Brushed direct-current motor

A technology of brushed DC motors and brushes, applied in DC commutators, DC interrupters, circuits, etc., can solve problems such as poor mechanical properties and unsuitable strength for use, and achieve low cost, simple structure, and firm structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

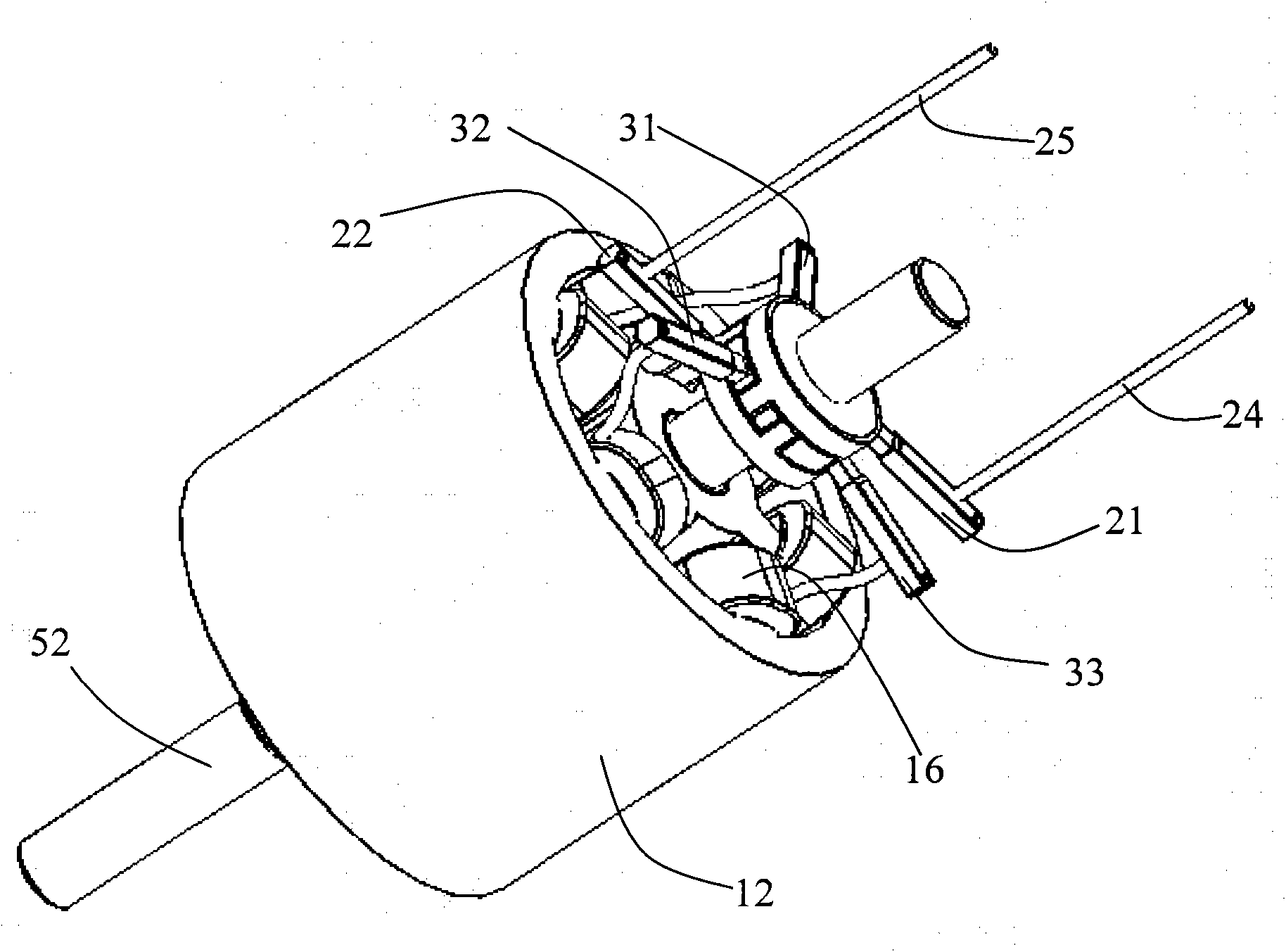

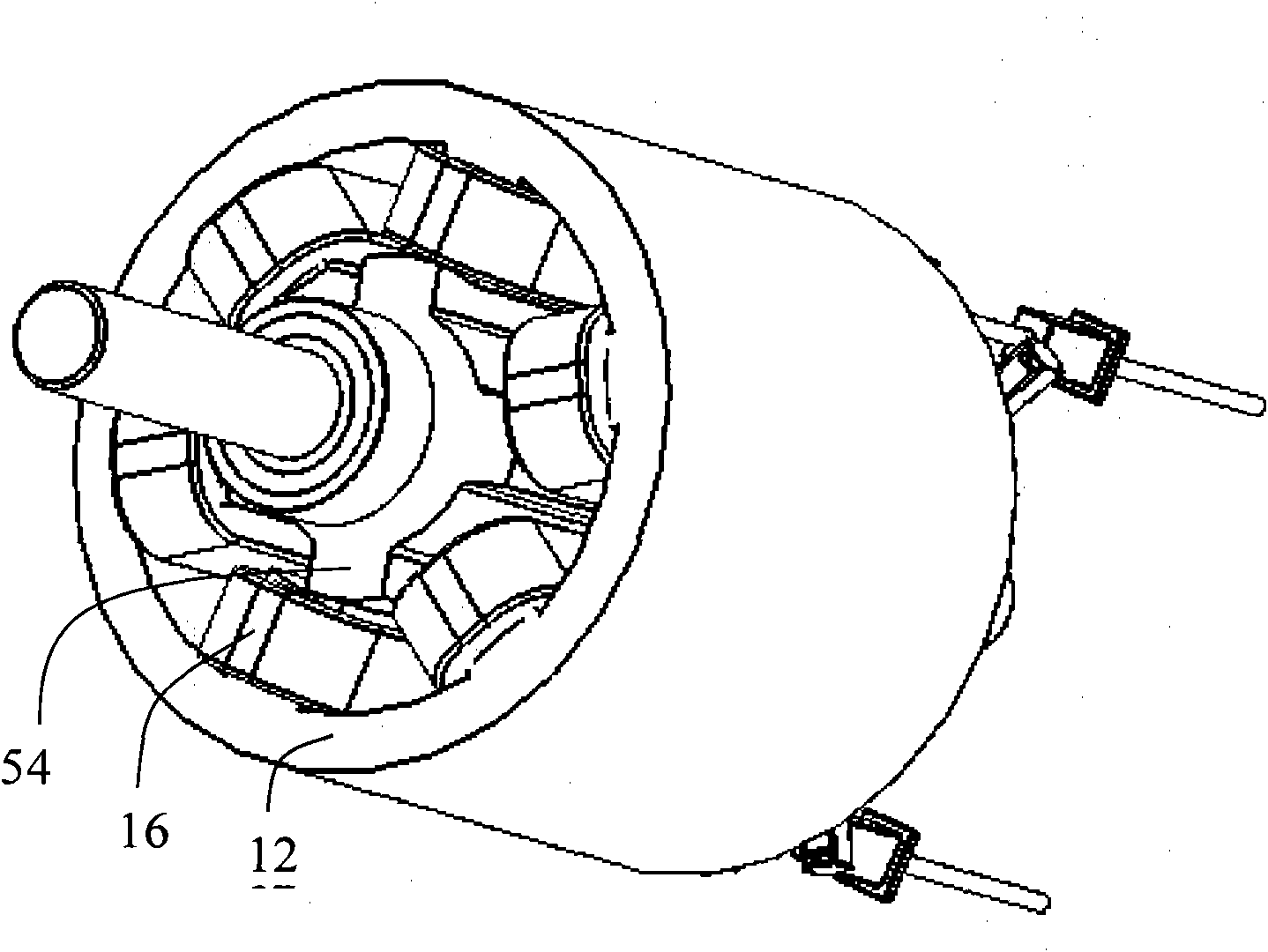

[0026] The technical solutions and other beneficial effects of the present invention will be apparent through the detailed description of specific embodiments of the present invention below in conjunction with the accompanying drawings.

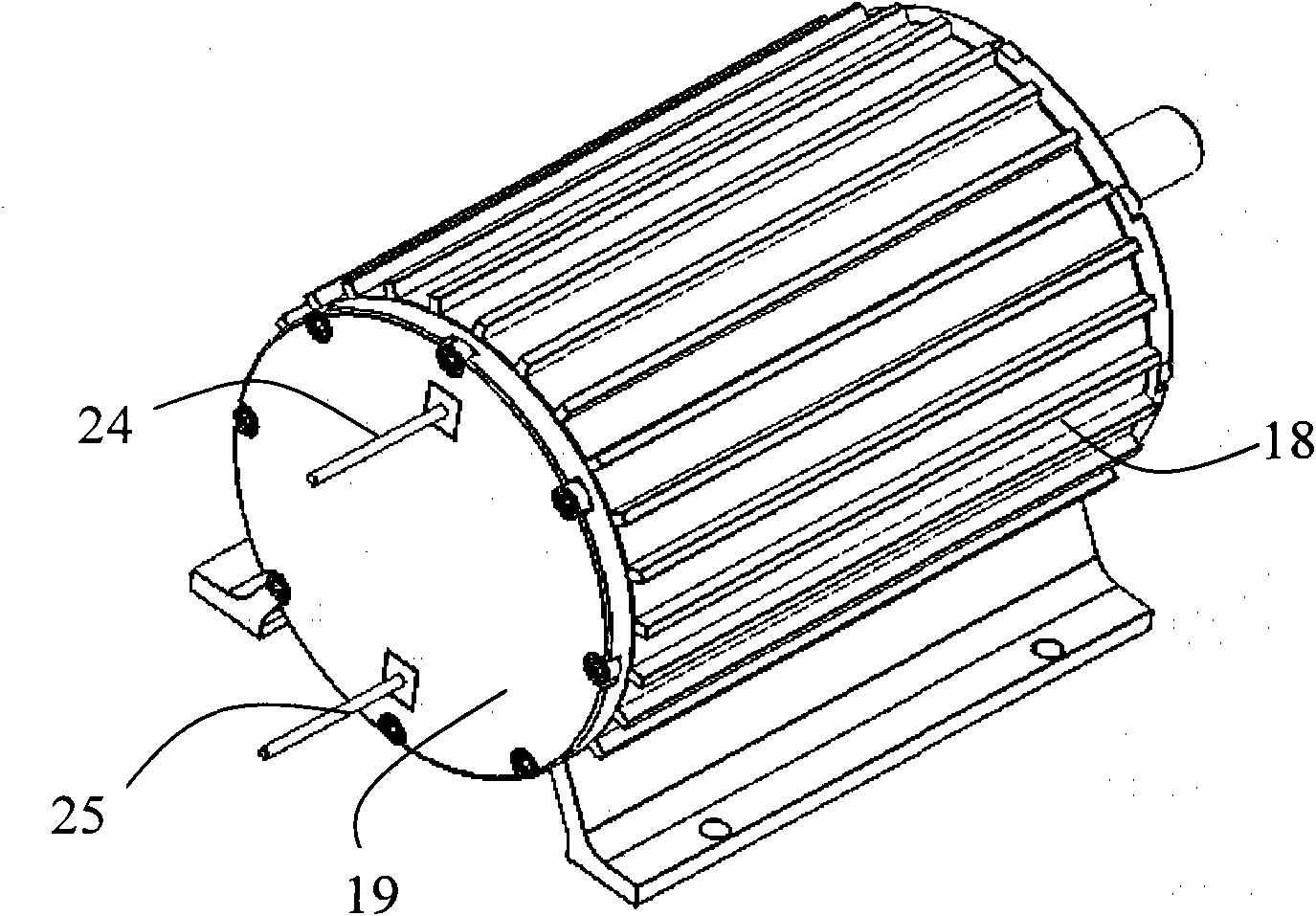

[0027] see Figure 1 to Figure 5 , a brushed DC motor according to an embodiment of the present invention includes a stator and a rotor rotatable relative to the stator.

[0028] The stator includes an annular iron core 12 made of magnetically permeable material, and several windings 16 wound on the inwardly extending stator salient poles 14 of the iron core 12. In this embodiment, the windings 16 are concentrated windings ( That is, each winding 16 is only wound on one salient pole 14), the stator is provided with six salient poles 14, winding slots are formed between adjacent salient poles 14, and a winding is wound on each salient pole 14, thereby forming 6 windings 16. Preferably, the winding 16 is wound by aluminum wires, of course, ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com