Combined type junction box

A junction box and combined technology, applied in the direction of electrical components, etc., can solve the problems of time-consuming and labor-intensive threading, inability to combine at will, inconvenient threading, etc., and achieve the effect of convenient wiring, standardization, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

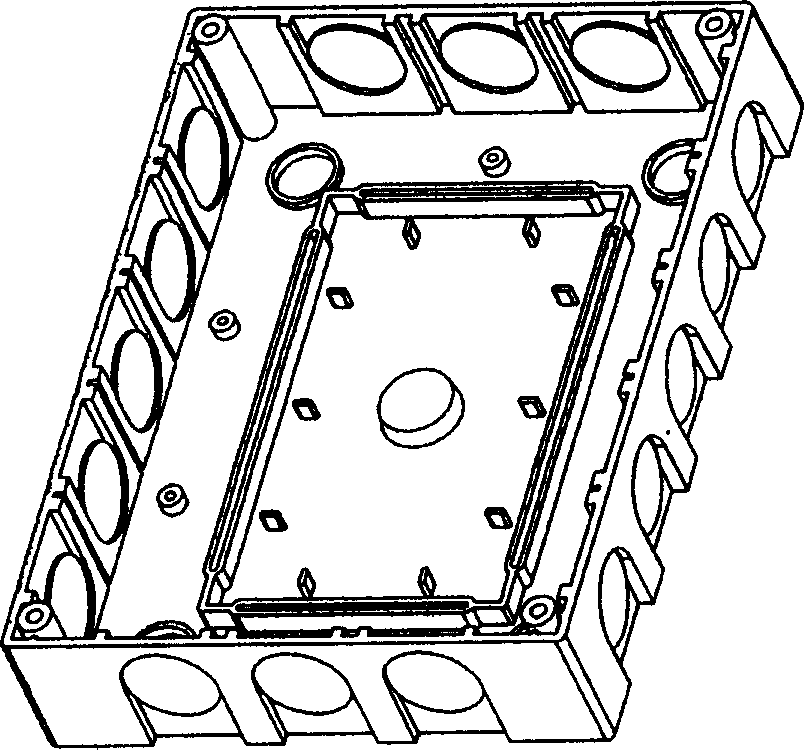

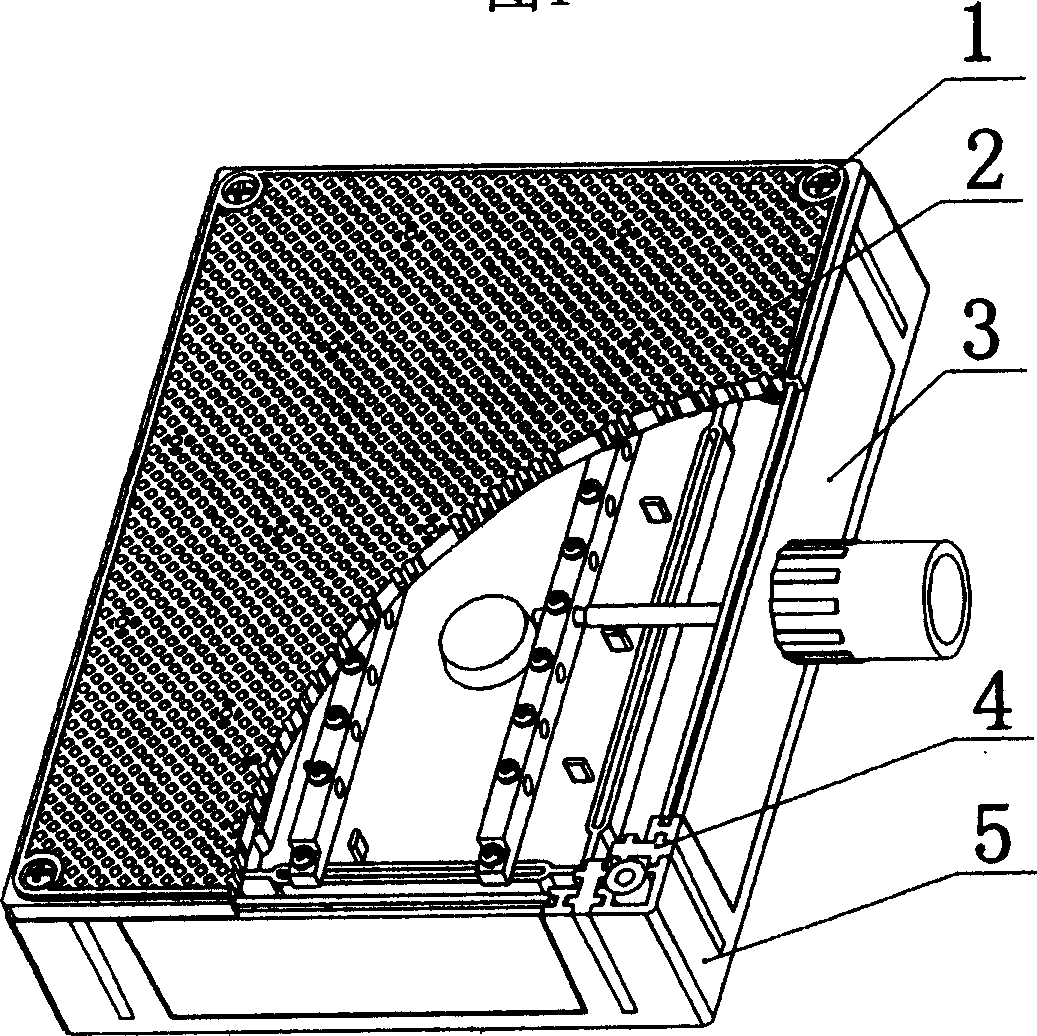

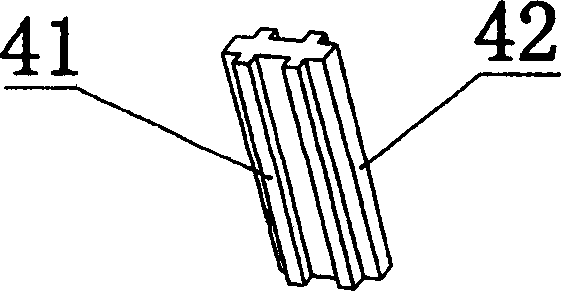

[0026] As shown in the figure, a combined junction box includes a cover 2 and a base 5 connected by screws 1 . The upper surface of the face cover 2 has mesh holes for self-tapping screw installation. A notch 51 and two connecting grooves 52 are respectively provided on the four side walls of the base. There is a groove 511 along the lip of the notch 51, the notch 51 is inserted with a flashboard 3, and the flashboard 3 has a shape corresponding to the notch and is inserted into the notch 511 from top to bottom to close the notch 51 (such as figure 2 ). The coupling groove 52 is arranged on both sides of the notch 51 , and the latch 4 is inserted into the coupling groove 52 from top to bottom. The latch 4 is composed of two identical, side-by-side, and integrated coupling parts 41 . One of the connecting parts 41 is located in the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com