Directly-down backlight assembly

A backlight component, a direct type technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of light leakage, cold cathode tube 13 light source utilization rate reduction, light leakage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

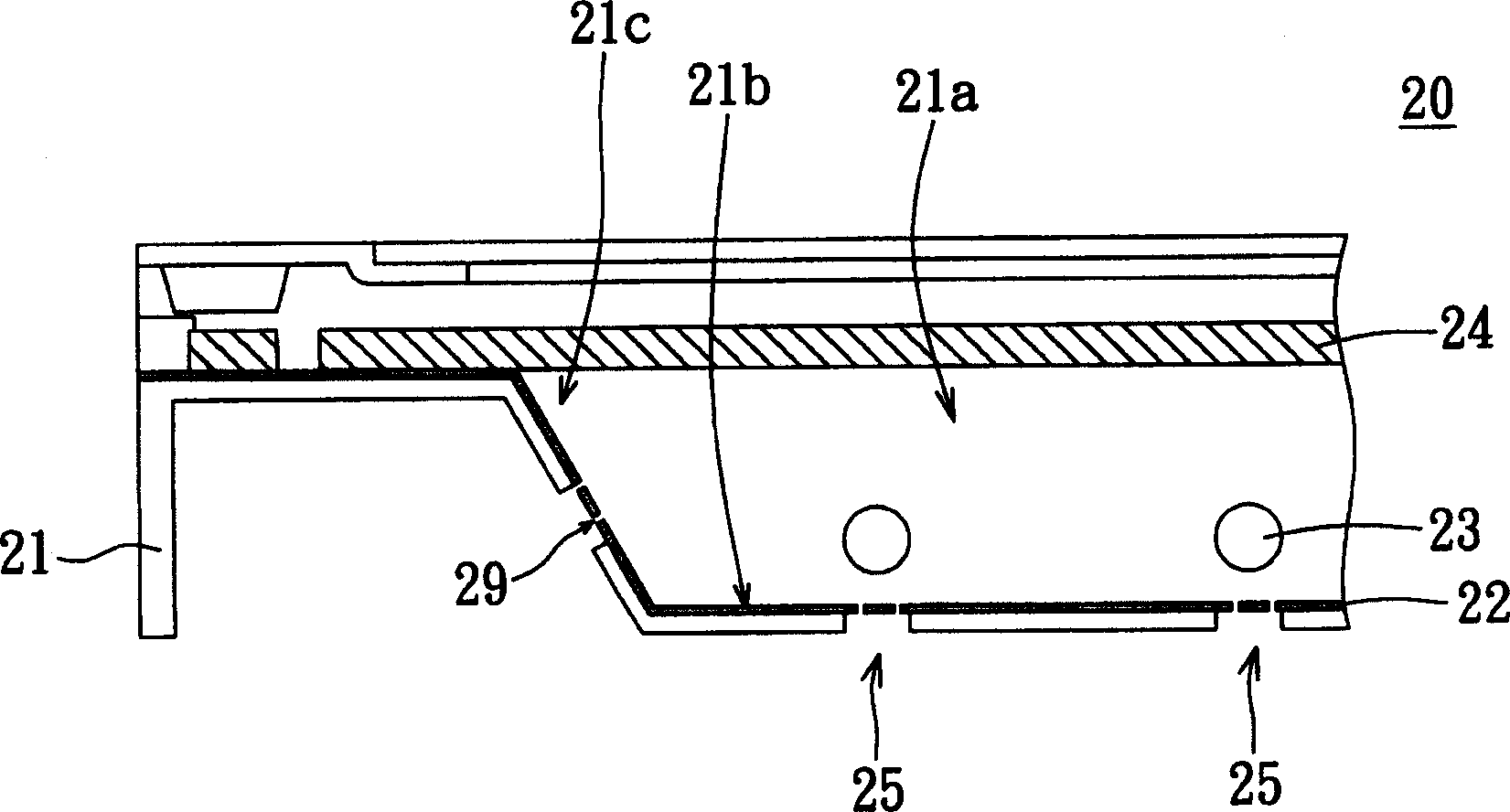

[0027] refer to figure 2 , figure 2 It is a partial sectional view showing a direct type backlight assembly according to a preferred embodiment of the present invention. figure 2 In the embodiment, the direct type backlight assembly 20 includes a bezel 21 , a reflecting sheet 22 and a plurality of light sources 23 . An accommodating groove 21 a is formed inside the frame 21 , and at least one through hole 25 is formed on the frame 21 through the accommodating groove 21 a to the outside. The shape of the perforation 25 can preferably be a long rectangle, and a plurality of perforations 25 are preferably arranged in parallel with each other, and are basically arranged relative to the light source 25. However, the present invention is not limited thereto, and perforations of other shapes and sizes can be made according to According to the actual effect or demand, it is adjusted accordingly to maintain the strength of the frame 21 within an acceptable range and achieve an opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com