Method for pressurizing, washing and purifying biogas and vacuum desorption discharge system

A pressurized water washing and discharge system technology, applied in the field of gas-liquid mass transfer, can solve the problems of incomplete desorption, achieve complete desorption, reduce energy consumption, and reduce refrigeration energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

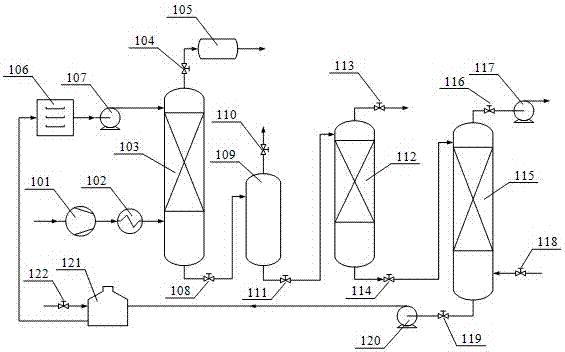

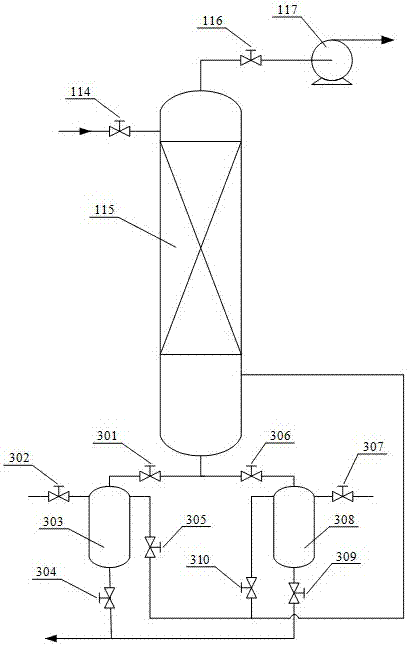

[0055] Such as figure 1 As shown, a vacuum desorption discharge system for pressurized water washing to purify biogas includes a biogas compressor 101, a heat exchanger 102, a dryer 105, a water chiller 106, a booster pump 107, a flash tower 109, and a Pressure tower 112, desorption tower 115, water storage tank 121, desorption tower vacuum pump 117, desorption tower vacuum discharge pump 120. The heat exchanger 102 communicated with the outlet of the biogas compressor 101 , the absorption tower 103 communicated with the outlet of the heat exchanger 102 , and the top of the absorption tower 103 communicates with the drier 105 through a valve 104 . The outlet of water storage tank 121 is communicated with chiller 106, and chiller 106 is communicated with absorption tower 103 through booster pump 107, and the bottom of absorption tower 103 communicates with flash tower 109 top through pipeline and valve 108, and the top of flash tower 109 is provided with The valve 110 is commu...

Embodiment 2

[0072] The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is:

[0073] The outside temperature is 15-18°C; the water discharged from the bottom of the desorption tower 115 enters the water storage tank 121 through the valve 119 and the vacuum discharge pump 120 of the desorption tower, and then returns after being pressurized by the booster pump 107 without being cooled by the chiller 106 In the absorption tower 103, the water temperature is maintained at 9.5-10.5°C.

[0074]According to the People's Republic of China Geological and Mineral Industry Standard DZT 0064.47-1993 "Groundwater Quality Inspection Method Titrimetric Determination of Free Carbon Dioxide" to measure CO in the water discharged from the bottom of the desorption tower 115 2 The content is 11.20 mg / L; the composition of the product gas measured by Wuhan Sifang Gasboard-3200 biogas analyzer is as follows: the methane content is 96.35% (volume percentage), the c...

Embodiment 3

[0076] Embodiment 3 (comparative example):

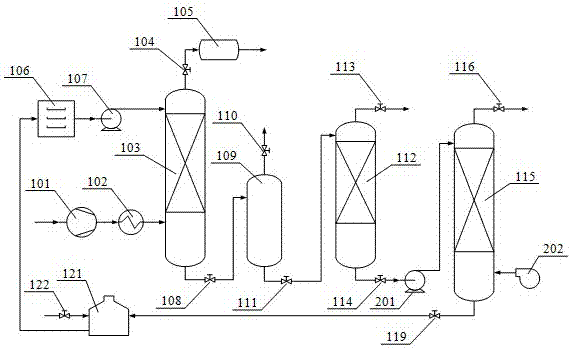

[0077] Such as figure 2 As shown, the process flow of pressurized absorption, purification and purification of biogas in the prior art includes a biogas compressor 101, a heat exchanger 102, an absorption tower 103, a dryer 105, a chiller 106, a booster pump 107, and a flash tower 109, Step-down tower 112, desorption tower 115, water storage tank 121, feed pump 201; blower 202.

[0078] The biogas compressor 101, heat exchanger 102, absorption tower 103, drier 105, water chiller 106, booster pump 107, flash tower 109, step-down tower 112, desorption tower 115, water storage tank 121 and implementation adopted in this implementation Example 1 is the same.

[0079] The methane content in the biogas is 53% (volume percentage), and the carbon dioxide content is 47% (volume percentage).

[0080] The outside temperature is 28-30°C.

[0081] Biogas purification and purification process is the same as embodiment 1 and will not be repea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com