Power boat

A power and hull technology, applied in the field of power ships that digest water resistance, can solve problems such as high transportation costs, more fuel, and difficulty in speeding up ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

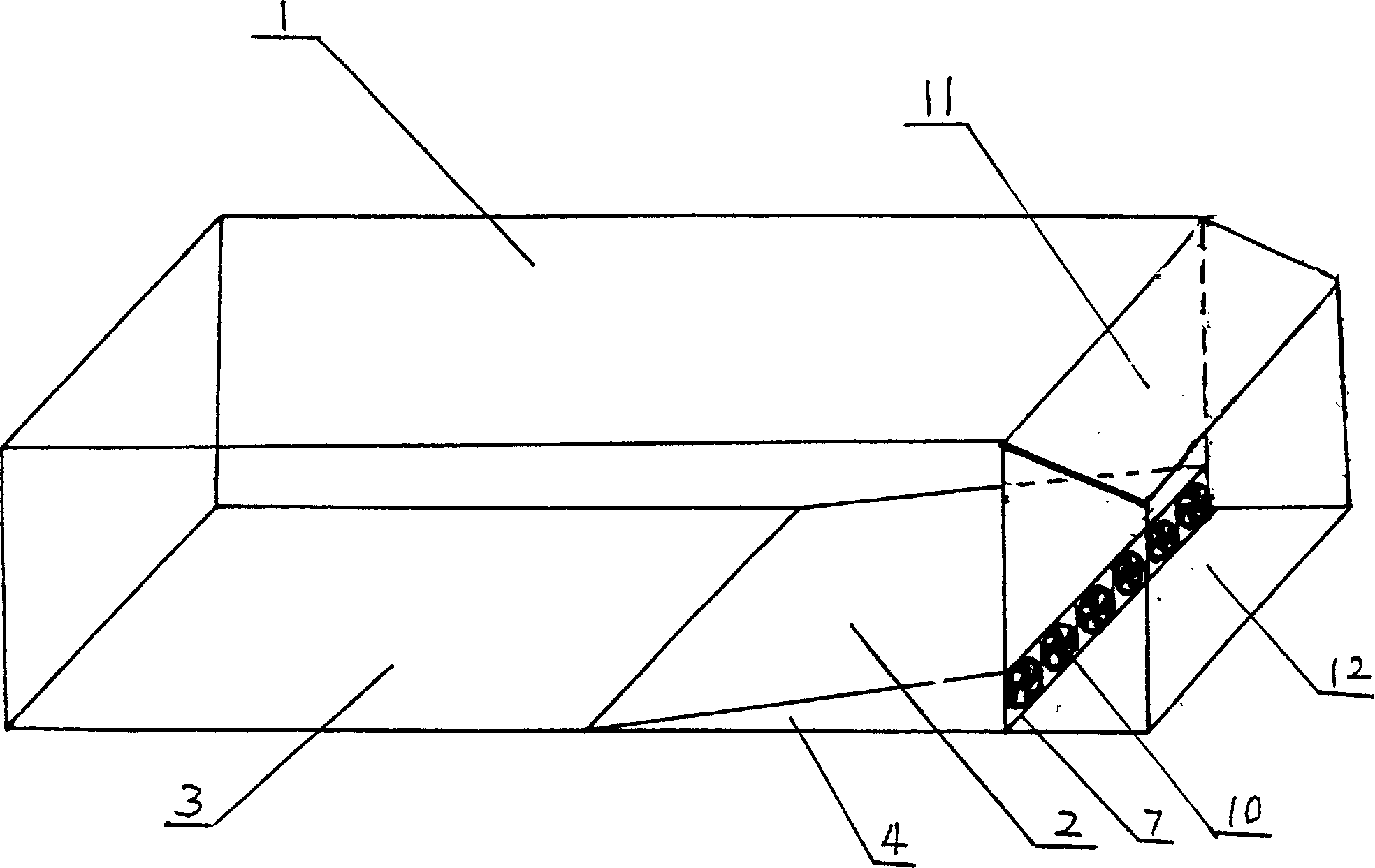

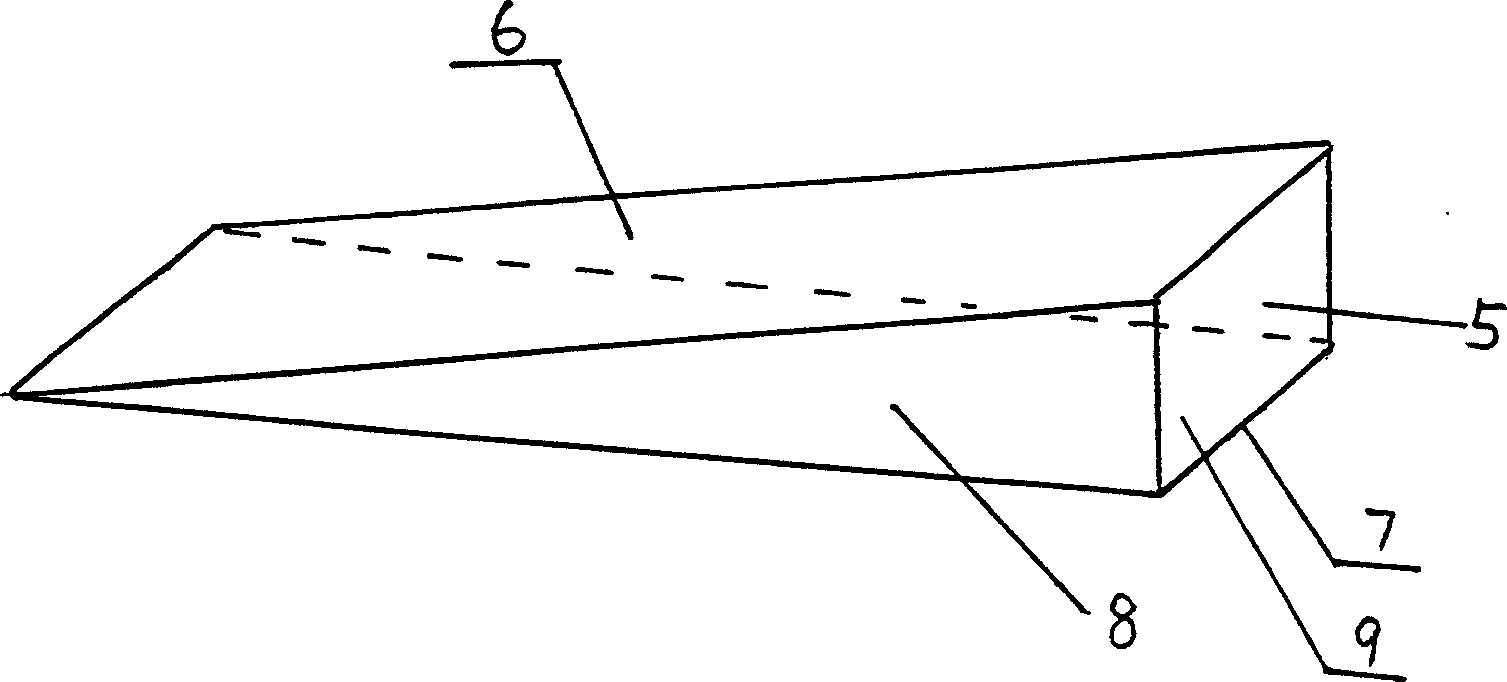

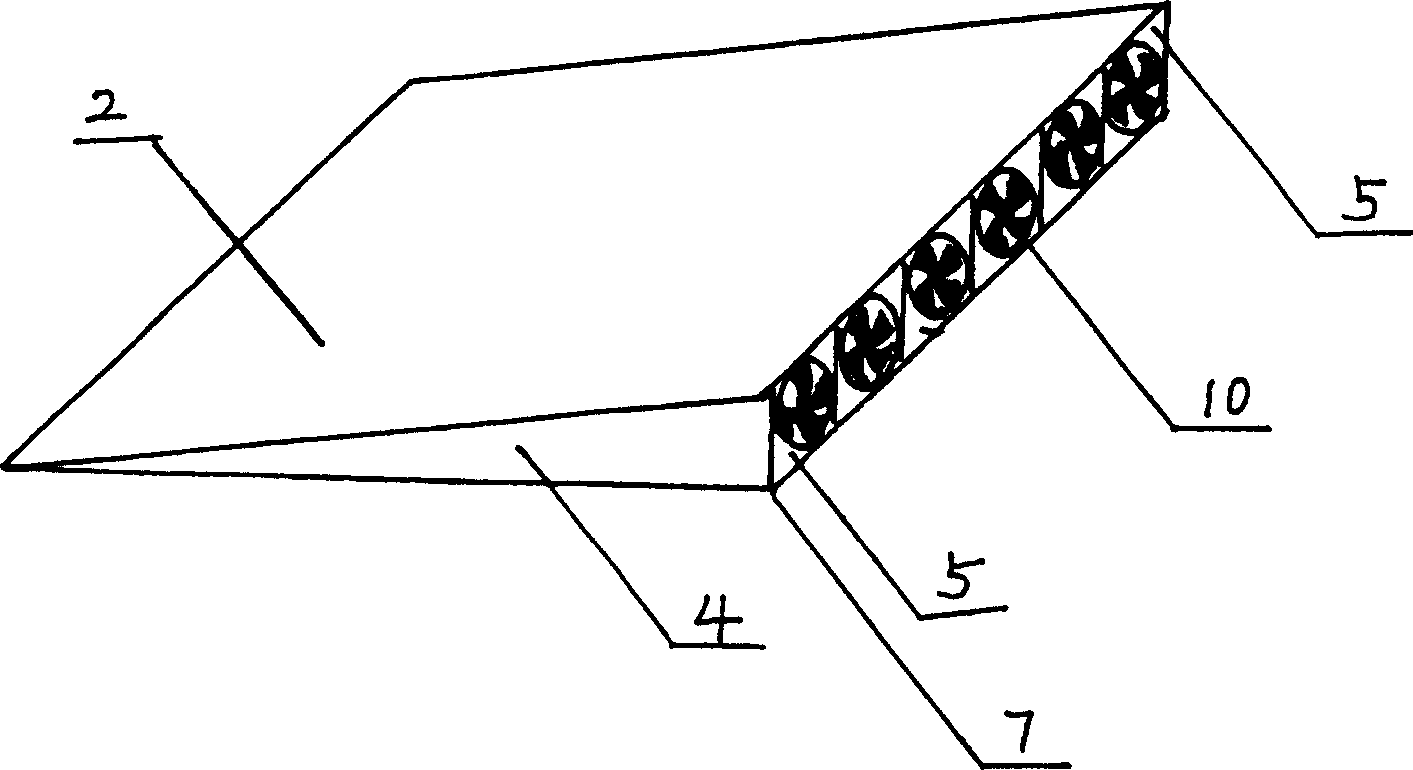

[0010] In conjunction with the accompanying drawings: the present embodiment is provided with a hull 1, the front bottom plate 2 of the ship becomes an inclined plane, the rear middle bottom plate 3 is a flat bottom surface, and the bottom of the front bottom plate 2 is provided with a slanting drainage channel 4 composed of 6 front high and low rear. A group of inclined drainage channels, the inclined drainage channels are composed of the crossing 5, the upper top 6, and the left and right two walls 8, the bottom 9 of the inclined downward drainage channel is an empty bottom, and the lower edge 7 of the crossing is connected with the rear and middle bottom plates of the ship. On the same plane, the top 6 of the sloping drainage channel constitutes the front bottom plate 2 of the ship, and the 6 propellers 10 are installed in the 6 crossings 5 of the slanting drainage channel respectively. A water inlet large hole 12 is provided in front of the front of the hull front 11 left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com