Hydraulic central gyrorotor

A rotary and central technology, applied in fluid pressure actuating devices, lifting devices, lifting frames, etc., can solve problems such as inconvenient operation and maintenance, short service life of pipelines, small rotation angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

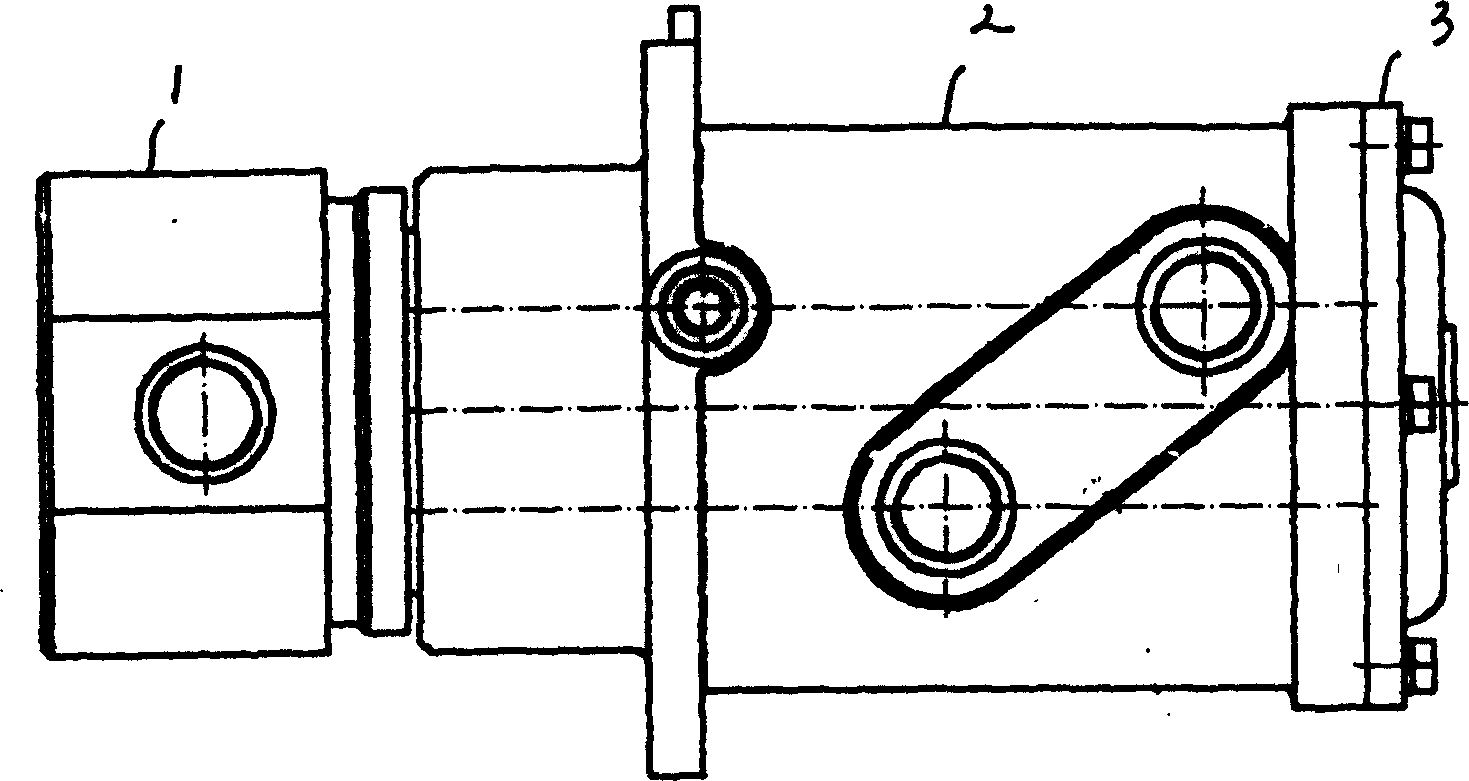

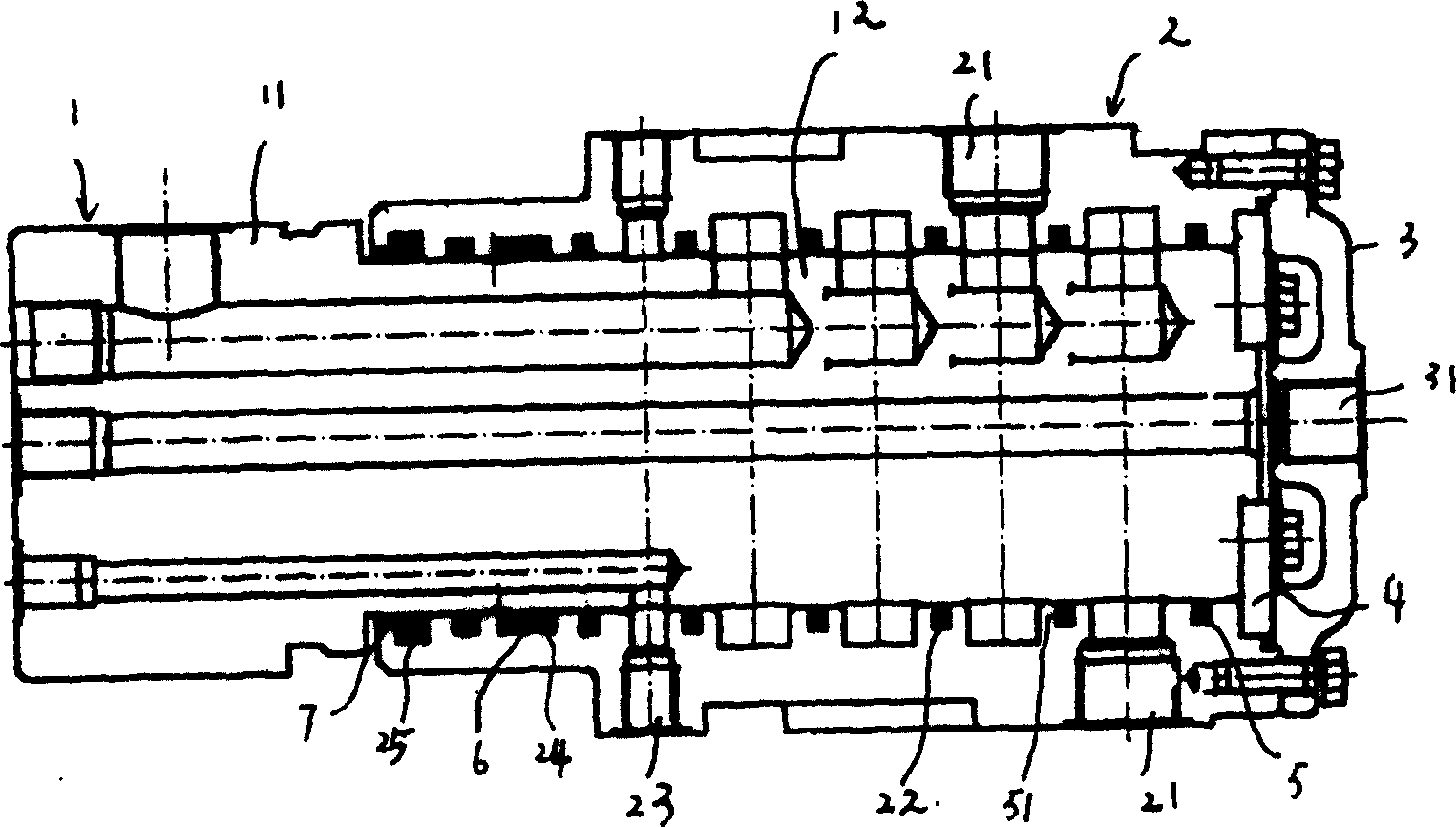

[0023] Such as Figure 1~4 , The present invention is a hydraulic central slewing body, which is mainly composed of a slewing body 2, a rotating shaft 1, an end cover 3, a positioning cover 4, a seal 5, a support ring 6 and a dust ring 7. The rotary shaft 1 is composed of a front pipeline connecting section 11 and a rear mounting section 12. The rear mounting section 12 of the rotary shaft 1 is inserted into the revolving body 2, the front pipeline connecting section 11 is placed at the outer front end of the revolving body 2, and the end cover 3 is placed at the outer rear end of the revolving body 2. The positioning cover 4 is embedded in the rear end of the rotating body 2 and connected with the rear end of the rotating shaft 1.

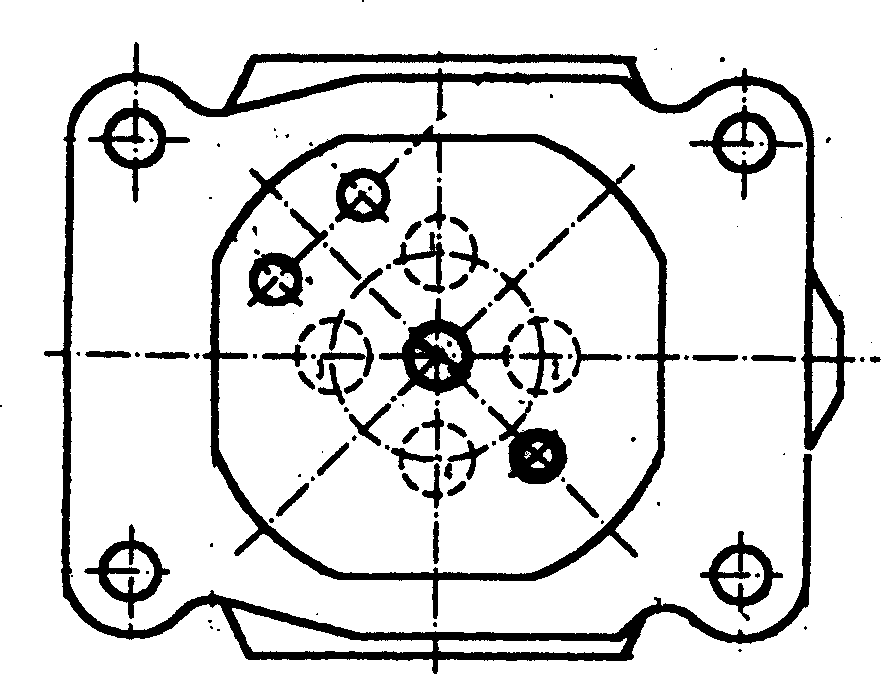

[0024] Such as Figure 5-14 , The front pipeline connecting section 11 and the rear mounting section 12 of the rotary shaft 1 are provided with a plurality of main oil passage holes 13 in the axial direction, and a plurality of main oil ports 111 and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com