A kind of intelligent shrinkage reducing agent for concrete and its preparation method and application

A technology of concrete and shrinkage reducing agent, applied in the field of intelligent shrinkage reducing agent for concrete and its preparation, can solve problems such as increasing concrete shrinkage, and achieve the effects of improving concrete shrinkage, solving drying shrinkage, and improving durability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

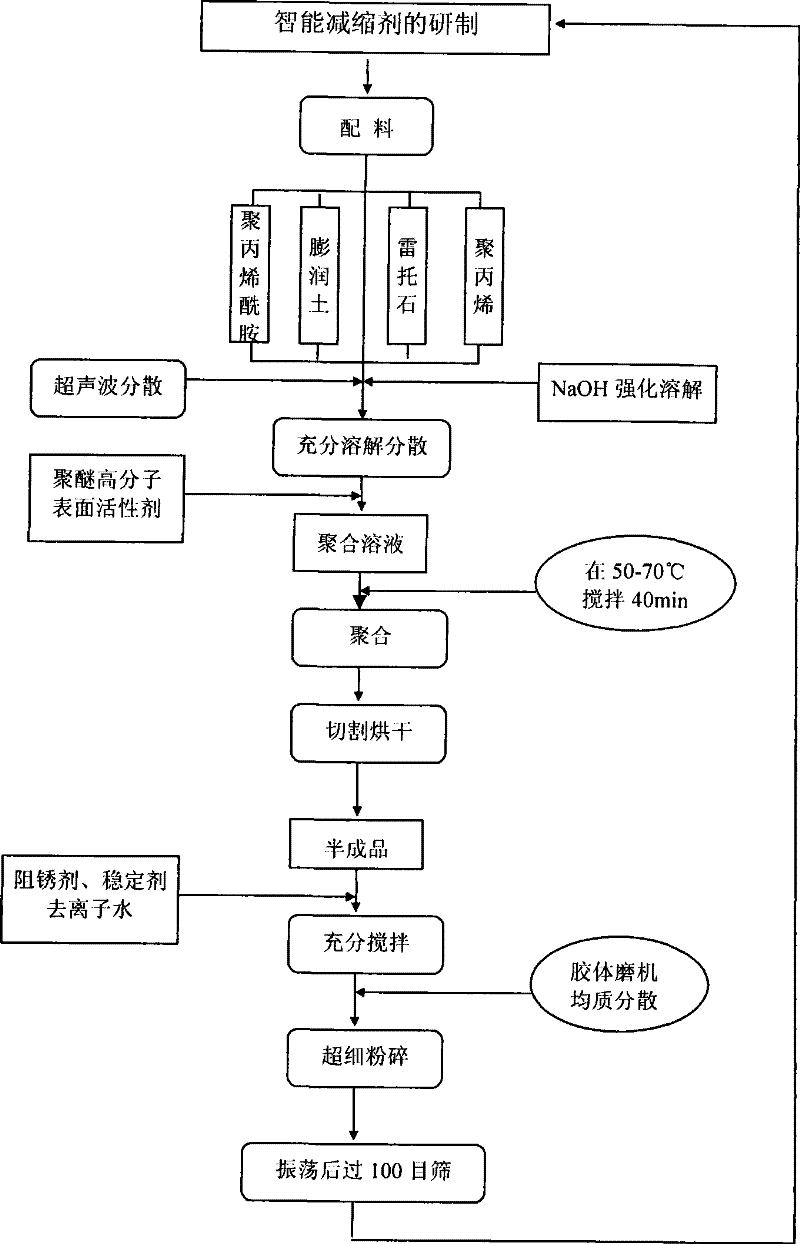

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the intelligent shrinkage reducing agent of the present invention is made of 10% polyacrylamide (average molecular weight 3,000,000), 7% polyether macromolecular surfactant (average molecular weight 1600), 18% bentonite, 50% rhettolite , 5% polypropylene (average molecular weight 6000); the above percentages are weight percentages.

Embodiment 2

[0027] Embodiment 2: the intelligent shrinkage reducing agent of the present invention is made of 20% polyacrylamide (average molecular weight 8,000,000), 2% polyether macromolecular surfactant (average molecular weight 1000), 22% bentonite, 44% rhettolite , 12% polypropylene (average molecular weight 10,000); the above percentages are percentages by weight.

Embodiment 3

[0028] Embodiment 3: the intelligent shrinkage reducing agent of the present invention is made of 12% polyacrylamide (average molecular weight 5,000,000), 5% polyether macromolecule surfactant (average molecular weight 1300), 33% bentonite, 42% rhettolite , 8% polypropylene (average molecular weight 8000); the above percentages are percentages by weight.

[0029] 2. Application of intelligent shrinkage reducing agent in concrete

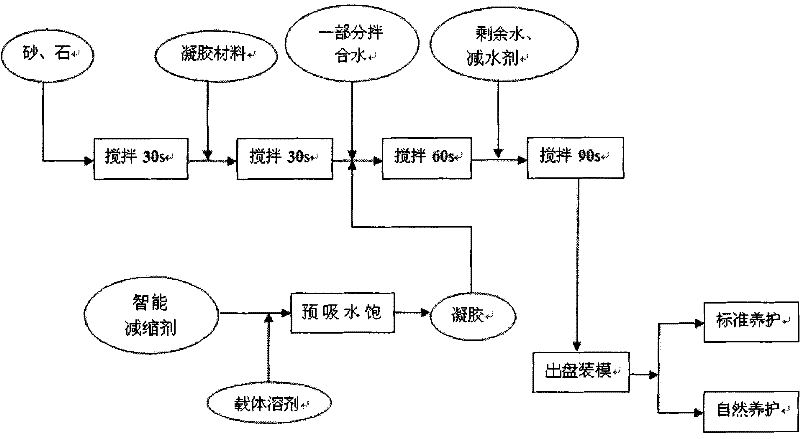

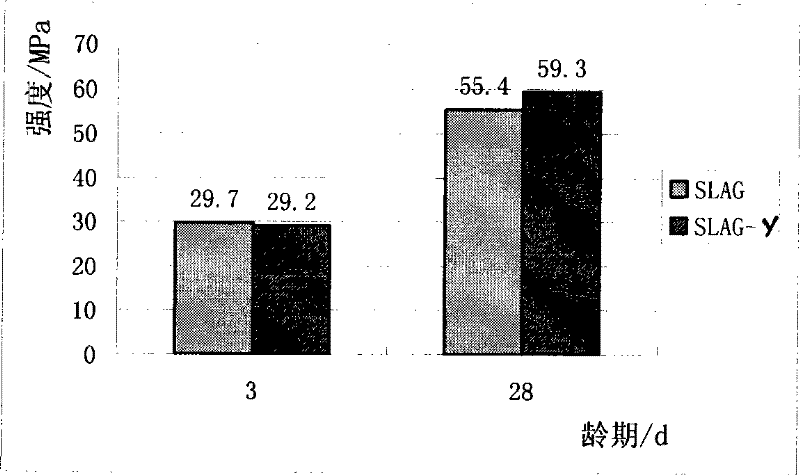

[0030] During the implementation, the intelligent shrinkage reducer is firstly used as a carrier solvent with water, so that the ground particles are saturated with water in advance. Through the water absorption test in the early stage, it is determined that when the water absorption ratio is 140, a saturated gel can be obtained. First add sand and stone aggregates in the test mix ratio shown in Table 1, stir for 30 seconds, then add cementitious materials (cement and slag), and stir together for 30 seconds. Then add water-absorbing saturated gel an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com