Embroidery machine

An embroidery machine and cantilever technology, which is applied to embroidery machines, embroidery machine mechanisms, sewing machine components, etc., can solve the problems of not being able to maintain it for a long time, the elasticity of the spring plate is easy to drop, and the cost is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

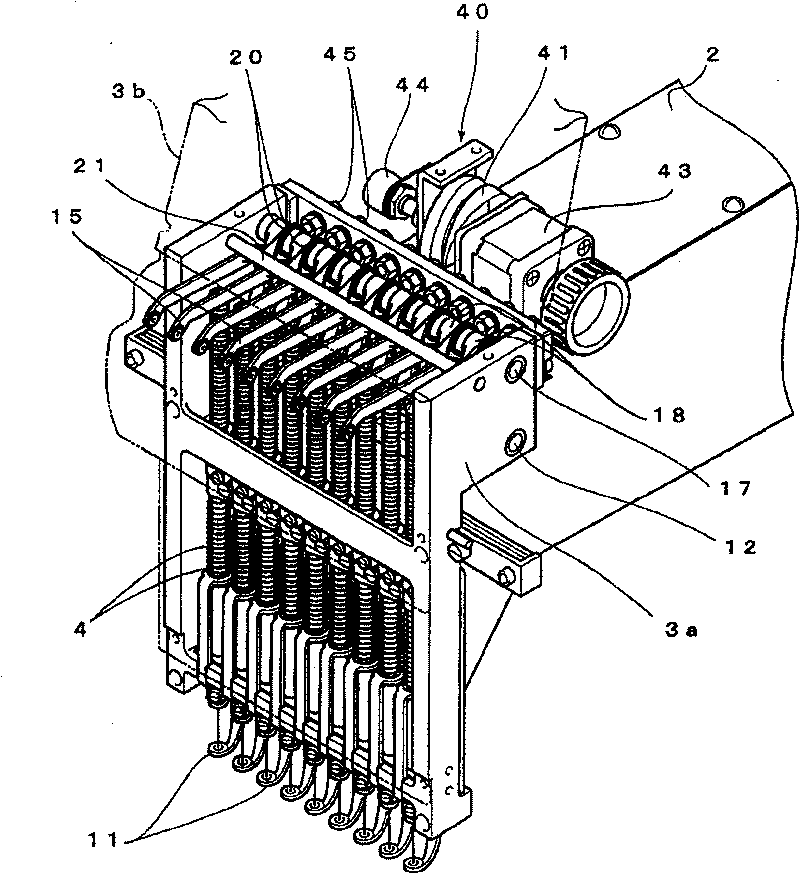

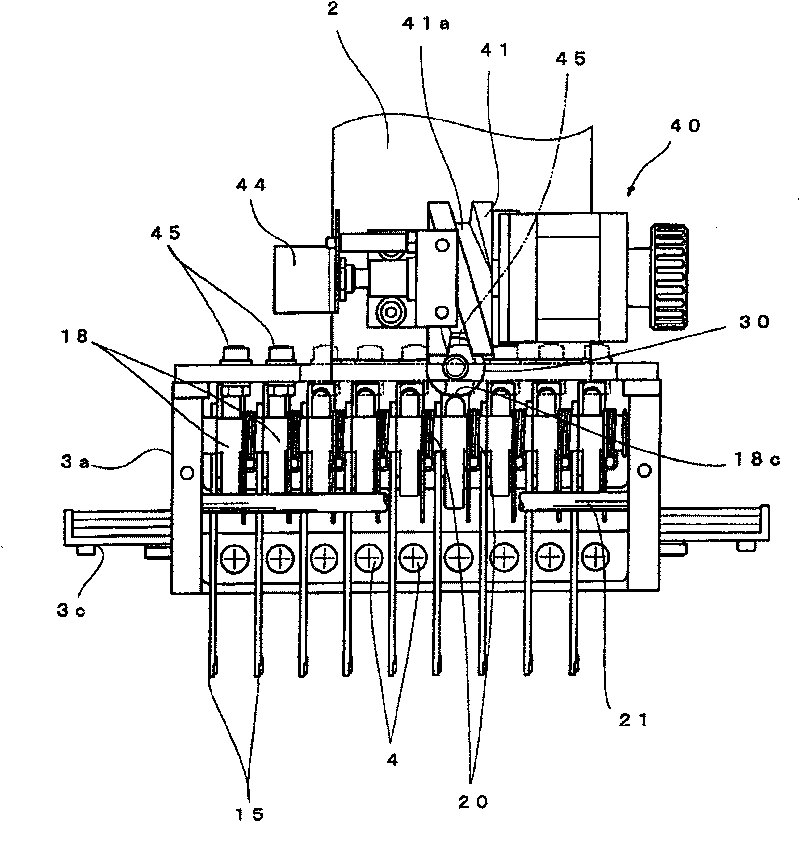

[0012] An embodiment of the present invention will be described below with reference to the accompanying drawings.

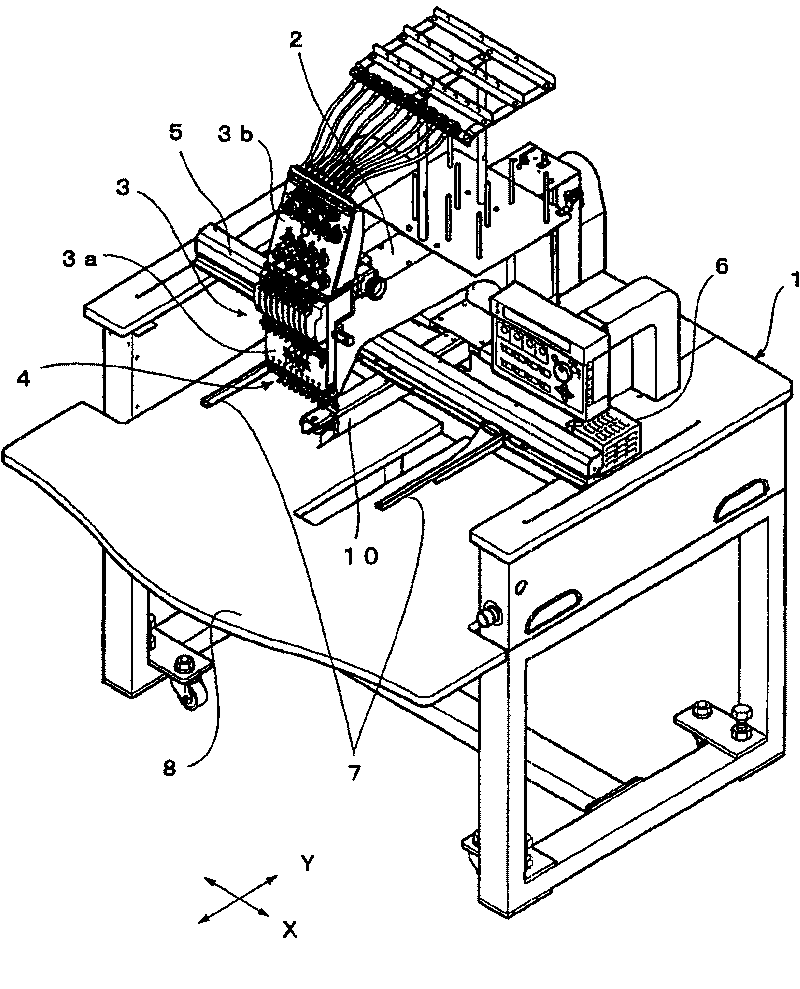

[0013] figure 1 It is a perspective view showing the appearance of the single-head embroidery machine of this embodiment. figure 1 Among them, the machine arm 2 is set on the machine table 1 constituting the embroidery machine body. The machine arm 2 is erected from the rear end of the approximate center of the machine table 1, and the front end is extended toward the front (the side where the operator is located) and is arranged to extend forward and backward (Y direction). On the top, the head 3 is supported so as to be slidable in both left and right directions (X direction). The machine head 3 is composed of a support body 3a and a yarn adjustment table 3b. The support body 3a is located below the machine head 3 and supports a plurality of needle bars 4 (nine in the illustrated example), and the yarn adjustment table 3b is installed on the machine head 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com