Submarine Current Thruster

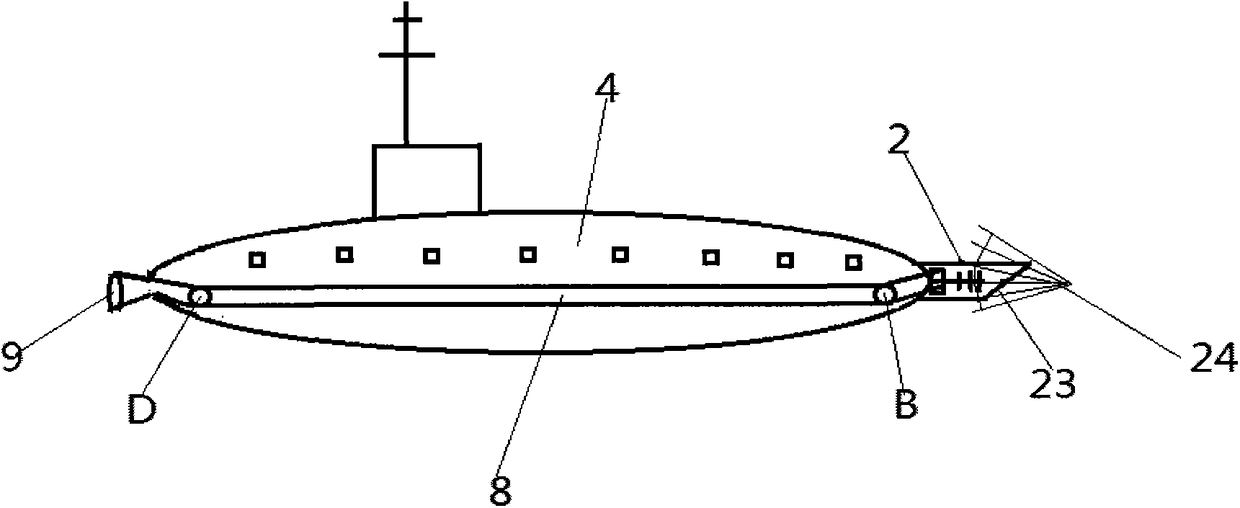

A water flow propulsion and propulsion system technology, applied in ship propulsion, propulsion components, ships, etc., can solve the problems of slow steering speed, slow submarine speed, slow emergency stop response, etc., to achieve convenient production and installation, improve combat capability, improve The effect of sailing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

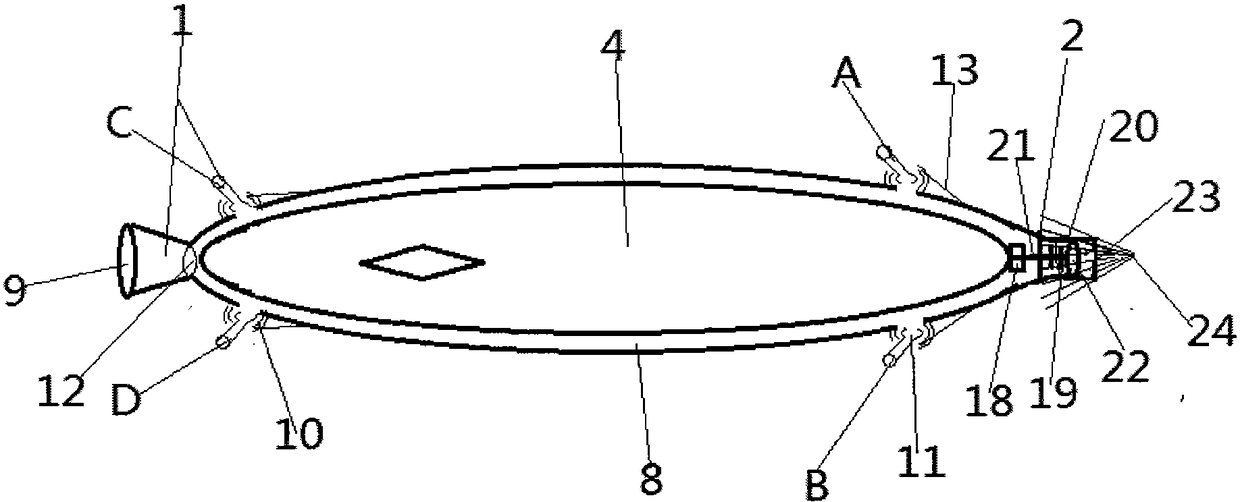

[0036] Embodiment three, when the submarine 4 floats up, while discharging the counterweight water in it, operate the lifting handle 7, and the nozzles of the A spout, the B spout, the C spout and the D spout rotate to the bottom and spray water vertically below the submarine 4 at the same time. Under the action of the C, D nozzles and the tail nozzle 9, the submarine 4 floats forward horizontally. If it needs to float vertically upwards, the tail flow valve 12 of the tail nozzle 9 will be closed. If it needs to float while driving, the tail flow valve 12 will not be closed. , if you need to dive, operate the lifting handle 7 to make the A, B, C, and D nozzles upward, and at the same time inject water into the counterweight box. The spout is adjusted downwards to adjust the spraying direction, as A spout and B spout spray water to the submarine 4 top when diving, and complete oblique angle diving.

Embodiment 4

[0037] Embodiment four, when a warship or a civilian ship sails in a straight line or stops or reverses, its operation is all as described in embodiment one, and its operation as turning or doing a 360-degree rotation is then as shown in embodiment two.

Embodiment 5

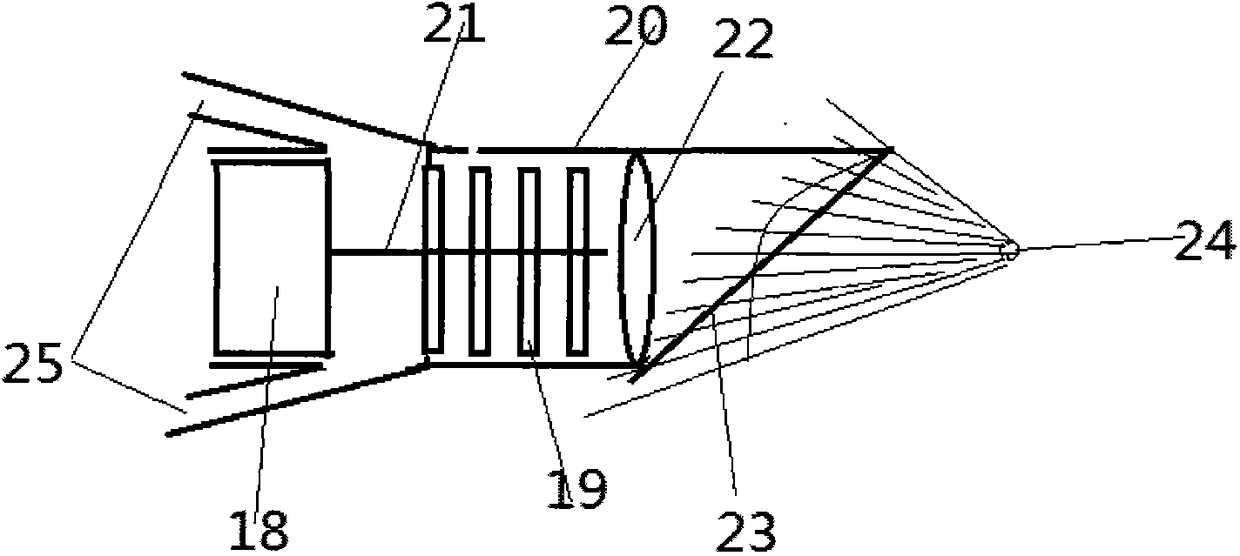

[0038] Embodiment five, when submarine 4 or ship, ship 5 are sailing, when the filter screen 24 that water absorbing device 2 is provided with has sundry to adhere to, most of all can extend the filter bar on the filter screen 24 to slide to the rear end (filter screen 24 structure It is fixed by a plurality of hard bar beams along the course, and is conical.) In case of special debris and the debris cannot be guided to the outside of the water absorbing device 2 by sailing speed, the solution is: turn off the speed-regulating submersible motor 18 Drop it, the effect is that in a short period of time, the water inlet 22 has no suction and the sundries are naturally directed to the rear. If this effect does not work, then the speed-regulating submersible motor 18 will run in the opposite direction for a while, and the sundries will be ejected by the water inlet Backflow blows away.

[0039] The water flow propulsion system of various military and civilian aircraft provided by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com