Energy-saving motor

A technology of electromagnets and stators, which is applied in the direction of electrical components, electromechanical devices, DC interrupters, etc., can solve the problems of low efficiency and achieve the effects of saving energy, improving work efficiency, and reducing magnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

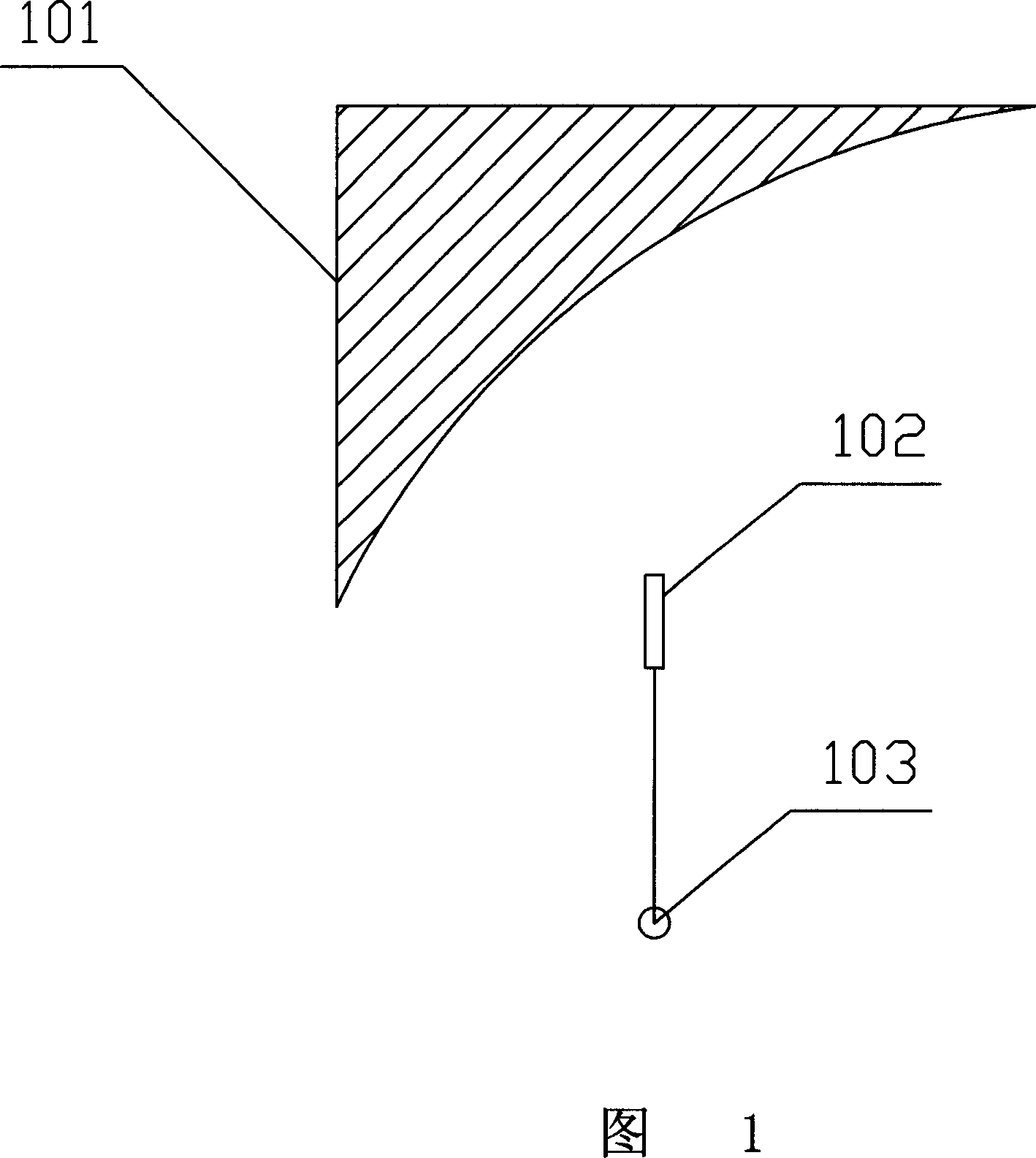

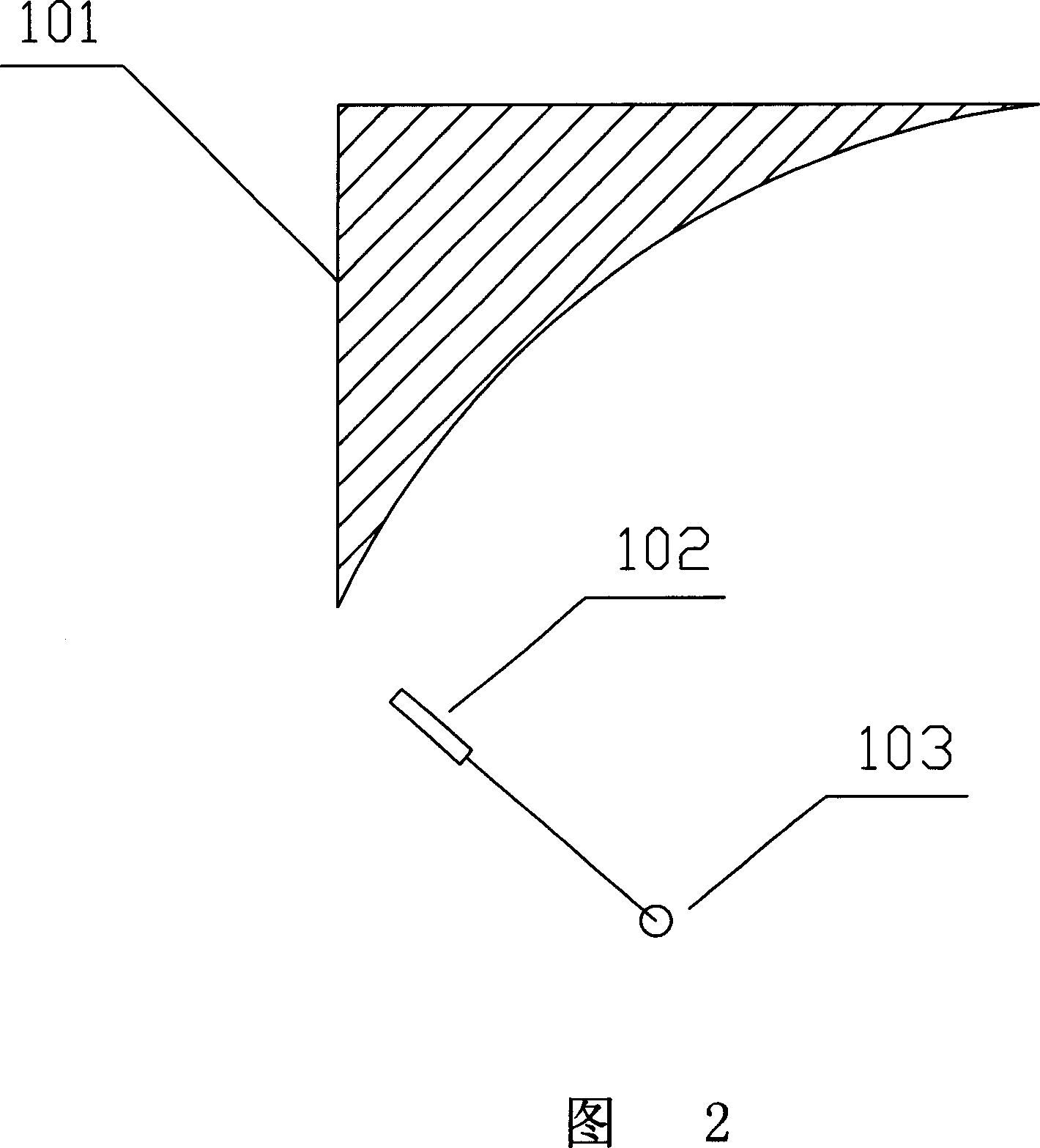

[0019] The theoretical basis of the present invention is that when the magnet can only move around the center of the circle, if it encounters an arc-shaped magnet, the position of the magnet closest to the center of the circle will generate the greatest suction force on the magnet. If do a test, set up an environment as shown in Figure 1, magnet 102 can rotate around circle center 103, be provided with an involute arc type magnetizer 101 outside the magnet, magnet 102 can move to this magnetizer closest to under the action of magnetic force The part of the center of the circle is the position shown in Figure 2.

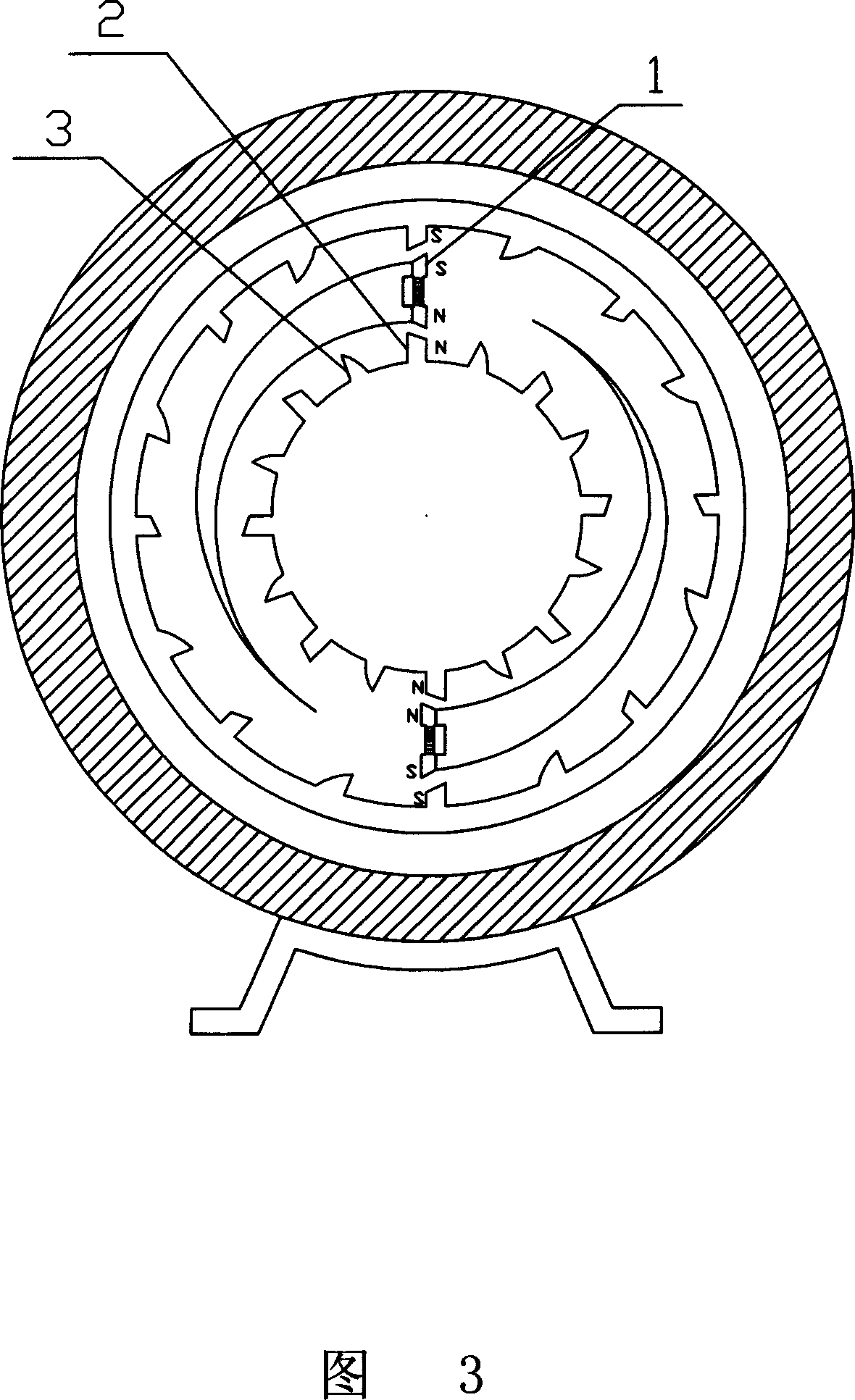

[0020] According to the above principles, the present invention proposes an energy-saving motor, including:

[0021] An inner rotor made of non-magnetic material, two or more permanent magnets are equidistantly arranged on the circumference of the inner rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com