Method for the manufactur of a printed circuit and planar antenna manufactured with this printed circuit

A technology of printed circuit and planar antenna, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve problems such as substrate limitation, and achieve the effect of high conductivity, low resistance, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

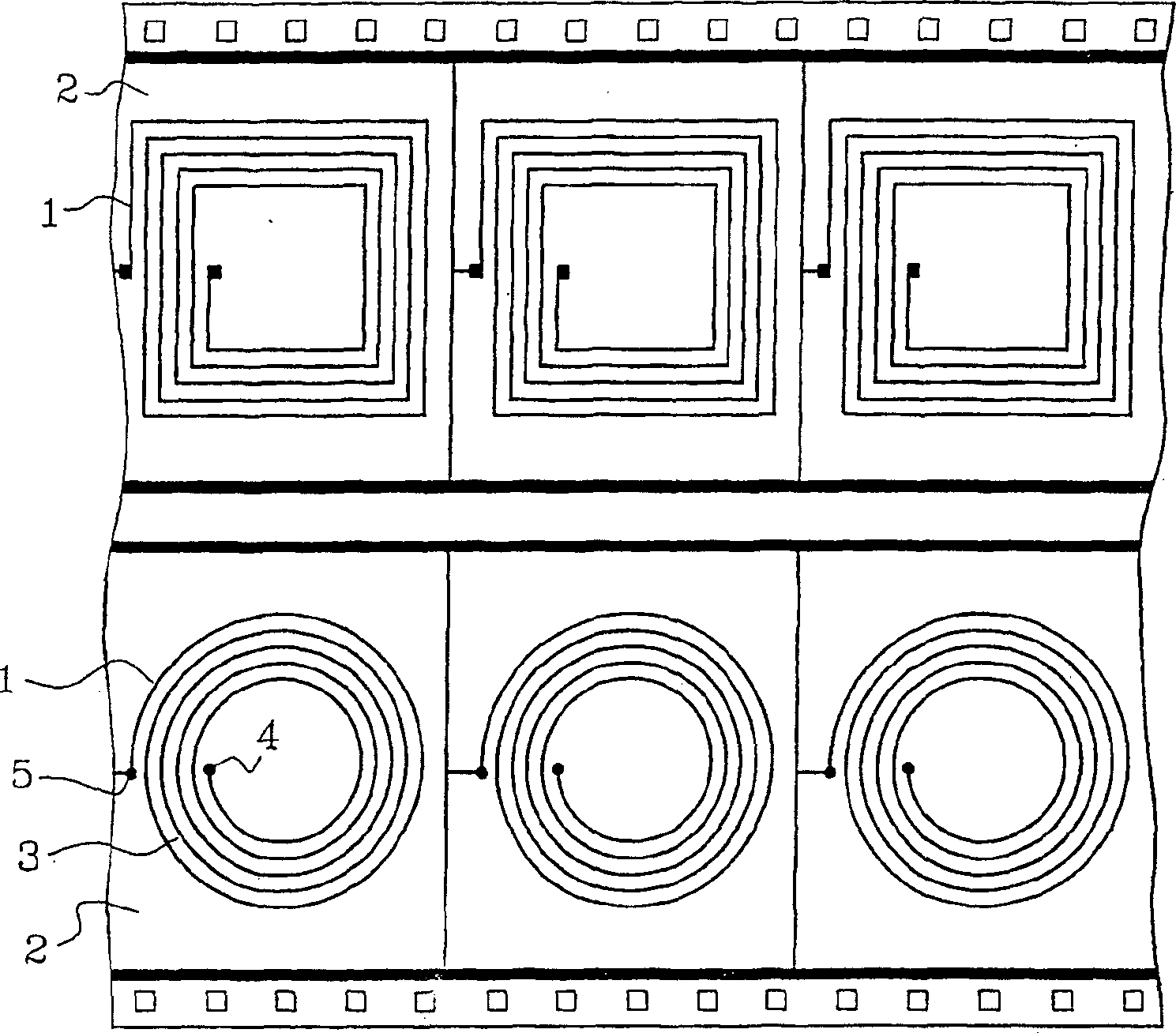

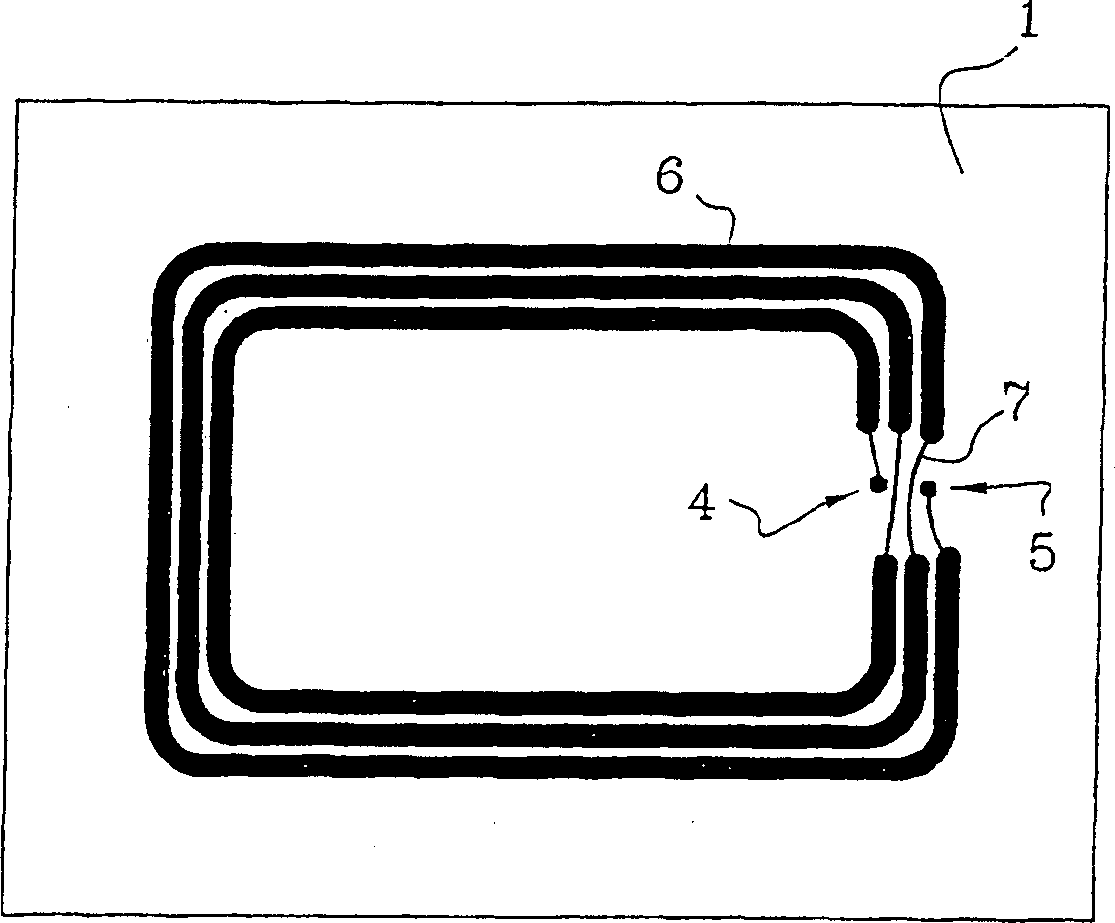

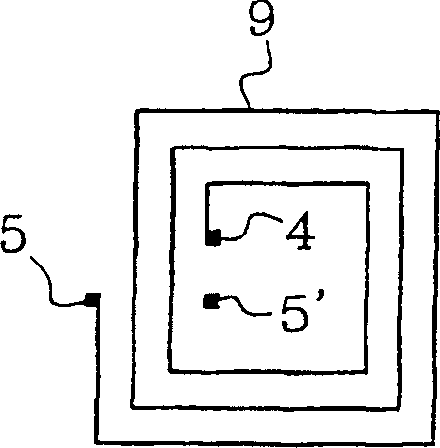

[0021] The manufacturing method according to the invention basically has two steps: in the first step, the pattern 1 of the circuit to be printed, i.e. in figure 1 The planar antenna in the case shown is coated on an insulating substrate 2 with conductive ink.

[0022] It has been found that not all conceivable printing methods are equally suitable for applying conductive ink.

[0023] According to the invention, a circuit pattern is produced on a gravure printed cylinder using electrochemical methods, chemical methods or laser etching methods. The conductive ink must be prepared in such a way that it is suitable for gravure printing from the viewpoint of the viscosity and other physical / chemical properties of the conductive ink. The electrical resistance of the circuit pattern produced by the gravure printing method is lower than that of the circuit pattern produced by other printing methods, so that an acceptable resistance is obtained for the final product with a thin meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com