Installing method for refrigerator and its temperature sensor

A technology of temperature sensor and installation method, which is applied in household refrigerators, household refrigeration devices, evaporators/condensers, etc., and can solve problems such as unstable installation, large changes in perceived temperature, and inability to quickly control the on/off of compressor 8 , to achieve the effect of easy transportation or storage, and shorten the opening/closing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail below with reference to the drawings.

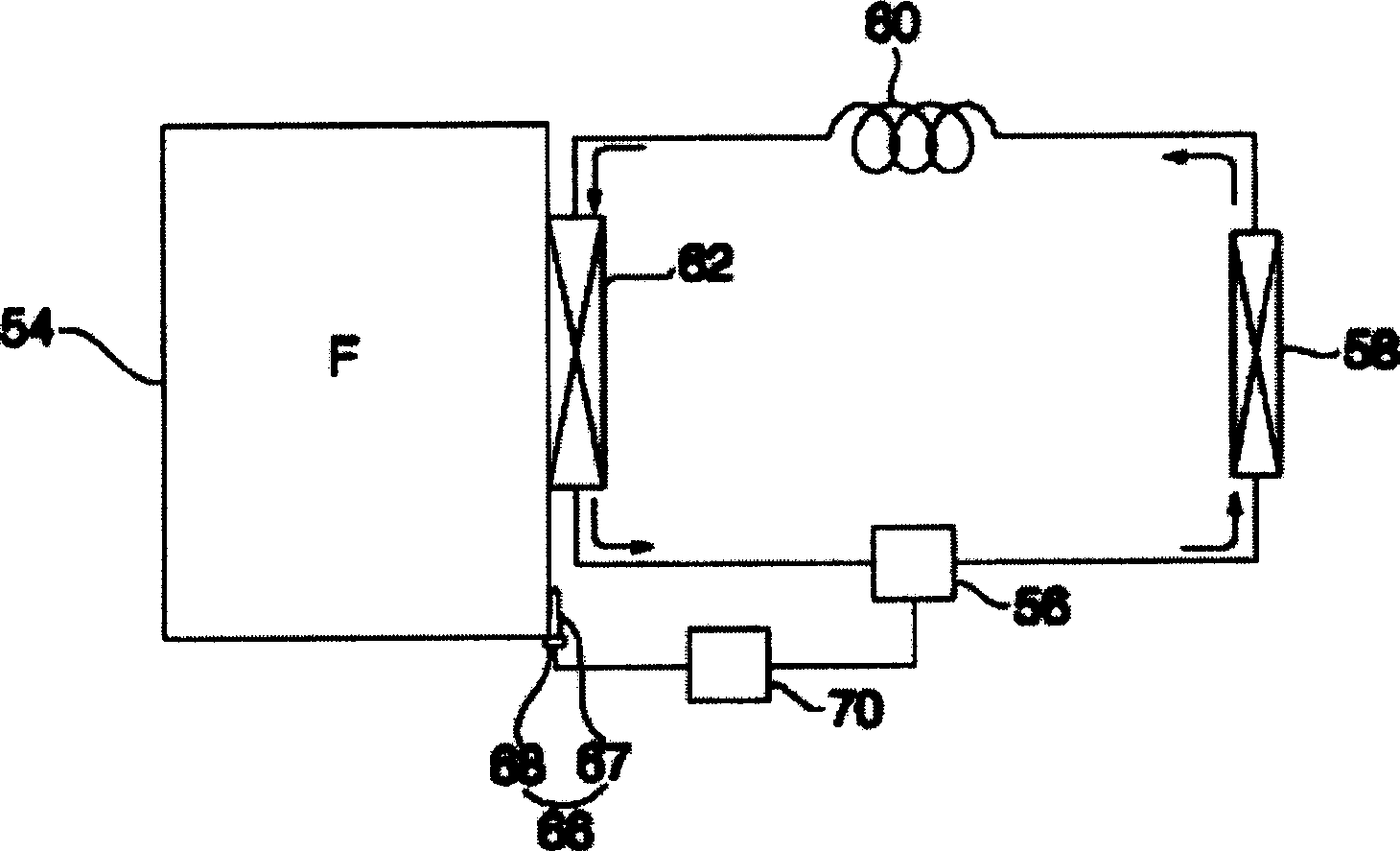

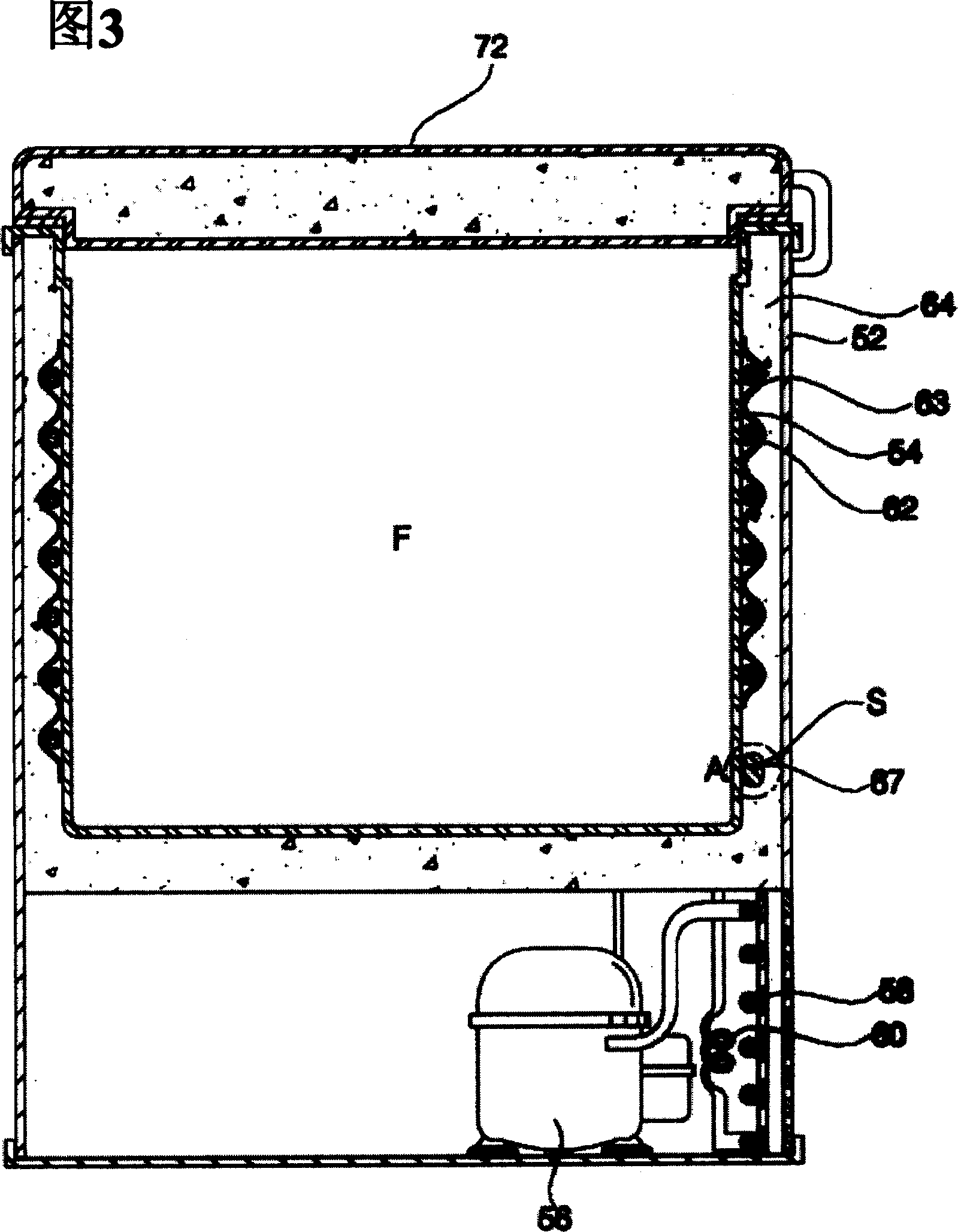

[0035] figure 2 It is a block diagram showing the cycle of the first embodiment of the direct cooling refrigerator of the present invention, and Fig. 3 is an internal structure diagram showing the first embodiment of the direct cooling refrigerator of the present invention, Figure 4 It is an enlarged view of part A shown in FIG. 3 .

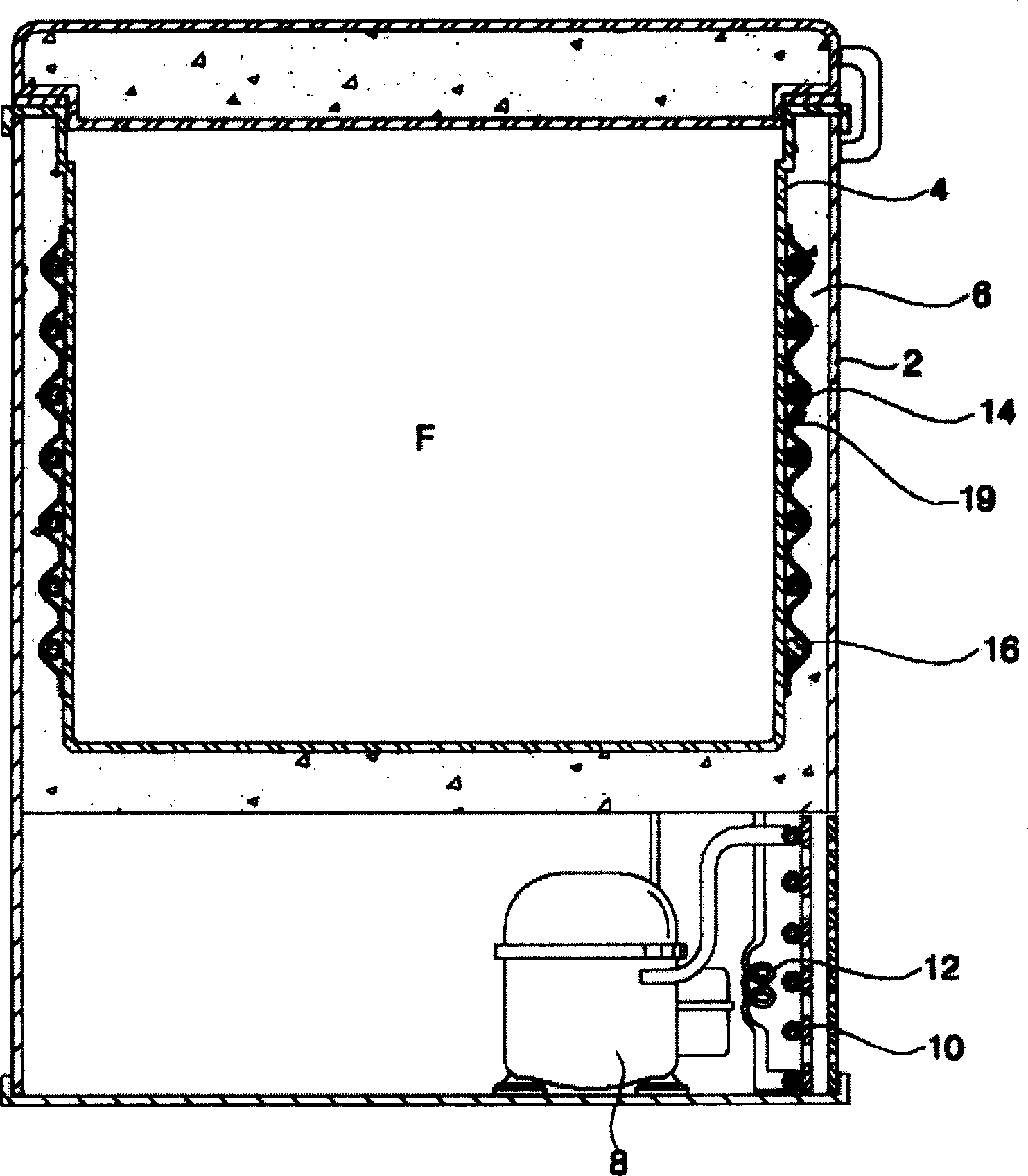

[0036] Such as Figure 2 to Figure 4 As shown, the direct cooling refrigerator of the present embodiment includes an outer casing 52 forming the outer shape of the refrigerator; an inner casing 54 forming a storage chamber F arranged in the aforementioned outer casing 52; a compressor for compressing refrigerant 56; a condenser 58 for condensing the high-pressure refrigerant gas passing through the compressor 56 into a liquid state; an expansion mechanism 60 for decompressing the refrigerant passing through the condenser 58; the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com