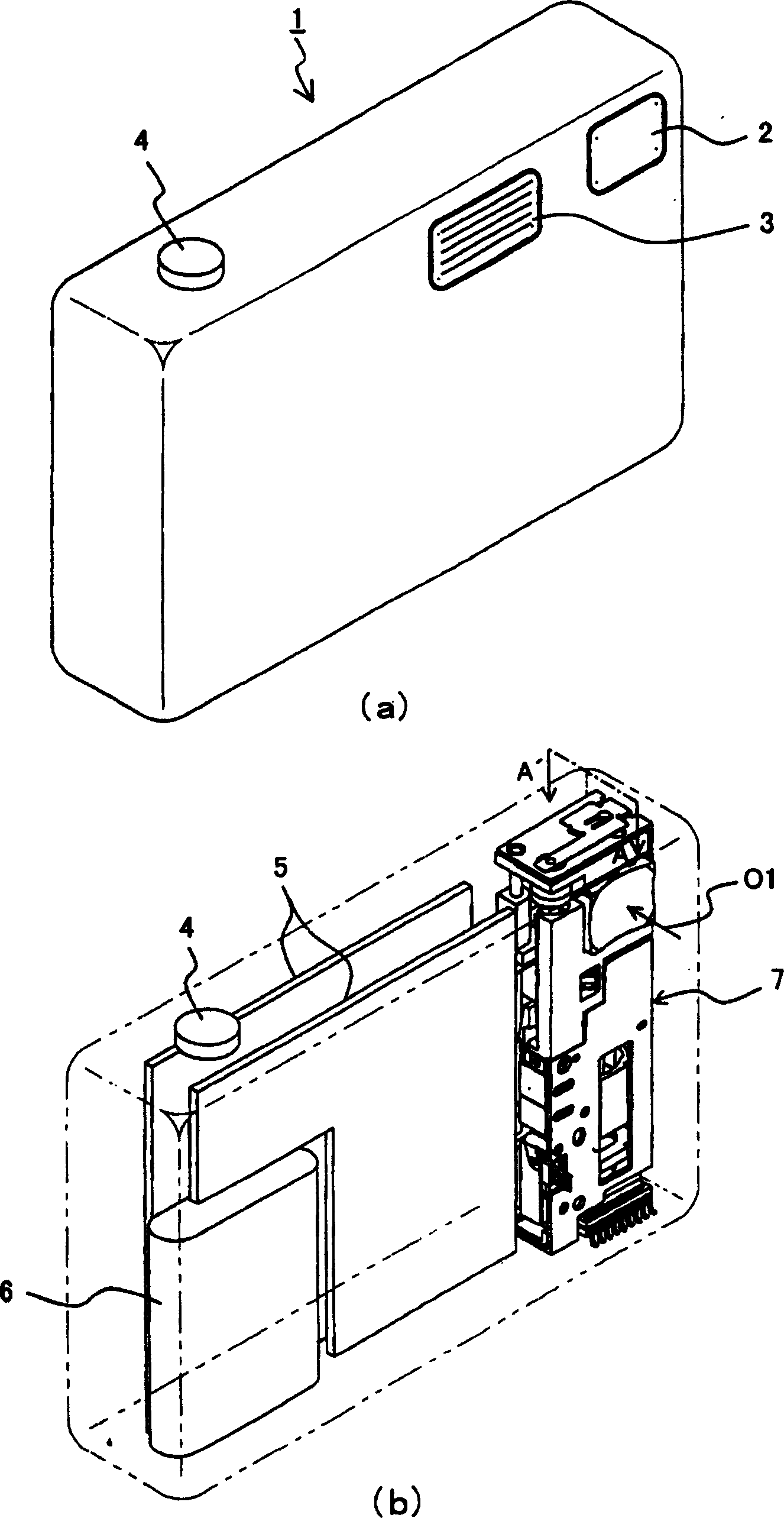

Lens device and digital camera using same

A lens and frame technology, which can be used in installations, static cameras, components of color TVs, etc., and can solve the problem that the connection method cannot be directly used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

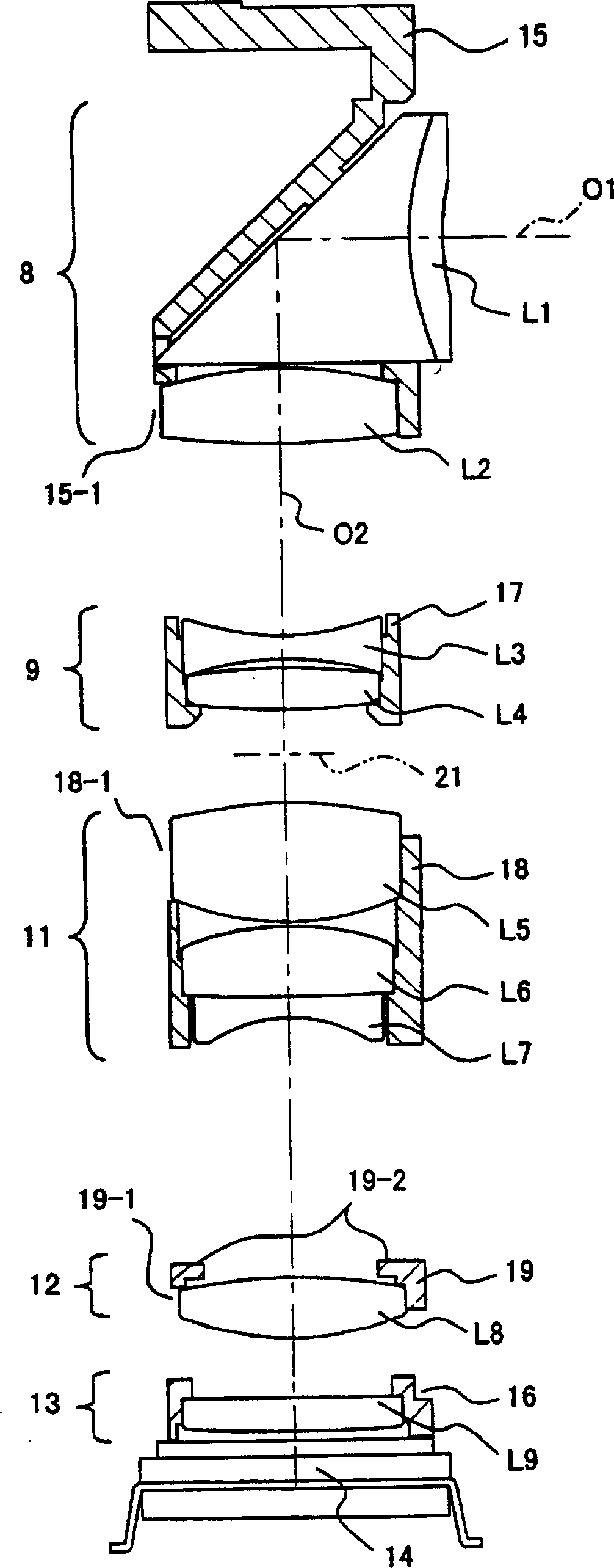

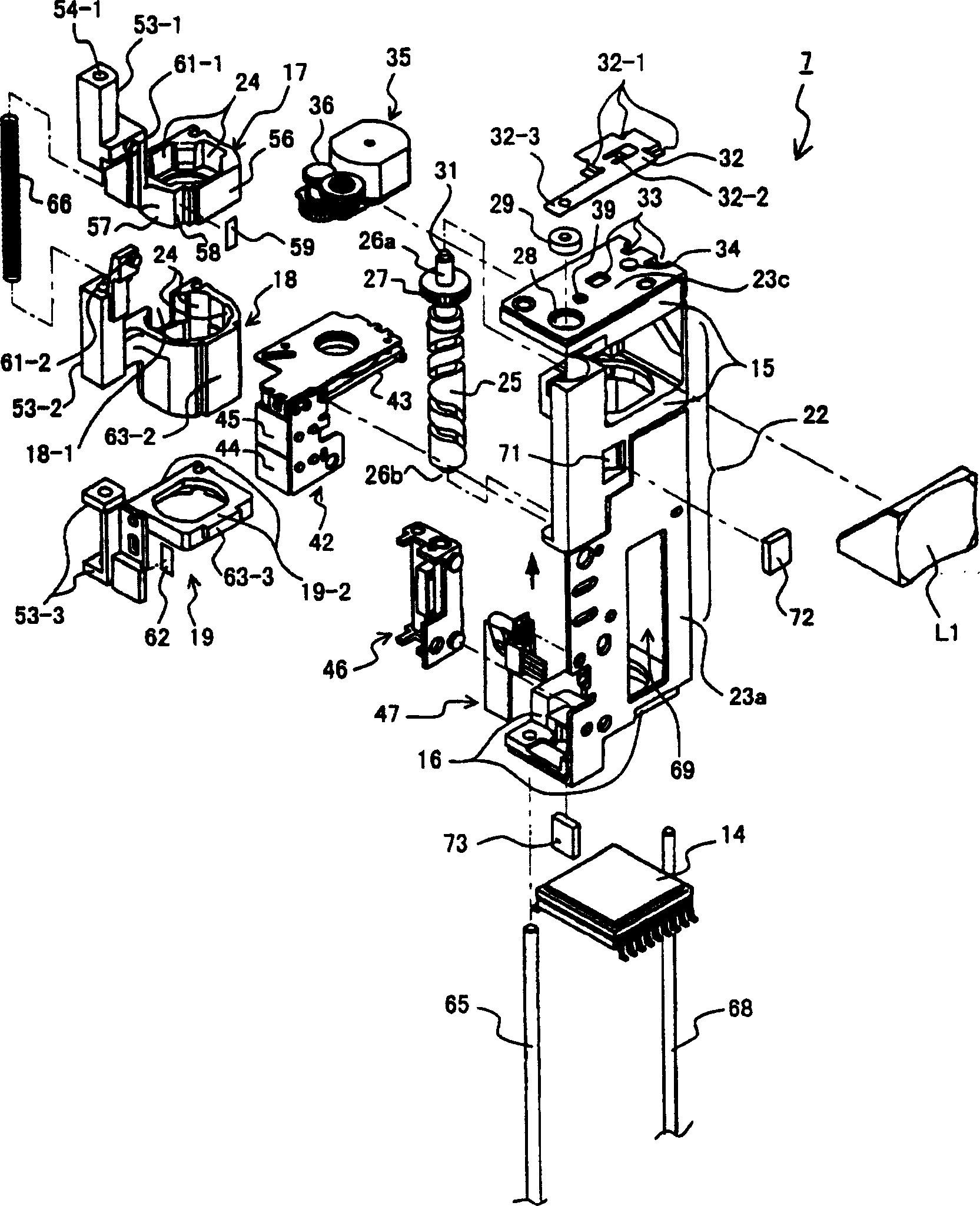

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in the following description, the above-mentioned one main surface is composed of, for example, the surface of the metal frame 23a and the surface of the first fixed mirror frame part 15 integrally formed with the metal frame 23a, and the opposite main surface is composed of an open surface. In addition, the optical element is constituted by, for example, a prism L1, lenses L2 to L9, and the like, and the reflective optical element is constituted by a prism L1 and the like. In addition, the above-mentioned forming part is composed of, for example, the first fixed frame part 15 and the second fixed frame part 16, etc., the above-mentioned one side is composed of, for example, a metal frame 23b, and the other side facing it is composed of an open surface. Moreover, the said 1st guide member is comprised by the 1st guide shaft 65 etc., for example, and the said ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com