Porous sound-insulating structure

A structural and porous technology, applied in the direction of sound insulation, insulation layer, building components, etc., can solve the problems of unexpected low-frequency sound insulation effect, large amount of materials, low sound absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

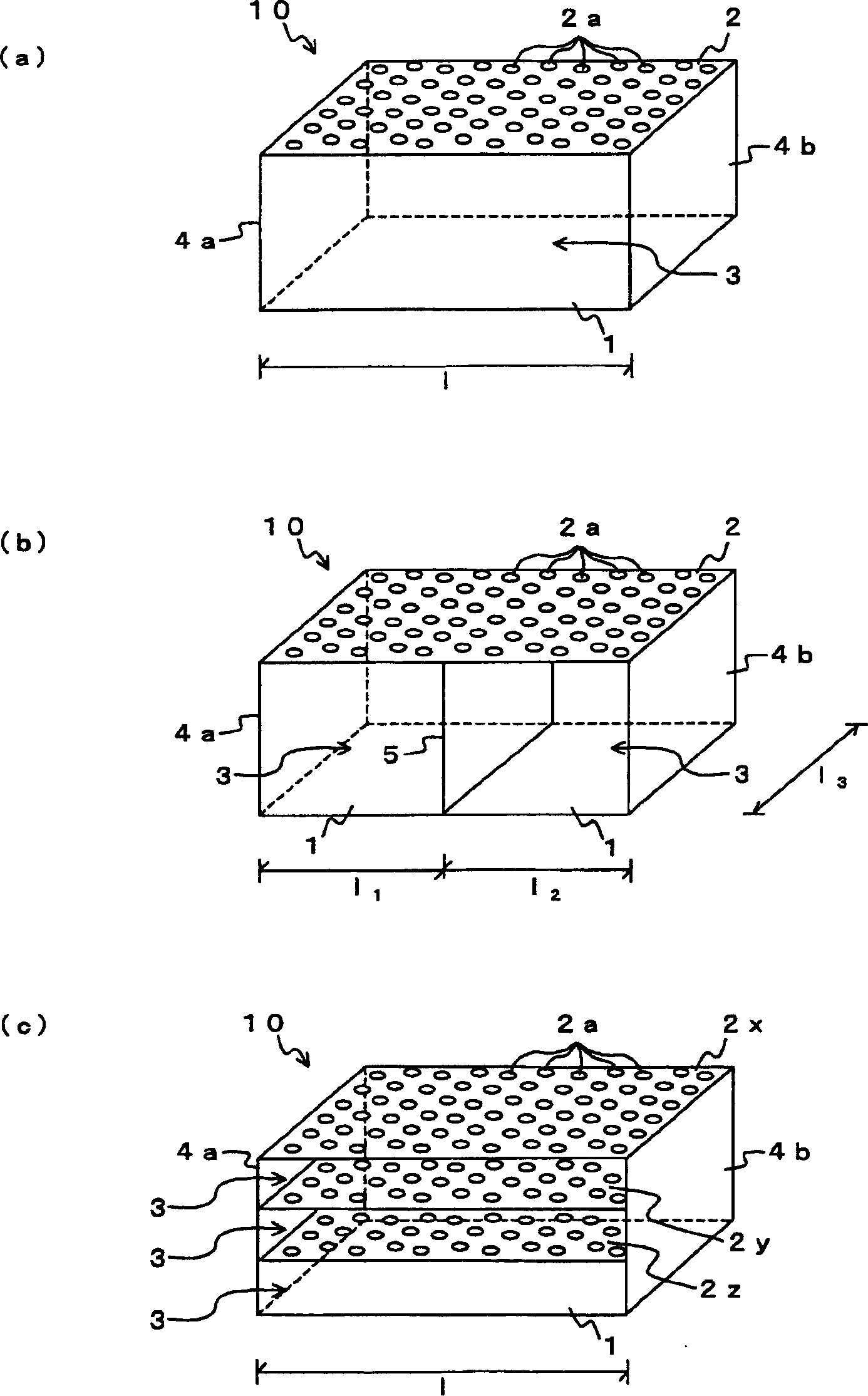

[0056] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

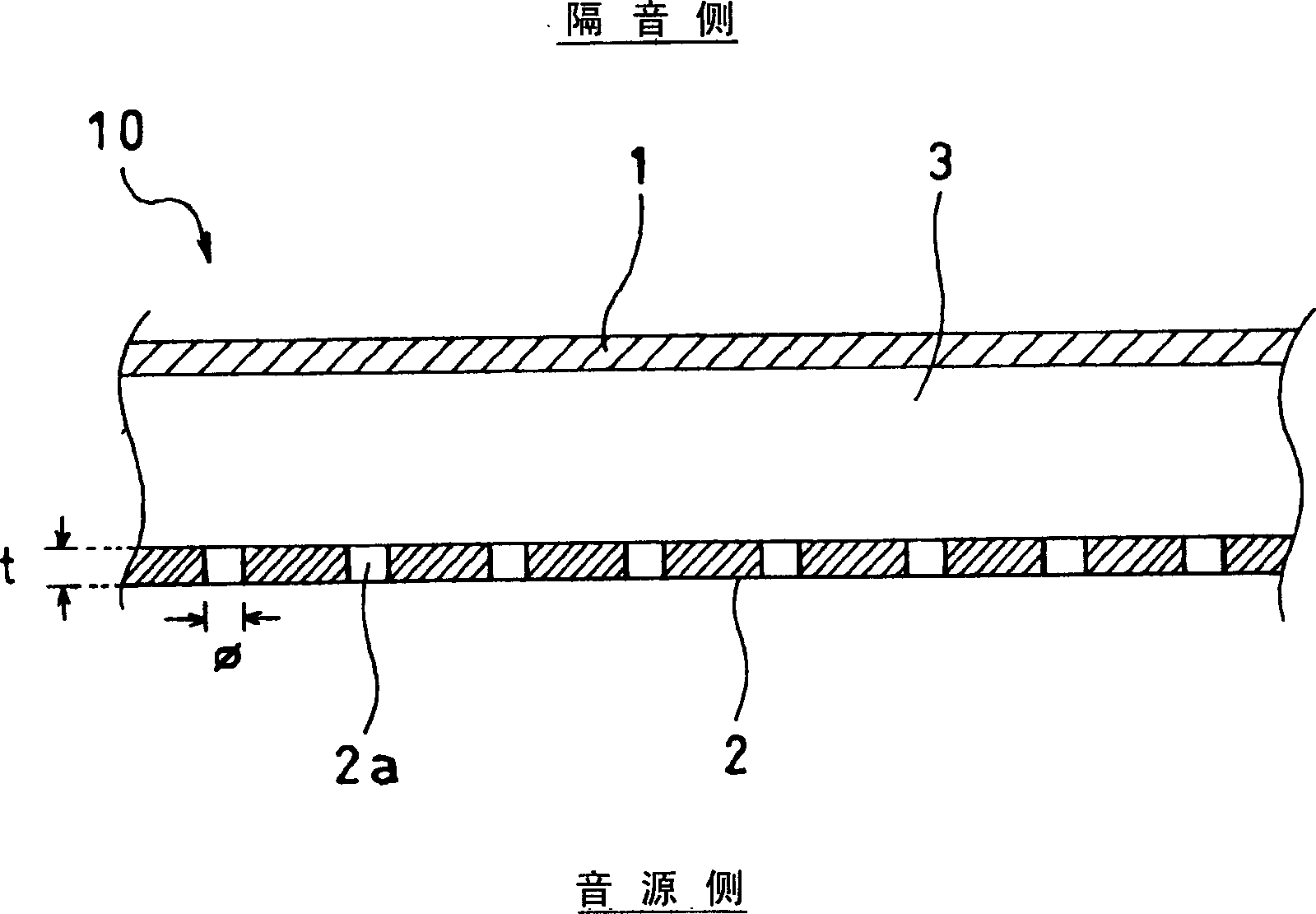

[0057] figure 1 It is a cross-sectional view showing a state in which an outer member and an inner porous plate are arranged to face each other in a porous sound-insulating structure according to an embodiment of the present invention. Such as figure 1 As shown, the porous sound-insulating structure 10 of the present embodiment is composed of an outer member 1 and an inner member 2 disposed substantially parallel to each other with an air layer 3 interposed therebetween.

[0058] Both the outer member 1 and the inner member 2 may be made of metal such as iron or aluminum, resin, cement, and other various materials. In addition, it is preferable that the outer member 1 and the inner member 2 are made of the same material so that they do not need to be handled separately at the time of recycling.

[0059] The inner member 2 disposed on the sound source side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap