Adhesive-free aluminium and plastic compounded polyethylene film and manufacturing method thereof

A technology of polyethylene film and aluminum plastic, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of harsh production environment, resource waste, and many processes, and achieve the reduction of organic solvents and adhesives. The use of binder, the reduction of resource and energy consumption, and the effect of simple application operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

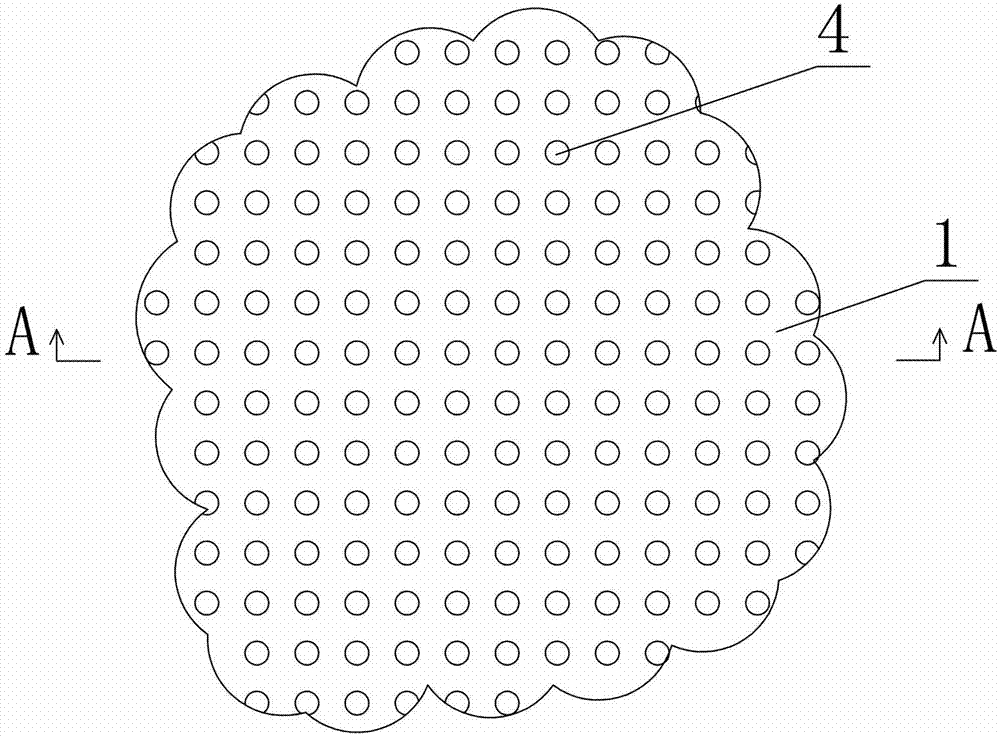

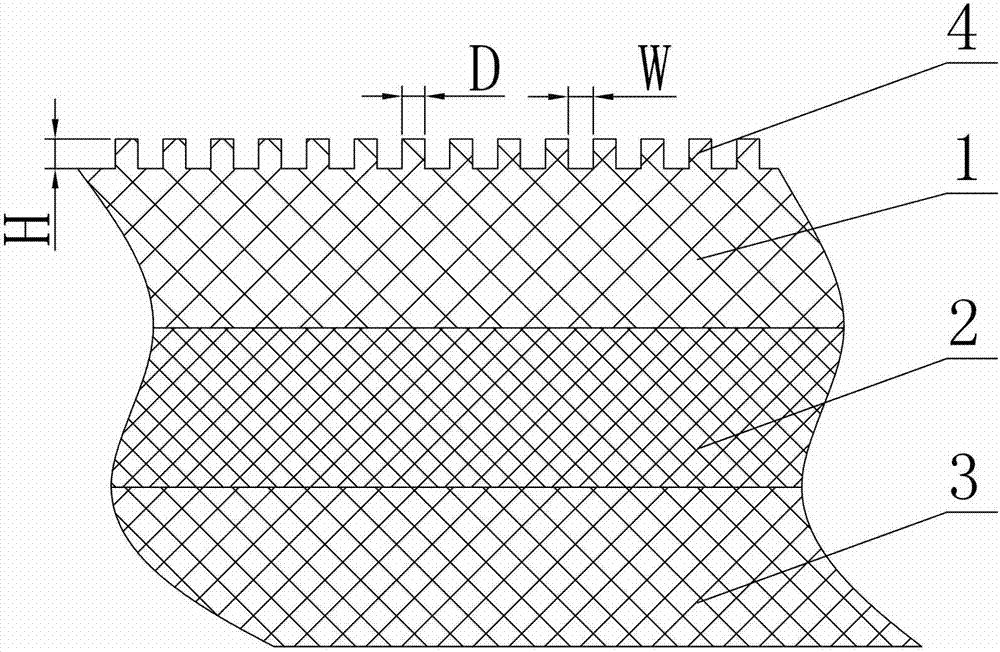

[0043] a kind of likefigure 1 , figure 2 The polyethylene film for aluminum-plastic adhesive-free composite of the present invention is shown, and the polyethylene film includes an adhesive-free composite layer 1 in contact with an external aluminum foil, a middle main body layer 2 and a heat-sealing layer of the inner layer from the outside to the inside 3. The outer surface of the adhesive-free composite layer 1 is provided with a nano-array structure similar to gecko feet. In this embodiment, the thicknesses of the adhesive-free composite layer 1 , the main body layer 2 and the heat-sealing layer 3 are all 5 μm. The nano-array structure includes nano-scale protrusions 4 distributed in an array. The pitch W of the nanoscale protrusions 4 is 5 nm. The height H of the nanoscale protrusions 4 is 50 nm. The nanoscale protrusions 4 are arranged in a cylindrical shape (or a cuboid shape), and the diameter D of the bottom surface of the cylindrical nanoscale protrusions is 10 n...

Embodiment 2

[0064] a kind of like figure 1 , figure 2 The polyethylene film for aluminum-plastic adhesive-free composite of the present invention is shown, and the polyethylene film includes an adhesive-free composite layer 1 in contact with an external aluminum foil, a middle main body layer 2 and a heat-sealing layer of the inner layer from the outside to the inside 3. The outer surface of the adhesive-free composite layer 1 is provided with a nano-array structure similar to gecko feet. In this embodiment, the thicknesses of the adhesive-free composite layer 1 , the main body layer 2 and the heat-sealing layer 3 are all 5 μm. The nano-array structure includes nano-scale protrusions 4 distributed in an array. The pitch W of the nanoscale protrusions 4 is 8 nm. The height H of the nanoscale protrusions 4 is 60 nm. The nanoscale protrusions 4 are arranged in a cylindrical shape (or a cuboid shape), and the diameter D of the bottom surface of the cylindrical nanoscale protrusions is 15...

Embodiment 3

[0085] a kind of like figure 1 , figure 2 The polyethylene film for aluminum-plastic adhesive-free composite of the present invention is shown, and the polyethylene film includes an adhesive-free composite layer 1 in contact with an external aluminum foil, a middle main body layer 2 and a heat-sealing layer of the inner layer from the outside to the inside 3. The outer surface of the adhesive-free composite layer 1 is provided with a nano-array structure similar to gecko feet. In this embodiment, the thicknesses of the adhesive-free composite layer 1 , the main body layer 2 and the heat-sealing layer 3 are all 10 μm. The nano-array structure includes nano-scale protrusions 4 distributed in an array. The pitch W of the nanoscale protrusions 4 is 10 nm. The height H of the nanoscale protrusions 4 is 70 nm. The nanoscale protrusions 4 are arranged in a cylindrical shape (or a cuboid shape), and the diameter D of the bottom surface of the cylindrical nanoscale protrusions is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com