'cabin inside cabin' type working space for welding subwater pipeline in dry mode and under normal pressure

An underwater pipeline and work cabin technology, applied in the field of work cabins, can solve problems such as difficulty in establishing an atmospheric welding environment, and achieve the effects of excellent and reliable welding quality and reduced sealing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

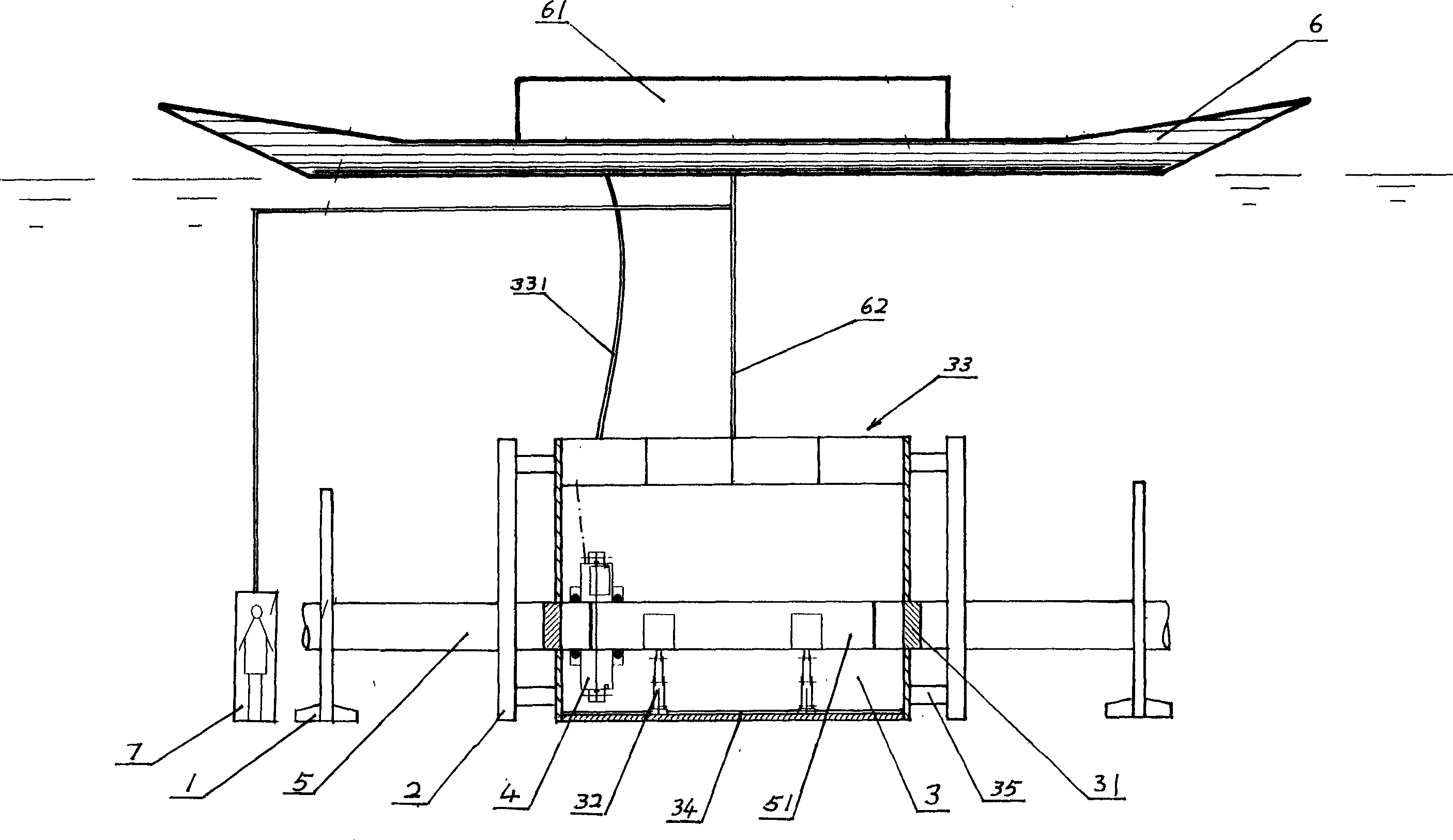

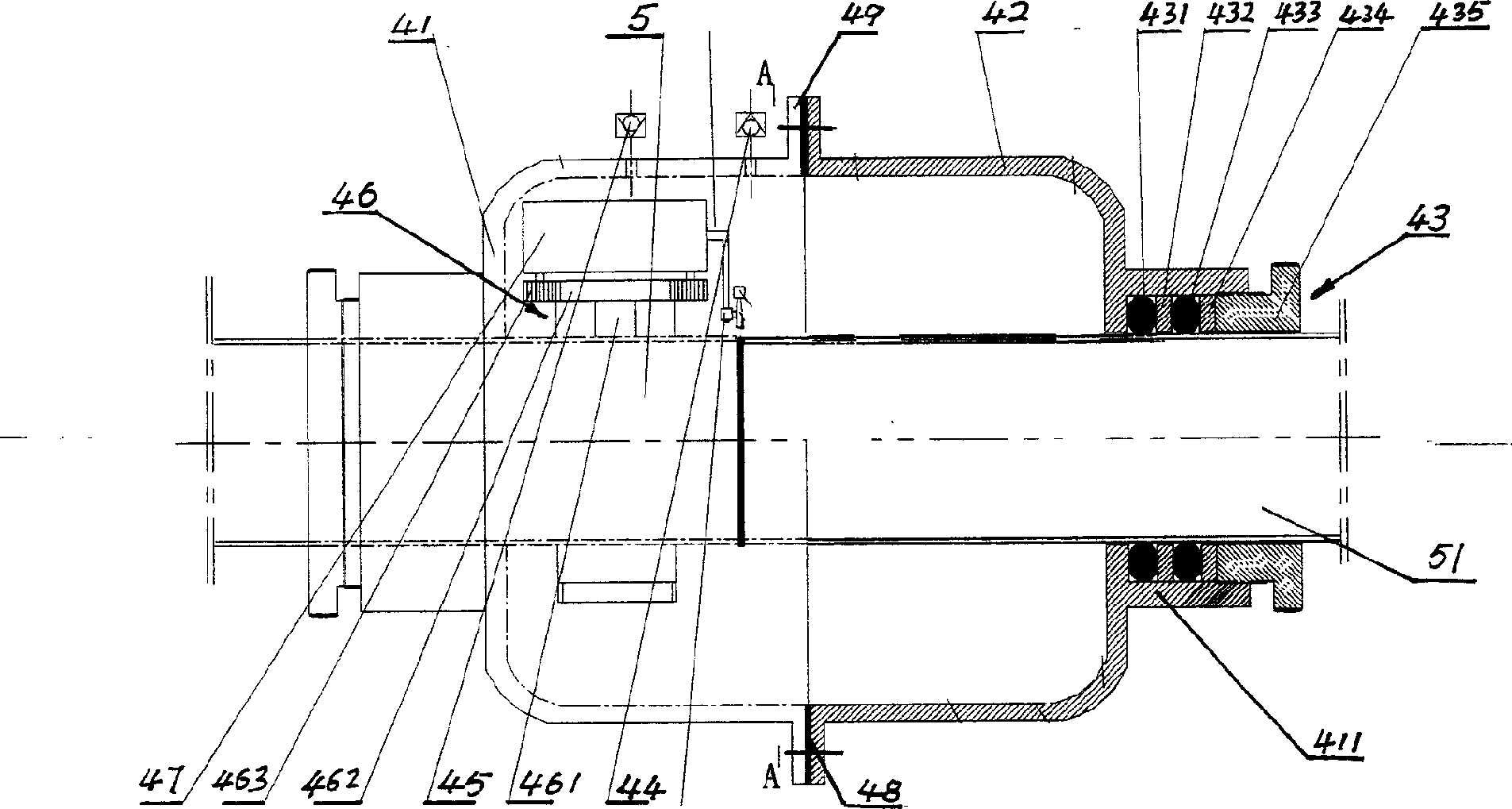

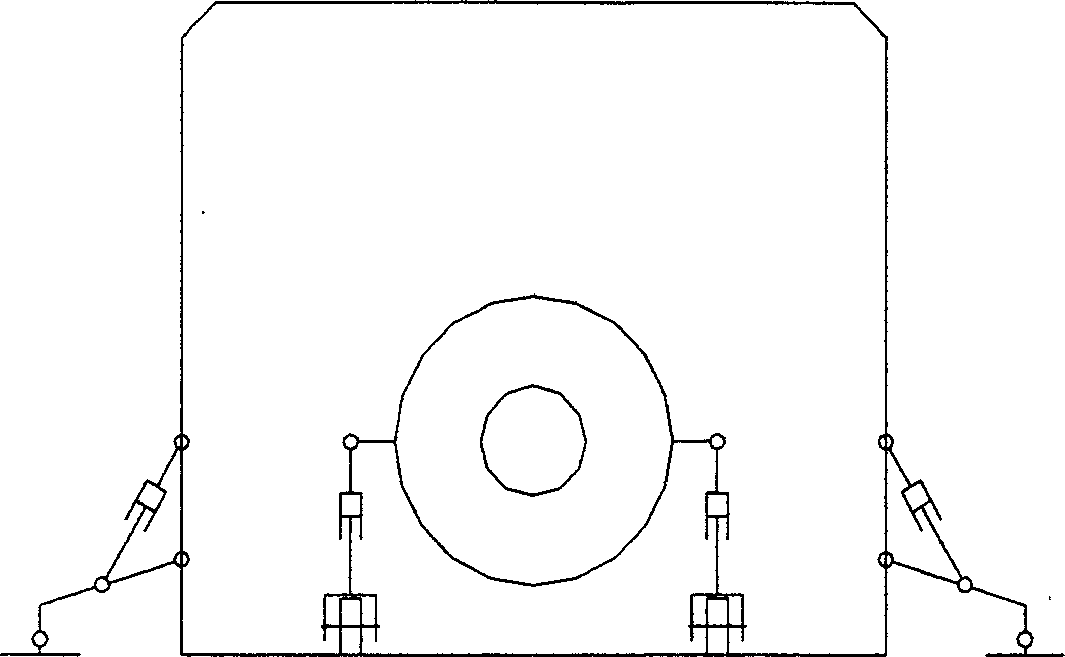

[0017] Depend on Figure 1A , Figure 1B It is shown that a "cabin in a cabin" type underwater pipeline normal pressure dry welding working cabin is mainly composed of a main adjustment frame 1, an auxiliary adjustment frame 2, a hyperbaric cabin 3 and a normal pressure cabin 4, wherein the main adjustment frame 1 It is connected with the pipeline 5 to be repaired, and the auxiliary adjustment frame 2 supports the pipeline 5 to be repaired, and is connected with the end 35 of the hyperbaric chamber 3, and is sealed with the pipeline 5 to be repaired by a hydraulic sealing ram 31, and fixed in the hyperbaric chamber The articulated auxiliary manipulator 32 on the bottom guide rail 34 adjusts and supports the replacement pipe 51; the mobile atmospheric cabin 4 is set on the pipeline 5 to be repaired through the annular special-shaped sealing device 43 on the cabin body of the atmospheric pressure cabin 4, and the annular special-shaped seal Device 43 realizes the sealing with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com