rotational blade to the shaft. A proximity magnetic sensor is connected at both ends of the two ended rotational blade. A stationary housing surrounds the shaft and the first two ended rotational blade. Several self-aligning repulsion electro-magnets are connected to the stationary housing and a proximity switch is connected with each of the self-aligning repulsion electro-magnets. An electronic ignition distributor is connected to each proximity switch connected with the self-aligning repulsion electro-magnets and a battery is connected to the electronic ignition distributor. A generator is connected to the shaft, the electronic ignition distributor and the battery where in response to the proximity magnetic sensor on the ends of the first two ended rotational blade detecting a proximity switch connected with a self-aligning repulsion electro-magnet the electronic ignition distributer sends power to the self-aligning repulsion electro-magnet which generates repulsive magnetic force on the proximity magnetic sensor at the ends of the first two ended rotational blade.

Owner:GARRISON ROY LEE +1

Switched Reluctance Motor

Disclosed herein is a switched reluctance motor including a rotor having a coil wound therearound; commutators connected to both ends of the rotor; brushes mechanically contacting the commutators by rotation of the rotor; and a stator having the brushes fixed thereto and having stator poles, wherein the brushes are moved by an advance angle from a connection axis of stator poles counterclockwise, and a dwell angle, a voltage application period is controlled by arc angles of the commutator and the brush.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

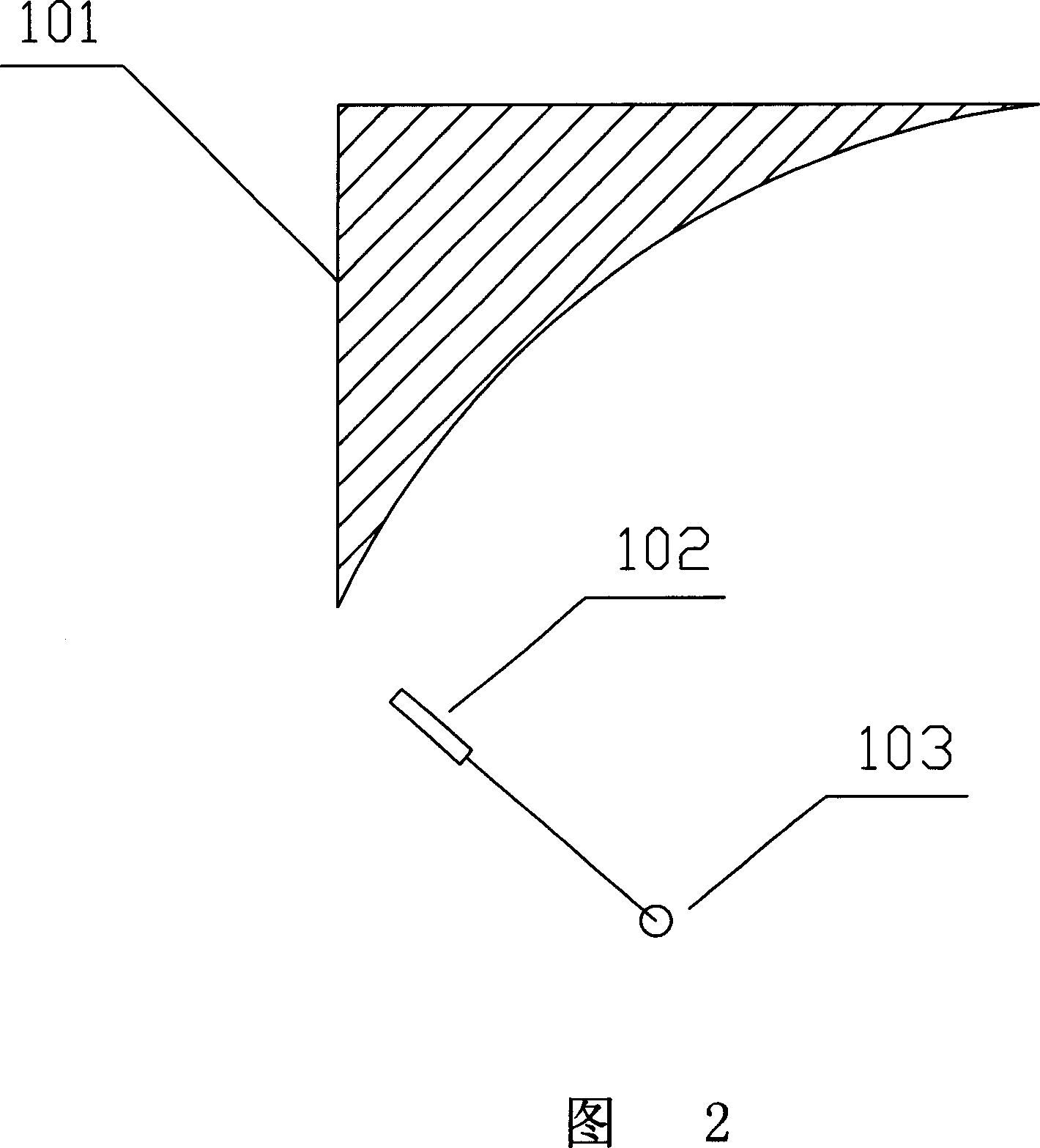

Tile type magnetic-fluxleakage permanent magnet electric motor

InactiveCN101521448AHigh power saving rateMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityElectric machine

The invention provides a tile type magnetic-fluxleakage permanent magnet electric motor, comprising a stator, a rotor, a direct current (DC) magnetic coil and an accessory. The poleface of the permanent-magnet pole of the rotor has the same pole as the poleface and the polarity which are printed at the centre of the stator; and the two sides of the rotor are the magnetic poles of the permanent magnet with the same standard of the heterospolar of the stator. A sharp tile-shaped magnetic-fluxleakage passive iron is fixed on the poleface of the permanent-magnet pole of the rotor so that a main magnetic circuit thereof is a tile-shaped magnetic-fluxleakage magnetic field; two pieces of tile-shaped magnetic-fluxleakage passive irons and magnetizer of DC coil polariton are fixed on the poleface of the permanent-magnet pole of heteropolar stator at the two sides so that the magnetic potential thereof rises to pole terminal; and non kinematic potential is produced when the sharp tile-shaped magnetic-fluxleakage passive iron of the rotor enters the poleface of the permanent-magnet pole, and orientated magnetic kinematic potential from the poleface to the pole terminal is produced when the sharp tile-shaped magnetic-fluxleakage passive iron of the rotor enters the half of the poleface of the permanent-magnet pole. Electromagnetic field with the same polarity which is produced on the pole terminal shields the magnetic-fluxleakage magnetic resistance, resumes the state without magnetic kinematic potential and switches off when entering the next orientated magnetic kinematic potential magnetic field. The orientated magnetic kinematic potential of the electric motor is larger than the magnetic-fluxleakage magnetic resistance when the electric motor is out of service; and the electricity-saving rate is extremely high.

Owner:罗永

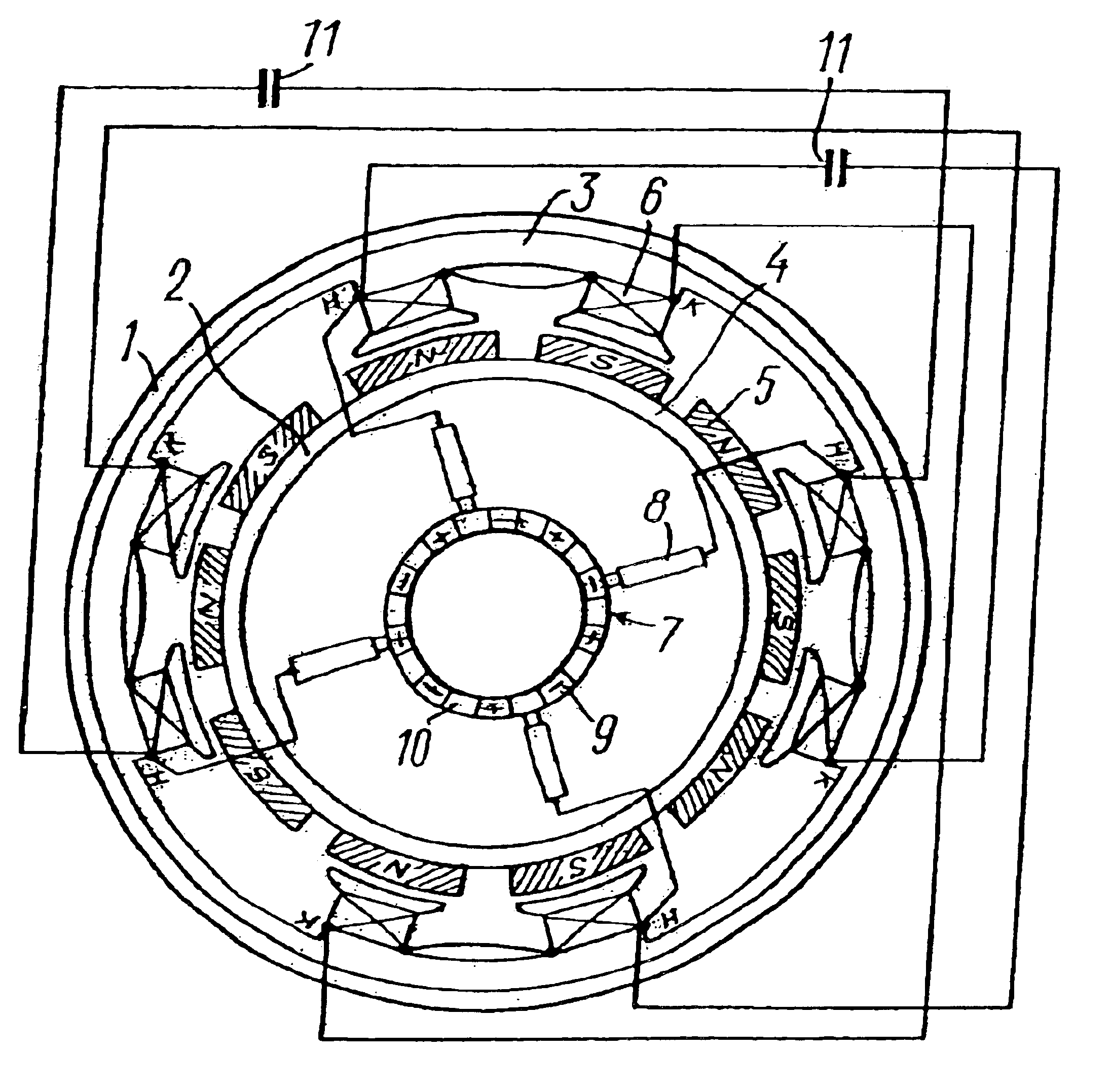

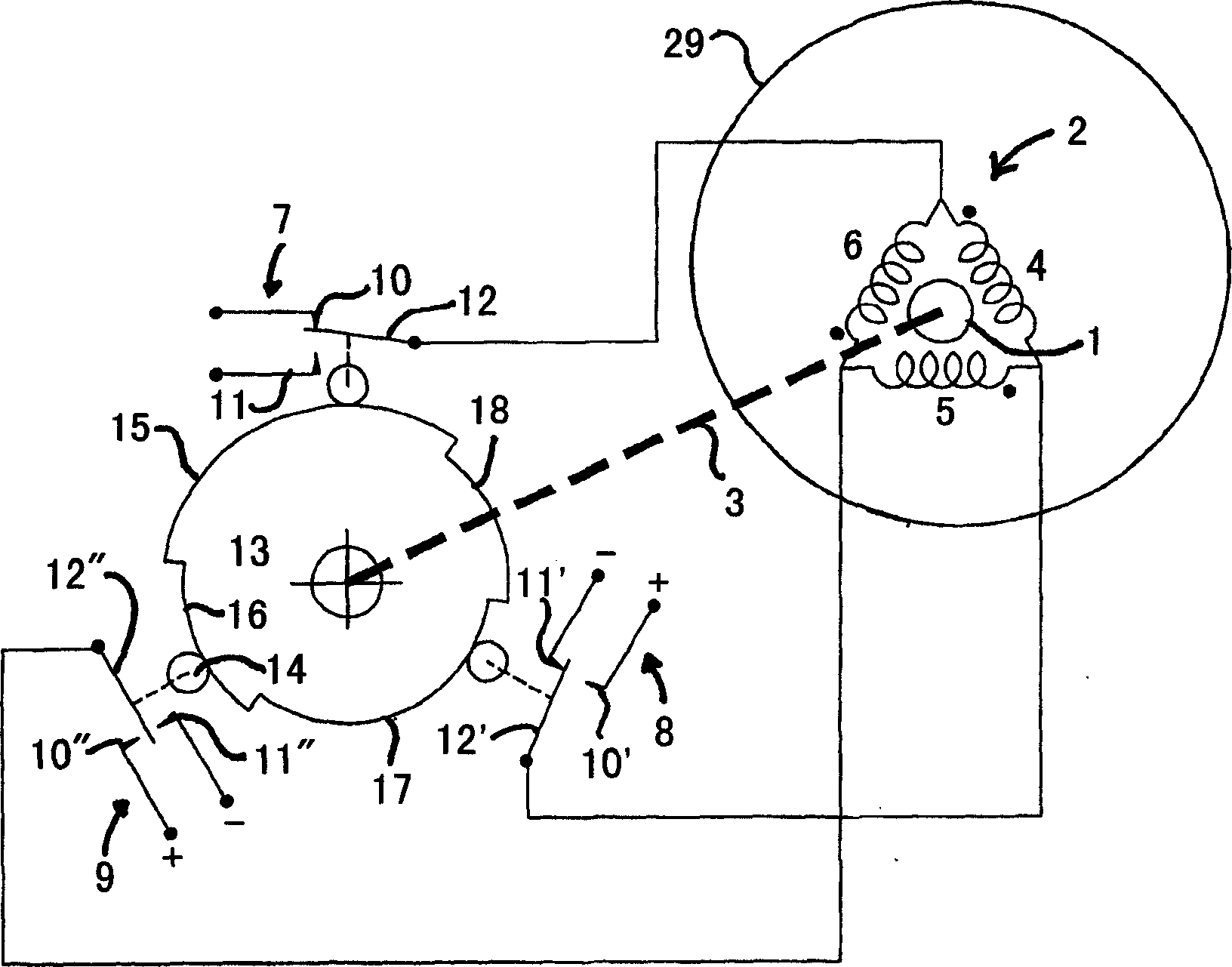

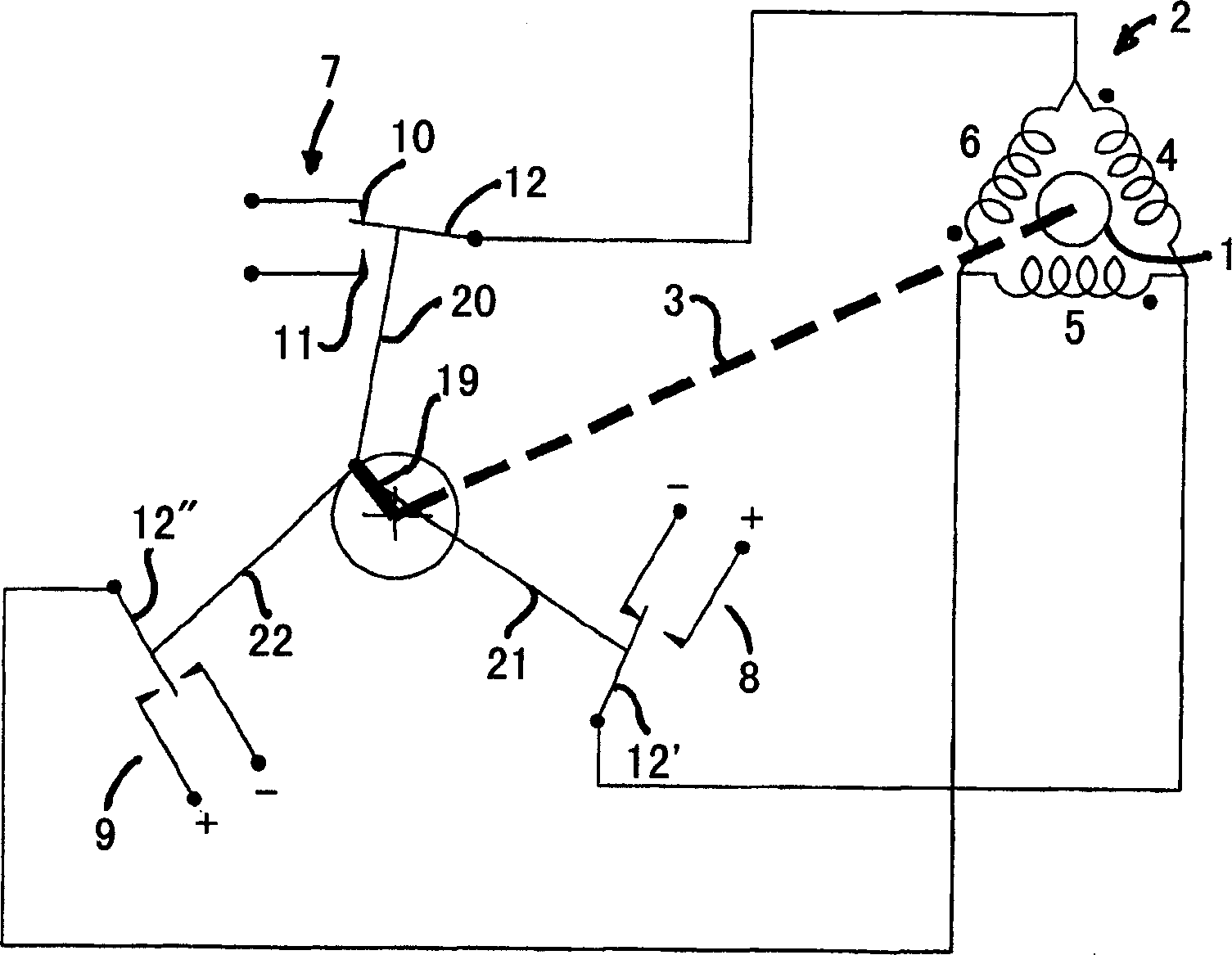

Rotating electrical machine

InactiveUS7323842B2Low manufacturing and maintenance costsElectric signal transmission systemsDC motor speed/torque controlMagnetic polesEngineering

A rotating electrical machine has a housing with a shaft mounted rotatably in it. A rotor is fixed to the shaft and has a plurality of magnetic poles. A stator is positioned about the rotor and has a winding. A switch is mounted within the housing and has a first position for allowing current in one direction through the winding and a second position for allowing current in an opposite direction through the winding. A mechanical activator is movable with or by the shaft and acts on the switch to move it between the first and second positions.

Owner:DOLPHIN ELECTRIC HLDG

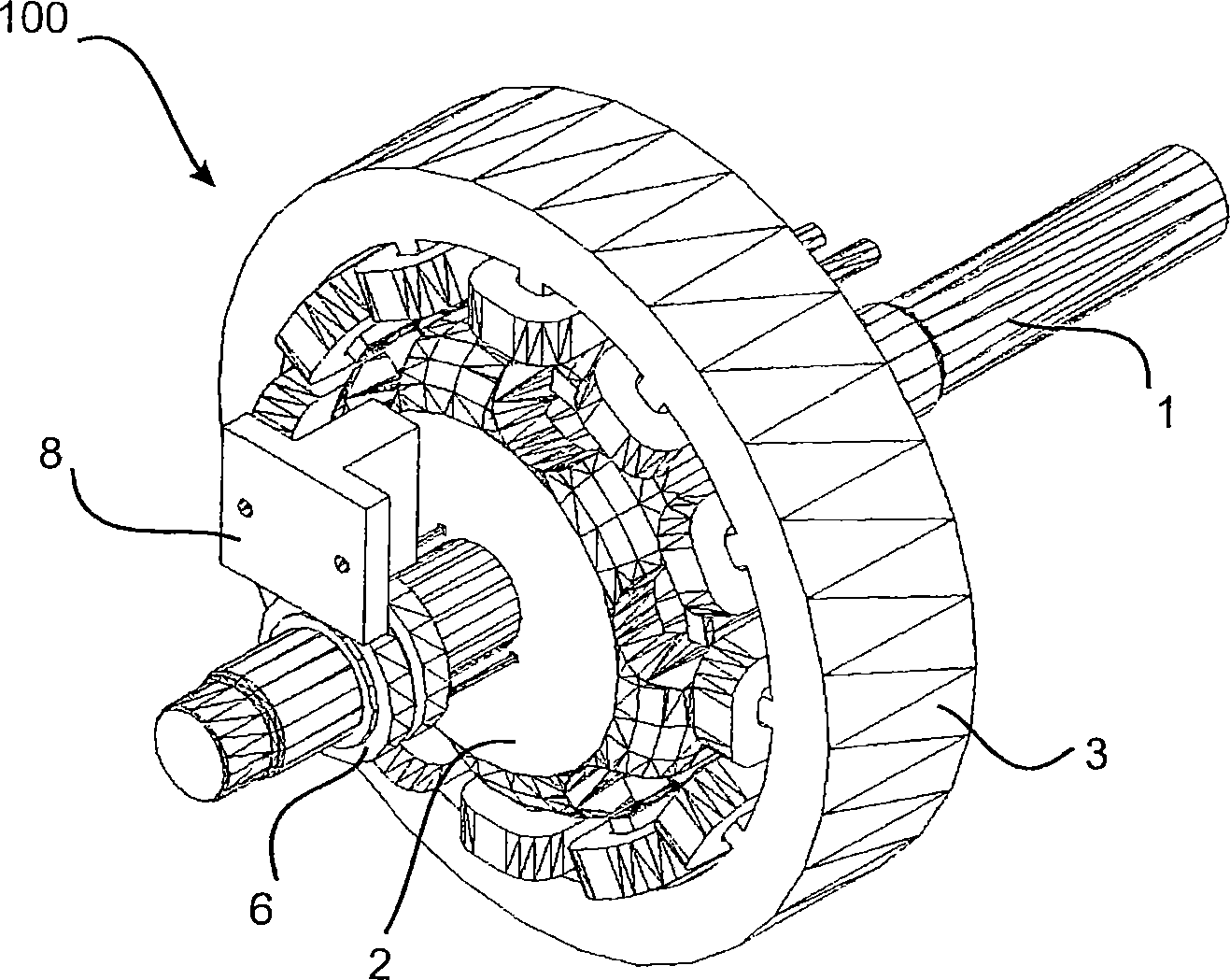

Switched DC electrical machine

InactiveCN1906828ASynchronous generatorsElectronic commutation motor controlLow voltageMagnetization

A switched DC rotating electrical machine (100) comprising a stator (3), a rotor (2) and switching means (11a, 11b, 18a, 18b), an excitation winding (5) associated with one of the stator (3) or the rotor (2) having a pair of inputs, the excitation winding (5) being adapted to cause magnetization of a plurality of magnetic poles (4a - 4l), the switching means (11a, 11b, 18a, 18b) being adapted to be associated with a DC voltage source (19) to switch the output thereof to the first and a second input of the excitation winding (5), the DC voltage source (19) providing a low voltage output (-V), an intermediate voltage output (0V) and a high voltage output (+V), wherein in use the intermediate voltage output is continuously connected to the first input of said excitation winding 19 and the second input is switched in a cyclic operation by the switching means between connection with the high voltage output (+V) and the low voltage output (-V).

Owner:PRECURSOR ENG

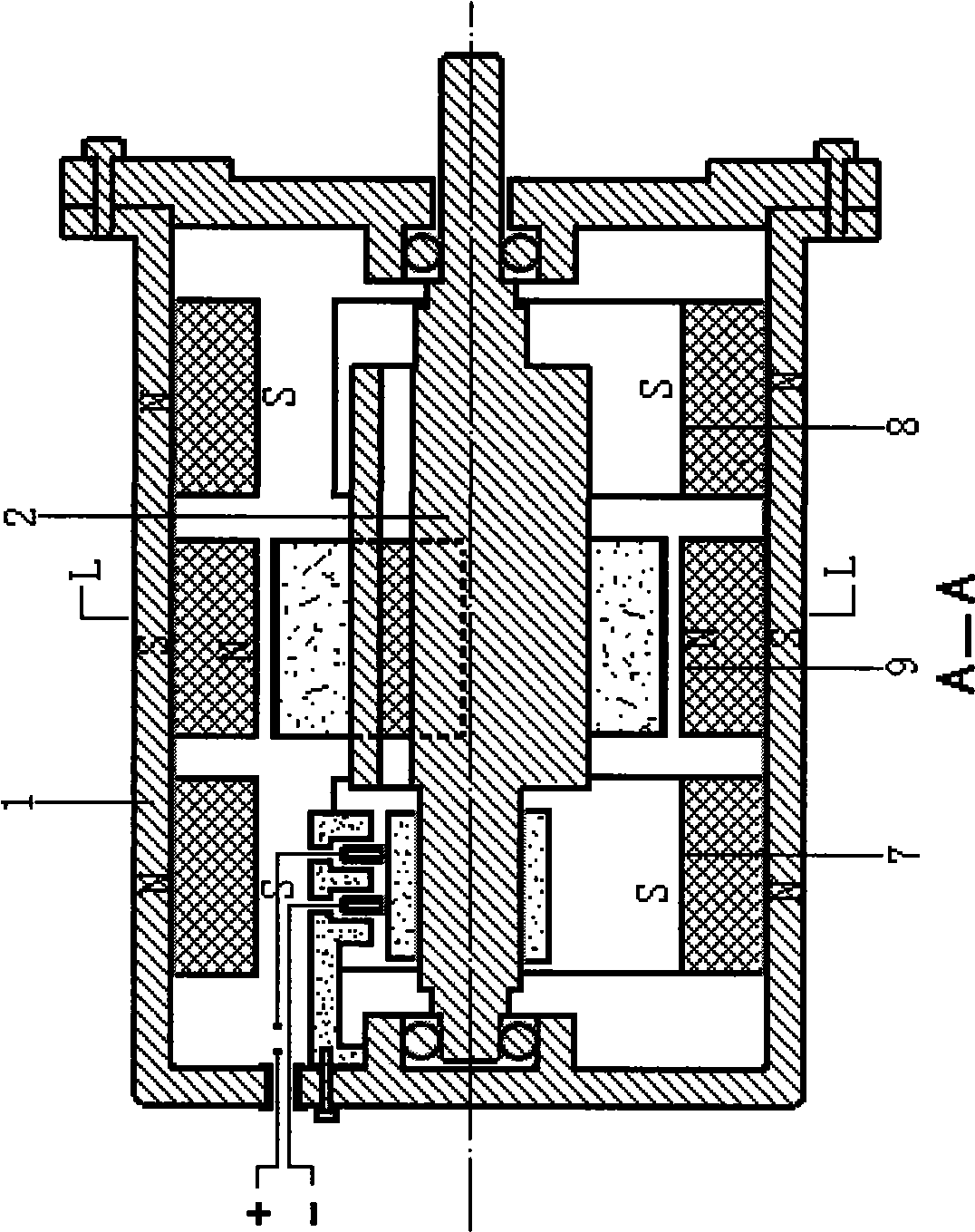

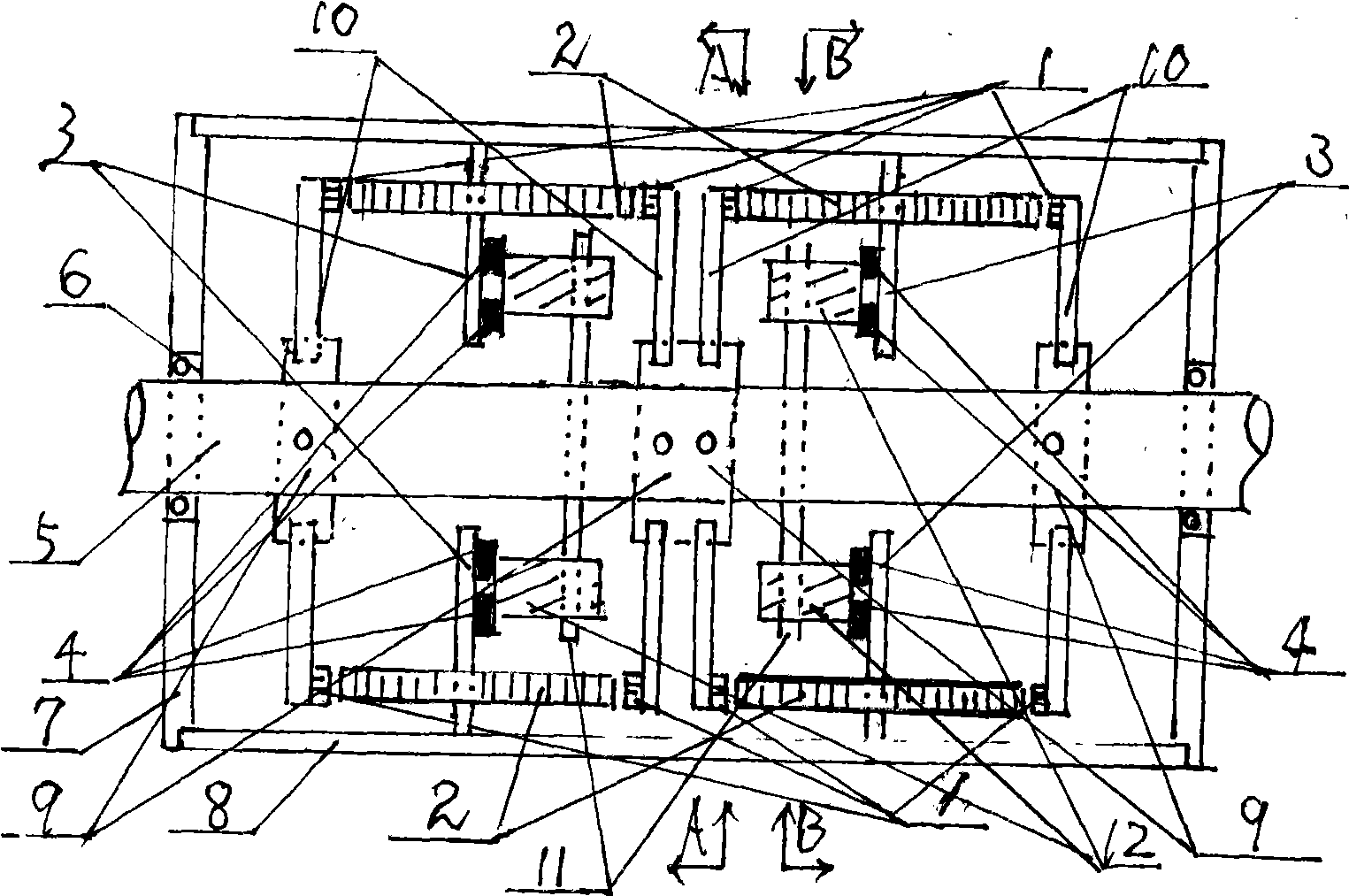

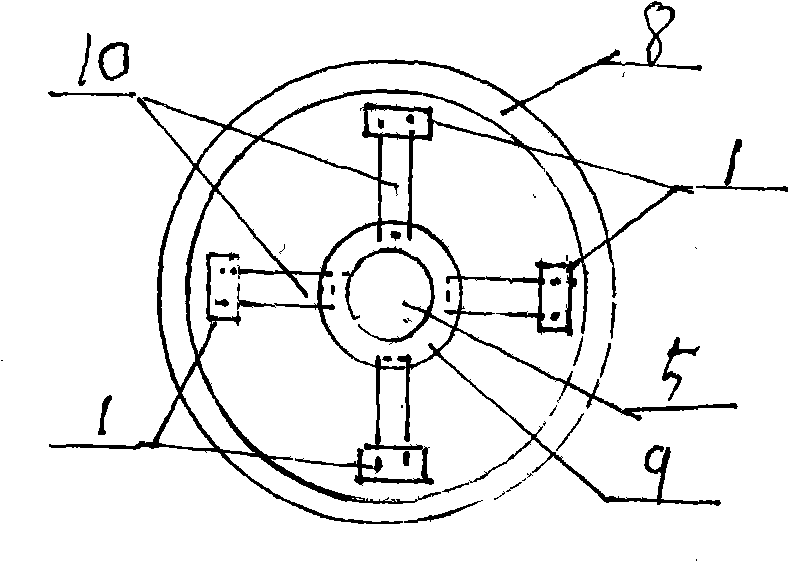

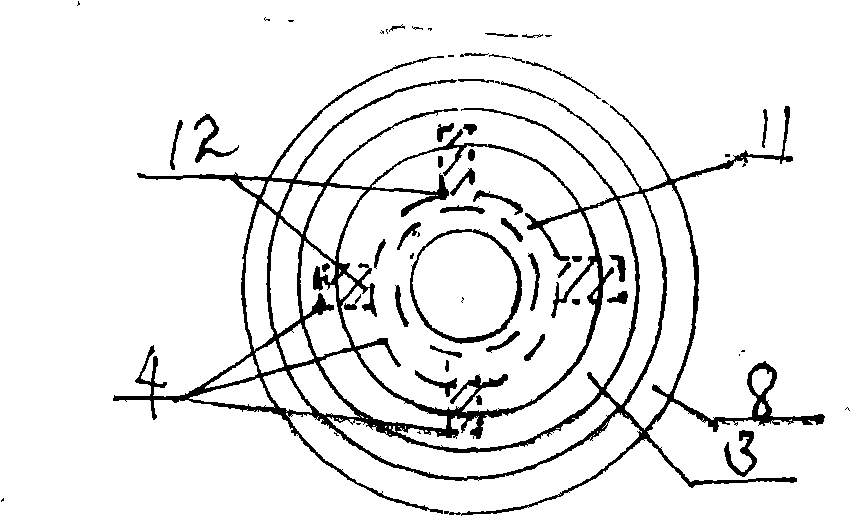

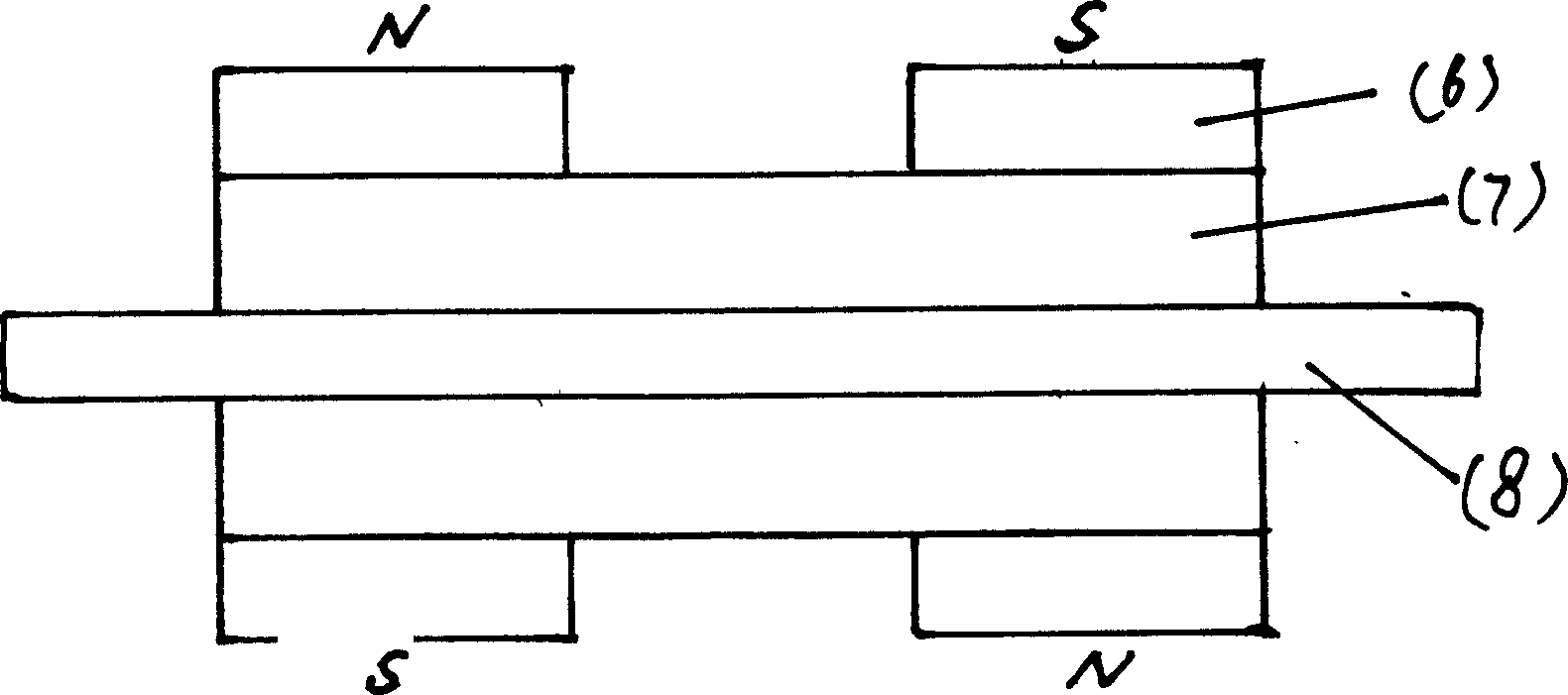

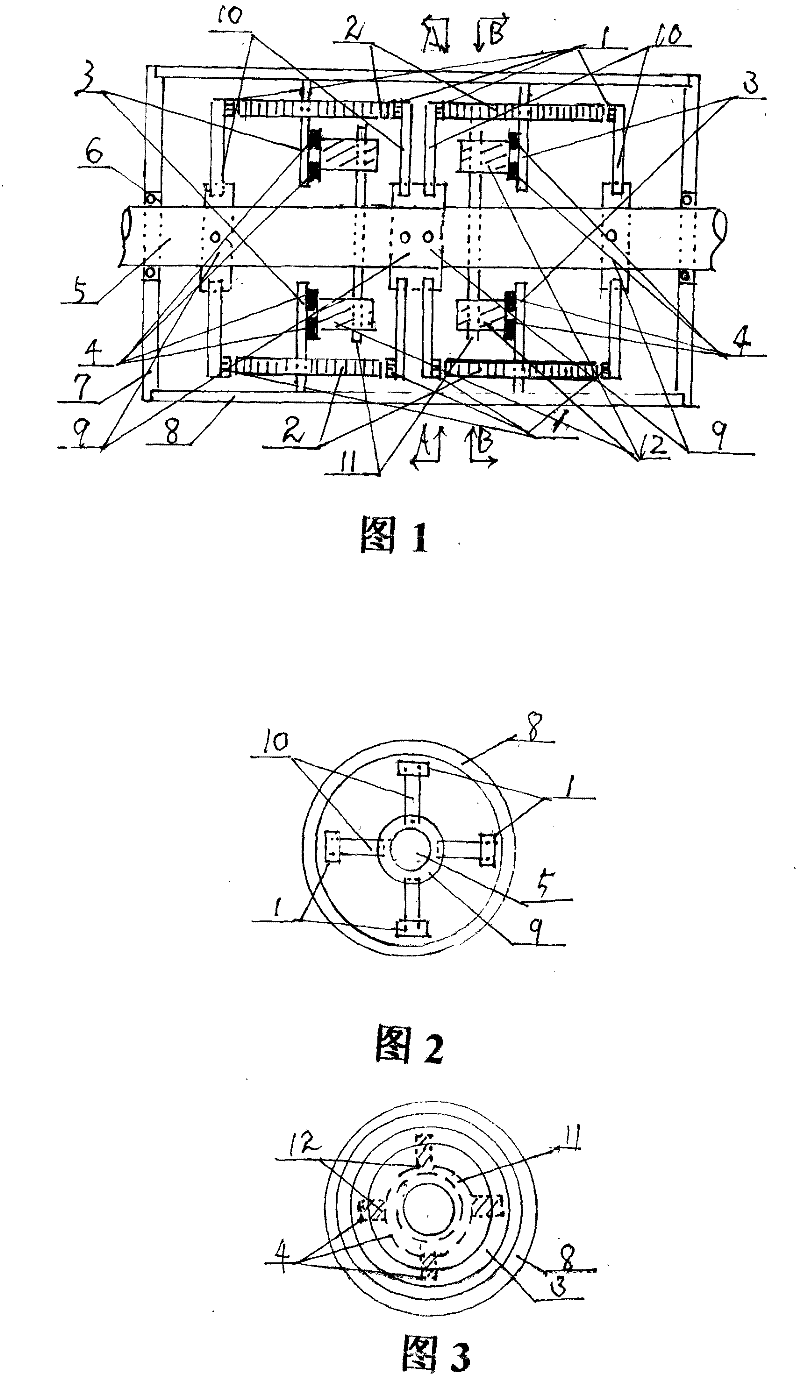

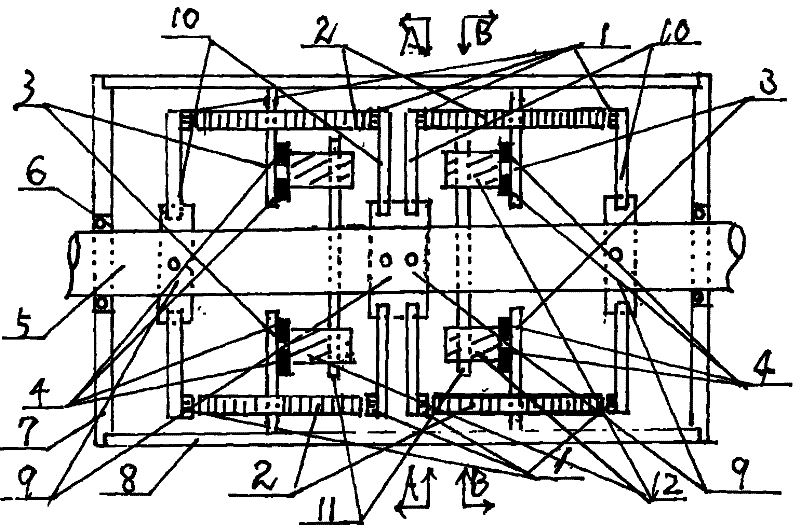

Multiple magnetic wheel motor

InactiveCN101488695AMagnetic circuit rotating partsSupports/enclosures/casingsMagnetic tension forceRepulsion force

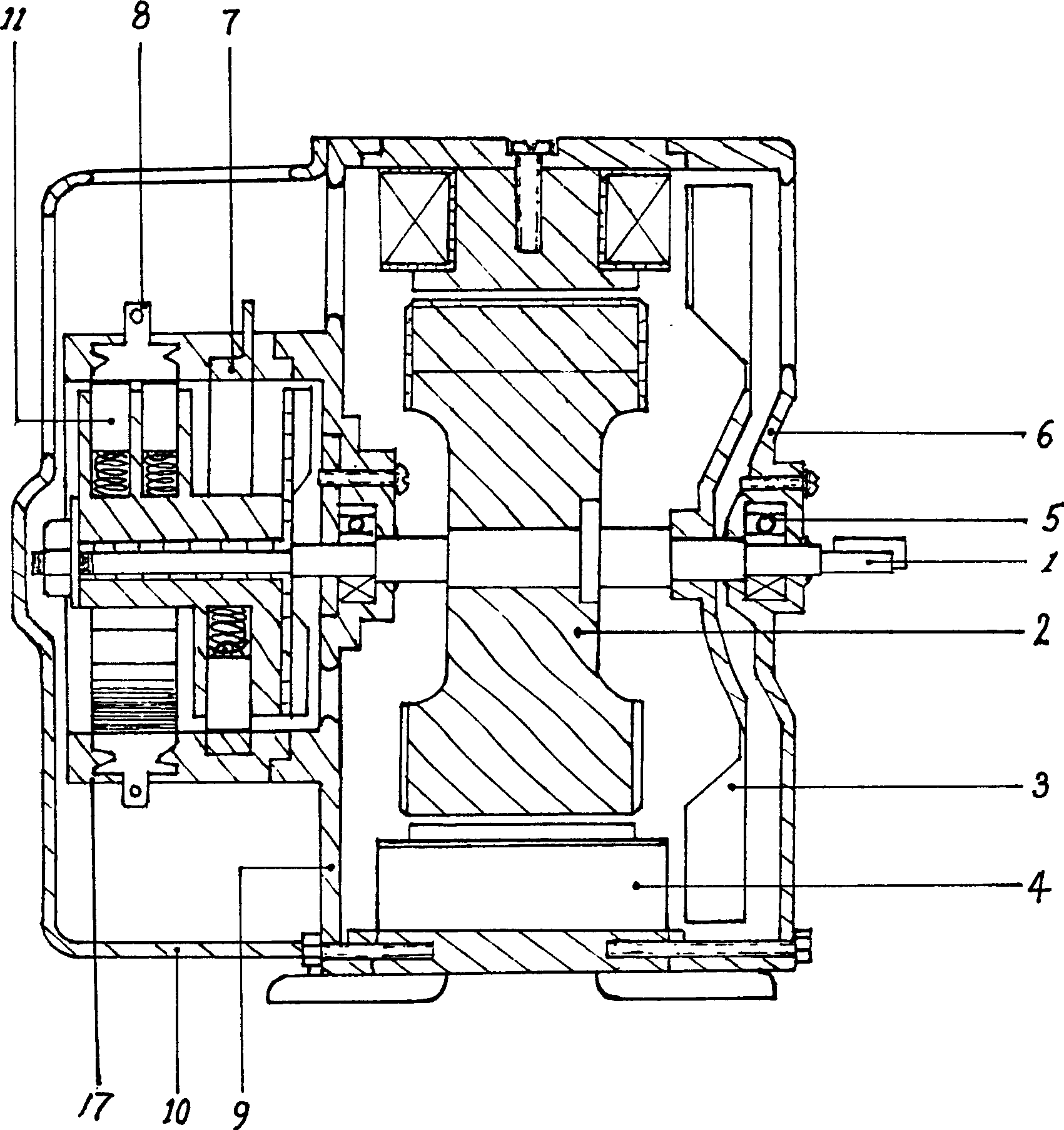

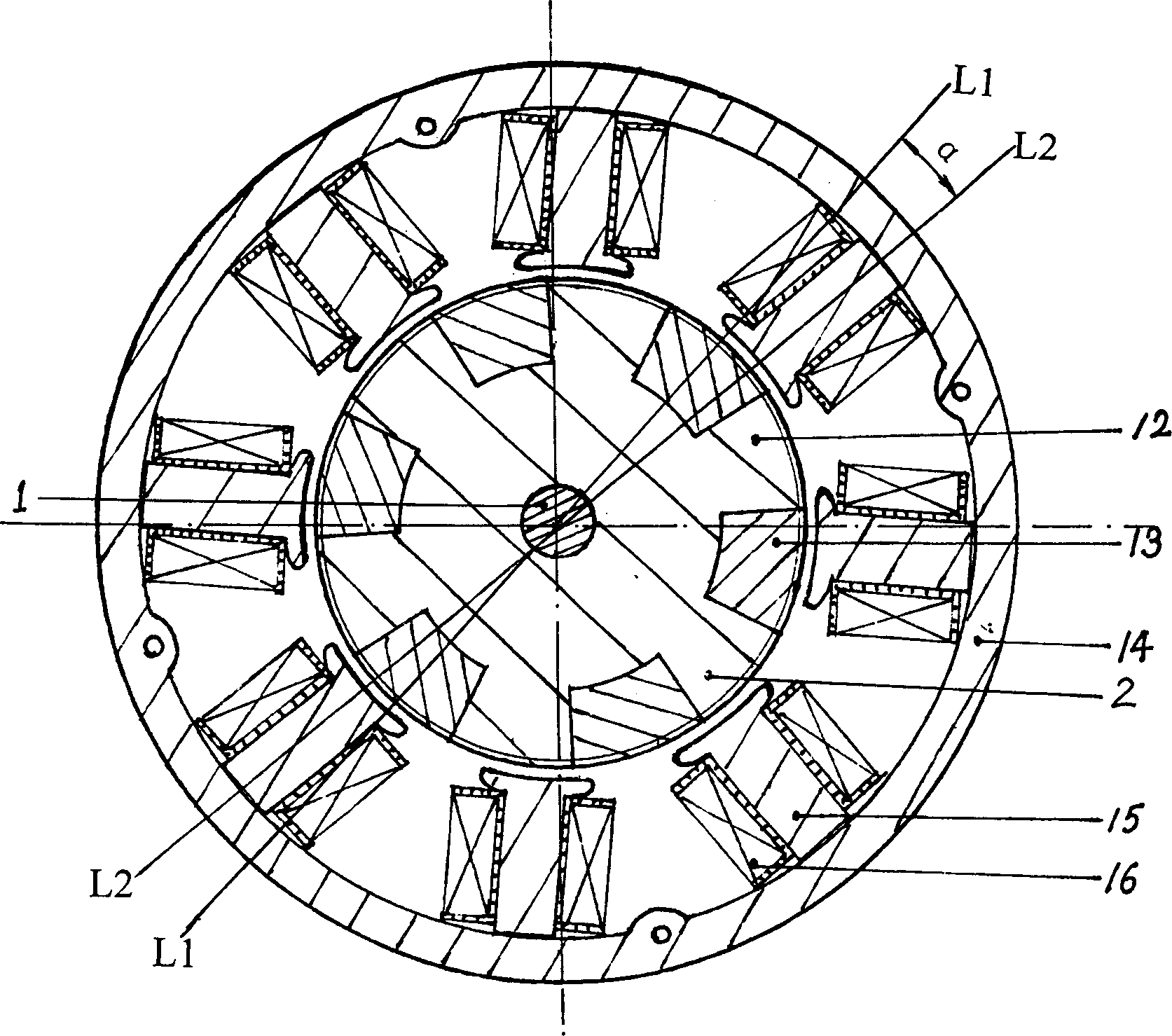

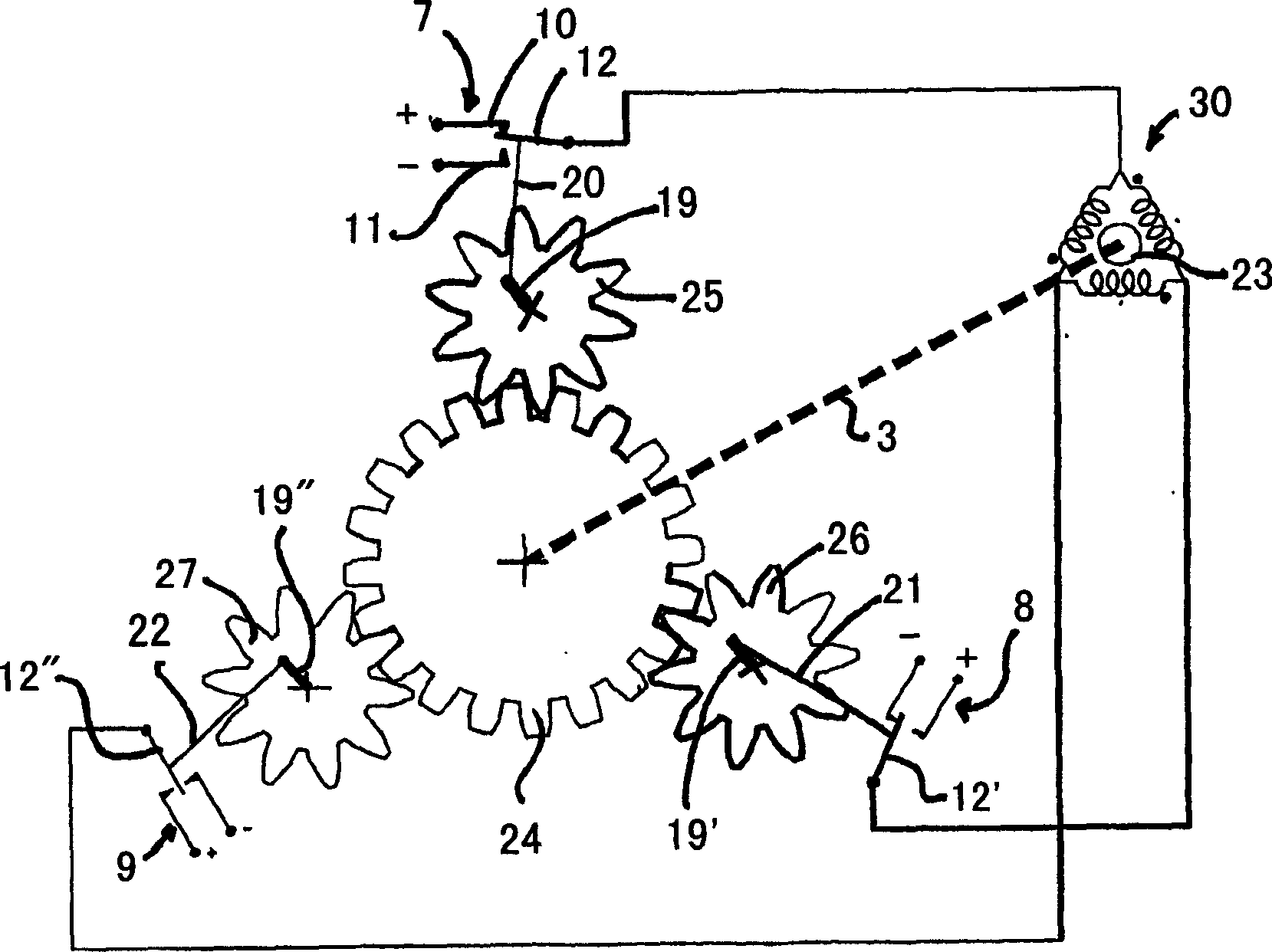

The invention relates to an engine provided with a plurality of magnet-wheels, which consists of a permanent magnet (1), an electromagnet (2), an electromagnet seat (3), an electric conduction copper ring (4), a straight shaft (5), a bearing (6), an end cover (7), a shell (8), a spoked wheel (9), a spoke (10), a carbon brush holder (11) and a carbon brush (12), and has the advantages of light weight, simple structure, no tail gas emission, energy conservation, etc. The engine combines part of the technology of a steam turbine with magnetic force, and has the advantages of large arm of force and moment as well as no dead center. By properly selecting the number of the spoked wheels (9) and the number of each line of spokes (10), the area of a magnetic pole, the intensity of a magnetic field and the length of the spoke (10) are properly chosen, and the engine having the required power can be designed, thus making contribution to opening up new power source. The principle of the action of the engine is that repulsion force is generated between the like magnetic poles which are the permanent magnet (1) and the electromagnet (2), component force which is vertical to the radial direction of the spoke is generated when the repulsion force is transmitted to the inclined plane at the end of the spoke (10) used for fixing the permanent magnet (1), and moment is formed; while, the same moment with opposite direction is generated by another spoke (10) which is symmetrical with the spoke (10) along the radial direction; the two moments form torque force to lead the straight shaft (5) to rotate.

Owner:孙宗德

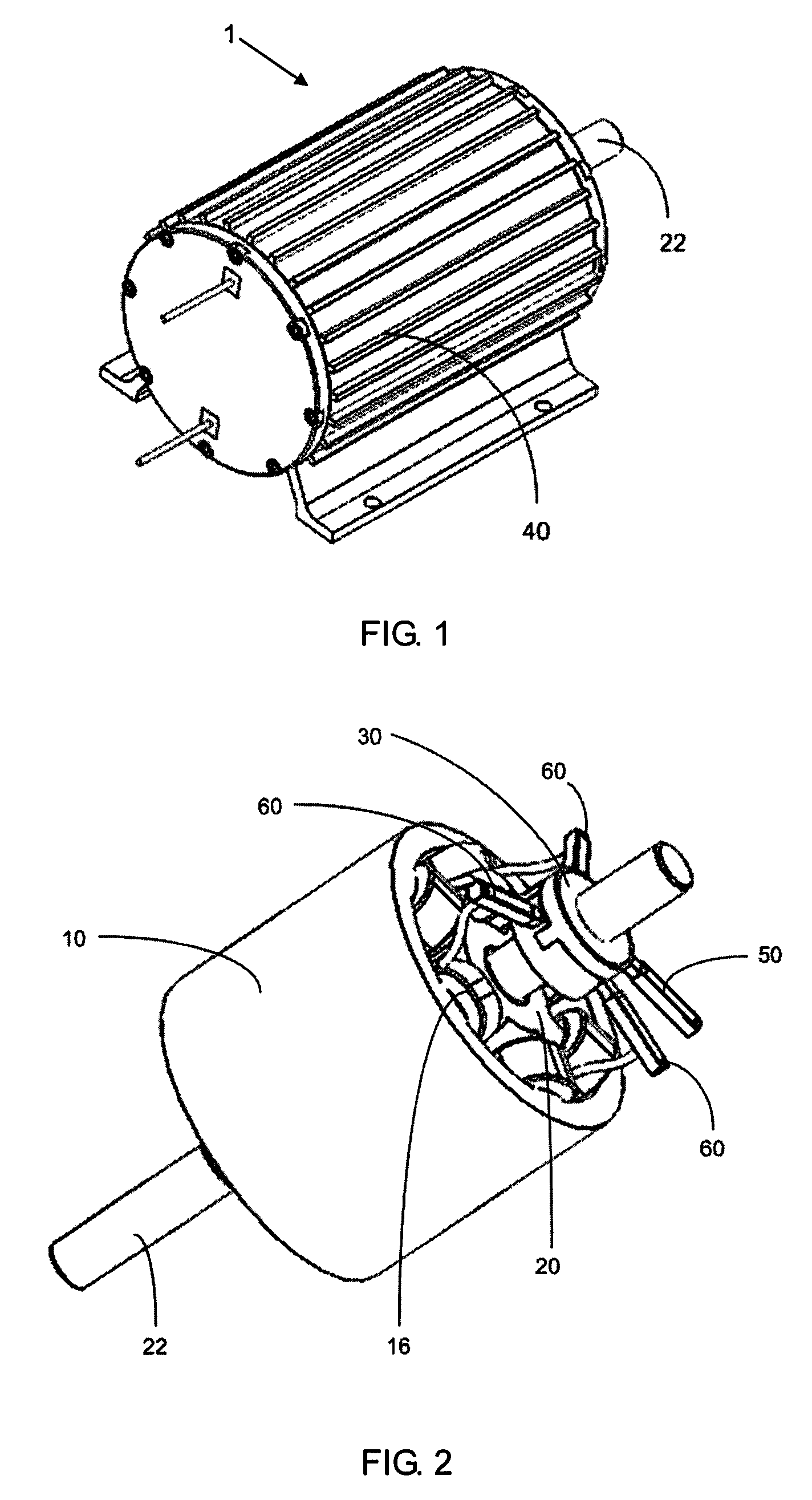

Electric motor

InactiveUS20120274170A1Improve production efficiencyRotary current collectorDC commutatorEngineeringAlternating current

A brush direct current motor has a stator with a plurality of coils that correspond to a number of stator windings, a rotor with a number of poles, and a commutator. The commutator is connected to a first terminal of a direct current power source to convert the power into N phase alternating current. One end of each stator winding is connected to a respective phase of the alternating current via a brush and the other ends of the stator windings are connected to the second terminal of the direct current power source.

Owner:JOHNSON ELECTRIC SA

Magnetic engine

This invented magnetic motor is composed of a permanent magnet, soft materials and electric magnetic coils, mainly for developing permanent magnetic energy to make the rotor rotate continuously, overcome loader resistance and transport mechanical energy to outside. The device uses soft magnetic materials to generate close action to magnetic flux of the stator magnet and uses DC electric magnet tostop the flux of the stator which two sets of magnetic poles circulate to generate a same way rotating force to the rotor magnetic pole to make the rotor rotate continuously and the power of this power source keeps constant along with it.

Owner:王建功

Brushed direct-current motor

InactiveCN102761223ALow costStable structureRotary current collectorMagnetic circuit rotating partsElectricityPower flow

The invention relates to a brushed direct-current motor, which comprises a stator and a rotor. The stator comprises a plurality of windings and a stator magnetically-conductive salient pole core. The rotor comprises a rotor magnetically-conductive salient pole core and two mutually insulated reversing devices, wherein each reversing device comprises electrically-conductive parts and a plurality of reversing parts. The stator further comprises two first electric brushes and a plurality of second electric brushes, wherein the first electric brushes are connected with one electrode of a power supply through a select switch and is in sliding contact with the two electrically-conductive parts respectively; the second electric brushes are connected with the windings respectively; the other end of each winding is connected with the other electrode of the power supply; the select switch selectively conducts one of the two first electric brushes to one electrode of the power supply, so that the motor can rotate in one of two opposite directions; and the second electric brushes are in sliding contact with the reversing parts so as to alternately provide single-polarity electric excitation for each winding. According to the brushed direct-current motor provided by the invention, the windings are arranged on the stator and no magnet is arranged on the rotor, so that the brushed direct-current motor is firm; and the windings adopt a single-polarity excitation mode, so that fewer electric brushes are needed and the reversing devices have simple structures.

Owner:JOHNSON ELECTRIC SHENZHEN

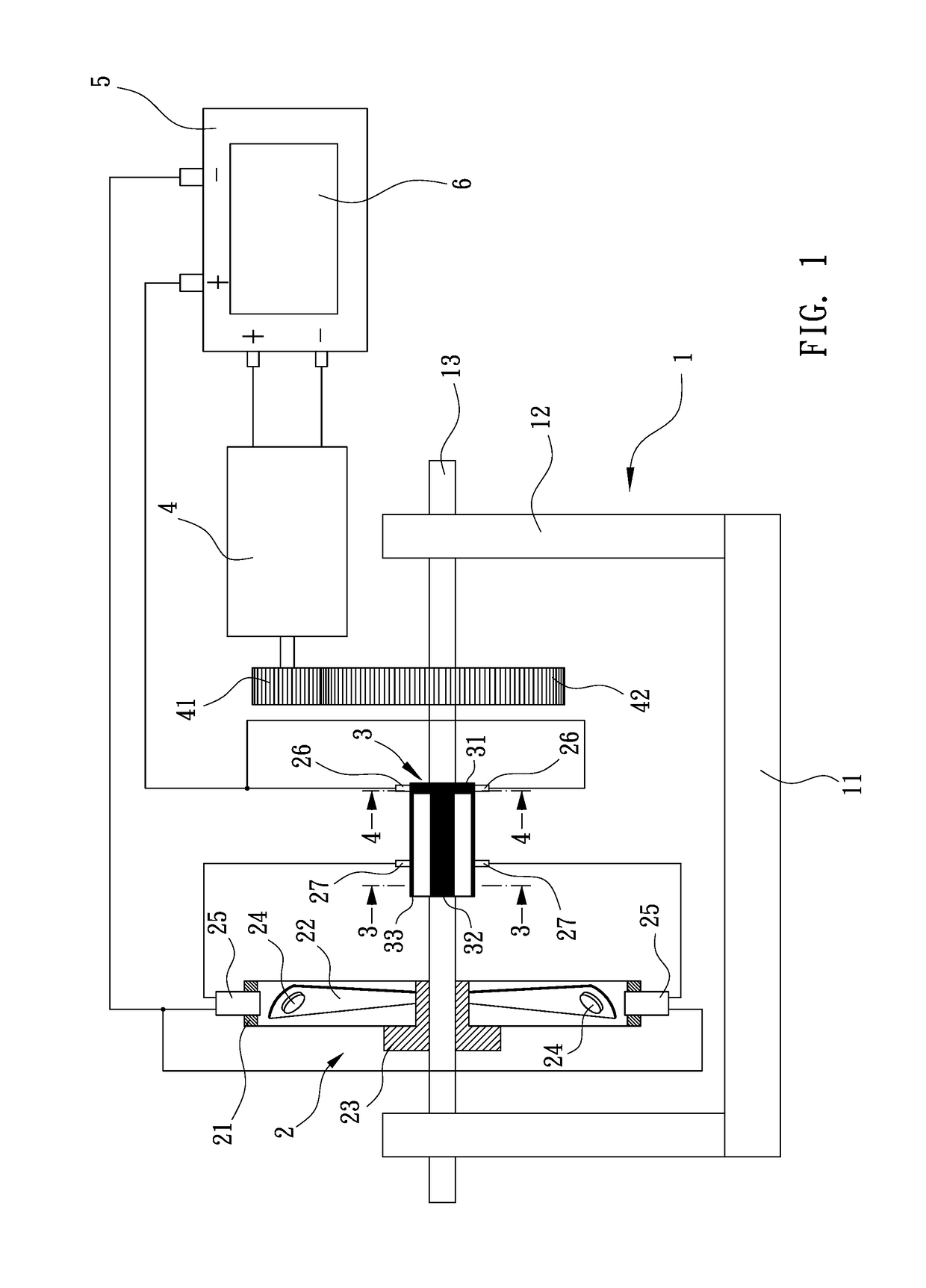

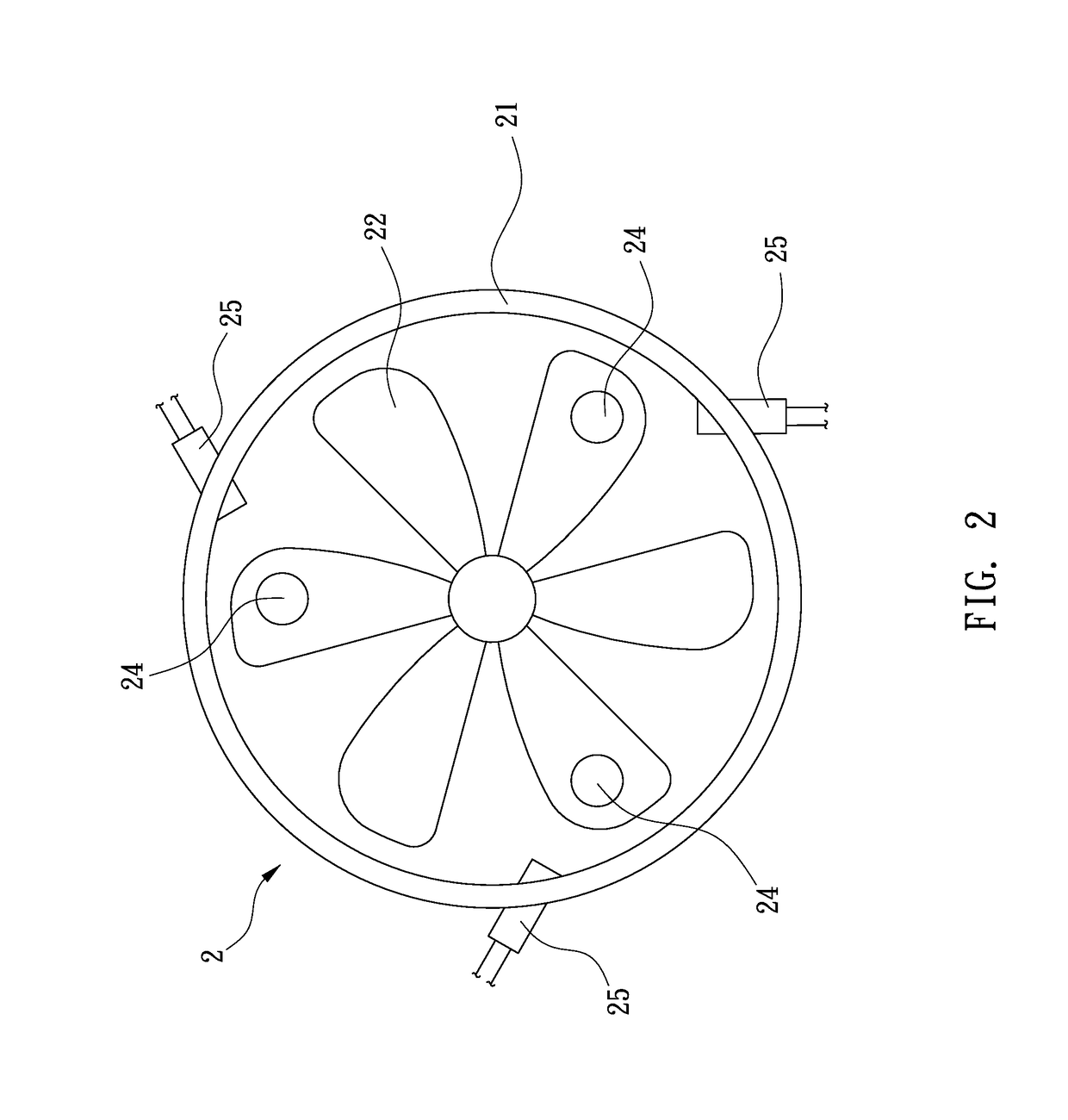

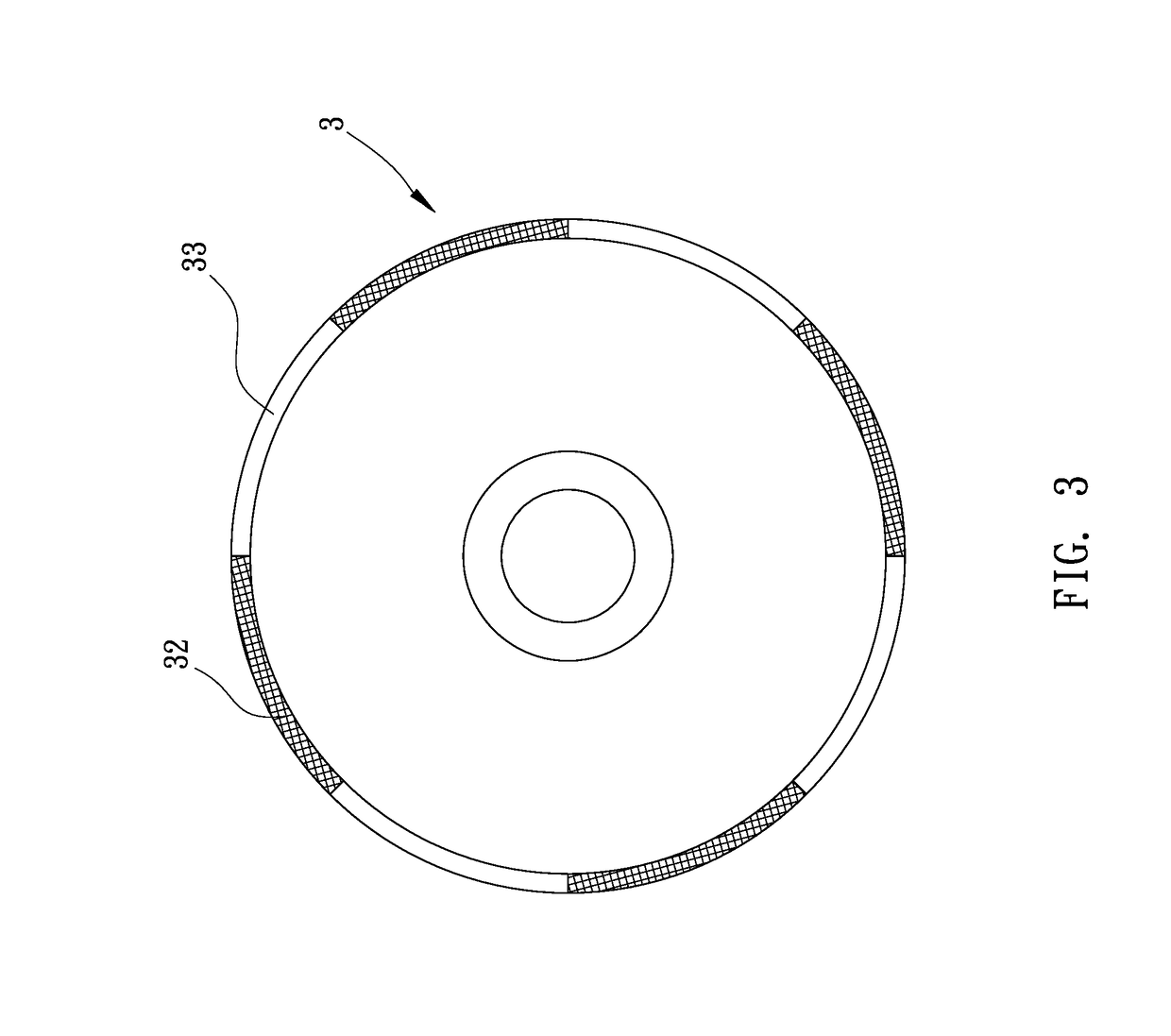

Low-energy-consumption and high-efficiency circulating electric motor

InactiveUS20190089236A1High-efficiency circulating electric motorBatteries circuit arrangementsElectric powerElectricityMagnetic tension force

A low-energy-consumption and high-efficiency circulating electric motor that a fan and a circular cylinder-body are disposed on a rotating-shaft and a permanent magnet is disposed on at least one blade of the fan, and at least a permanent magnet is disposed in a frame; wherein the outer diameter surface of the circular cylinder-body is set with a continuous circumferential conductive portion, and a plurality of axial conductive portions are lined in interval and connected with the circumferential conductive portion; wherein a DC generator is connected with the rotating-shaft and a storage battery is electrically connected with a control unit, the DC generator, the circumferential conductive portion, and the DC electromagnet; at the same time, the DC electromagnet intermittently generates a magnetic force by orderly contacting and not contacting the axial conductive portions; and the fan is continuously rotated by the intermittent magnetic force interacting with the permanent magnet.

Owner:WANG MENG THENG

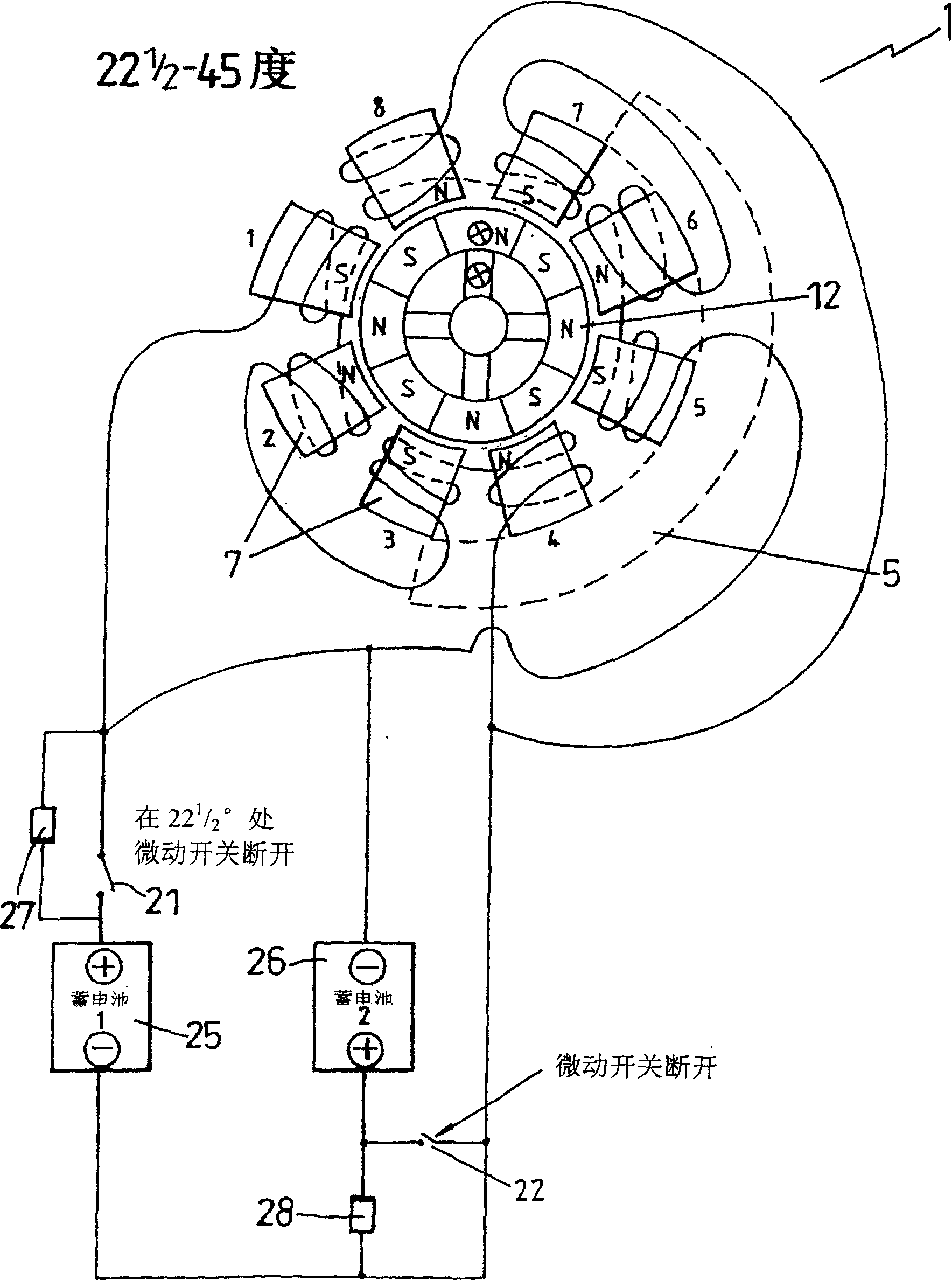

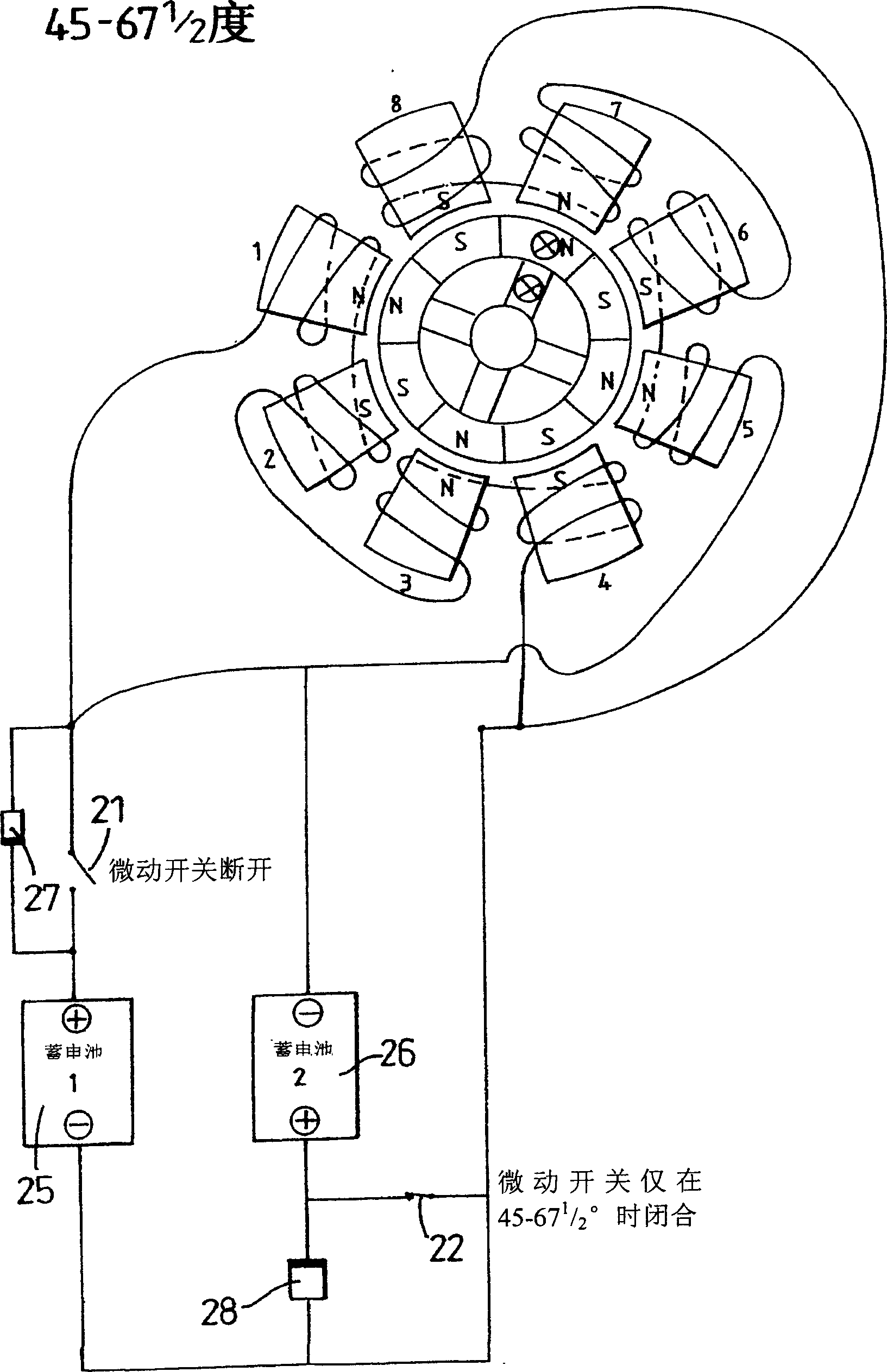

Improved electric motor

InactiveCN1524332ASynchronous machines with stationary armatures and rotating magnetsDC interruptersElectrolytic capacitorStator poles

An electric motor has a stator and a roto. The stator (1) comprises an annular armature (5) having a plurality of poles (7) evenly spaced about the inner circumferential surface of the armature (5) and directed towards a central longitudinal axis defined by the rotor shaft. A pair of firing / accumulator circuits (14,16) are connected in common and in series with respective sets of coils wound about the stator poles. The circuits are switched into and out of contact with their respective coil sets according to the position of the rotor with respect to the stator via position sensing elements which operate switches in the accumulator circuits. In an alternative embodiment firing and accumulation is effected using commutators and electrolytic capacitors (ECP, ECN). The motor is adapted to retrieve breakdown energy of the magnetic fields to realise a more efficient motor.

Owner:威廉 M 克鲁克斯

Rotating electrical machine

InactiveCN1759527AReduce manufacturing costReduce maintenance costsElectric signal transmission systemsMechanical apparatusMagnetic polesEngineering

A rotating electrical machine has a housing with a shaft mounted rotatably in it. A rotor is fixed to the shaft and has a plurality of magnetic poles. A stator is positioned about the rotor and has a winding. A switch is mounted within the housing and has a first position for allowing current in one direction through the winding and a second position for allowing current in an opposite direction through the winding. A mechanical activator is movable with or by the shaft and acts on the switch to move it between the first and second positions.

Owner:DOLPHIN ELECTRIC HLDG

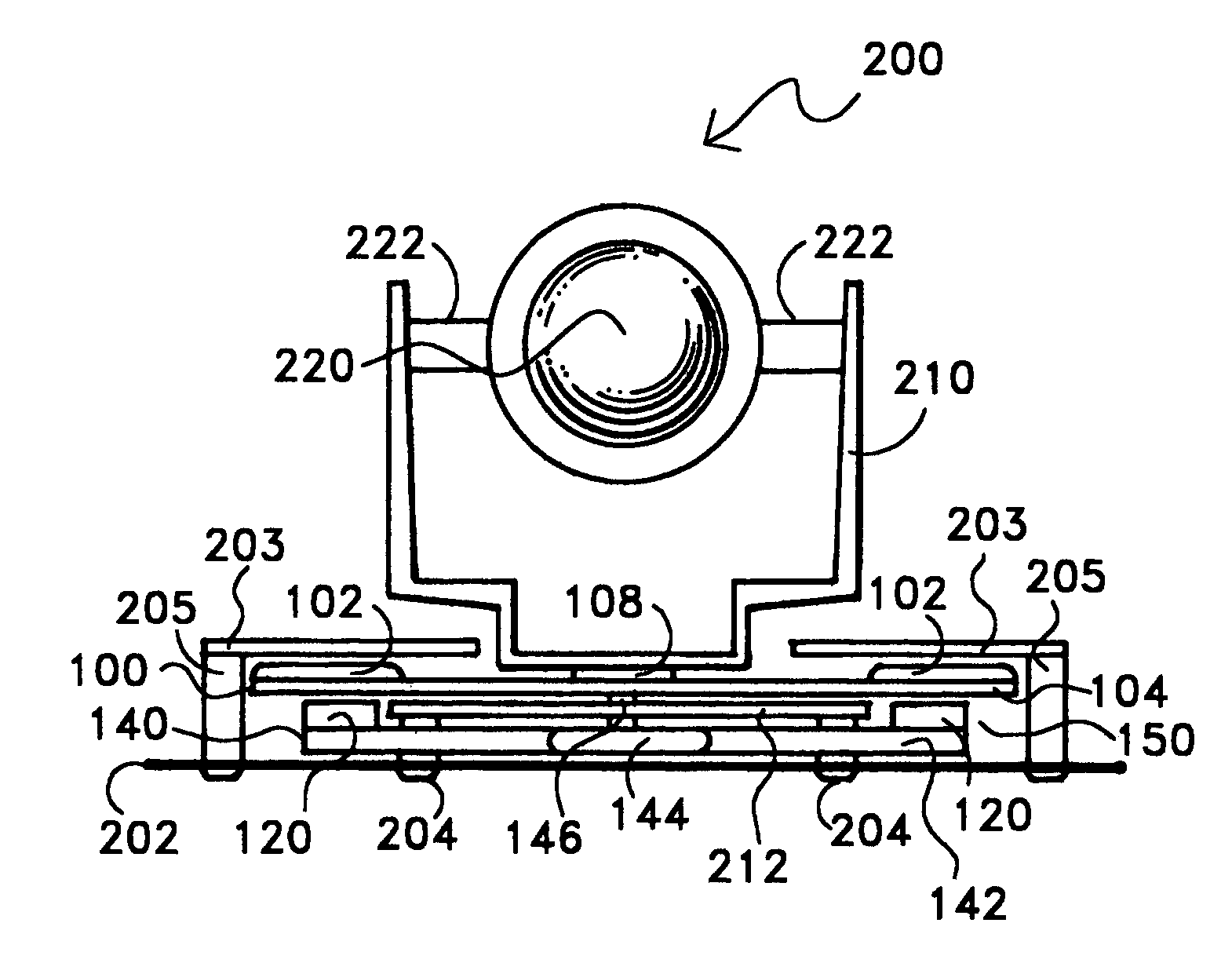

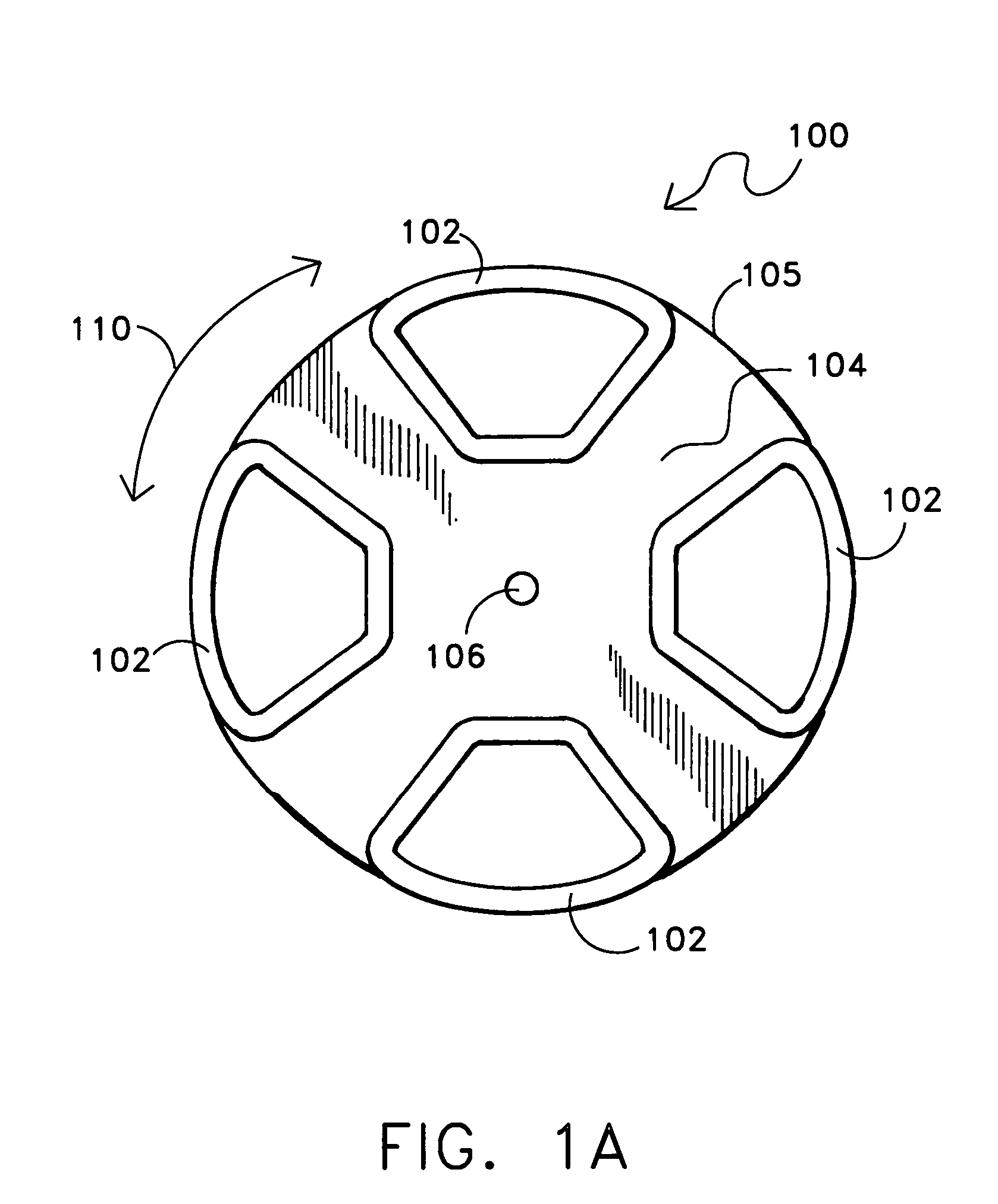

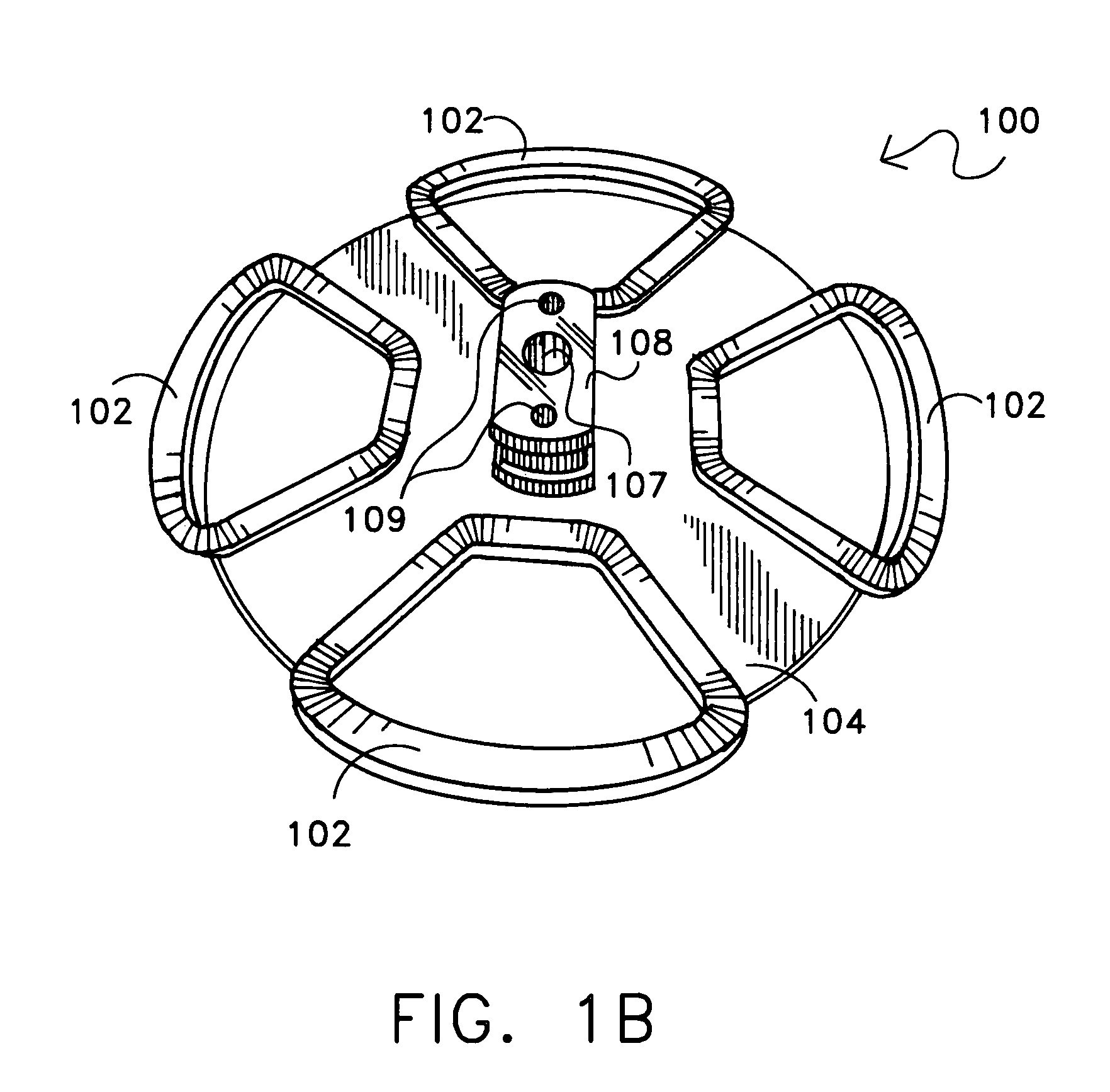

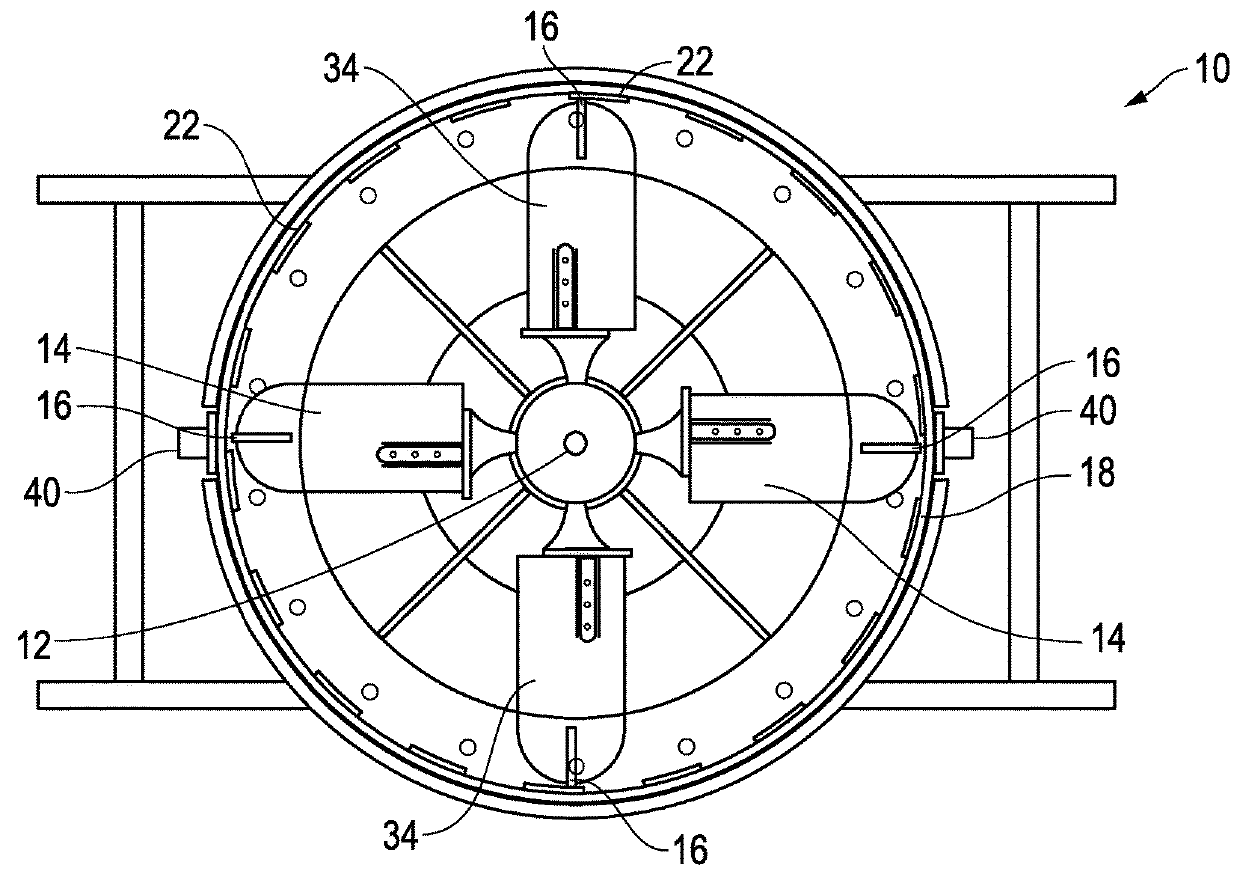

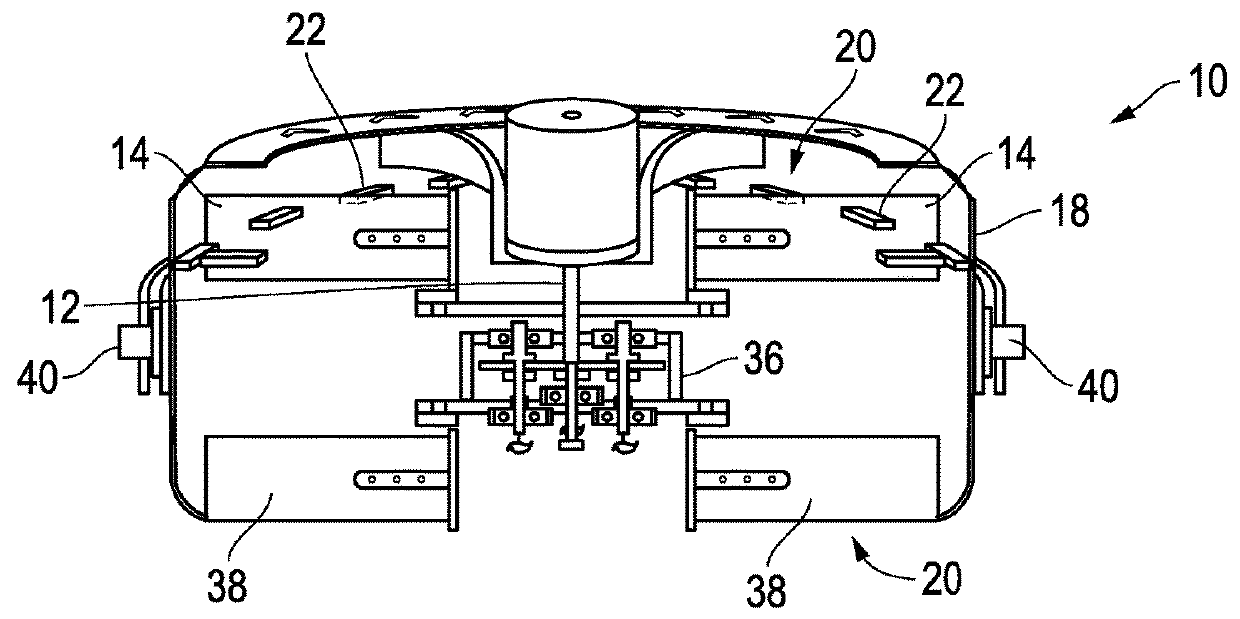

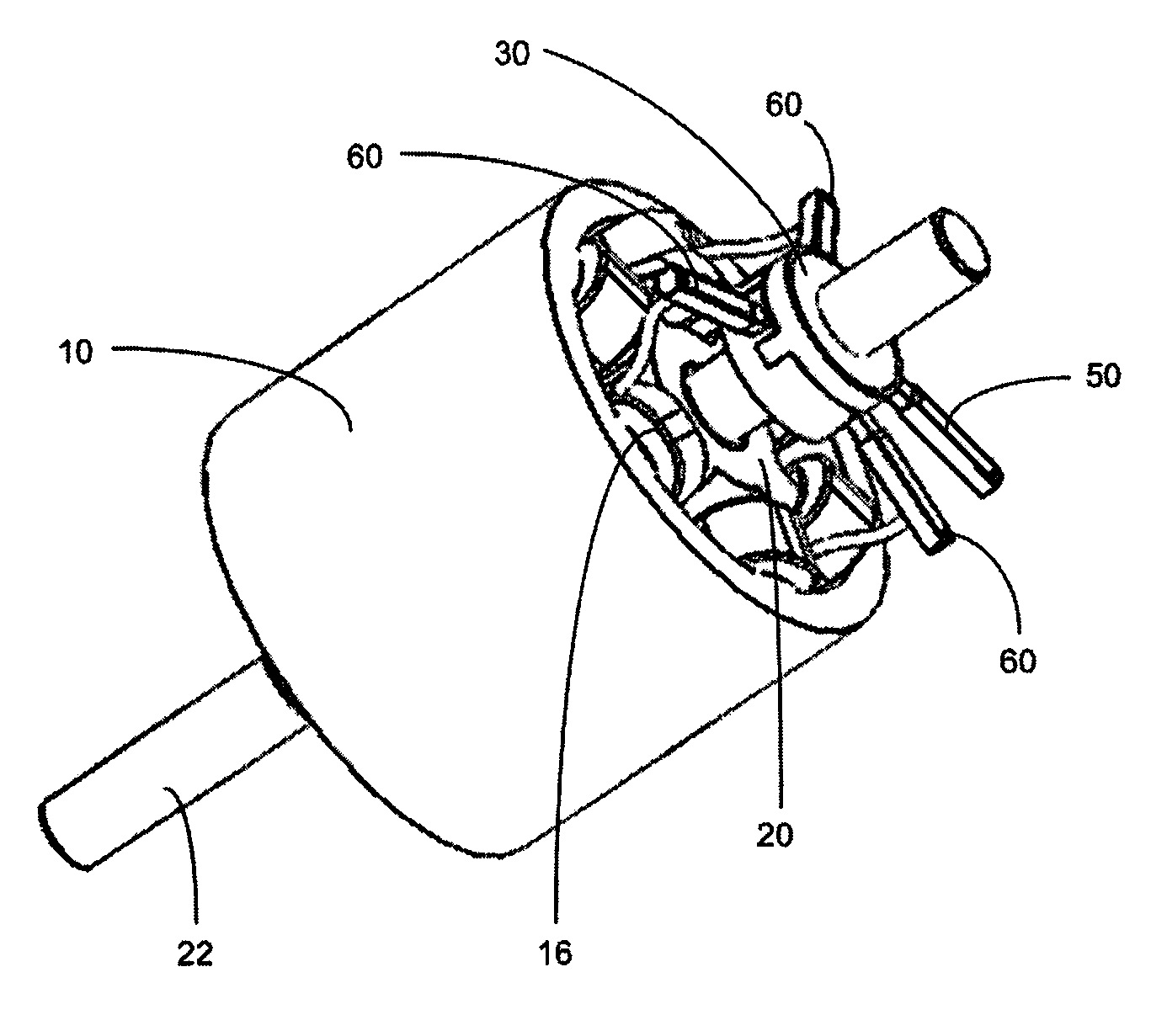

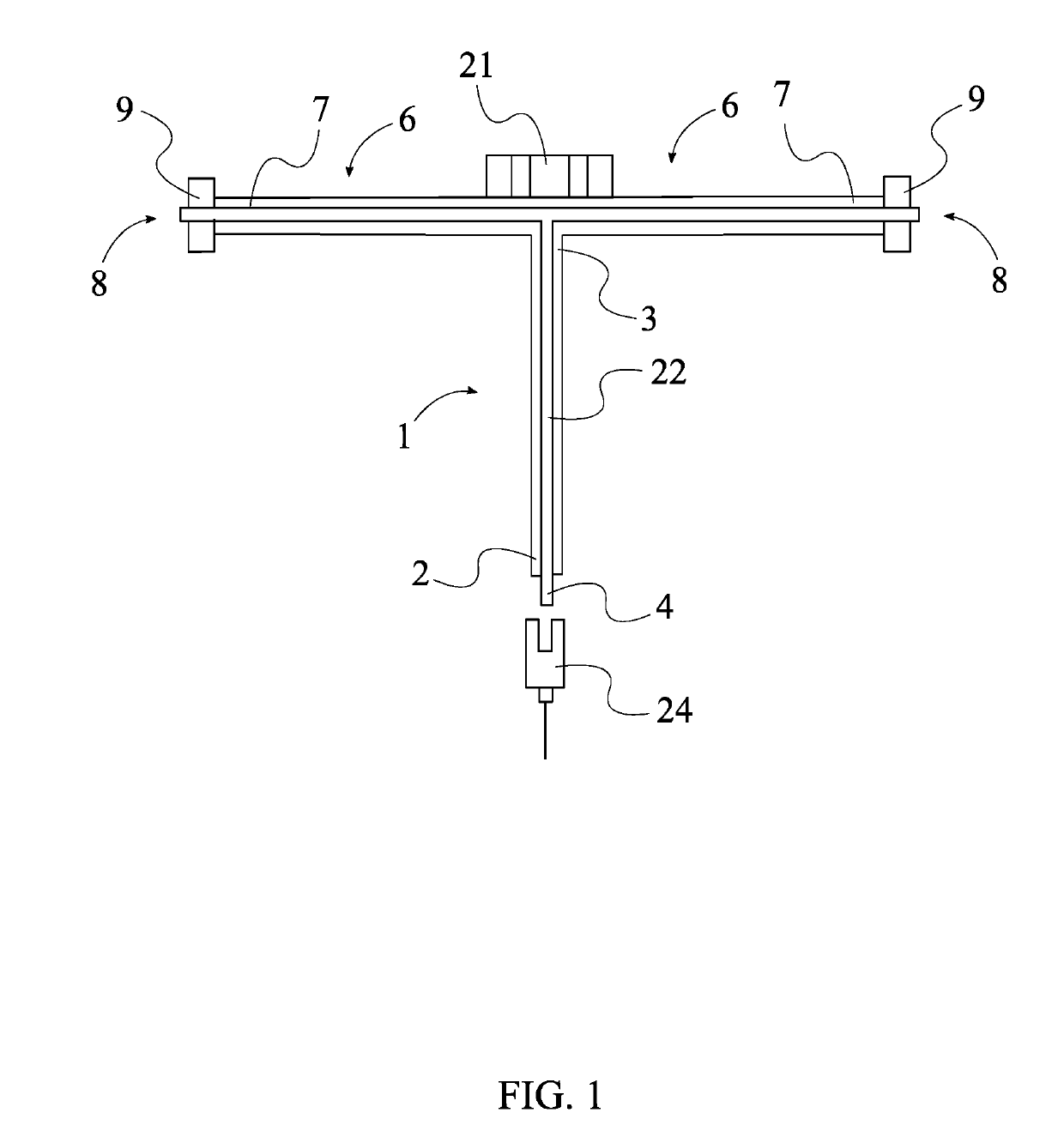

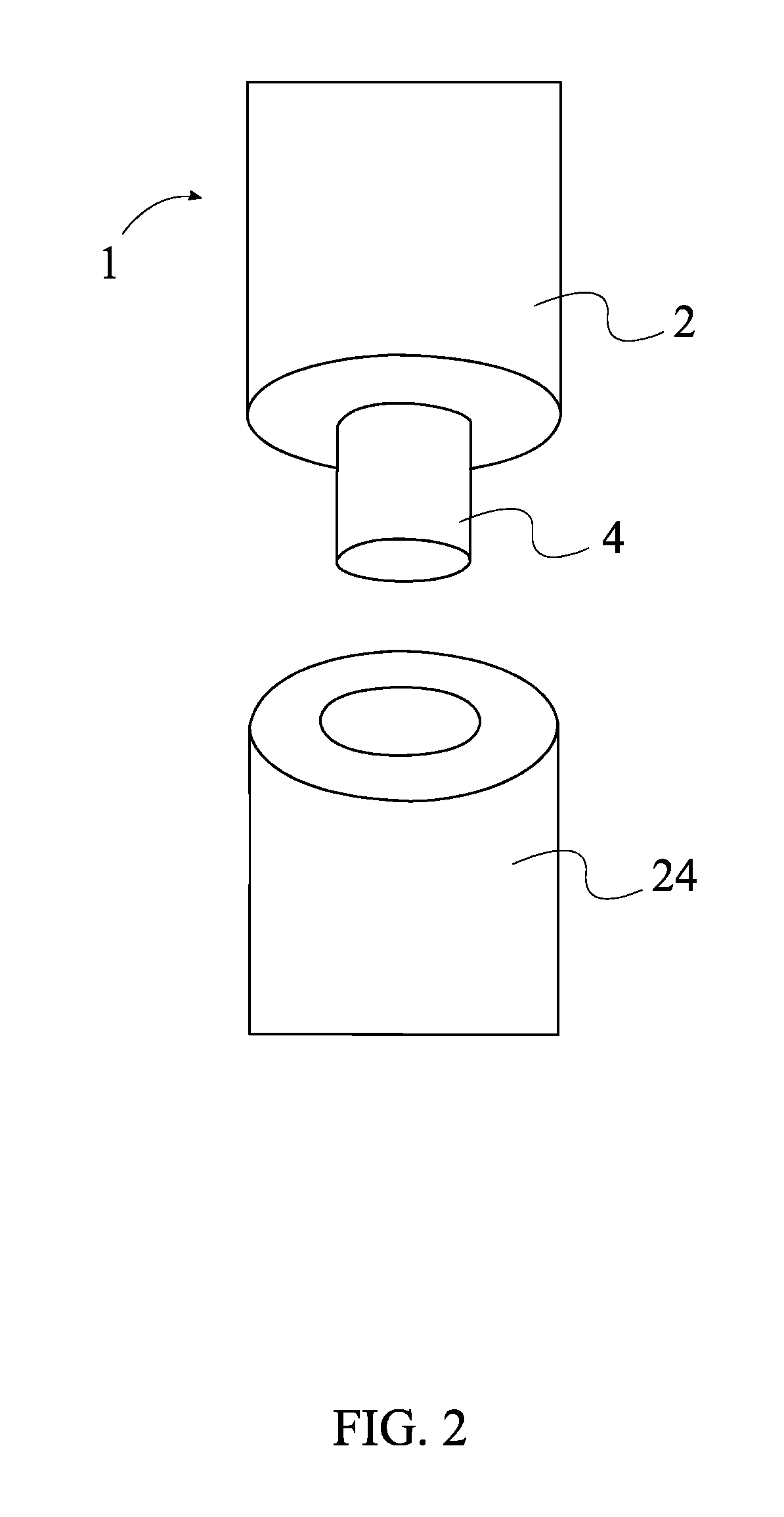

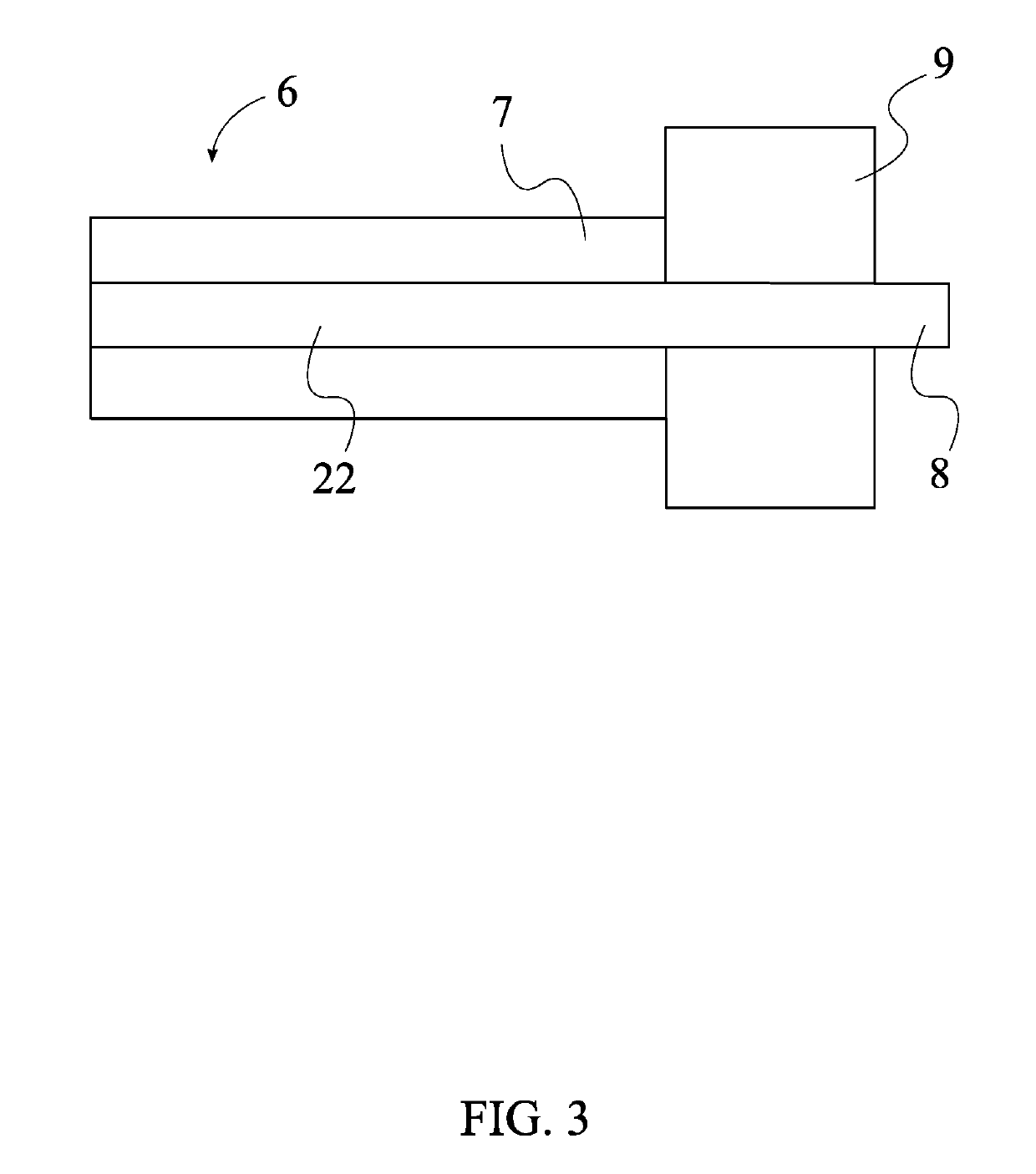

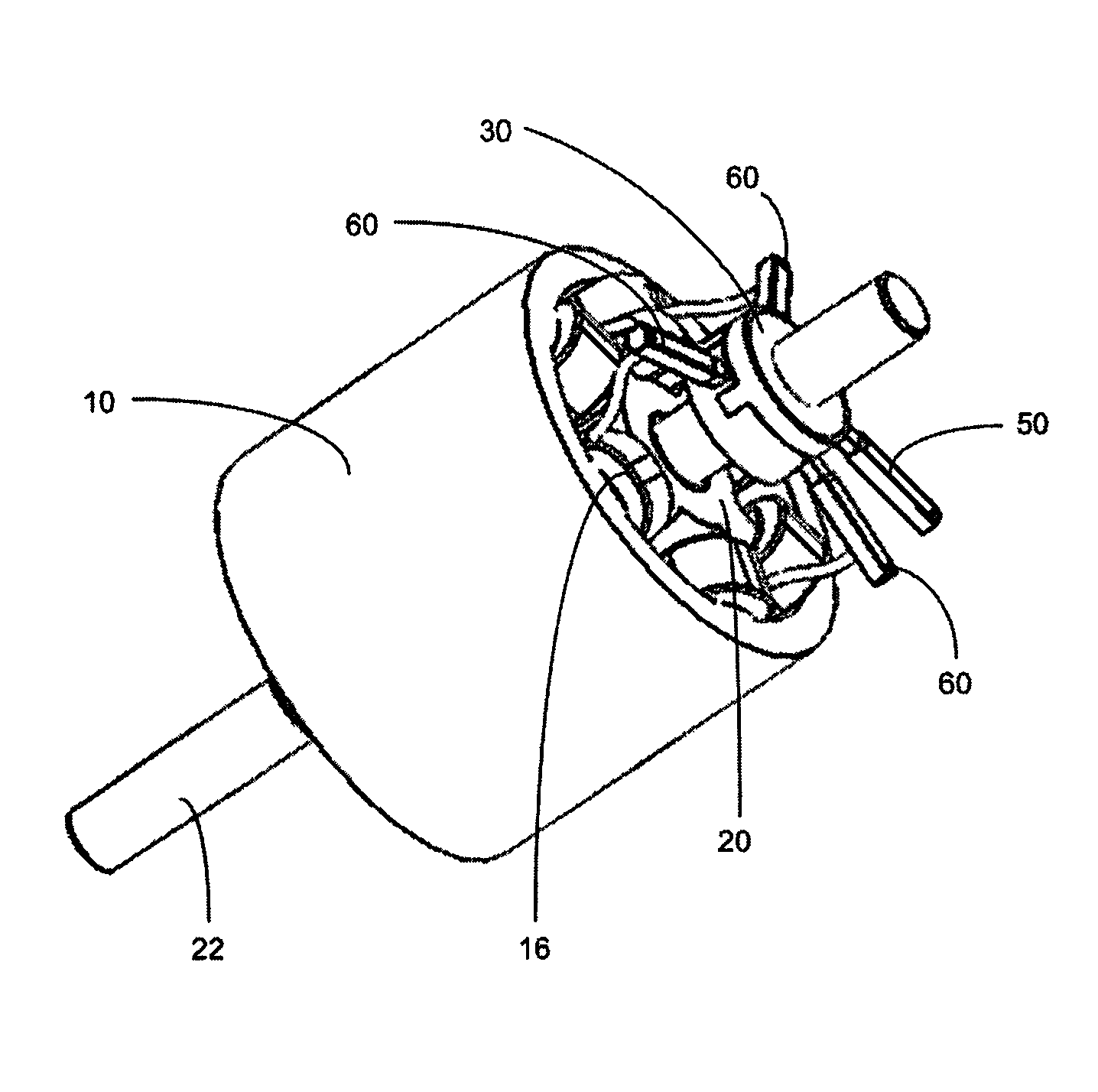

Electromagnetic Rotary Motor

ActiveUS20190173361A1Association with control/drive circuitsAssociation with grounding devicesDrive shaftMechanical energy

An electromagnetic rotary motor is an apparatus used to convert electrical energy into mechanical energy. The apparatus is also configured to utilize minimal electrical power input due to the arrangement of components and the cycle for energy conversion. The apparatus includes a drive shaft, an input terminal, an annular housing, a plurality of brushes, and a plurality of electromagnetic (EM) mechanisms. The drive shaft is a cylindrical extrusion that rotates about its axis. The input terminal is a connector which provides electrical potential to the plurality of brushes through the drive shaft. The annular housing is a ring-shaped enclosure that protects the components of the apparatus. The plurality of EM mechanisms is a set of electrical components that react to the influence of the plurality of brushes. The general configuration of the aforementioned components allows the apparatus to efficiently and effectively convert electrical energy into mechanical energy.

Owner:BLANKENSHIP MAXWELL JORDAN

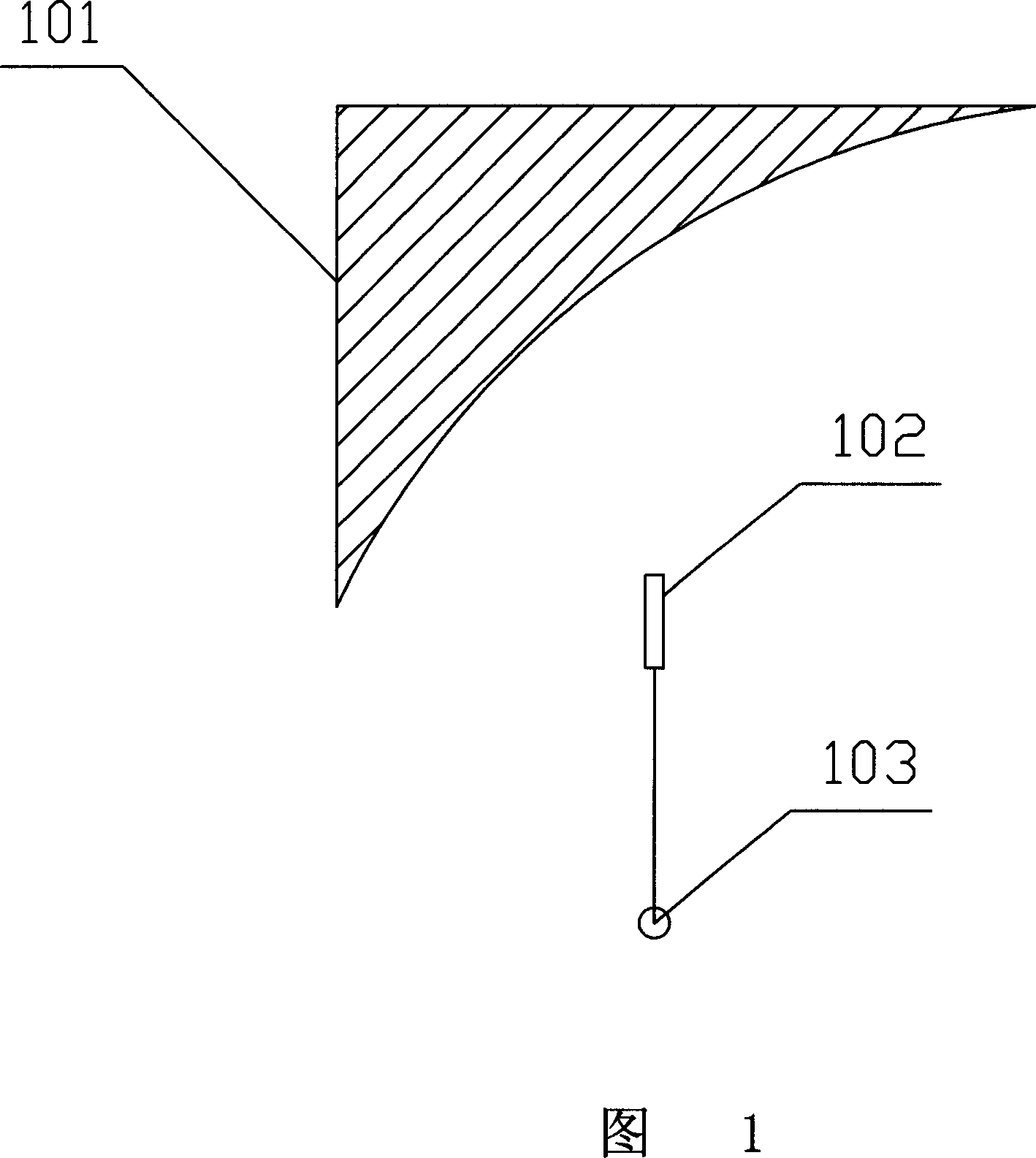

All-magnetic power machine with electromagnetic pulse flux control device

InactiveCN104953896ASmooth continuous rotationPlay a role in changing magnetismDC motor speed/torque controlMagnetic circuit stationary partsElectromagnetic pulseEngineering

The invention relates to an all-magnetic power machine with an electromagnetic pulse flux control device. The all-magnetic power machine adopts a rotating outer casing and inner stator type or a fixed outer casing and rotating inner pivot type; the all-magnetic power machine comprises the stator, turntables, an electromagnetic induction pulse programming governor, composite heads, a power generator, a speed regulator and an electric energy storage component; a closed magnetic circuit formed by combination of a plurality of permanent magnets and stator iron rings is mounted on the surface of a stator, and the U-shaped composite heads are mounted on the stator iron rings; the electric energy storage component is used for supplying electricity, so that after the all-magnetic power machine is started, the power generator works to charge the electric energy storage component; in the working process of the power generator, controllable induced pulse electromagnetic fields are generated by a pulse regulator to play a variable magnetism role; the generated electromagnetic fields have a stacking disturbing phenomenon to reduce the magnetic resistance; smooth continuous rotating of the permanent magnets correspondingly mounted on the turntables under the action of magnetic energy acting force is facilitated; the electric energy storage component needs to be supplemented with electricity in time according to an electric quantity indicator light; the use time of the electric energy storage component after being charged fully each time is prolonged; the quantity of traditional storage batteries can be reduced. The all-magnetic power machine is an environmental-friendly new renewable energy resource.

Owner:章宪

Electromagnetic rotary motor

ActiveUS10811943B2Association with control/drive circuitsAssociation with grounding devicesElectric machineDrive shaft

An electromagnetic rotary motor is an apparatus used to convert electrical energy into mechanical energy. The apparatus is also configured to utilize minimal electrical power input due to the arrangement of components and the cycle for energy conversion. The apparatus includes a drive shaft, an input terminal, an annular housing, a plurality of brushes, and a plurality of electromagnetic (EM) mechanisms. The drive shaft is a cylindrical extrusion that rotates about its axis. The input terminal is a connector which provides electrical potential to the plurality of brushes through the drive shaft. The annular housing is a ring-shaped enclosure that protects the components of the apparatus. The plurality of EM mechanisms is a set of electrical components that react to the influence of the plurality of brushes.

Owner:BLANKENSHIP MAXWELL JORDAN

Brushed direct current electric motor with salient pole rotor

InactiveUS9099909B2Improve production efficiencyRotary current collectorDC commutatorAlternate currentBrushed DC electric motor

A brush direct current motor has a stator with a plurality of coils that correspond to a number of stator windings, a rotor with a number of poles, and a commutator. The commutator is connected to a first terminal of a direct current power source to convert the power into N phase alternating current. One end of each stator winding is connected to a respective phase of the alternating current via a brush and the other ends of the stator windings are connected to the second terminal of the direct current power source.

Owner:JOHNSON ELECTRIC SA

Multiple magnetic wheel motor

InactiveCN101488695BMagnetic circuit rotating partsSupports/enclosures/casingsMagnetic tension forceMagnetic poles

The invention relates to an engine provided with a plurality of magnet-wheels, which consists of a permanent magnet (1), an electromagnet (2), an electromagnet seat (3), an electric conduction copper ring (4), a straight shaft (5), a bearing (6), an end cover (7), a shell (8), a spoked wheel (9), a spoke (10), a carbon brush holder (11) and a carbon brush (12), and has the advantages of light weight, simple structure, no tail gas emission, energy conservation, etc. The engine combines part of the technology of a steam turbine with magnetic force, and has the advantages of large arm of force and moment as well as no dead center. By properly selecting the number of the spoked wheels (9) and the number of each line of spokes (10), the area of a magnetic pole, the intensity of a magnetic field and the length of the spoke (10) are properly chosen, and the engine having the required power can be designed, thus making contribution to opening up new power source. The principle of the action of the engine is that repulsion force is generated between the like magnetic poles which are the permanent magnet (1) and the electromagnet (2), component force which is vertical to the radial direction of the spoke is generated when the repulsion force is transmitted to the inclined plane at the end of the spoke (10) used for fixing the permanent magnet (1), and moment is formed; while, the same moment with opposite direction is generated by another spoke (10) which is symmetrical with the spoke (10) along the radial direction; the two moments form torque force to lead the straight shaft (5) to rotate.

Owner:孙宗德

Energy-saving motor

InactiveCN101056026AImprove work efficiencyMake full use of the magnetic forceDC interruptersMagnetic tension forceEnergy source

The present invention provides an energy-saving electric motor to solve the problems of serious waste of magnetic force in the prior electric motor. An inner rotor made of the material having no magnetoconductivity, a permanent-magnet equally spaced on the circle, and a magnetizer positioned in the center of two adjacent permanent-magnets are provided in the present invention; two or more rotors made of the material having magnetoconductivity are distributed on a same circle of the external of the inner rotor, and said rotors that near the axes of the inner rotor is arc shaped, and the distances from the two endpoints to the axes of the inner rotor are different, wherein, the end that closer to the axes is provided with an electromagnet, and the electromagnets of any two stators are not adjacent. The energy-saving electric motor provided in the present invention has took full use of the function of magnetic force comparing the prior art, and the magnetic force needed in the rotating of the rotators is reduced on the premise of not adding equipment. As a result, the energy sources are saved and the efficiency of the electric motor is improved.

Owner:郭振中

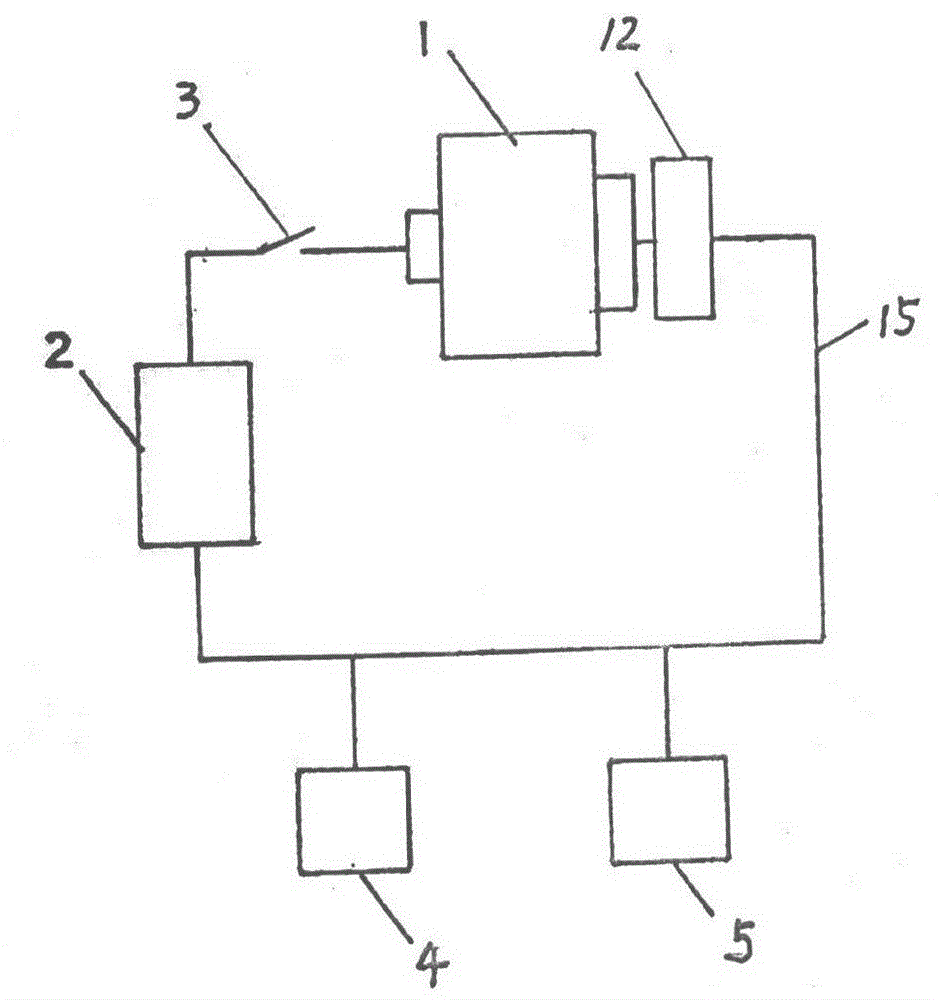

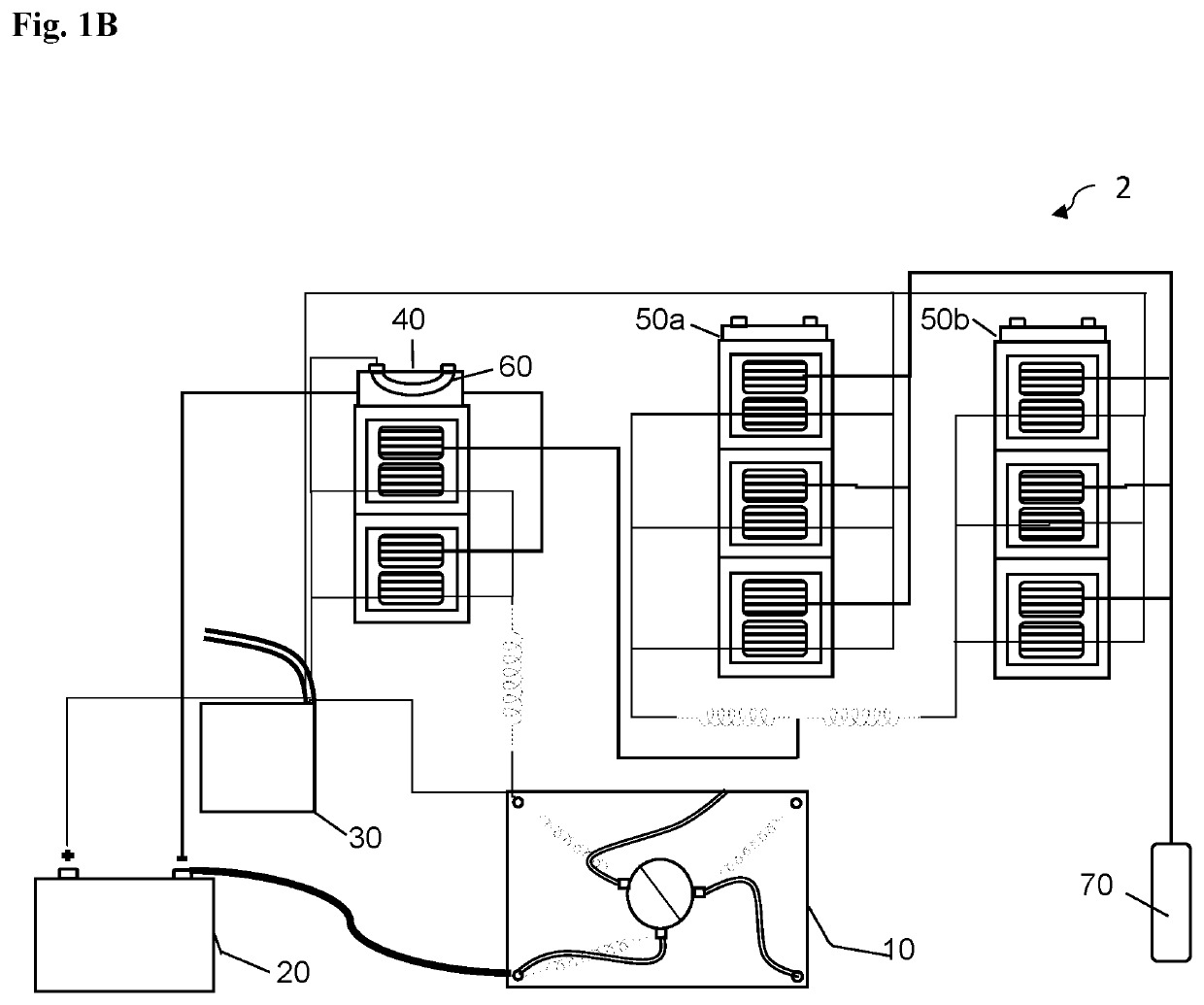

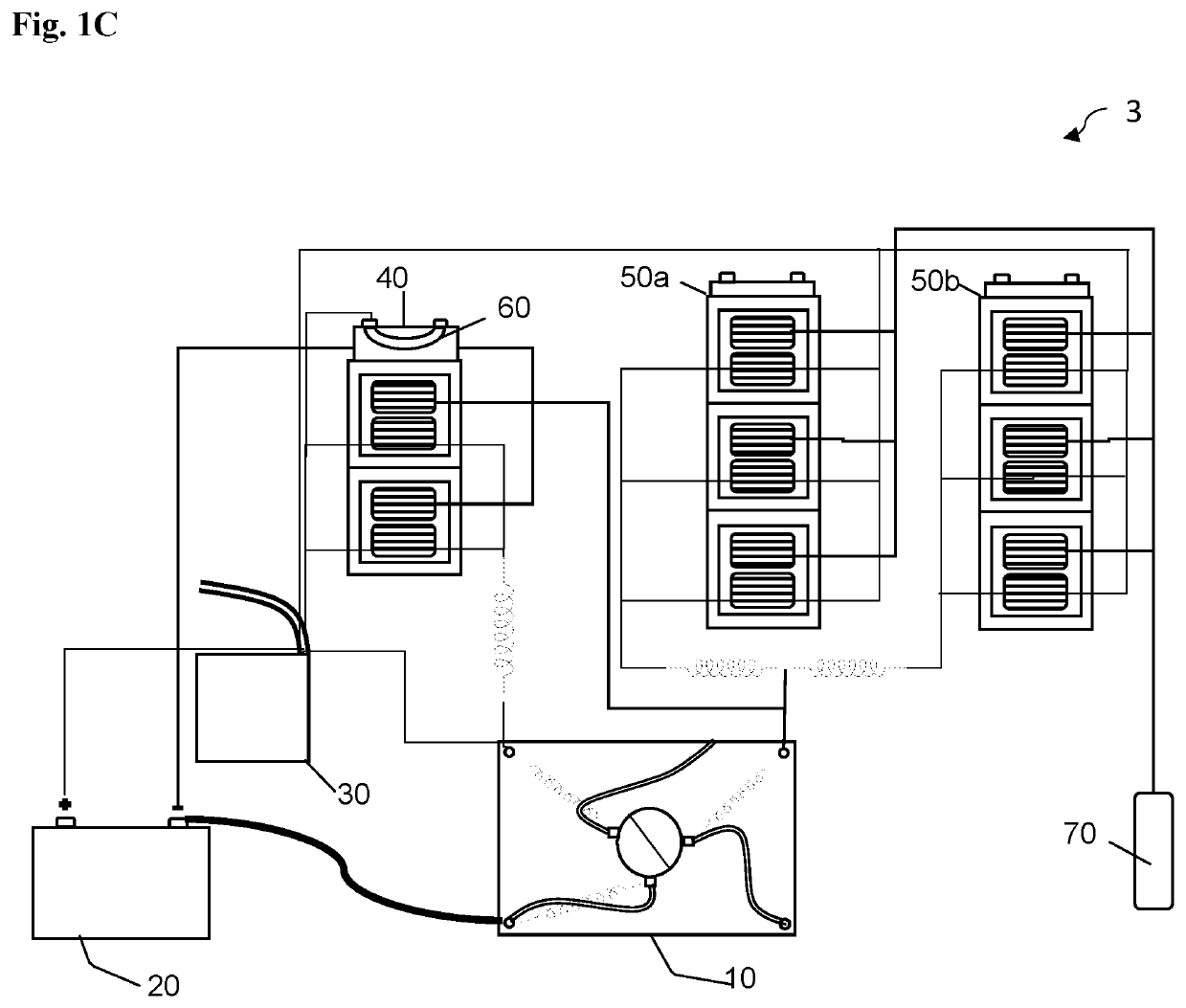

Recharging electric generator system

ActiveUS11196332B1Reduce in quantityPrevent over-chargingBatteries circuit arrangementsAc-dc conversion without reversalTransformerAlternating current

A recharging electric generator system which generates electrical energy and recharges itself, and methods thereof. A recharging electric generator system comprises at least one inverting apparatus; at least one power source / storage device to start the system and store electrical energy; at least one switching device; at least one transformer unit to adjust the voltage of the electrical energy, at least one rectifying unit to convert a portion of the electrical energy from alternating current to direct current and to transfer electrical energy to recharge the at least one power source / storage device; and at least one power outlet / output terminal to distribute electrical energy for further use. A recharging electric generator system seeks to provide of renewable source of energy which could be applied to different sectors and is conducive to conditions in both developed and developing countries.

Owner:GARDINER COTTRELL SALISBURY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com