Straw disinfection equipment, method for producing straw disinfection apparatus and disinfected straw product

A technology for disinfection equipment and disinfection devices, which can be used in devices, applications, animal husbandry, etc. to capture or kill insects, and can solve problems such as material pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

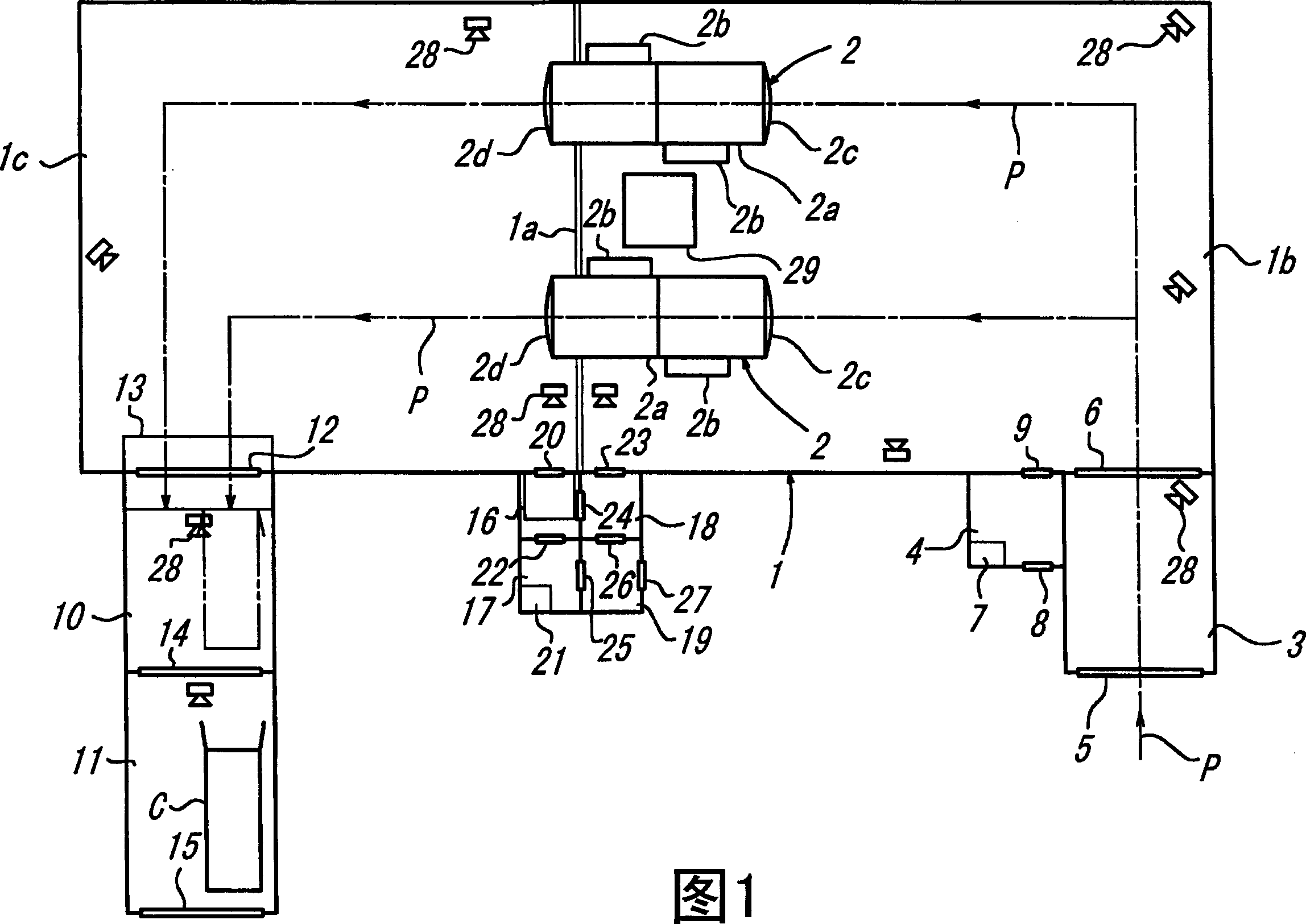

[0035] Hereinafter, embodiments of the rice straw disinfection equipment, the manufacturing method of the disinfection device and the rice straw disinfection product of the present invention will be described with reference to the accompanying drawings.

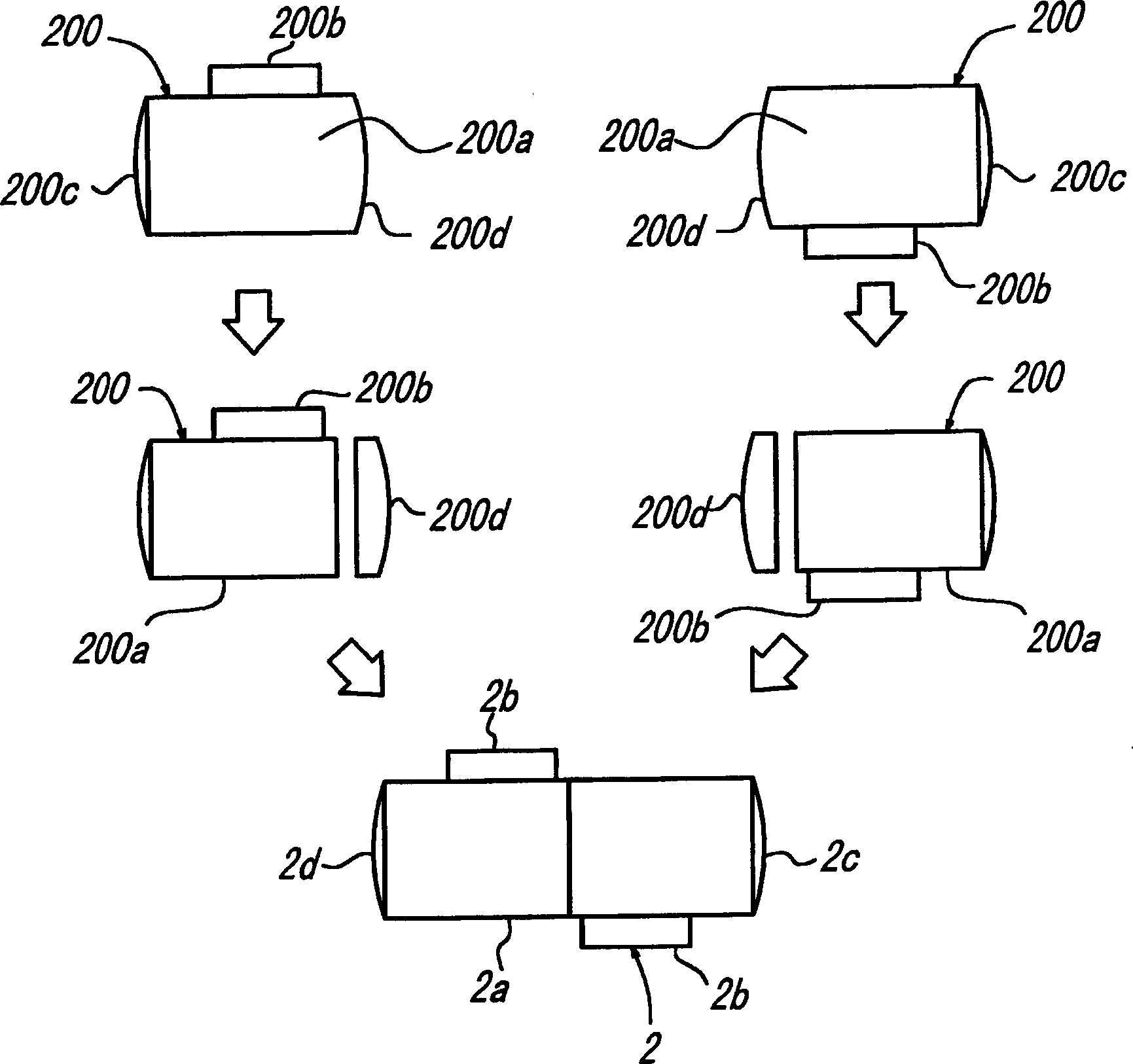

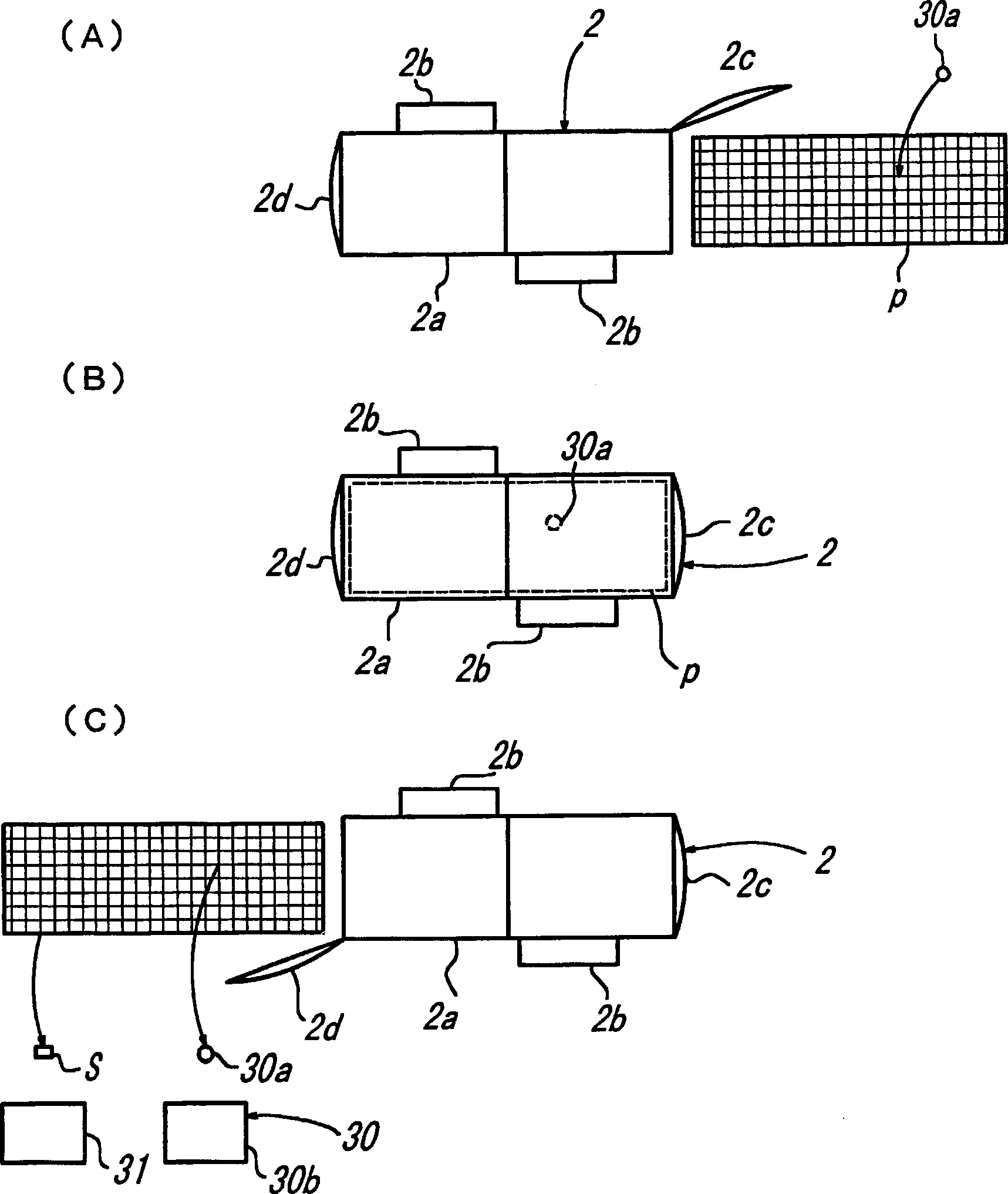

[0036] Figure 1~ Figure 5 The first embodiment of the rice straw disinfection equipment, the manufacturing method of the disinfection device, and the rice straw disinfection product of the present invention is shown.

[0037] In this embodiment, as shown in FIG. 1 , two disinfection devices 2 are installed in a disinfection workplace 1 constructed as a square-shaped building. Furthermore, the material P to be sterilized in this embodiment is obtained by cutting harvested rice stalks into appropriate lengths, bundling them into bundles, packing them in mesh bags, etc., and forming blocks. Here, rice straws refer to rice straws, wheat straws, grasses, and the like.

[0038] The disinfection workplace 1 is divided into two pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com