Thrust mechanical energy output device

A technology for outputting device and mechanical energy, applied in electromechanical devices, controlling mechanical energy, mechanical equipment, etc., can solve the problems of complex structure, high fuel consumption, and difficult manufacturing of jet aircraft engines, and achieve convenient and fast travel and logistics, and fast sailing speed. , the effect of flexible turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

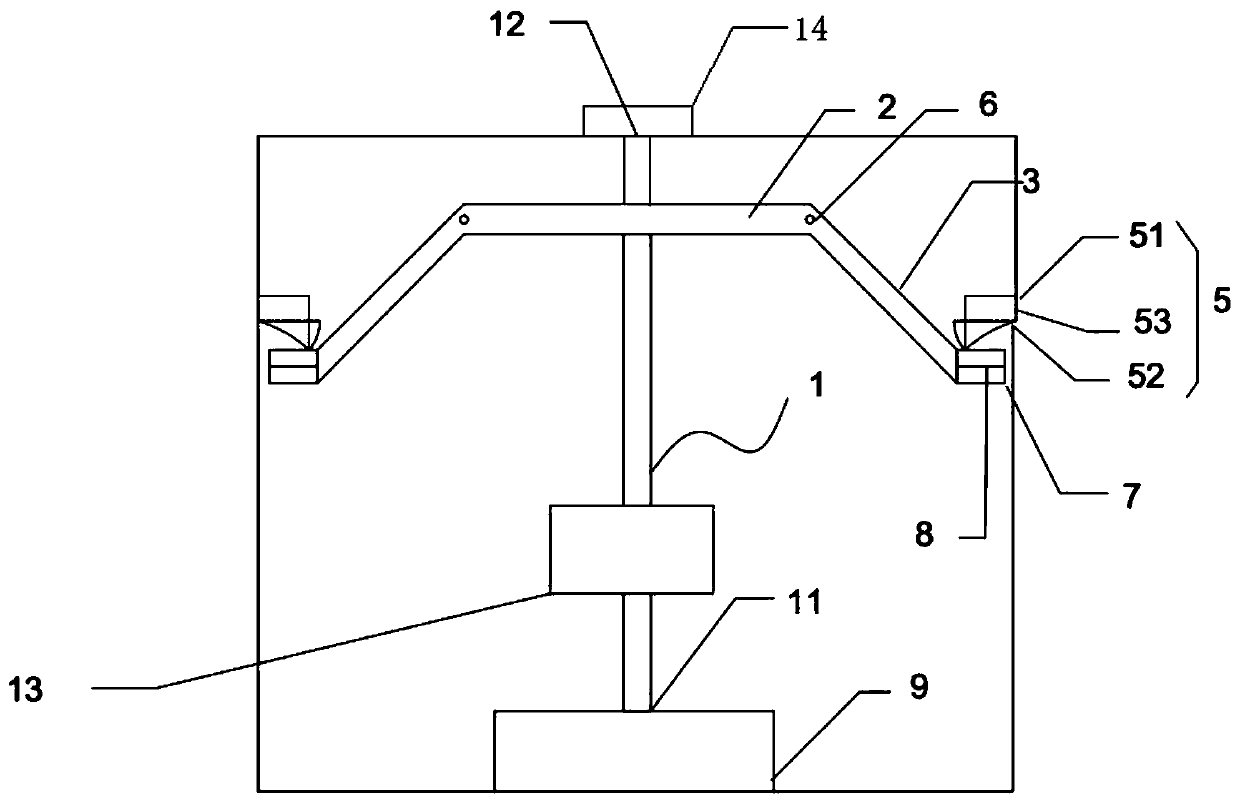

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

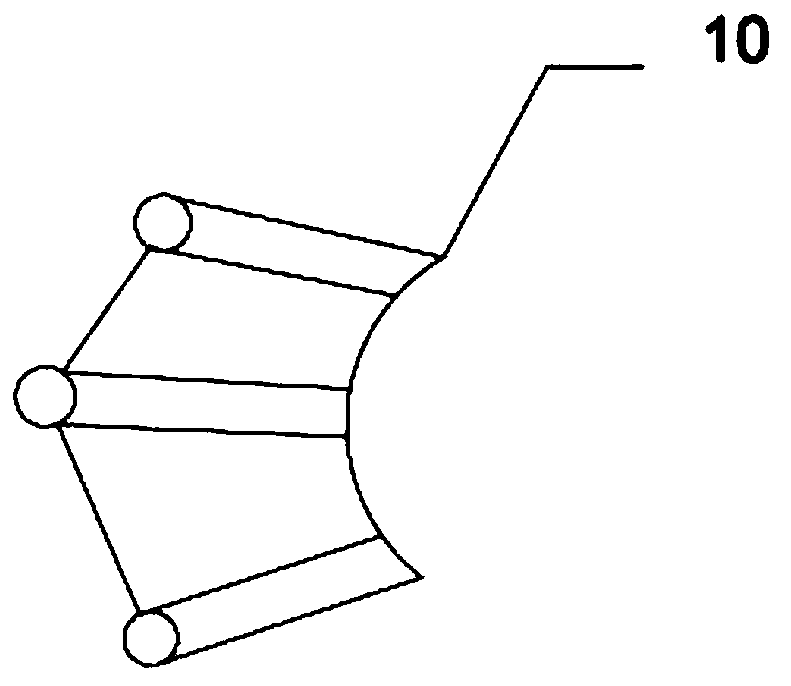

[0022] combined with figure 1 , a thrust mechanical energy output device, including a cylindrical body 12, an input shaft 1 located inside the cylindrical body 12, a turntable 2 pierced on the input shaft 1, and a plurality of centrally symmetrical rocker arms 3 are movable on the turntable 2 , the other end of the rocker arm 3 is provided with a load body 4, and the load body 4 makes a circular motion under the drive of the rocker arm 3; one end of the input shaft 1 is set as the input end 11, and the input end 11 is axially connected to the driving power mechanism 9, and It is connected with the equipment to be driven; the rocker arms 3 are connected through a three-axis hinge 10, and output rotational kinetic energy. A support bearing 13 is provided on the input shaft 11 and inside the cylindrical body 1 .

[0023] The rocker arm 3 is connected to the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com