Earth leakage breaker

A leakage circuit breaker, main circuit technology, applied to circuits, electrical components, switches operated by ground fault current, etc., can solve the problems of not increasing the space for withstand voltage test switches, large development costs and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

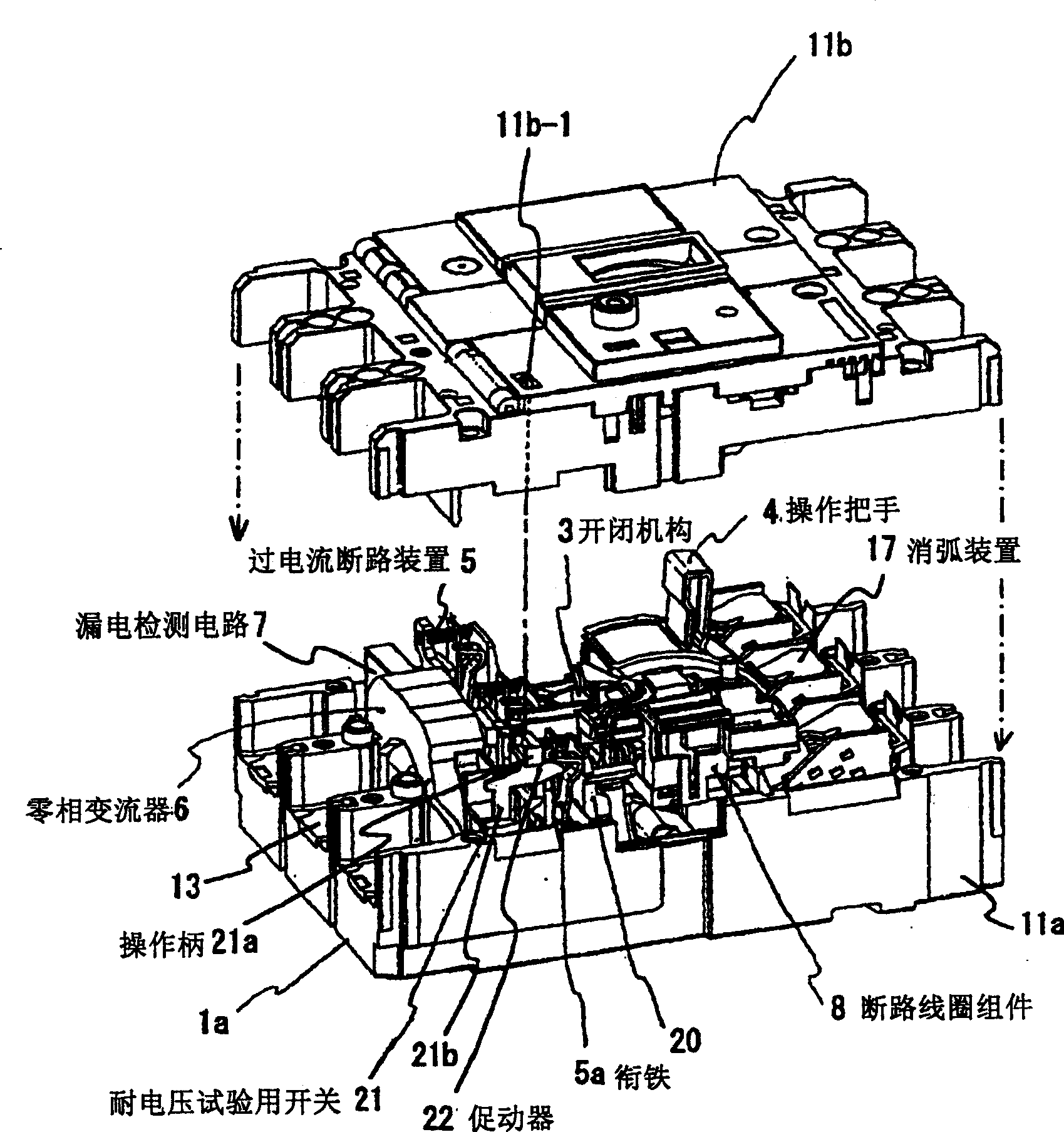

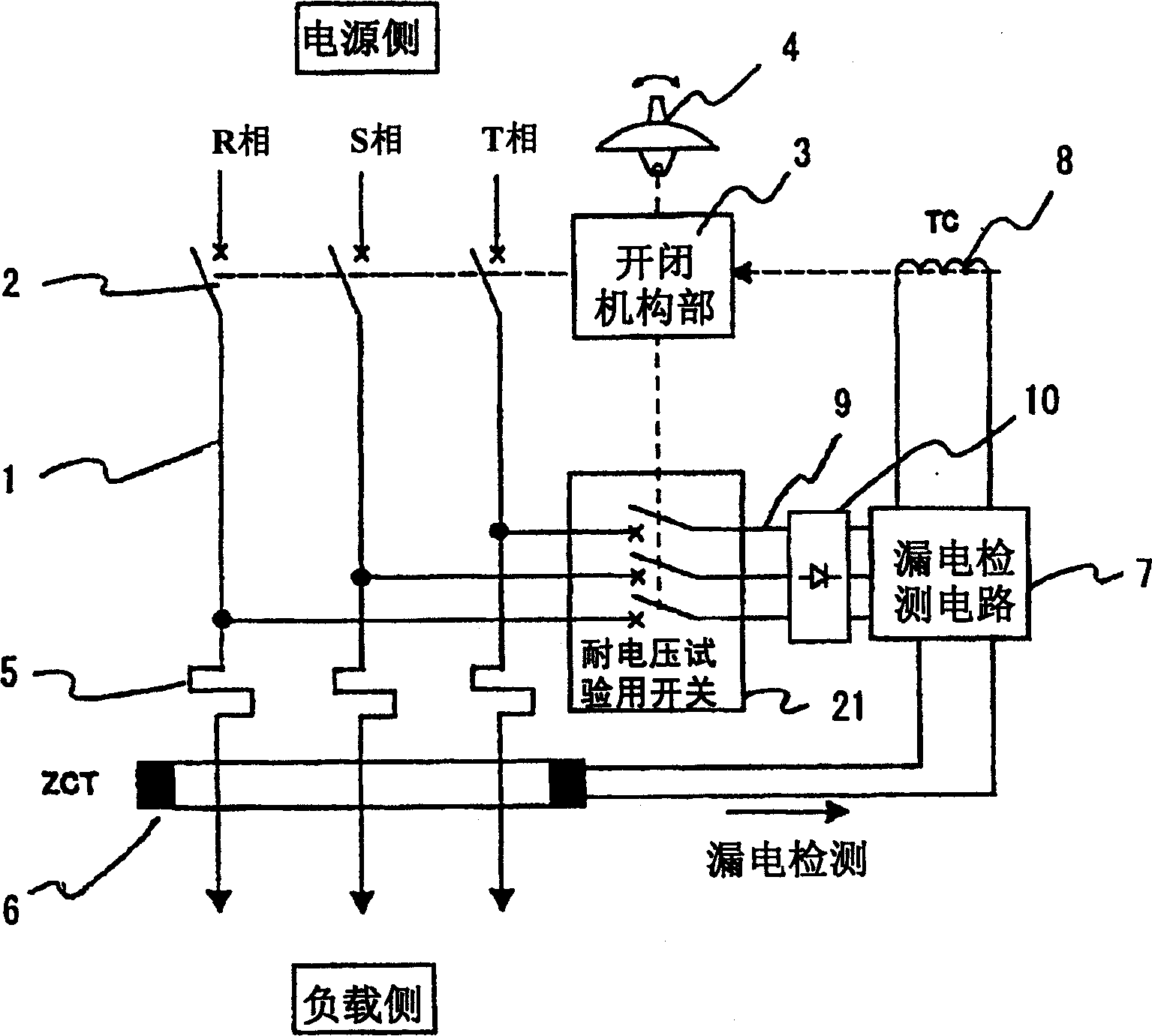

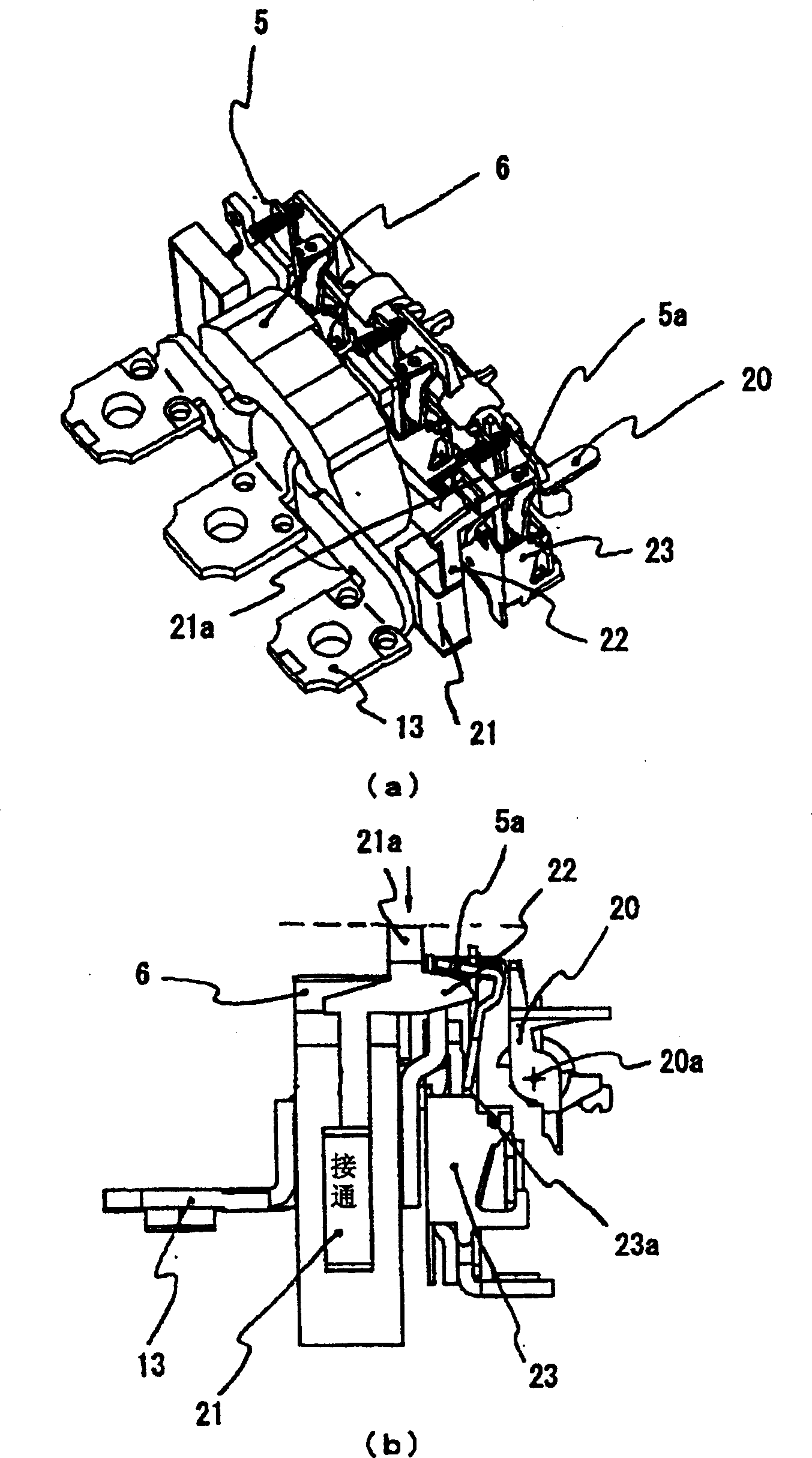

[0035] Figure 1 ~ Figure 4 It is a configuration diagram of an embodiment corresponding to aspects 1 to 3 of the present invention. The earth leakage circuit breaker of this embodiment and Figure 7 ~ Figure 9 The existing configuration shown is basically the same, and as shown in the circuit diagram of an earth leakage circuit breaker for a three-phase power supply in FIG. superior. Moreover, in the circuit diagram of FIG. 2, three power lines 9 corresponding to each of the R, S, and T phases are wired between the main circuit 1 and the leakage detection circuit 7, and the three-phase AC power is converted into DC by a rectifier circuit 10. , to supply power for the leakage detection circuit 7, and match with three power lines 9, the switch 21 for withstand voltage test has three contacts, but in such as Figure 7 In the case where the phase-to-phase voltage of the R-T phase of the main circuit 1 is supplied to the leakage detection circuit 7 as shown, the switch 21 for th...

Embodiment 2

[0044] Next, use Figure 5 , Figure 6 The configuration and operation of an embodiment corresponding to the fourth aspect of the present invention will be described.

[0045] In the structure of the above-mentioned embodiment 1, the actuator 22 provided on the operating rod of the switch 21 for withstand voltage test is interlocked with the armature 5a as the operating end of the overcurrent breaking device 5, so that the armature 5a will open the circuit breaker horizontally. Lever 20 is driven to the snib release position. On the other hand, in this embodiment, the actuator 22 provided on the switch 21 for the withstand voltage test is connected to the disconnecting coil assembly 8 as an earth leakage circuit breaker (refer to Figure 7 , Figure 9 ) is interlocked with the sliding body 8a at the operating end, and the breaking cross bar 20 is driven to the latch release position through the protrusion 8a-1 provided on the sliding body (slider) 8a.

[0046] That is, on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com