Two-dimensional laser scanning method for detecting overload of freight train

A technology of two-dimensional laser and scanning method, which is applied in the direction of railway car body parts, freight cars, measuring devices, etc., can solve the problems such as difficult to complete the measurement requirements, and achieve the effect of high precision, strong anti-interference ability and clear principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

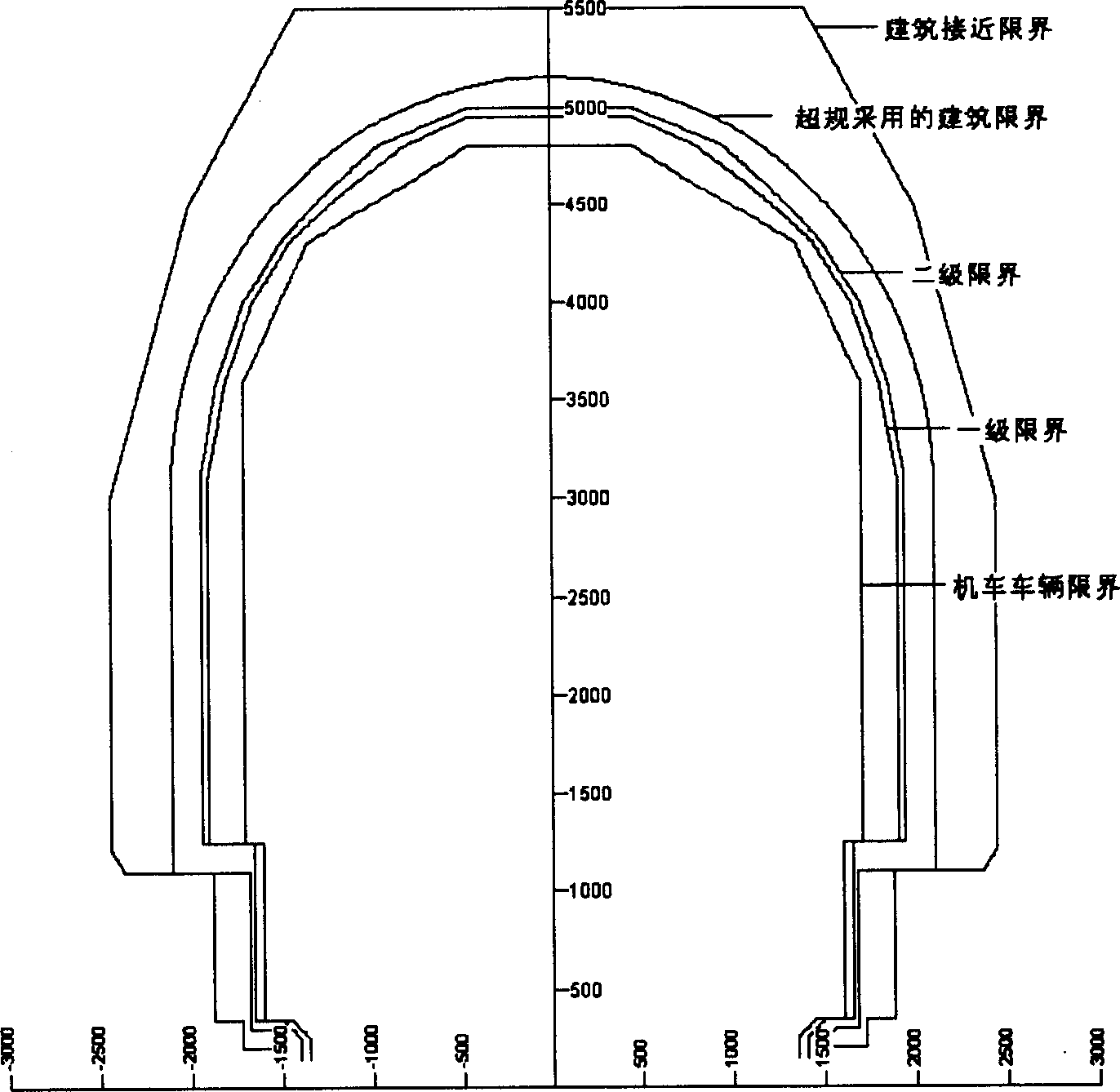

[0014] figure 1 Shown is a schematic representation of the various constraints related to vehicle loading. It can be seen from the figure that the boundaries at all levels are polygonal. At different heights, the allowed loading width is different; at different widths, the allowed loading height is also different. Therefore, only obtaining the maximum height and maximum width of the vehicle and cargo cannot accurately determine whether the vehicle and cargo exceed the limit. Only after the full-section contour data of vehicles and goods are measured and compared with the specified limit data can it be accurately judged whether the vehicles and goods are overrun, and the overrun position, overrun level and overrun value of the vehicle and goods can be provided in detail. information.

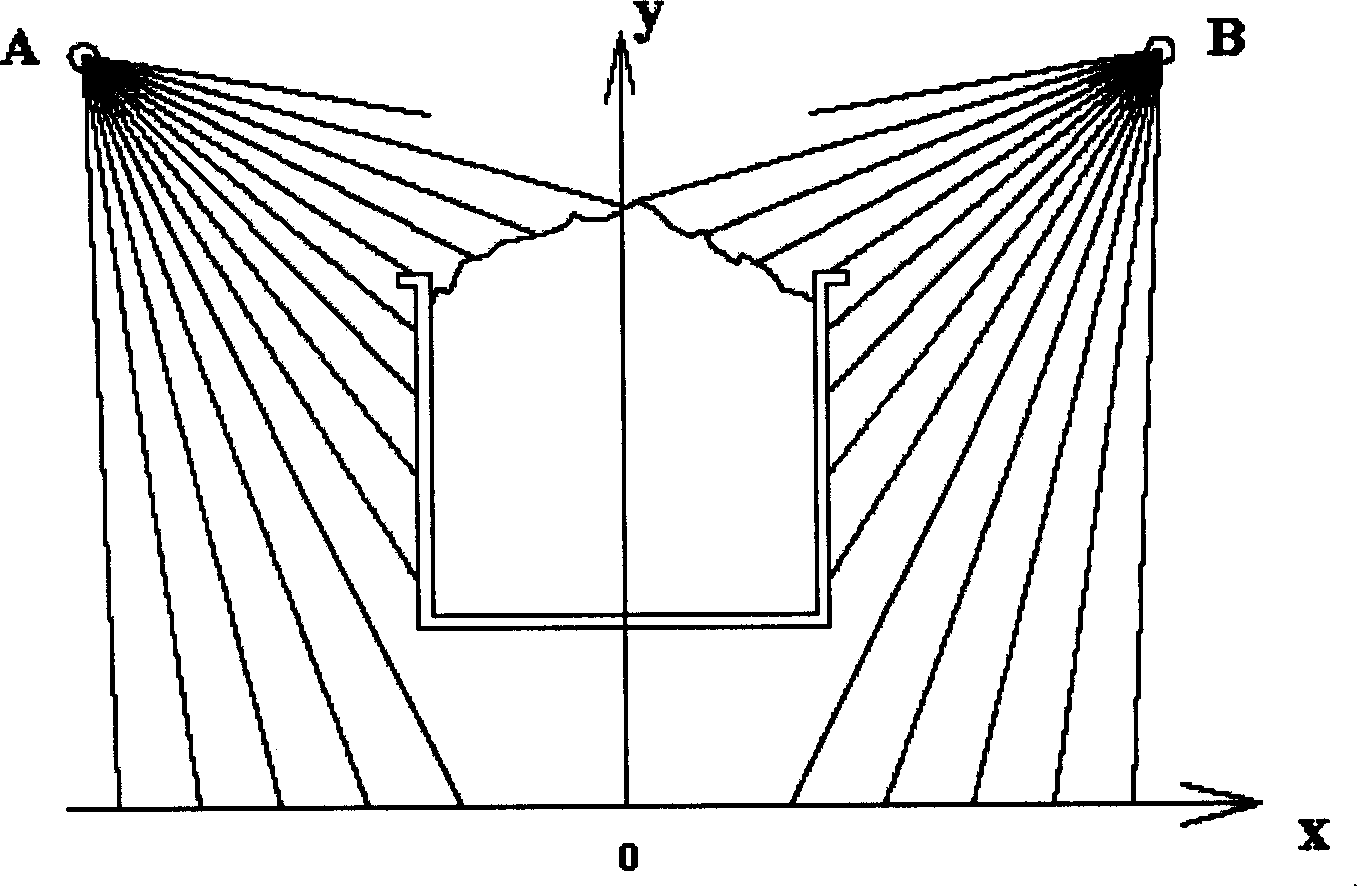

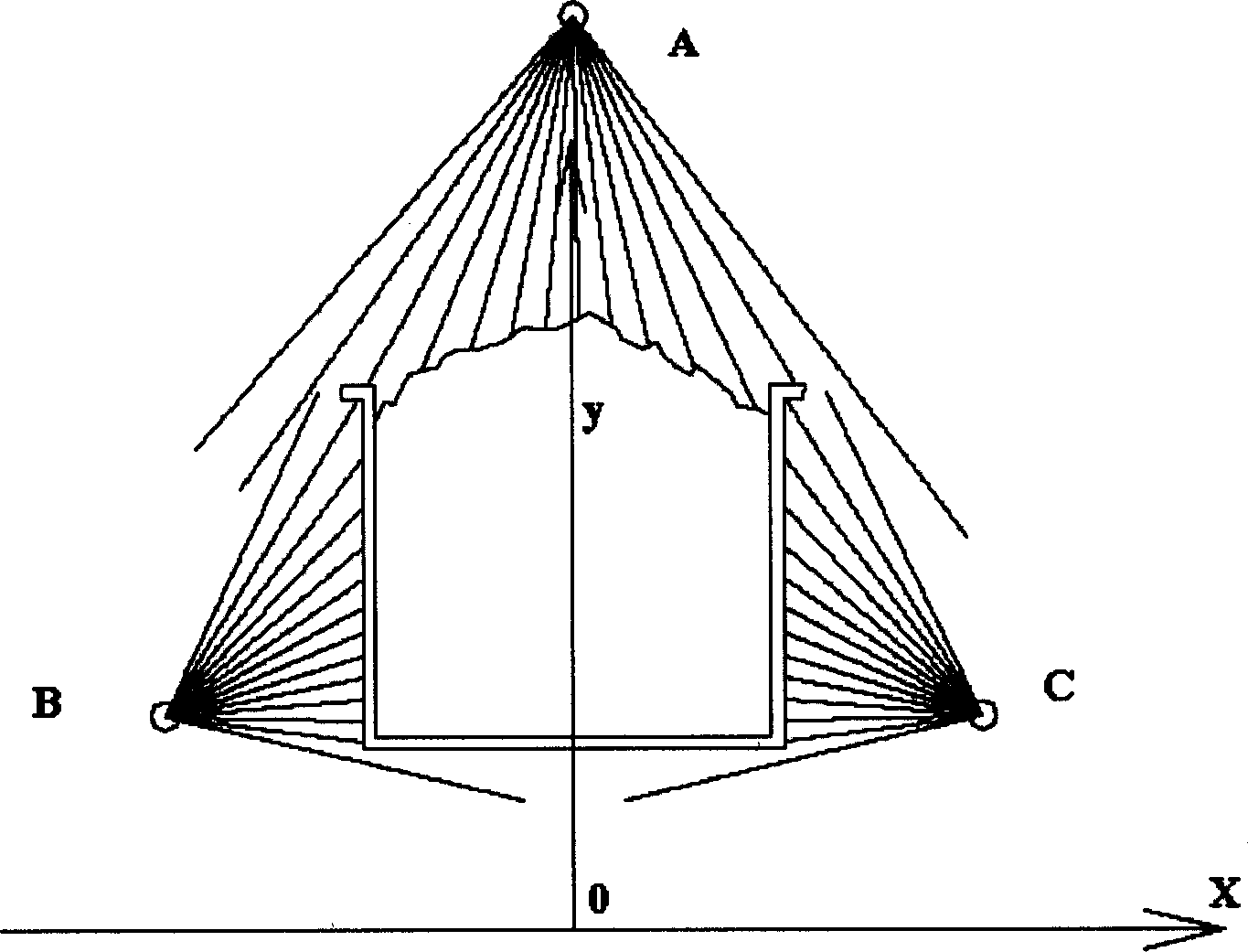

[0015] exist figure 2 In the shown embodiment, two laser sensors A and B are used, which is the most economical solution. The two sensors are arranged obliquely above the line, and each sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com