DC exciting magnetic motor

A technology of excitation and magnetic force, which is applied in the field of DC excitation magnetic force motor, can solve the problems of restricting the development and application of DC motor, difficult to increase the power, complex structure, etc., and achieve the effects of energy saving, easy control, long working life and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

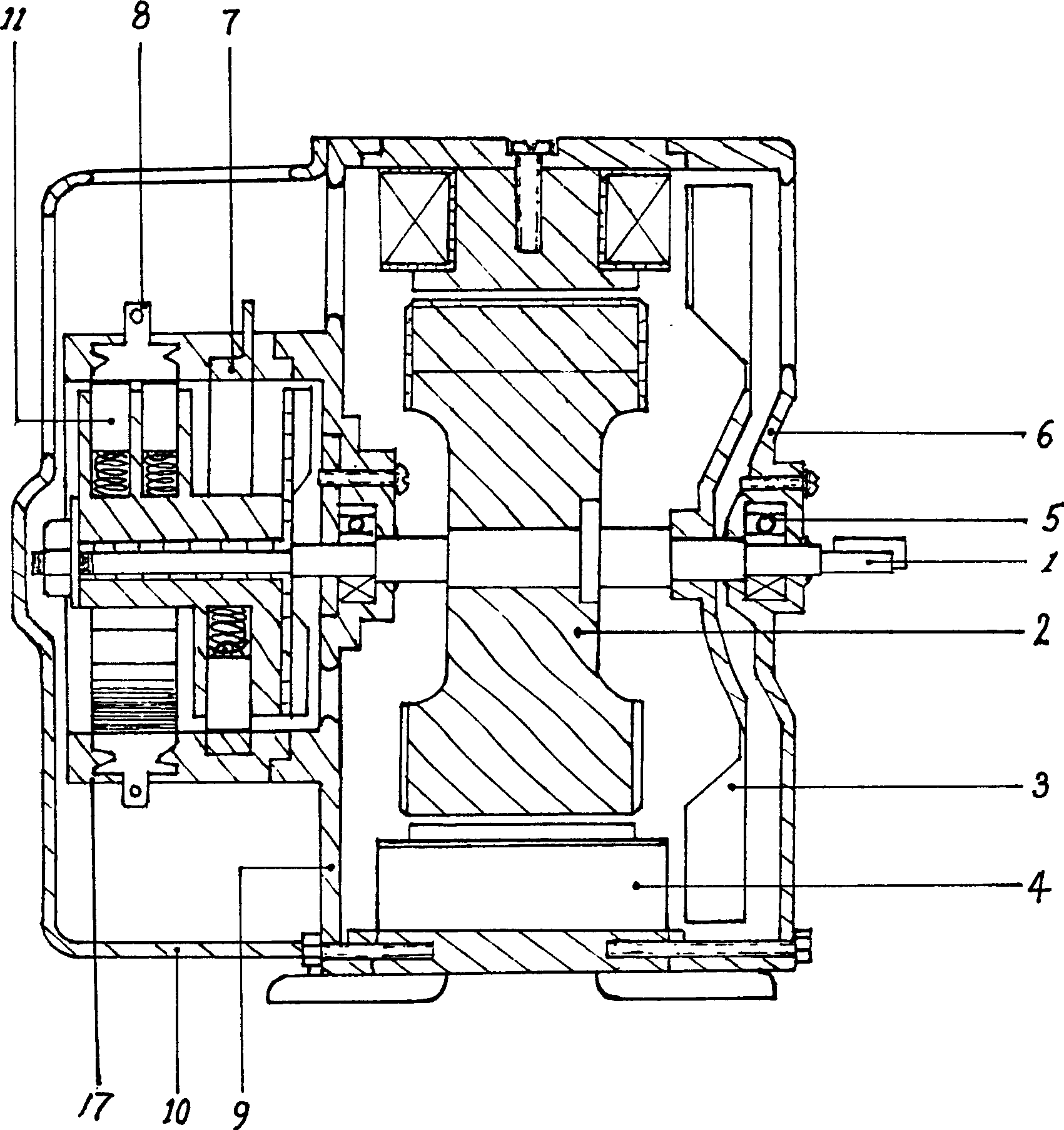

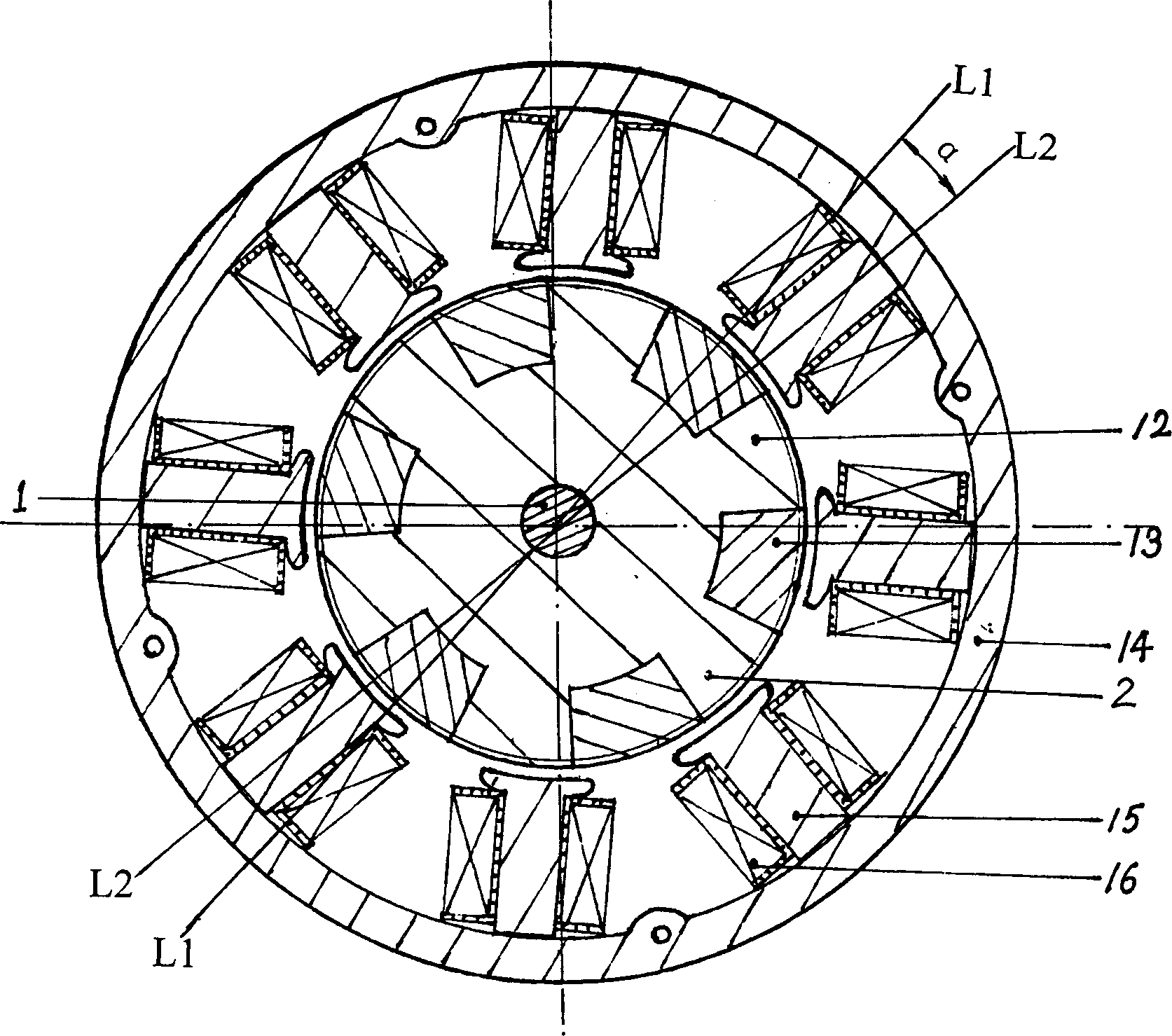

[0026] figure 1 is an embodiment of the present invention.

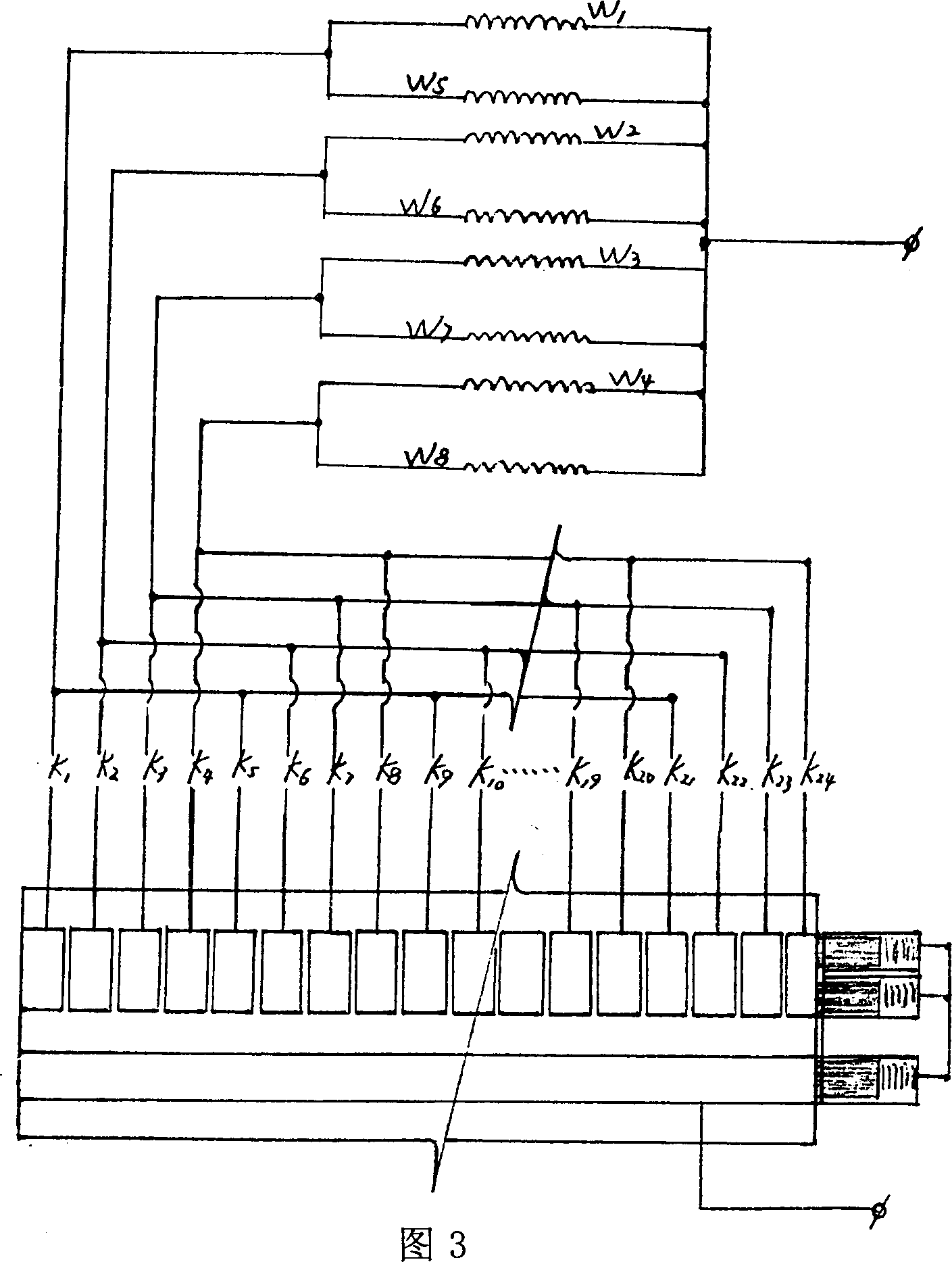

[0027]The working principle of the invention is to generate beneficial magnetic energy through the interaction of rotor and stator magnetic poles, and to implement regular and orderly magnetization control on the magnetic poles, so as to obtain directional torque. Except for the stator and machine base, other structural parts are made of non-magnetic metals and non-metallic materials. For the convenience of description, the rotor poles of this embodiment are permanent magnets, and the stator poles are excitation poles. In actual manufacturing, the rotor The magnetic poles can also be exciting magnetic poles, and the stator magnetic poles can also be permanent magnets, that is, the rotor can be used as a permanent magnetic pole, the stator can be used as an exciting magnetic pole, the rotor can be used as an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com