Double-coated optical fiber

An optical fiber and double-layer technology, which is applied in the field of double-layer coated optical fiber and its coating layer peeling force, can solve the problem of no outer diameter of the main coating layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. The skilled person will understand that the claimed invention is not limited to the embodiments shown in the drawings. For example, those skilled in the art can make many improvements within the spirit and scope of the present invention. For clarity and simplicity, well-known functions or constructions are not described in detail since they would obscure the invention in unnecessary detail.

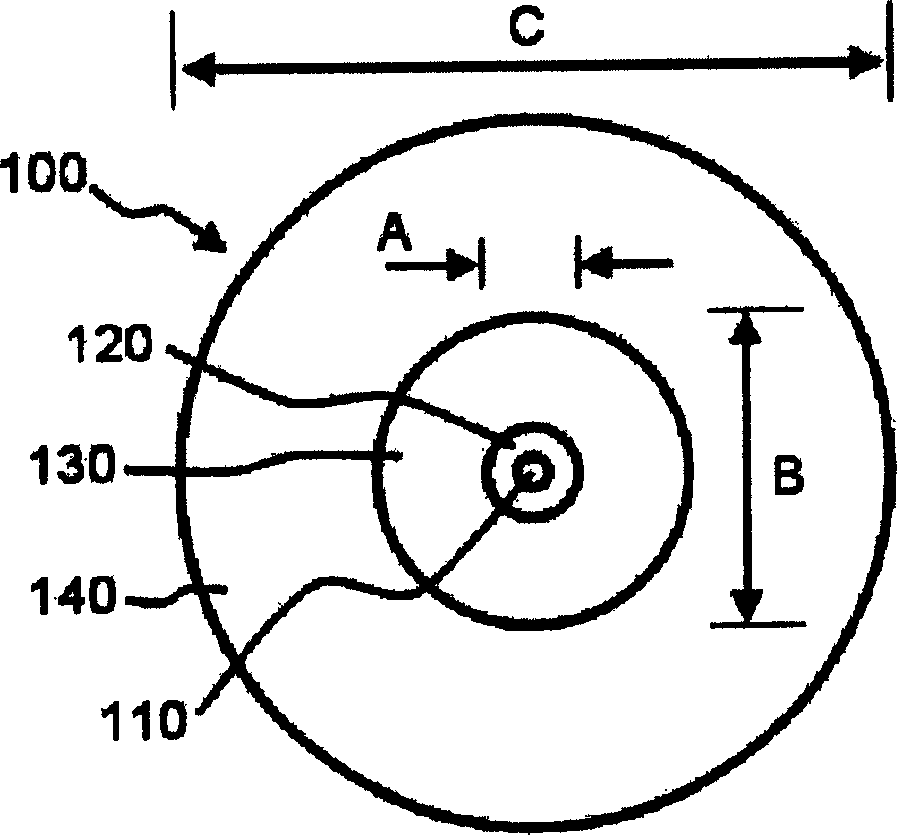

[0017] figure 1 It is a schematic cross-sectional view of a double-coated optical fiber according to a preferred embodiment of the present invention. refer to figure 1 , the optical fiber 100 includes a core 110 , a cladding 120 , a primary coating 130 and a secondary coating 140 .

[0018] All of the aforementioned components are generally arranged around a common central point. The core 110 is disposed at the center of the optical fiber 100 . Thus, the core ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com