Tile type magnetic-fluxleakage permanent magnet electric motor

A technology of permanent magnets and magnetic flux leakage, which is applied in the direction of electrical components, electromechanical devices, and static parts of magnetic circuits, can solve problems such as failure to generate, and achieve high power-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

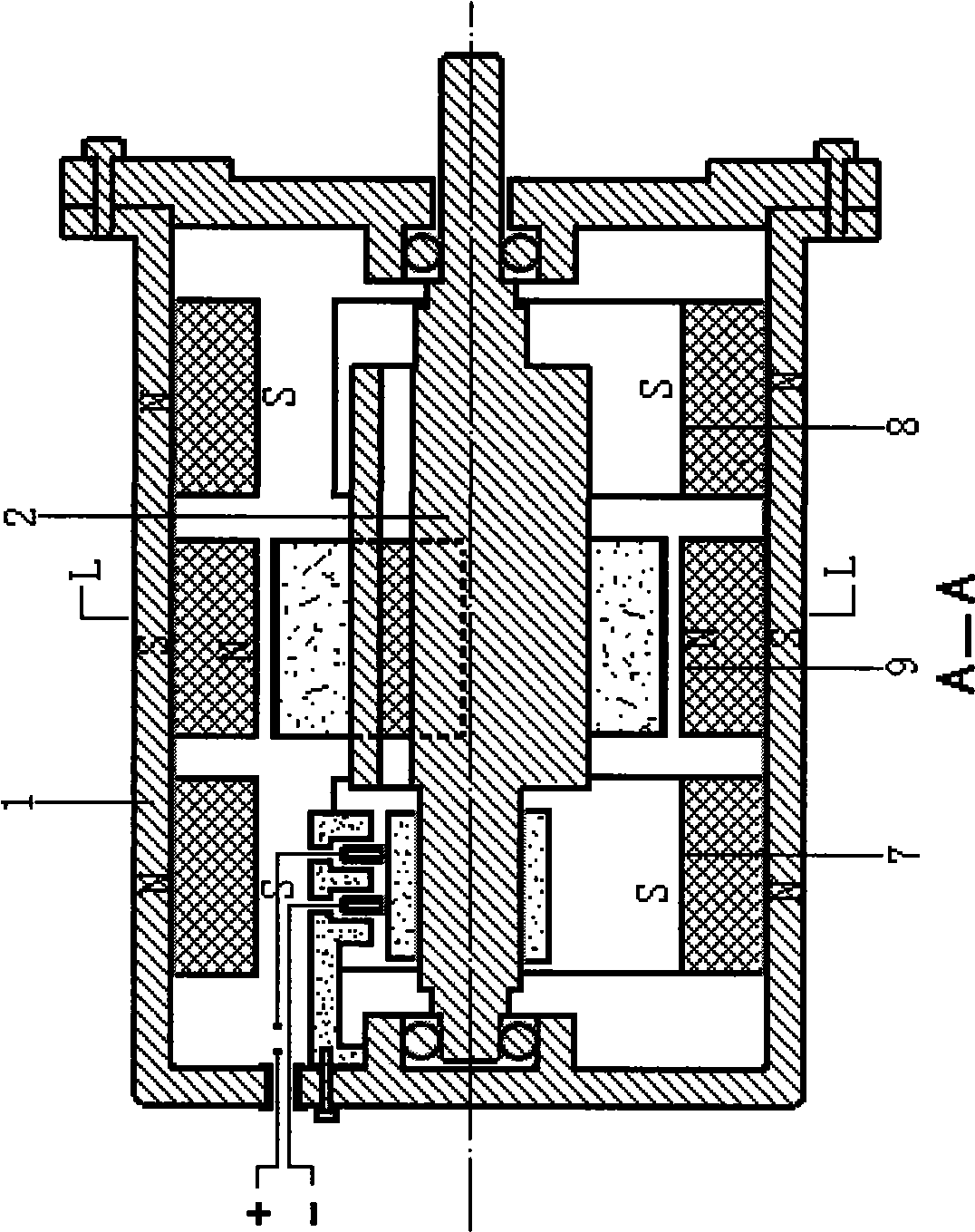

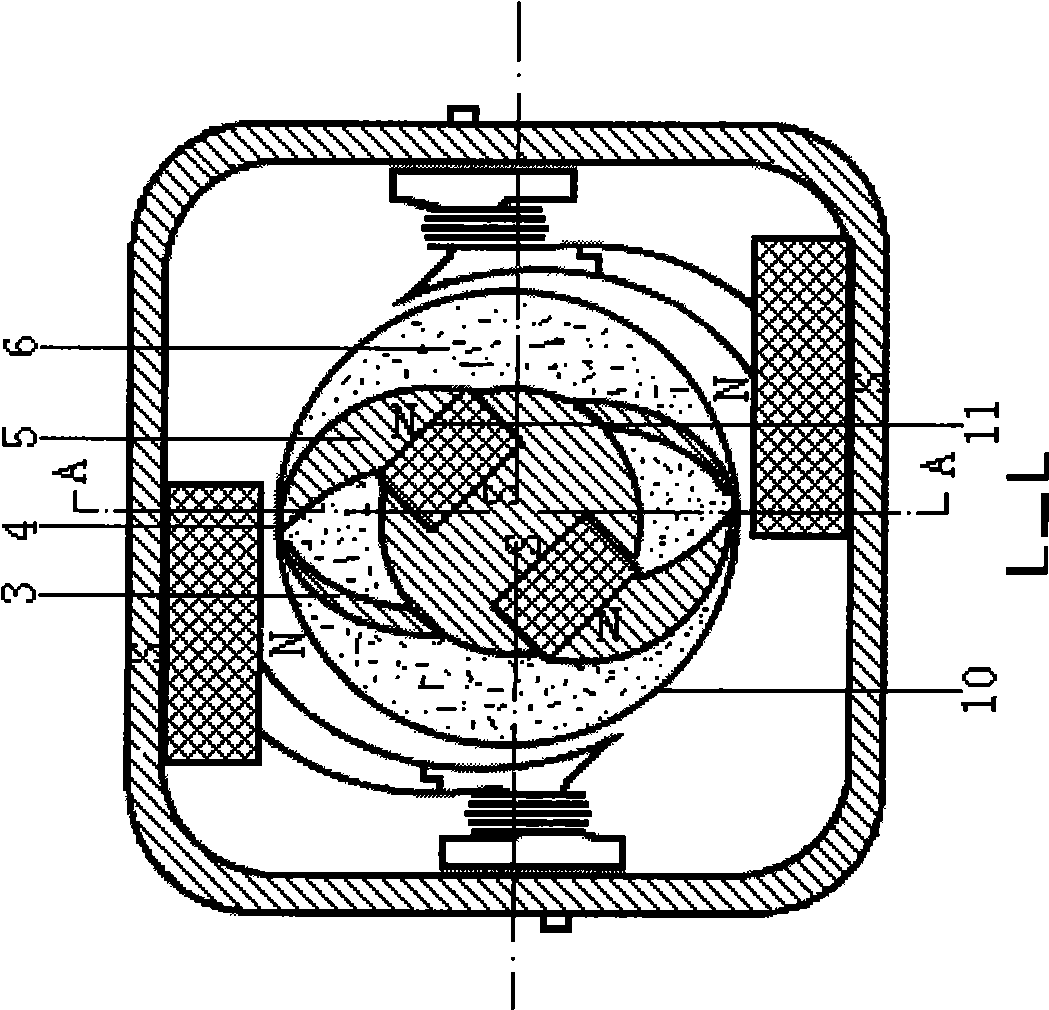

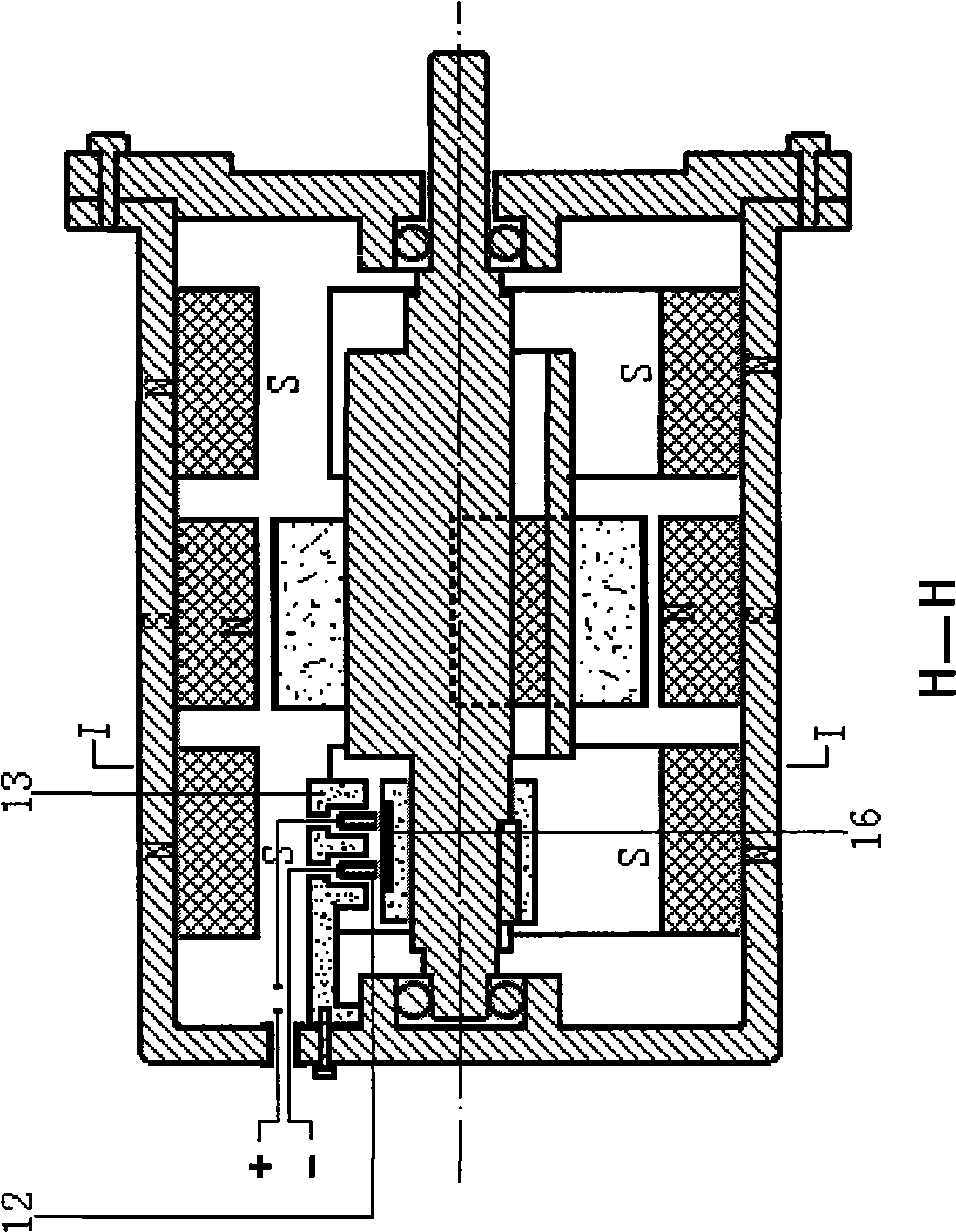

[0012] A tile-type flux leakage permanent magnet motor comprises a stator (1), a rotor (2), a DC electromagnetic coil and accessories. It is characterized in that: the permanent magnet pole face of the rotor is a rectangular permanent magnet facing inward and outward, which is fixed in the groove of the iron rotor; , the filling epoxy resin (6) is solidified, and the outer edge turns of the non-magnetic metal wire (10) are fixed, and the tile tip (4) is oriented to the direction of the magnetomotive force. The stator permanent magnet poles are fixed in three equal-sized, axially parallel, spaced apart, and the magnetic pole faces are rectangular permanent magnets facing inward and outward. It is the same-pole stator permanent magnet pole face (9), which is parallel to the width of the rotor tip tile-shaped leakage flux blunt iron (5). figure 1 ), the inner faces of the permanent magnets on both sides are the permanent magnet pole faces (7, 8) of the heteropolar stator, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com