V-shaped ultrasonic linear motor driving power supply and driving method thereof

A linear motor and drive power technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. Problems such as stepping motion and micro-displacement motion achieve the effect of improving control accuracy and response speed, convenient control, and high frequency accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

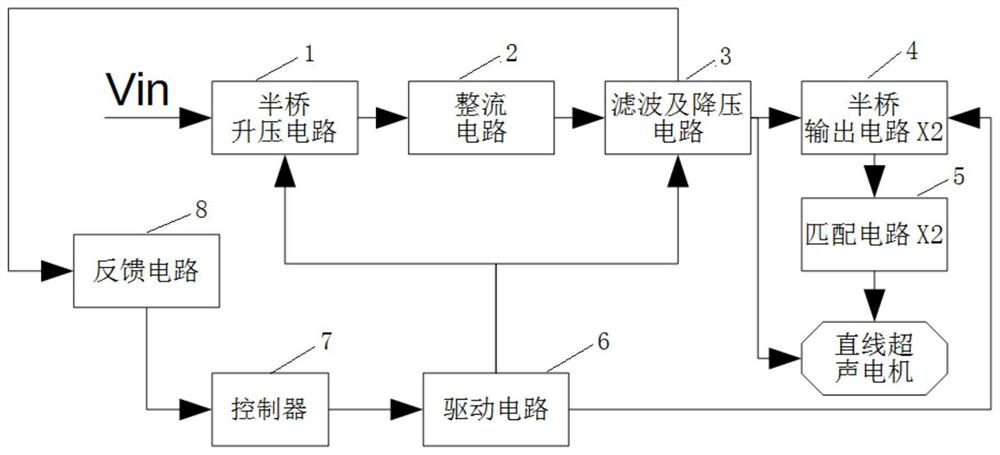

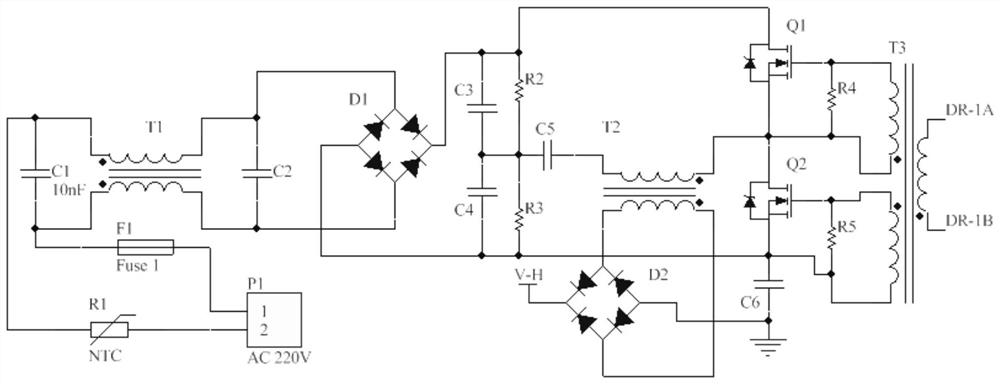

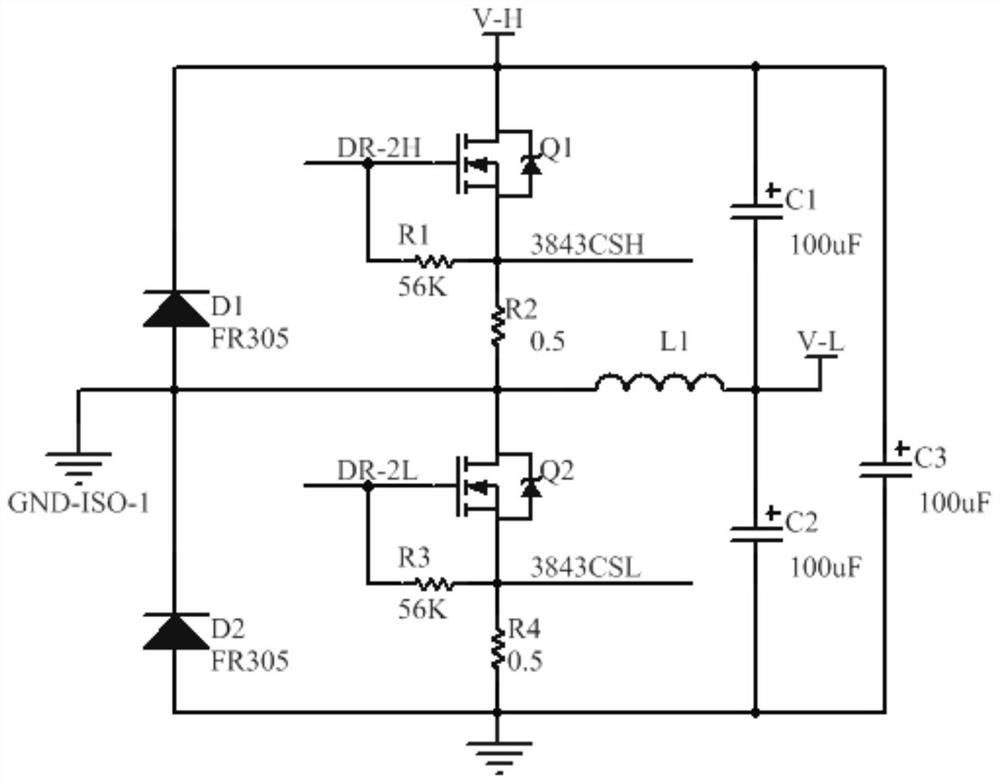

[0030] See attached Figure 1 to Figure 4 , the embodiment of the present invention provides a V-shaped ultrasonic linear motor driving power supply, which can realize the fast stepping motion of the V-shaped ultrasonic linear motor in the field of precision positioning, and can also realize the small displacement compensation motion between the stepping gaps, so that Both motion states are driven by a single power source. On the whole, the power supply system of this embodiment adopts a total of three-stage conversion circuits of AC-DC, DC-DC, and DC-AC. The first-stage AC-DC circuit is a combination of a half-bridge booster circuit and a rectifier circuit, which isolates and boosts the input mains power to the DC high voltage required by the V-shaped ultrasonic linear motor. The second-stage DC-DC circuit is used for the V-type ultrasonic linear motor to quickly adjust the piezoelectric ceramic voltage in the displacement compensation movement to achieve the micro-displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com